Of course, this is largely a matter of taste, trust and preference - what material to build your bathhouse from. But we advise you to pay attention to building a brick bathhouse with your own hands.

A long-proven, accessible material, the technology for working with it has been worked out to the smallest detail. By strictly observing some of the nuances associated with the specifics of such a structure as a bathhouse, you will never regret choosing this particular material.

>

We are building a bathhouse from bricks - and this is necessarily a full-fledged structure “for centuries”, which can decorate a site next to a residential building

Building a bathhouse step by step: site preparation

The first step is to work on the construction site. It consists of the following:

- We clean the future construction site of grass, debris, and stumps.

- We make markings for the project.

- We immediately determine the location of the drainage hole.

- We supply communications, electricity and water to make it convenient to work.

- Cleaning up the area

Advice! When starting construction, such a simple point as the supply of communications is often missed. And this is an extension cord, well grounded, a water supply hose. Simple needs that play a role in normal functioning.

Foundation

Foundation for

We will prepare a simple strip foundation for a lightweight structure. You will have to dig it out yourself; ordering an excavator for this work is irrational.

However, there is a small excavation here. Our trenches will be 20-30 cm wide and 30-40 cm deep. Simple strip foundation We dig along the markings, trying not to go to the sides. When the trenches are ready, we set up the formwork so that our foundation rises 10-15 centimeters above the ground. We set the formwork completely horizontally.

From the materials for the foundation we will need:

- Cement.

- Sand.

- Crushed stone.

- Reinforcement with a cross section of 10 mm.

- Red solid building brick that will go to the base.

This is where we immediately pay attention to the failed communications. To mix concrete, we need water and electricity if we have a concrete mixer. We knit the reinforcement, pour 10-15 cm of sand and gravel into the trenches, compact everything tightly, install the reinforcement and begin uniform pouring.

Advice! To make the foundation monolithic and of very high quality, we water it with water for several days in a row. This way it will dry evenly and will not crack.

Preparation of masonry

Which brick for a bath is best to choose?

Next, let's worry about laying the walls. If everything is clear with the solution, there will be nothing unusual in it, then which brick for a bathhouse is better to choose? A simple solid clay brick is ideal. It has all the necessary characteristics:

- Strength. We are building a brick building, and the walls in it must be strong.

- Low moisture absorption. In relation to the bathhouse, this is all the more important, since it will often be humid here.

- Frost resistance. It will be possible to build brick baths in any climatic conditions.

- Low thermal conductivity . The brick takes a very long time to heat up and cool down, so throughout the entire bathing procedure we will maintain an almost constant temperature.

- Easy to use . Even a beginner will be able to lay such solid bricks.

Flaws

https://www.youtube.com/watch?v=TYEXSz_lA0I

Of course, along with the advantages, there are also some disadvantages:

- The cost of building a brick bathhouse is always more expensive than a chopped one.

- Brick has a high heat capacity, so it takes more time to heat such a bath. This problem can be solved with good thermal insulation.

- Brick tends to get damp, as it has less vapor conductivity than wood. However, this drawback can also be corrected with the help of ventilation and vapor barrier.

Masonry

One and a half brick masonry

When building walls for a bathhouse, you can use several types of masonry:

- A simple type of masonry with one and a half and two bricks.

- Double masonry, two walls, and the gap between it is filled with insulation.

- Double wall with air gap.

We will choose a simple option that we can lay out with our own hands for the first time. In our work we will need:

- Master OK.

- A hammer with a small pick.

- Roulette.

- Twine with weights.

- Level and rule.

We put the first row on waterproofing and only from solid brick. Laying must begin from the corners and be carried out strictly according to the level. We will have a string stretched, but we still check the masonry with a level. For excellent adhesion of the brick, it can be moistened in water before laying it on the mortar. We try to keep the seam of the same thickness and remove excess mortar.

Advice! For additional strength of the walls, you can sometimes connect the rows with thin reinforcement or metal plates that are recessed into the joints of the masonry.

With this type of masonry, a brick bathhouse for 3-5 people is built quite quickly, and we finish the load-bearing walls in a few days.

Russian bathhouse: brick or log house?

Building a good Russian bathhouse is far from being as simple as it seems at first glance. During this work, you will encounter a lot of different troubles, you will have to make many difficult decisions, you will need to decide on its style, and it will depend on your taste and financial capabilities.

It is important to decide on the materials that you plan to use; their variety on the market is now very large, however, as before, the main ones are wood, brick and stone. Brick baths are very strong and durable, so such a bath will last you much longer than a wooden one, its performance and external qualities will be maintained at a very high level. The thermal conductivity of stone walls is higher than that of wooden ones, therefore, in order for it to be warm and comfortable, they must be thick enough. Stone and brick are much more fire resistant than wood; in the event of a fire, they will simply become less durable, but will remain structurally intact.

It is very important that the heating and electrical systems of your bathhouse are sufficiently reliable and properly operated. Stone baths are more expressive and varied in their architecture; when building such a bath, you can make almost any of your fantasies come true, in addition, you will have many different options for its decoration. Its walls can be lined with both natural and artificial materials: tiles and bricks; the color and texture of the finish can be absolutely any. The main disadvantage of a brick bath is its relatively high cost. As for wooden baths, they are, accordingly, cheaper, as well as more environmentally friendly and healthier; designs for log baths are presented quite widely, from simple to elite. The atmosphere of such a bathhouse is literally filled with forest and pine aromas; the sunny and warm colors of the walls will not leave anyone indifferent. In such a bathhouse you will have a great rest and relaxation after a hard day at a crazy city pace. The thermal conductivity of wood is very low, that is, the walls of such a bathhouse retain heat much better than brick walls, so their thickness can be significantly less, and accordingly, you will seriously save on construction costs.

The weight of the tree is also small, which means you can save on the foundation. It is much easier to warm up such a bathhouse than a brick one. You will never feel damp in it, since the wood is able to “breathe”, all moisture will escape from the room to the outside. From an architectural point of view, a wooden bathhouse is somewhat less expressive than a stone one (although ancient Russian architecture indicates the opposite), on the other hand, it gives confidence and symbolizes sustainability in life; you will always feel comfortable and cozy in it. Wooden baths are built from rounded logs and profiled timber. The surface of the timber is well processed, so it can be painted and varnished with a variety of compositions; periodically it will be necessary to renew the coating. After the final shrinkage of the bathhouse, it will need to be sheathed on the outside; for this you can use polymer lining or siding; it will make the bathhouse more modern, in addition, it does not require virtually any maintenance.

A wooden bathhouse is less fire-resistant than a stone one, so it is especially important to correctly install and operate electrical appliances. It is very important to calculate the required power of the electrical network when installing stoves and fireplaces, strictly follow the design requirements, in this case you will not be afraid of fires.

Find a repairman

—

—

—

Window coverings

Window coverings from a corner

When building a brick bathhouse with ceilings, questions may arise, after all, we do everything ourselves. However, this design is complex only at first glance.

We can choose from several types of flooring:

- Metal corner.

- Concrete lintel in the form of a finished beam.

- Self-made concrete lintel.

- Wedge brickwork.

By the way, the last option is the most beautiful; you can also use double sand-lime brick M 150 for it, but it is also the most difficult option. The easiest way is to install a metal corner and continue building the walls.

Brick bath projects

Having chosen brick as the main material for building a bathhouse, it is worth thinking about the layout of the structure. There are many designs for brick baths, but most of them are variations of several basic ones.

Bathhouse 4x6

The structure is divided into 3 main rooms:

- Sink (area 1.75 m2);

- Steam room (4.75 m2);

- Recreation room (10.4 m2).

Fans of bath procedures consider this layout not very successful, since the direct entrance from the street to the relaxation room will lead to the rapid cooling of the bath. There are several ways to fix this problem:

- Extension of a vestibule (preferably insulated);

- Organization of a covered veranda;

- Installation of an additional partition, which creates a small vestibule.

A stove heated with wood from the rest room will help ensure maximum functionality of the bathhouse. This point needs to be thought through at the stage of installing the partition, in which a passage is made that is slightly larger than the firebox. Subsequently, the metal casing is covered with a heat insulator, and the remaining empty spaces are filled with brickwork.

Insulation and waterproofing of walls

Insulation of a brick bath

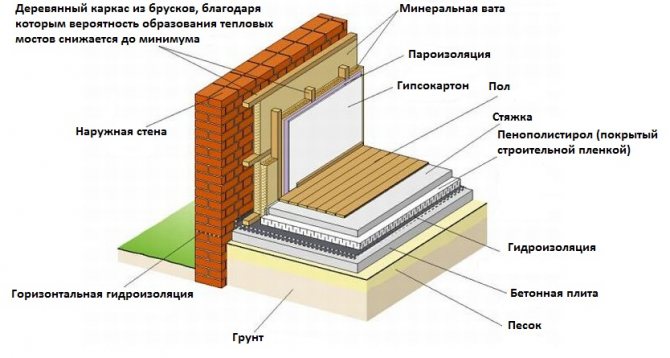

When there is a debate about which bathhouse is better, brick or log, you always need to take into account a lot of nuances, and it is impossible to simply answer the question. But we can definitely say that a bathhouse built of brick and insulated with mineral wool is simply a great option.

Wall insulation is carried out after the walls are erected and the roof is installed. It's practically finishing.

First we waterproof the walls. The easiest way is to paint the walls in several layers with mastic. You can also apply roofing felt. The main thing for us is to achieve waterproofing, so we choose a simple option.

Next, we apply lathing to the wall, it can be wood or metal, and lay mineral insulation. This is the most effective and efficient method, which both insulates the bathhouse and allows air to circulate, the mineral wool “breathes”, and for a bathhouse this is very important.

Design Features

The design of the bathhouse must take into account all possible nuances of operation, reliability and stability indicators. After comprehensive development of the project, a construction estimate is drawn up. This includes the cost of materials and services before the facility is commissioned to the customer. The location for laying the foundation should be chosen dry, away from bodies of water at a distance of 30 m. Such a measure will prevent spring flooding and erosion of the foundation.

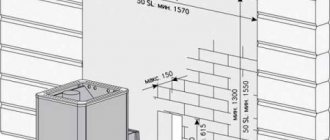

According to the rules, a wood-burning bathhouse should be 12 m away from the house; with a gas or electric boiler, 5 m is enough. The most budget-friendly option is a bathhouse built in conjunction with the house. Communication costs are saved, the foundation can be built simultaneously, and delivery costs are reduced when purchasing materials.

There are important points when designing and installing a brick bathhouse.

- It is recommended that the windows of the paired compartment be made from the west, then the natural light will last for a long time and less often you will need to turn on the electricity.

- The distance to the border of the neighboring plot (fence) should not be less than 6 m.

- Windows and doors must open outward to meet safety requirements.

- The heater firebox must be located opposite the door to the dressing room.

- Benches in the washroom should be located starting from half a meter from the floor.

We suggest you familiarize yourself with the height of the steps according to GOST

Having chosen the brick option and decided to build a small bathhouse on your own, you need to consult with specialists. If a wooden structure is assembled as a constructor, then a brick bathhouse requires a more strict attitude towards itself, the necessary calculations of the foundation, load-bearing walls and the installation of additional systems.

Interior finishing

Salt brick for interior decoration of a bathhouse

Internal work is always carried out at the request of the bathhouse owner. However, there is one more nuance that we want to talk about. To lay out the floor, you can use salt bricks for a bath, an excellent material that has amazing healing properties! Salt brick By the way, you can use this material to make a bathhouse made of bricks with your own hands. Salt material has an excellent healing effect, the skin becomes more elastic and soft, and the functioning of internal organs improves.

Option “Home bath”

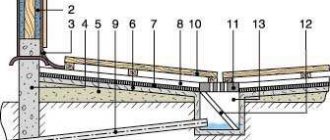

In cold weather, it is very difficult to put the bathhouse into operation (warm it up to working condition). Periodic operation prevents this, since in the cold the structure looks like a block of ice. The above method is also the best for these operating conditions. The load-bearing brick wall in this case serves as a support for the frame structure.

The vertical beam is attached to it using standard ventilated frame technology - on brackets or hangers for the profile of gypsum plasterboard systems. The thickness of the insulation is calculated in a special program; to do this, it is enough to indicate the existing parameters of each layer. You also need to look at the diagram where the dew point falls. Although in this case the occurrence of moisture on the internal walls is unimportant, since in the washing room and steam room moisture is present in any case.