log bathhouse projects

offers services for the design of wooden baths, as well as construction according to individual customer projects. We will take into account all the wishes of our clients, offer the most optimal way to implement our plans, and also suggest the best solution and optimal options.

The projects we offer are unique in their own way and inimitable, just like the personalities of our clients. Having experience in constructing various types of buildings, we are well acquainted with all the intricacies of wood working technologies and the specifics of this material. Log bathhouse projects are not a complete list of our services. We also carry out the construction and design of houses made of timber, and the construction of cottages, bathhouses for shrinkage and on a turnkey basis.

Material for bath walls

Wood

When choosing a material for walls , before building a bathhouse, you need to pay attention to some of its qualities. Wall materials must be durable during use, easy to process, and, importantly, inexpensive in price.

As has already been recognized, the best option is coniferous wood - pine, spruce, larch, fir and cedar. The resin they contain makes the wood most resistant to high temperatures and moisture. In addition, this material is easy to process, and its prices are not so high when compared with hardwood.

Pine is probably the most affordable and best material for building log baths. It has virtually no knots, is easy to process and, compared to other breeds, is inexpensive. In a word, what we talked about a little higher. I believe that this is the best option, not only for the construction of a bathhouse, but also for other wooden buildings.

Spruce is also durable, but is less resistant to rot than pine. It is more suitable, when building a bathhouse, for the rafters of the roof or beams.

Of the deciduous tree species, oak . Lightness and ease of processing, high strength qualities and resistance to rotting - oak logs are most often used in the lower crowns of a log house, where the risk of rotting is greatest.

Linden, birch, aspen, alder and ash are used for interior decoration of the bathhouse. They are used to make furniture and shelves in the steam room, and they are used to cover ceilings and walls. The wood of these species is best suited for finishing rooms with high air temperatures.

Log or timber bathhouse?

A log is an unprocessed tree, but only a tree cleared of bark, branches and knots. A beam is the same as a log, but has already been processed - hewn or sawn, with a rectangular or square cross-section.

Bathhouse made of timber

Before choosing the material that best meets all the requirements of a bathhouse, I would like to draw your attention to these points:

- When drying out, which occurs over time, the wood cracks . And if in beams the cracks have a chaotic direction, then in logs they are either vertically located or rush along the outer surface.

- Untreated whole logs have a natural shell that protects them from the effects of the external environment. Bars that lack this part are deprived of this protective layer (protective impregnations must be used).

- When using beams, building walls is quite easy and simple - anyone can do it. This is a big plus when choosing this material. It is cheaper to install a sauna made of timber than a sauna made of logs. For example, if the area of the proposed bathhouse is 16 m2, then its cost will cost you 40 thousand less than the same bathhouse made of logs. All this is due to the ceilings and walls.

- When constructing a bathhouse from timber, shrinkage occurs less - over the course of a year, a bathhouse made from timber will shrink by only 5-10 cm. During the same time, the shrinkage of a bathhouse made from logs is 10-15 cm.

- to make interior decoration of walls made of timber than the walls of a bathhouse built from logs.

- However, a bathhouse made of solid logs is a tribute to the tradition of real Russian bathhouses. Therefore, everyone for whom this is not an empty phrase should opt for log baths.

As you can see, both timber and logs have pros and cons. And it is obvious that it is better to base your choice on personal preferences and based on the specific situation, knowing these pros and cons, and taking them into account. Well, as an example, some may not be intimidated by the complexity of the internal finishing of the timber, while others generally want to leave it as is because they are delighted with the natural “nature”. In fact, there are countless nuances.

It would seem that having completed the construction of a country house, you can finally relax and unwind for your own pleasure. But then the thought comes to your mind that it would be nice, when you arrive at the dacha after a hard week of work, to take a steam bath in your own bathhouse. At first the idea seems difficult to implement, but then it turns out that a bathhouse made of rounded logs with your own hands is a completely feasible task. In addition, the process of its construction will take very little time. This article will tell you how to choose a site, where to buy logs and how to assemble them into a beautiful and comfortable building.

What is a rounded log?

In essence, a rounded log is a tree trunk processed on a special machine to give it a standard diameter. This means that all the logs in the set you purchase will be identical, and the mounting cut will perfectly match the convexity of the bottom log.

In addition, this treatment makes the wood more durable. In order to understand how this happens, you need to understand a little about the structure of wood. In addition to a small central part, the pith, the tree trunk consists of a durable core impregnated with resin or tannins and a younger part called sapwood. The core (or mature wood in deciduous trees) is the strongest and most durable part of the trunk. The sapwood is located directly under the bark and has significantly higher moisture content. This makes it more susceptible to rot and prone to warping and cracking.

During rounding, the sapwood is removed and the core is sanded. This allows you to make the log parts more durable. In addition, thanks to the ideal smoothness of the workpieces, finishing a bathhouse made of rounded logs becomes completely optional.

Why exactly a rounded log?

We can talk about the centuries-old traditions of wooden architecture for a very long time. Yes, wood has been used in our country for centuries, but when choosing a material for your own bathhouse, you should first of all take an interest not in its history, but in its physical characteristics. In the case of a wooden frame, our ancestors turned out to be much wiser than their descendants - the advantages of this material are obvious.

- Environmental friendliness - by filling the bathhouse with steam, you do not have to worry about the penetration of dangerous chemical elements into the air from the walls and floor. On the contrary, the essential oils released by wood can have the most beneficial effect on your health.

- Low thermal conductivity - a well-caulked log house retains heat well. Even in severe frosts, it is quite easy to heat such a bathhouse, and it will take a long time to cool down.

- Natural air exchange. This quality will allow you not only to save on installing ventilation, but will also protect you from colds - natural ventilation eliminates drafts.

- Durability – a properly installed log house can serve you for several decades. And types of wood such as larch and aspen only become stronger over the years.

- Cheap - a bathhouse made of rounded logs will cost much less than a brick or stone one.

- Ease of installation - the construction process will not take much time, which cannot be said about other building materials.

Choosing a site for construction

When choosing a place to build a bathhouse, you can be guided solely by your own taste. The only restriction applies only to buildings that have a swimming pool inside. In this case, it is necessary to select an area where the groundwater is low enough.

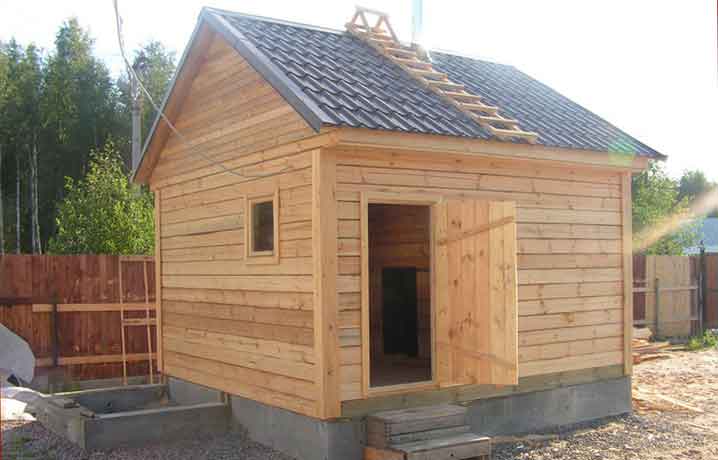

Project of a bathhouse made of rounded logs

In any large settlement you can easily find a company manufacturing standard bathhouses from rounded logs. In addition, for the most demanding clients, they are usually ready to develop and implement an individual project. Here are photos of several interesting solutions:

Let's get started

You can start construction even before the “constructor” made of logs is delivered to your site. Things will go much faster if by this moment you have a ready foundation. Ask the log manufacturers to provide you with a drawing of the future bathhouse and, based on it, begin pouring the foundation.

Foundation

For those who once built a house on their own, a bathhouse made of rounded logs will seem like just a children's construction set. A very heavy designer, it should be noted. This means that the foundation for it must be strong enough. As a rule, a shallow strip foundation is poured under the log house. The process is labor-intensive, but quite feasible.

Important! The foundation for a bathhouse made of rounded logs should lie below the freezing level of the soil.

First of all, it is necessary to correctly mark the site in horizontal and vertical planes and dig trenches:

- Lay out the foundation plan using a prism and a laser level. Make sure the corners are straight.

- Install the cast-off and tighten the marking threads.

- Now you can start digging trenches. Their depth depends on the type of soil, the depth of soil freezing in your region and the weight of the log house. In each individual case, the depth of the foundation is calculated individually by specialists.

This process is shown in more detail in the video.

When the trenches are ready, we proceed to installing the formwork and pouring the foundation:

- First, pour a layer of gravel 15 cm thick into the trenches and tamp it down.

Important! At this stage, it is important not to forget to make a technological hole for communications in the future foundation.

- Then we fill in the same layer of sand and compact it again.

- We assemble formwork from unedged boards and install it around the trench. Be sure to install external stops that will prevent the structure from collapsing under the weight of concrete.

- Let's start making the reinforcement. From a rod or reinforcement 10mm thick we assemble two gratings with a cell of approximately 20*20 cm. This is done by welding or knitting wire. One grid should be located 5cm from the bottom of the trench, and the second - 5cm from the top edge of the foundation. We connect the gratings together with pieces of rod. Now we install the reinforcement frame in the trench.

- Fill the formwork with concrete and level the surface. Waiting for it to dry.

The entire process of creating the foundation is shown in the following video:

The average hardening time for concrete based on Portland cement is 24 days. However, given the relatively light weight of the log house in comparison with brickwork, its construction can begin within a few days after pouring the foundation.

Foundation waterproofing

Before proceeding with the installation of the first crown, it is necessary to waterproof the foundation. Roofing material glued to molten bitumen is perfect for this:

- We lubricate the foundation with bitumen and put roofing felt on it.

- After the first layer has cooled, glue the second layer of roofing material in the same way and again wait until it cools completely.

Installation of the first crown

If you ordered a bathhouse project from a specialized enterprise, then the logs brought to you will definitely be numbered. In addition, a company representative must provide you with an assembly diagram.

- We begin the construction of a bathhouse from rounded logs by installing the first crown. The diagram will help you find the logs intended for it. As a rule, their diameter is slightly larger than the diameter of the others.

- Before connecting the beams to each other, it is necessary to check their position with a level - the first crown should be positioned strictly horizontally.

- We fill the gaps between the foundation and the logs with foam.

Walling

We lay insulation on the first crown. It could be tow or jute. Nowadays you can find modern inter-crown seals on sale, which greatly facilitate subsequent caulking.

Important! Inter-crown insulation should be placed between all logs of the log house.

Now we assemble the second crown, install it in place and fasten it with metal pins or wooden dowels. The holes for them must be drilled during manufacture.

The subsequent assembly of a bathhouse from rounded logs is carried out in the same way, in full accordance with the diagram.

Important! The two upper crowns should not be fastened. After shrinking, they will need to be removed to install the ceiling beams.

At this stage, the process of making a log house must be suspended. This is necessary for natural “shrinkage” of the structure to occur. Some manufacturers of rounded timber claim that their products do not shrink. However, practice shows that no one has yet been able to completely get rid of this property of wood. If you nevertheless decide to finish building the bathhouse right away, after a year of operation it must be caulked again.

In order to protect the structure from moisture during shrinkage, the log house is covered with unedged boards and roofing felt.

In buildings made of fairly dry timber, which gives minimal shrinkage, windows and doors can be installed immediately. But it’s better to do this after wintering.

Log caulking

In order to make the structure as airtight as possible, a technique such as caulking is used. At the same time, a sealant - tow - is driven into the cracks between the logs using a special tool (it is called the same as the process itself - caulk).

Tow is a short, coarse matted fiber, which is a waste product from the primary processing of bast crops (hemp, flax, etc.)

The most common are linen and jute tow. The first is much softer, and therefore easier to work with, and the second, due to the high content of natural resin - ligin - is less susceptible to rotting.

Despite the variety of materials that can be used to insulate a bathhouse made of rounded logs, the prices for jute and flax tow, combined with the good quality of these materials, make them the most popular.

You can see the necessary tools and basic operating principles in the following video:

As you can see, this process is quite simple, but it also has some subtleties:

- Using a caulk and a mallet, we drive into the gap between the logs the hanging fragments of the sealant placed between the crowns when assembling the log house.

Important! Instead of a special tool, you can use a regular chisel or chisel. You can make wooden caulk from scrap boards by simply cutting out the required shape and sharpening the end.

- Work should begin from the bottom, walking along the perimeter of the building.

Important! You cannot caulk only one wall of the log house, this can lead to distortion.

- After you have caulked the gap between two logs from the inside, do the same on the outside of the building. Only then proceed to caulk the next joint.

- Each subsequent joint should be caulked with less force, and the tow can only be lightly tucked under the upper crowns without using a hammer.

Roof

The roof of a wooden bathhouse can be either single or gable. It is erected according to the same principles as the roof of any other building.

As for the choice of material that will cover your bathhouse made of rounded logs, cost probably plays the main role here. Of course, natural tiles look most harmonious in combination with wood. But if the budget does not allow you to purchase such expensive materials, you can get by with ordinary galvanized steel or ondulin.

To create a harmonious ensemble, you can cover all buildings on the site with the same roofing material.

Important! When designing and building a roof for a bathhouse, take into account the fact that shrinkage of the log house is possible for several years.

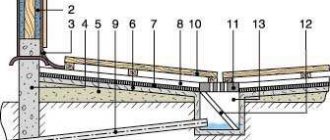

As a rule, the structure of such a roof consists of a ridge girder laid on racks, rafters and sheathing.

Interior of a bathhouse made of rounded logs

When the building is completely ready, all that remains is to think about its interior. Smooth logs themselves look quite attractive and often do not require additional finishing. All that remains is to cover the floor with tiles, install the stove and hang decorative elements. Here are several options for designing a steam room and dressing room; perhaps you can find something interesting for yourself:

based on materials from the site strport.ru

Bathhouse made of solid logs

When constructing a log house, freshly cut trees are used that have retained their natural moisture. The most valuable buildings are considered to be bathhouses built from solid logs , since they still have a natural shell.

Bathhouse made of solid logs

If you follow all operating rules, then such a bathhouse will last at least 50 years . They are resistant to destructive atmospheric influences even without treatment with special impregnations and antiseptics, because they have almost no open pores.

The cost of a bathhouse made from solid logs is around 3,000 rubles per m3 and more.

Features of rounded logs

Logs for this construction should be pre-rounded . They are wood trunks, processed in a special way, and have the same diameter along the entire length. Depending on the application of the machine used to produce the material, the shape and dimensions of the profile depend.

The rounded log from which baths are made has the following characteristics:

- it is resistant to external influences - the logs are dried and treated with antiseptics and fire retardants. This protects the material from fungus, moisture, fires and insects;

- heat capacity - the properties of rounded logs in this regard are five times better than those of bricks and concrete. They help maintain heat in the bath, extend service life and reduce exposure to moisture and temperature fluctuations;

- humidity - wood has a natural humidity of up to 70 percent; after construction, a log bathhouse made of galvanized logs is left to stand for about a year;

- attractive appearance - modern technologies make it possible to implement various attractive projects from rounded logs at different prices. In the photo you can choose what you like most. The logs have verified dimensions and parameters, their surface is smooth, and their length is up to 12 meters. The wood has a red and yellow tint, the pattern is pronounced, which adds aesthetics to the bathhouse.

Baths made of profiled timber and rounded logs

To give a log a special profile or an even rounded shape , it is processed on a machine using special cutters. During processing, its upper shell is removed, which makes the log unprotected. To protect it, it is impregnated with special compounds. Despite the loss of natural protection, a mechanically processed log has an advantage over an untreated log. Even when making rounded logs or beams, it is easy to calculate the dimensions of the grooves, bowls and make corner cuts. This significantly facilitates the installation of the log house and improves the quality of the bathhouses and buildings built from it.

The cost of such baths starts from 7,000 rubles for the same meter.

Glued laminated timber for the construction of a bathhouse

If special accuracy and minimal threat of deformation of the beams are important, then they use technology for manufacturing laminated veneer lumber .

Bathhouse made of laminated veneer lumber

This is done simply: several longitudinal wooden blocks are glued together, taking into account the direction of the wood fibers, and processed on a special machine.

Before gluing , all knots are removed, which allows the bars to fit tightly to each other and makes the laminated veneer lumber much stronger. The best wood for it is considered to be from trees growing in the north of Russia. The climate there does not allow trees to grow quickly. Because of this, their core trunks have special durability and density.

An important point when purchasing a ready-made log house for a bathhouse is that all logs or beams must be numbered. Otherwise, installation of the log house will be difficult. The cost of a log house made of laminated veneer lumber is from 18,000 rubles per m3.

Average prices of rounded baths

The price of a bathhouse made of rounded logs depends on factors such as:

- type of material;

- wood class;

- wall parameters;

- bath area.

In addition, the final price is also affected by whether you assemble a bathhouse from logs with your own hands, or attract specialized specialists for this work. In any case, log baths differ from other projects in their affordable price and high quality. In finished form, their cost, depending on the complexity of the project, ranges on average from 300 thousand to 2 million rubles and more.

From photos on the Internet you can decide how they will look.

Binding walls with wooden dowels

After a year or a year and a half from the moment of laying, the log house finally settles . Changes in humidity, temperature and the influence of its own weight continue the life of the logs. There is another way to strengthen the position of your log house: tie the logs with special 25-30 mm rods (dowels). Three logs are tied together with one dowel.

And so that it does not interfere with the settlement of the log house, it is made a quarter less than the depth of the hole. as a material for dowels .

To fix the logs (or beams), the dowel is driven end to end. So that it does not interfere with the laying of overlying logs, its end is deepened by 20-30 mm. But so that the lower end does not rest against the lower unfastened log. This guarantees free shrinkage of the log house.

The first dowel is driven in at a distance of 0.20-0.25 m from the corner notch. Subsequent dowels lag behind the previous one by 1.5-2 m from each other. The latter is driven to the same distance from the corner as the first. The holes for the dowels are drilled in a staggered pattern so that each crown is connected to both the lower and the upper crown.

Driving dowels into timber

Installation

We adjusted the crown and marked the centers of the holes for the dowels. Using a drill or drill, we drilled holes in the three upper rims and drove in the dowel. And so on until the very top crown.

If inter-crown insulation is installed during installation, it will wrap around the drill during drilling. To prevent this from happening, make a gap in the insulation where the drill will go through. During the final caulking of the bathhouse frame, this place can be sealed.

After the last crown is laid , you can proceed to the following actions: install the lower and upper floors, make door and window openings in the walls, truss the roof and erect internal partitions.

Parameters of rounded logs

On sale there are rounded logs with a thickness of 18 to 32 cm and even more upon individual order.

It is best to choose logs with a diameter of 22 to 26 cm, however, if they have a smaller diameter, then it is better not to use them for building baths. Naturally, the price of such wood is lower, but it will retain heat worse.

In such cases, the owners try to insulate the bathhouse both inside and outside. But the tree does not like this, which can cause air exchange and the appearance of the building to suffer. In addition, the price of such a solution will be considerable.

Frame construction

What about frame construction of baths? Many will ask. Yes, somehow it was not widespread in Rus', but so be it, let’s consider it.

The advantages of frame baths are obvious - they are quite inexpensive, and the construction speed is high. In addition, just like lumber, it is seismically resistant. Average cost from 5 tr. per sq.m. The frame structure is lightweight, which means the foundation for the bathhouse can be built lightweight.

However, with frame construction, not everything is as rosy as it might seem at first glance, let's talk about the disadvantages. Timber or logs do not require insulation; they retain heat perfectly. But for a frame bath, insulation is definitely needed. But even with it, it will not hold heat so well; frame baths cool down very quickly . If you have seen statements somewhere that frame baths retain heat no worse than timber baths , then this is most likely from companies that are engaged in the construction of frame baths. How can it keep warm for a long time if the modern insulation materials used have practically no heat capacity of their own? (not to be confused with thermal insulation properties).

Budget foam cannot be used as insulation (since it is flammable); it is necessary to use mineral wool (stone or basalt), and it should be the least hygroscopic (absorb moisture). As a result, with good quality insulation of sufficient thickness + finishing, a frame bathhouse can cost no less than a timber bathhouse (but definitely cheaper than a brick one).

Well, the environmental friendliness of the materials used... remains questionable for many. Yes, manufacturers claim that their mineral wool is environmentally friendly, there is even ecowool, for example. Nowadays it’s generally fashionable to attach the word “eco” to everything, obviously against the backdrop of the eco-boom, wanting to increase sales. But is this really so?

Among the disadvantages of frame baths, they also note the fact that fungus quickly forms on their walls (apparently due to the fact that their walls, lined with synthetic materials, insulation and vapor barrier, do not breathe well, and very good ventilation must be arranged), and in general they are so quickly "getting old."