Construction of a foundation for a bathhouse made of expanded clay blocks

Since ancient times, bathhouses have been built from wooden materials, using ordinary strip foundations with sand and gravel pads for the base. But modern technologies have suggested the use of expanded clay concrete or FBS blocks for small and light structures instead of monolithic filling of trenches with mortar. And now, building foundations for small buildings with your own hands takes little time and money. But you should first decide what material the base of the bathhouse will be made of.

Selecting material for the foundation of a bathhouse

Building a base for a bathhouse with your own hands involves choosing a material not only based on its cost, but also depending on the soil on which the structure will be built. For the optimal selection of blocks from which the base will be made, it is worth knowing the basic parameters of the materials used.

If the soil in the area where the building will be erected, with a large predominance of sand, is hard and durable, then it is worth using FBS blocks for the foundations. They are heavy and do not require additional time to shrink.

And on those soils that are highly loose or mobile, it is advisable to use fine-grain expanded clay concrete blocks for the foundation. Their weight allows you to quickly and easily build a foundation for a structure due to their good strength and high density.

The use of block foundations is also good because it has high flexibility due to the seams between the blocks, with increased heaving of the soil. This type of soil foundation will not be able to tear or damage during physical impact.

Many owners prefer to make the foundation for the building from foam blocks with their own hands. Such materials have their excellent properties:

- Resistance to low temperatures.

- Durability in use.

- High water-repellent parameters.

- Light weight and easy installation.

- Low degree of toxicity.

It is worth noting that foam block foundations are fastest to build when the trench is made slightly wider than the material used. Therefore, all that remains is to lay the blocks with your own hands, one after another, on the prepared pillow and connect them together with a solution. But for better shrinkage of foam blocks, it is worth using additional measures in the form of reinforcement not only with rods, but also with mesh . Therefore, preference is given to a base made of medium-sized expanded clay concrete slabs.

What materials are needed to build a bathhouse?

The most expensive will be blocks, roofing and finishing materials. If insulation and sound insulation are planned, then additional costs will be added to everything else. The cost of windows, doors (depending on the design of the bathhouse), finishing the rest room and the stove itself is calculated separately.

Depending on the area and the intended rooms, it is calculated how much money is needed to realize your bath dream.

The cost of a bathhouse of 18 m? on average it will cost 250,000 rubles, but if you decide to build a bathhouse from expanded clay concrete blocks with your own hands , it will be cheaper. The advantages of such an area are obvious: the presence of a spacious steam room, shower room and relaxation room.

The advantages of expanded clay block are the budget price of the material. Consumer reviews in 90% of cases show the advantages of the selected building material.

The method of construction also affects the total cost; if the work is carried out by specialists, then on average the price varies from 15,000 rubles. for m?. When you build a sauna from expanded clay yourself, you can build exactly the project that you like, and at the same time save on paying the craftsmen. The advantage of self-construction is that you can finance the project gradually, without significantly depriving the family budget.

Depending on the type of material chosen, insulation and sound insulation will require additional investment. For solid blocks, external insulation is sufficient, but for hollow ones, additional use of expanded polystyrene . If the bathhouse is located far from the house, then sound insulation is not needed at all.

The blocks have significant advantages, many positive reviews and a relatively budget price, so when building a bathhouse, do not forget about expanded clay concrete.

Among the many options for baths, one of the most attractive at the moment is the construction of expanded clay concrete. But in order to enjoy its benefits and not encounter operational problems, it is recommended to strictly follow the operating technology. And it, although not too complicated, contains quite a lot of nuances.

Options for bath foundation types

Since the bathhouse building is a lightweight structure, the load on the foundation will be small. Therefore, you can make the base yourself using the simplest options:

- columnar method - the foundation consists of 4 corner pillars, and several additional supports, which are placed at a distance of 2 m from each other. The pillars are connected using the method of tying metal corners or channels. Walls are placed on the resulting structure;

- strip method - the foundation looks like a continuous strip along the entire perimeter of the future building. Expanded clay concrete blocks are laid on a cushion and reinforced on top with rods of medium section.

There are several other types of foundation masonry, but they are very expensive and take a long time to create.

In relation to a small bathhouse, when the building occupies a small area and does not need a basement, the ideal option would be a columnar foundation, which is easy to make with your own hands with a small investment. Here, the consumption of expanded clay concrete materials or foam blocks for the base is minimized. And the work is carried out quickly, which allows you to get a structure in a short period of time.

If the bathhouse is large, with a basement or garage, then you should give preference to a strip-type base made of expanded clay concrete materials or FBS blocks, which can withstand significant loads and have almost no shrinkage after complete drying in the finished foundation. The use of foam blocks in this case is impractical and wasteful.

Having chosen the preferred option, it is worth starting work on the construction of the foundation for the bathhouse, which is often done with your own hands, without the involvement of specialists.

Preliminary work on the foundation

Basically, owners prefer to install a strip-type foundation for a bathhouse with a shallow depth. This allows you to save money, since the cost of foam blocks is considerable, and for a standard depth it will cost a little more. You can, of course, use FBS, but still the consumption of materials at a standard depth will be greater.

To begin any construction operation on the ground, it is worthwhile to carefully mark the future structure. But before that, you should remove the top layer of soil and level the area for the building.

Marking is not difficult and can be done with your own hands, carefully transferring the dimensions from the project drawing to the plot of land. You need to mark not only the corners of the building, but also the partitions, which will then be in the middle of the room. Trenches also need to be laid under the partitions so that the load on the foundation is uniform.

Once all the dimensions have been transferred to the plot of land and marked with stakes, you can begin digging trenches. The width of each trench can be made 15 cm larger than the size of the blocks used for the base. You can go only half a meter deep, although sometimes the depth can be only 40 cm.

It is necessary to calculate the depth of depth depending on the expanded clay concrete materials. The average depth for such a foundation is quite suitable. But for the use of lightweight foam blocks, the depth is 10 cm greater than usual standards.

Trenches for foundations, for which FBS slabs are taken, can be made in standard sizes. Since slabs made of such material are quite heavy, they themselves will compact the soil and cause sufficient deep settlement during the pouring and cooling of the solution.

Stages of work to create a foundation for a bathhouse

When the trenches are ready, construction of the foundation of the building can begin. All construction work is divided into several stages:

- Laying a sand-gravel or sand-crushed stone cushion.

- Creation of a waterproofing layer.

- Construction of the first base layer from FBS or expanded clay concrete blocks.

- Reinforcement of the foundation with corrugated rods of medium section.

- Filling trenches with concrete solution.

It is worth remembering that the blocks must be bonded together with a solution before the main pouring. The optimal dimensions of the seams should not be more than 1 cm.

Secondary moisture insulation must be installed after the foundation tape has completely dried. This way there is a greater chance of preserving the foundation from constant dampness.

Bathhouse made of expanded clay concrete blocks: foundation, finishing, insulation

Wood has been a traditional material for building baths for centuries. But time does not stand still; new methods for producing affordable building materials are emerging. Today, blocks made of expanded clay concrete are a more affordable, but no less durable alternative to wood.

The good thing about the material is that it is highly resistant to rotting, does not contain toxic elements, and is excellent at removing moisture. This is especially important for a bathhouse where stoves will be installed. Building a bathhouse from expanded clay concrete blocks is quite simple, so you can do the work yourself. This material describes in detail the foundation, finishing, and insulation of the building.

Owner reviews

Those who have built a bathhouse for themselves from expanded clay concrete blocks note that it is more economical than a structure made from timber. As for possible shortcomings, experts recommend paying attention to protection against moisture penetration into the walls. This is quite enough to guarantee long service and active use of the bathhouse without any consequences.

All work can be completed within a few months, and then the building can be immediately used for its intended purpose. What is important is that professional teams constructing custom-made expanded clay concrete baths extremely rarely encounter customer complaints.

To learn how to build a bathhouse from expanded clay concrete blocks, see the following video.

Preparation for construction

In order for the design to be reliable, it is necessary to take ready-made projects. They indicate in detail the dimensions of the future bathhouse and the necessary materials. It is recommended to think about renting construction equipment, as it will make the work go faster.

The tools we will need are:

- Building level or alternative electronic tool;

- Spatulas - it is recommended to take tools of different sizes;

- Pegs for marking;

- Rope;

- Rollers, including rubber ones, for leveling the surface.

- Tools for digging a trench - these can be replaced by rented construction equipment.

Blocks must be purchased from a trusted place; when choosing, check whether there are any chips or cracks on the blocks. To build a bathhouse, you don’t need many of them, so you can spend time checking the blocks.

Construction of the foundation

For a bathhouse made of such material, two main projects are now used:

- On a columnar base;

- On a shallow strip foundation.

If you plan to build a bathhouse yourself, then it is best to take material with a fine fraction. Before laying the foundation, it is necessary to prepare a two-layer cushion of gravel and sand. The thickness of such a pillow depends on the soil on the site.

Helpful advice! If you plan to build a small structure, then the foundation can be pillars made of expanded clay concrete blocks, installed in the corners and at a certain distance under the walls. A harness is installed on them. The next step is to build the walls, floor and ceiling.

If you plan to build a large bathhouse with a swimming pool and a separate recreation area, then it is better to make a strip foundation. It is better to take ready-made projects developed by professional builders.

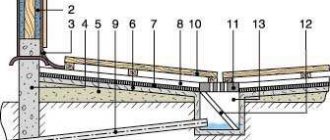

The foundation is erected according to the following scheme:

- Work begins with removing the top layer of soil on the site where the bathhouse will be built. Using pegs, you need to mark the line of the walls and corners. The pegs are driven into the ground, then you should take a rope and stretch it between the beacons. The base tapes must also pass under the partitions.

- Under the strip foundation, you should dig a trench with a depth of 40-50 cm. The trench is filled with a 20 cm layer of crushed stone, and then with a 20 cm layer of sand. The pillow must be thoroughly compacted and watered.

- The next stage will be the insulation of the future floor - it is done using roofing felt, which is laid in a double layer. Waterproofing floors is required to protect the structure from moisture from the soil.

- Next, the foundation itself is built from the blocks. Standard projects involve three or four rows of blocks; the number of rows must be calculated based on the height of the base. The masonry must be carried out together with dressing of the sand-cement mixture. In order for the structure to be insulated and strong, the thickness of the seam should be within 0.7-1 cm.

- It is important to ensure tensile strength. To do this, use reinforcement mesh, which is placed between the rows. An important tool during installation is the building level. If the blocks are laid unevenly, this will affect the strength and stability of the building in the future.

- The main advantage of this design is that the foundation dries in only 1–2 days, since concrete blocks are not used here. The most important thing is that the seams between the blocks dry completely.

- The next step is to waterproof the base, which is done with bitumen mastic. It is important that the waterproofing material covers all sides of the foundation. The horizontal plane should be covered with roofing felt.

Insulation of expanded clay concrete walls

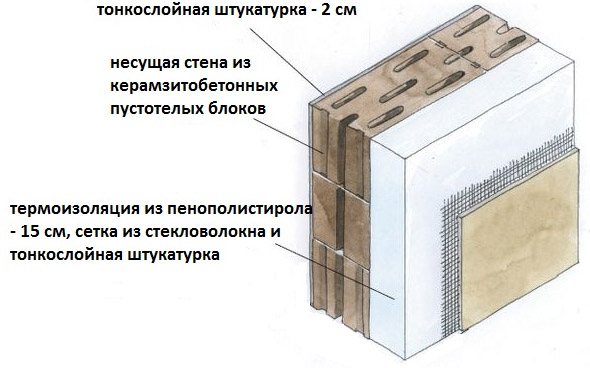

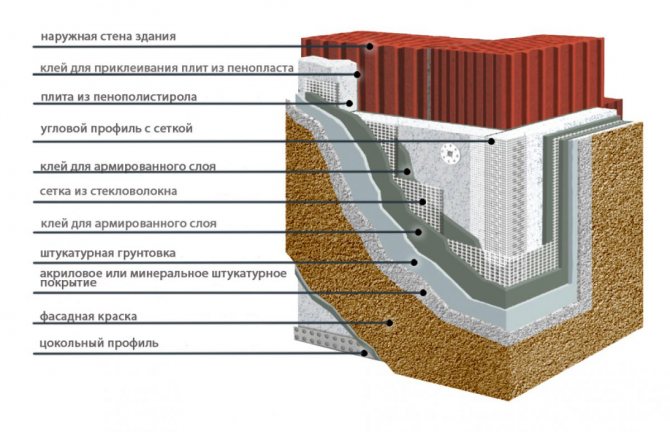

Expanded clay concrete blocks must be reliably protected from moisture and wind. First, you should start with the exterior decoration of the walls. Standard cement plaster is the main protective layer for walls. It is recommended to take cement and sand in proportions of 1:4, then the solution will obtain the desired consistency.

Exterior finishing is carried out according to the following scheme:

- First, the walls are plastered with the first layer.

- Next, using a grater, the walls must be rubbed so that the surface is uniform.

- The plaster dries in about 12–15 hours, the next layer can be applied the next day, then the grouting procedure should be repeated. Ideally, the plaster layer should be 1.5–2 cm.

- When the plaster has dried, you can proceed to applying primer in one layer, and then facade paint. It is best to use acrylic-based paint.

Internal insulation and finishing of walls and ceilings

The insulation of a bathhouse made of expanded clay concrete blocks is carried out from the inside; on the outside, protection of the ceiling and load-bearing walls from moisture and wind will be provided by soil and acrylic paint. The building must warm up quickly and also maintain a high temperature. If the construction of walls and floors is carried out from expanded clay concrete blocks, then the bathhouse must be insulated from the inside with natural wood or mineral wool. It is safe and the most suitable material for this purpose.

Particular attention should be paid to the ceiling, since it is through it that the main heat loss occurs. Most often, ceilings in bathhouses are made of wood, so the most common means of insulating ceilings can be either mineral wool or sawdust sprinkled with clay. Previously, only sawdust was used to insulate the ceiling due to the lack of other materials, but this does not mean that they are obsolete. Thermal conductivity characteristics are not much worse than expanded polystyrene, and the cost is several times lower. Due to common prejudices and lack of demand, sawdust can be found for free, only transport costs.

For interior decoration of floors, ceilings and walls, it is best to use varieties such as alder, linden and aspen. It is recommended to use tiles for the washing compartment. As for the rest room, you can choose any materials for the floors, ceiling and walls.

Furnace structure

You cannot ignore such a moment as choosing a stove bath. The main criterion for this choice is the achieved thermal power and the ability to adjust it. The size of the steam room helps determine whether sufficient heat is generated. On summer days it will warm up in an average of 30 minutes, and in winter about an hour.

When calculating the heated area, the dimensions of not only the walls, but also the floor and ceiling are taken into account.

Taking into account the heating of the oven, the stones in it and the water tank, the resulting figure can be safely increased by 2.5–3 times. When calculating, they also take into account what the walls and floor are covered with, how powerful the thermal insulation is provided, and how much heating of the bath is required. Adjusting power is easiest for gas and electric heaters; it is a little more difficult to do with wood heaters. The adjustment methods are as follows:

- air control;

- heat removal to the outside;

- adjusting the flow of fuel inside.

You cannot install a low-power device that would reduce costs. After all, even if such a furnace manages to work properly, it will have to produce all possible power and continuously work to the point of wear and tear. Therefore, the service life is noticeably reduced. A traditional-looking stone stove will only be acceptable if you have a professional stove maker in mind. Adherence to tradition will force you to put up with prolonged heating and difficulties during ignition.

The firebox can be either elongated for installation in a wall, or regular. The first type has lower fire risks and allows you to create a comfortable microclimate, but may be more expensive. To reproduce a real Russian stove, it is recommended to buy an autonomous electric steam generator; it can cope with all possible problems.

A high-quality stove should be able to heat the air right under the ceiling to 80 degrees so that you can steam there comfortably. Heaters are made open or closed according to design.

In the open format, the air is heated by the stones themselves, heated on the fire. This solution is ideal for a heavily visited bathhouse: the air in the steam room is thoroughly warmed up very quickly and cooled down in the same way. The closed oven is equipped with a special damper that helps isolate the top row of stones. But long-term retention of heat results in slower heating overall. Among other parameters, it is always worth finding out how long the stove can heat a room without receiving additional fuel.

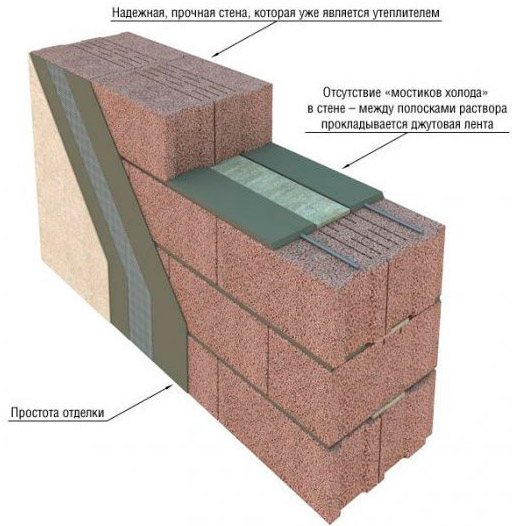

Bathhouse made of expanded clay concrete blocks

A bathhouse made of expanded clay concrete blocks is not necessarily additionally insulated. If the thickness of the expanded clay concrete bathhouse wall is 700 mm or more, you can plaster it and the house will be warm and the bathhouse will be quite effective. But a free-standing bathhouse building with walls made of expanded clay concrete blocks less than 0.7 m thick, as well as a bathhouse in a cold northern climate, requires additional thermal insulation. Briefly about expanded clay concrete blocks: this is a fairly traditional wall material that has some advantages over cinder blocks and brick materials. A filler made of expanded clay granules (foamed baked clay) serves as a coarse aggregate in the composition of expanded clay concrete, a fine aggregate is sand, and the binder is Portland cement. The blocks are molded and vibrated to produce an excellent and inexpensive wall building material with excellent thermal insulation properties, quite durable and yet lightweight. For more than half a century of use, expanded clay concrete has shown many advantages and confirmed one extremely unpleasant disadvantage - strong moisture absorption. Expanded clay blocks, unprotected from atmospheric moisture, absorb water, freeze and collapse in winter. Taking into account the fact that the walls of expanded clay concrete baths in the central zone of our country are usually built with a thickness of half a block, or 300 mm, and less often two blocks - a little more than half a meter, it is clear that one cannot do without thermal insulation in harsh winter conditions.

Owner reviews

“I am the owner of a private house, and when choosing the type and material of the bathhouse, I chose expanded clay blocks and the option of adding an extension to an old building. I made the base separate: between the main foundation wall and the new tape I placed a layer of polystyrene foam insulation. For tying, I used anchors, corners, bottoms, and reinforced each 3rd row with mesh. I did not insulate the interior; I covered all the walls in the steam room with foil and lavsan, and protected the outside of the bathhouse with mineral wool and plaster. With the exception of coloring the edges when cutting, I didn’t find any disadvantages.”

“I built a bathhouse from expanded clay concrete blocks two years ago, used hollow ones on all rows except for the bottom two, insulated with mineral wool from the outside around the entire perimeter, plus inside the steam room. Overall, I was satisfied, but a couple of times there were problems during laying, you should be prepared for high consumption of cement-sand mortar - it took me at least 100 kg per 1 cubic meter with a minimum thickness of seams of 6 mm, the walls are far from ideal.”

Pavel, Nizhny Novgorod.

“I ordered a turnkey detached bathhouse, with dimensions of 8x6 m, a shallow concrete foundation and walls made of expanded clay blocks, the company’s services cost me 280,000 rubles. The advantages of the masonry material include lightness, fire safety and a good microclimate; there is no dampness inside and there are no foreign odors. The disadvantages are the high costs of insulation and vapor barrier, but I don’t think that another type would require less protection.”

“As the owner of a bathhouse made of expanded clay concrete, I can note that it crumbles without insulation; measures to protect against freezing and steam must always be taken immediately, no matter how thick the walls are. In my opinion, it is possible to do without its thermal insulation only in the south. Otherwise, I didn’t notice any special differences between expanded clay concrete and cellular grades: the same need for reinforcement, protection of basement areas and immediate finishing from moisture.”

“I used expanded clay concrete to build a bathhouse, erected the walls in one block, followed by thermal insulation with basalt wool slabs 50 mm thick. The products are quite durable, but can crumble if dropped from a great height, I advise you to provide a reserve. I didn’t find any other disadvantages; among the advantages I can note good heat and sound insulation.”

“When choosing masonry building materials for the walls of the bathhouse, I chose expanded clay blocks for two reasons: fire safety (I calmly installed an iron stove next to the wall) and affordable cost. According to my calculations, construction cost me 1.5 times less than timber, and besides, I personally found laying it easier than joining wood. On the advice of experienced builders, I used ready-made mixtures as a solution; with their help, the seams were no thicker than 5 mm.”

Advantages and disadvantages of baths built from expanded clay concrete blocks

The clear advantages include:

- Lightness: with the same volume of masonry, expanded clay concrete weighs 2.5 times less than brick. At the same time, it outperforms gas and foam concrete in compressive strength. This property allows you to build baths with reduced foundation requirements.

- Fire safety. Expanded clay blocks can withstand open flame for up to 7-10 hours without losing their shape and strength, then they simply crumble without releasing toxins or smoke.

- Providing good sound insulation.

- Quite low thermal conductivity; masonry in one wall block and additional insulation with mineral wool no thicker than 50 cm is considered optimal. The material ensures good heat retention inside the room.

- Low labor costs for masonry.

- The ability to breathe, providing a good microclimate.

Checking the certificate and clarifying the composition is a mandatory stage of purchase. The considered disadvantages and limitations of any expanded clay concrete include:

- Formation of cold bridges during the laying process. The recommended seam thickness is 2-5 mm; only experienced builders can achieve it. The situation is complicated by the fact that geometric accuracy is not always observed.

- The need for frost protection (additional insulation). In practice, home owners note the destruction of building materials (or a decrease in its strength) in the absence of a thermal insulation layer. It all depends on the operating conditions: with a weak impact of frost heaving of the soil and a warm climate, the basement sections of the bathhouse are boldly laid from expanded clay blocks, but in the middle zone they, on the contrary, are isolated from the base with a layer of cement mortar at least 3 cm thick, the walls must be insulated.

- Shedding and uneven edges during processing (cutting).

- The need to strengthen structures. This condition is relevant primarily for residential buildings, but openings, corners and lower rows are reinforced even in light buildings.

Low frost resistance is the main drawback; by taking protective measures, the owner will receive a lightweight, durable (from 50 years and above) building that is not afraid of shrinkage, high temperatures, rotting and moisture.

Bathhouse construction costs

The cost of the products themselves depends on their hollowness and brand; on average, one high-quality three-slit block with a standard size of 400×200×200 mm will cost 50 rubles (from 3150 per 1 m3), solid ones (recommended for the lower rows) - from 57. On sale There are cheaper options, but due to the risk of containing synthetic bath additives, they are not worth buying. The minimum cost for masonry when contacting professionals is 2,000 rubles per 1 m3 (when using ready-made mixtures and plastic reinforcement, including the cost of all building materials).

Insulation of a bathhouse made of expanded clay concrete blocks

Of the traditional insulation systems, the most reliable, time-tested option is two-layer wall structures with cladding. The walls are covered with facing bricks and the gap between the wall of the house (any wall - frame or block) is filled with thermal insulator. In addition, effective waterproofing is required - cut-off from capillary moisture along the upper edge of the foundation, insulation technology without creating cold bridges, consumables - masonry mesh for cladding, expensive facing bricks, plastic disc anchors for fastening thermal insulation to expanded clay blocks. Cladding in half a brick is a job for a qualified mason, and the cost of this insulation will be considerable. For a bathhouse, this is hardly a rational expense. But there are also insulation materials and insulation technologies that allow you to reduce costs and obtain effective thermal insulation for a bathhouse.

One of the almost ideal insulation materials is basalt mineral wool mats, based on volcanic rocks, available in different density levels. The material is absolutely non-flammable and easy to install. Another plus is that stone wool does not attract mice and their entire company; there will be no beetles or microflora either. Basalt wool is absolutely not biodegradable. The structure consists of fibers, but the product is quite dense and elastic, and the thermal protection indicator is one of the highest among analogues. The only negative is that, like any material with a fibrous structure, basalt wool has hygroscopic properties, which requires the cost of a vapor barrier membrane from inside the bathhouse premises. In terms of density, more expensive mats are preferable for work, that is, denser ones, especially for insulating vertical surfaces.

For comparison, you can consider the option of glass wool - the thermal protection is not much lower than basalt mats, but the fastening technology will require protecting the skin, eyes and lungs - small glass needles are dangerous to health. When moistened, glass wool mats shrink and require replacement; for bathhouse walls, this option makes the use of glass wool irrational. Insulation from sheet foam is technologically advanced, a dense sheet is easy to install, and this material practically does not absorb water, and it has high heat-protective properties. The disadvantage is the flammability and toxic properties of smoke, as well as the fluidity of the material when ignited - foam insulation can spread fire throughout structures in a matter of minutes. For mice and birds, this completely synthetic material, not surprisingly, is very attractive - dense, the burrows are durable and there is access to air. Plus - the price of polystyrene foam is low, and the insulation can be closed in a “wet facade” system to prevent the possibility of ignition.

Extruded polystyrene foam is more expensive, but much stronger than polystyrene foam, and even under heavy load it does not crumble into granules, as is the case with low-quality foam plastic. But the vapor-permeable properties of all polystyrene foam are zero, which is excellent for thermal insulation on a concrete foundation, but unacceptable for bathhouse walls. Another option is backfill insulation made from expanded clay gravel of medium fraction, an excellent option for filling the gaps between the facing brick wall and expanded clay blocks, as well as for insulating the floor and ceiling from the attic.

For reasons of practicality, all of the above options can be reduced to two: a dense mineral wool basalt mat as insulation in a ventilated facade system, taking into account the fact that you will have to spend money, but have high-quality insulation for several decades. The second option is foam insulation for plaster finishing using the “wet facade” type and decorative plaster to look like stone or bark beetle.

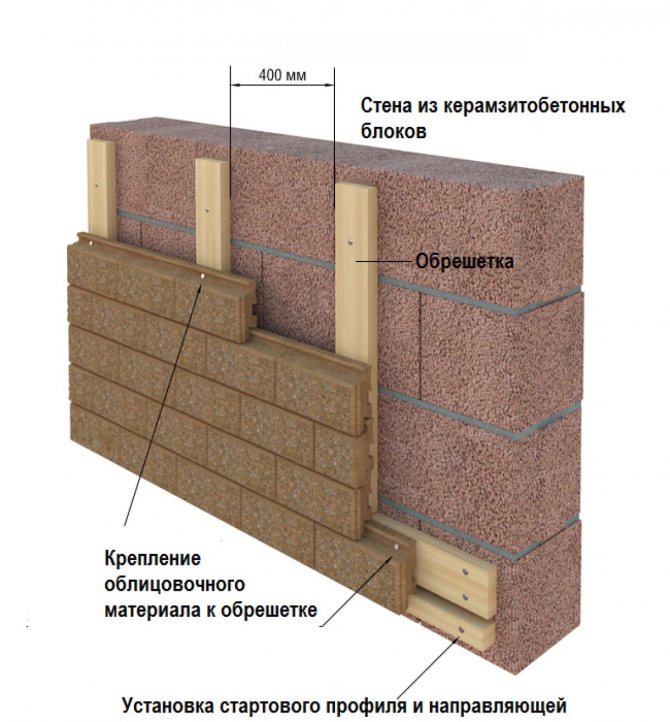

For any insulation method and material, a porous expanded clay concrete wall is treated with penetrating primers twice, with each layer completely drying to strengthen the surface. an insulation system with mineral wool basalt mats similar to a ventilated facade requires fasteners, and you can use either a wooden block for lathing and counter-lattice, or a special metal profile (rack profiles and guides for plasterboard facings). When fastened, the metal frame gives quite high point loads on porous expanded clay concrete blocks, so many craftsmen choose a classic wooden block. When choosing a beam section of 50*100 or 50*150, take into account the thickness of the insulation - 100 or 150 mm. The thickness of the timber should not be less than the thickness of the thermal insulation. The wood is antiseptic and treated with a fire retardant before installation.

Under basalt mats it is possible to exclude a vapor barrier membrane, but for a bathhouse a vapor barrier will not be reinsurance. The rolled sheet is wrapped around the wooden sheathing and the insulation is secured with staples. The insulating mats are tightly inserted between the guides (their pitch is selected taking into account the width of the mat and its shrinkage of approximately 30-50 mm, as well as for installation in a clamp. The insulation is fixed with plastic disc dowels. Next, a layer of windproof diffuse membrane is laid. The membrane should provide waterproofing , just like a vapor barrier from the outside, but steam must escape from the wall into the atmosphere freely. The technology includes a mandatory clearance between the diffuse anisotropic membrane and the outer cladding. The clearance is provided by a counter-lattice, which is stuffed along the load-bearing posts of the sheathing frame, the material is a 40*40 block ; 50 * 50 mm. The minimum clearance width should be 25 mm. A beam with a cross-section of less than 40 * 40 mm is not suitable for subsequent fastening of siding or block house lining. Budget options for plastic siding are also possible, but for a bathhouse a wooden finish is desirable. As a result, the thickness of the expanded clay concrete wall with insulation, finishing inside and outside will be approximately 650 mm, and in terms of heat-insulating properties, this wall pie is similar to a brick fence with an unreal thickness of more than 900 mm - for a wet, periodically heated bathhouse, such insulation will not be unnecessary.

Insulation of a bathhouse from the inside is carried out based on the condition that it is unacceptable to “lock” moisture in the wall - especially in a steam room. The use of basalt wool is justified by its characteristics - stone wool is not afraid of any heat, it can withstand a thousand degrees. But the mats are too hygroscopic, and waterproofing requires complex vapor removal systems in the wall cake. One of the methods for insulating a steam room wall made of expanded clay concrete blocks from the inside is to use a subsystem made of a wooden block of small cross-section (30*40 mm) in two rows with a layer of foil-coated heat-reflecting material and a clearance for ventilation. The finishing on the inside is usually done with wooden lining made of alder, linden or other moisture-resistant wood species.

Thermal insulation materials for expanded clay concrete blocks

This building material has the following advantages:

- environmental friendliness and absolute non-toxicity;

- insignificant moisture absorption, non-susceptibility to the destructive effects of steam and liquid;

- excellent thermal insulation properties that help retain heat in the room;

- relatively light weight expanded clay concrete blocks.

Thermal protection of a bathhouse, due to the specific use of this building, requires the use of various methods of thermal insulation in each section. For this reason, it is necessary to have knowledge and experience on how to insulate a bathhouse made of expanded clay concrete blocks shown in the photo.

To ensure high-quality thermal protection, you need to take into account the structural features of the structure and the influence of the environment on its various elements. Of course, insulating a bathhouse made of expanded clay concrete blocks from the inside differs from external thermal insulation.

This building material is made from several components using vibrocompression technology. The process consists in the fact that baked and foamed clay (expanded clay is made of it), as well as sand and cement, are thoroughly mixed and compacted under high pressure and vibration loads. The resulting expanded clay concrete block is characterized by lightness and at the same time increased strength.

Insulation of a bathhouse made of expanded clay concrete blocks from the outside is carried out using glass wool, mineral wool or polystyrene foam. First, the walls are checked for stability and calculations are made of the designed facade and the load exerted by thermal insulation and finishing materials is calculated.

It is necessary to take into account that:

- The walls must be reinforced with a mesh that provides the entire structure with the required stability.

- When the thickness of bath walls is more than 70 centimeters, there is no need to install powerful thermal protection, since expanded clay concrete blocks are a heat-saving building material.

You can insulate walls from such blocks in one of the following ways:

- Brick lining of the outer part of the bathhouse building, but this option is quite expensive and therefore few people use it.

- By using a thermal insulation material such as thermal fiber, mineral wool or polystyrene foam. All of them have good heat-saving qualities and relatively low cost.

To carry out heat protection measures when building block baths, the following are most often used:

- Thermal fiber. The advantage of glass wool is its environmental friendliness and safety for human health. It is used as thermal protection for both internal and external walls. Before installing the insulation, you need to clean, dry the wall and plaster it. Plaster enhances the thermal insulation properties of enclosing structures.

- Minvatu. Before insulating a bathhouse made of blocks using this material, it is necessary to clean the wall and build a frame in advance. Then only you can install the mineral wool. Its greatest advantage is its environmental friendliness. This material is able to resist the spread of fire and prevent heat loss. When carrying out thermal insulation work, the mineral wool is certainly covered with a layer of vapor barrier.

- Styrofoam. Its main advantage is its affordable price. Among the disadvantages, noteworthy is the flammability of the material and its damage by insects. He also needs protection from rodents. When using polystyrene foam, the thermal insulation layer must be covered with a reinforced mesh.

Insulation of baths made of expanded clay concrete blocks with foam plastic. Expanded clay blocks are an inexpensive and accessible building material. But its thermal insulation qualities are significantly inferior to those of natural wood, so a bathhouse built from expanded clay concrete needs insulation.

Functionally, the bathhouse is intended for healing procedures, therefore all materials used for its construction must be of high quality and environmentally friendly. This also applies to insulation materials, whose action is aimed at maintaining a comfortable temperature in the premises. The negative impact of samples that are not resistant to its changes and emit harmful substances is greatly enhanced by the extreme “climatic” conditions of the bathhouse.

We invite you to familiarize yourself with How to implement a bathhouse project with a kitchen

This fibrous insulation is obtained by processing basalt rocks. The natural composition of the insulation guarantees its absolute harmlessness. Sometimes the reputation of basalt wool is spoiled by some manufacturers who add slag impurities to it, trying to reduce the cost of their products.

The insulation does not rot and is not edible by insects and rodents. This guarantees trouble-free service of the material for at least half a century. Regardless of its fibrous structure, the material is quite strong and has a “strength” indicator of 80 kPa.

Basalt wool is a type of non-combustible material. It can easily withstand temperatures up to one thousand degrees Celsius.

This material is used for external and internal insulation of baths, as it is produced in the form of rigid slabs, semi-rigid mats and soft rolls with varying densities of their structure.

Glass wool for bath insulation

The insulation has a fibrous structure, but is inferior to basalt wool in its technical characteristics. The material is made from broken glass with the addition of sand, dolomite, soda, etc.

Having a thermal conductivity coefficient of 0.052 W/K*m, it has good insulating properties, but is completely unsuitable for internal insulation of a steam bath for the only reason: glass wool cannot withstand temperatures above 450 degrees. Therefore, it is not recommended to insulate the area that is located in close proximity to the stove.

Glass wool is used for thermal insulation of the attic and bathhouse roof, reducing the cost of this process by 20-30% compared to the use of basalt insulation.

Expanded clay for insulating floors and ceilings

“Airy” expanded clay granules are obtained by quickly firing low-melting clay. This material is used in the form of backfilling the horizontal elements of the bath structure - the ceiling and floor.

Various calibers of insulation in the form of gravel, crushed stone and sand are used in construction. The insulation effect is obtained from expanded clay when it is poured onto the surface in a layer of over 25 cm.

Foam plastic for thermal insulation of baths

Bathroom insulation with this material is ideal for external wall surfaces. The facades of buildings are covered with polystyrene foam, and then they are plastered or covered with decorative finishes.

It cannot be used inside bathhouses due to the harmful phenol fumes emitted by the foam and its flammability.

External insulation of a bathhouse refers to options for thermal insulation of walls and foundations. Let's consider this issue in more detail.

Thermal insulation diagram of the bathhouse facade

High-quality insulation of a bathhouse made of expanded clay concrete blocks from the outside is carried out by facing masonry with the placement of insulation between the bricks and the main wall. This is an expensive insulation option and, despite its effectiveness, is not used often. The problem is the high price of facing bricks and the complexity of its installation.

The second method involves external cladding of walls made of expanded clay concrete blocks with PVC panels or siding, under which insulation is placed. As an acceptable option, 50 mm thick foam plastic sheets can be attached to the walls as a heat insulator in two rows in a checkerboard pattern with overlapping seams. The panels are fixed on pre-installed vertical guides. Instead of polystyrene foam, you can use basalt insulation, covered with a vapor barrier material to protect against moisture.

Another option for insulating walls from the outside is lining the bathhouse with slab insulating material, for example, polystyrene foam. It is attached to the wall with glue and plastic dowels. A reinforcing mesh is glued onto the foam plastic, which is covered with decorative plaster.

Insulation of the foundation of a bathhouse made of expanded clay concrete

To thermally insulate the foundation of a bathhouse, they use materials that are moisture resistant, inedible for rodents and are not afraid of temperature fluctuations. The ideal and most popular option is polystyrene foam. After the concrete has polymerized, the outer side of the foundation is covered with waterproofing and covered with heat insulation slabs. They are located on the surface of the base in a checkerboard pattern in two layers of 50 mm each. Then the insulation can be covered with “warm” plaster.

The complex of works for insulating a bathhouse made of expanded clay concrete blocks from the inside includes thermal insulation of the floor, walls and ceilings. Each of these structures deserves special attention.

Insulation of a wooden bath floor

The principle of thermal insulation is the same - laying insulation between rigid layers and protecting it with insulating membranes. In a wooden structure, the heat insulator is located between the subfloor and the finished floor, and in a concrete structure, between the base and outer layers of cement mortar.

The wooden floor is insulated in the following sequence:

- On both sides of the lower edge of the beams along their entire length, cranial bars are stuffed, which are necessary for constructing a subfloor.

- Low grade boards, pre-cut to a size slightly smaller than the pitch of the beams, are placed on the cranial beam.

- The subfloor is ready. Then it is covered with waterproofing. It is better to choose a membrane with vapor barrier properties. It is spread to cover all the beams and cover the perimeter of the lower parts of the walls with a start of 20 cm. The material is fastened to the structural elements with a stapler, the joints of the sheets are taped.

- Insulation is laid on the vapor barrier layer, which is covered with a layer of waterproofing material. The expensive membrane can be replaced with a layer of roofing felt with carefully taped seams. The free space around the floor drain pipe is filled with foam.

- To complete the insulation process, clean floor boards are laid, excess insulation is cut off, and baseboards are screwed in place.

There should be an air ventilation gap of 3-4 cm under the finished floor to dry the structure.

Construction of a bathhouse from expanded clay concrete - 6 stages of DIY construction

A self-built bathhouse made of expanded clay concrete blocks with an attic and veranda will delight the owner with a pleasant microclimate, ease of operation and durability. However, in order not to encounter difficulties in construction and further use, it is important to strictly adhere to the technology and stages of construction, as there are nuances and subtleties here.

We build with our own hands

Layout

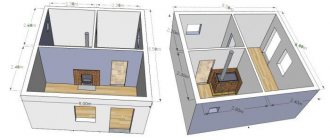

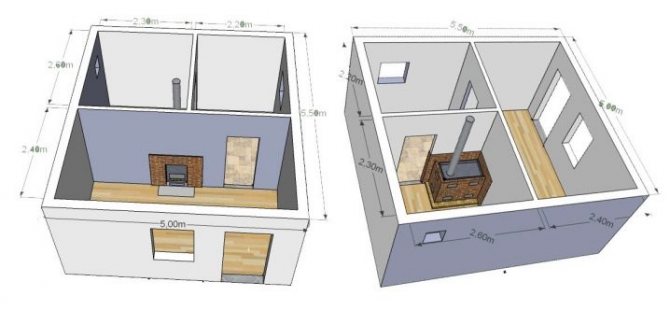

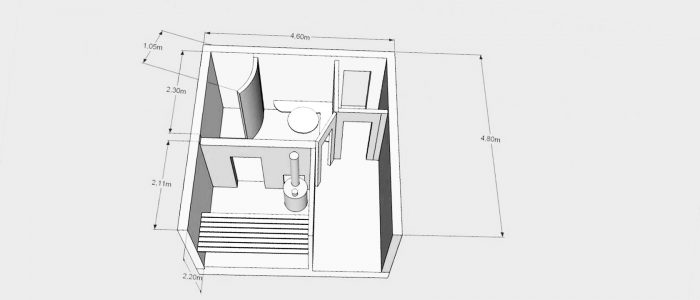

The first step in construction is the preparation of the project. At this stage it is ensured:

- formation of a building model;

- selection of locations for steam rooms, showers and other parts;

- calculation of justified dimensions;

- determining the location of openings for windows and doors;

- calculating the amount of building materials needed.

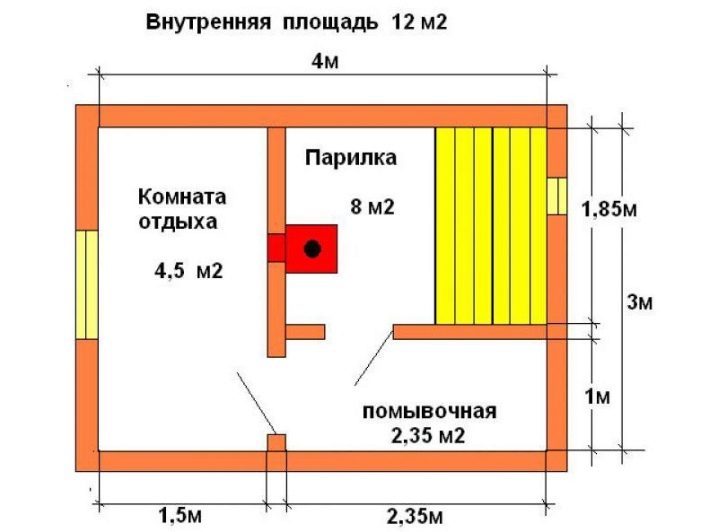

It should be borne in mind that even the best baths made of expanded clay concrete blocks are inferior to wooden structures in terms of thermal protection. Dried pine beams transmit half as much heat as insulating expanded clay concrete, and if construction is carried out using frameless technology, the difference becomes fivefold. The specific gravity of the material is approximately 1000 kg per 1 cubic meter. m. More precise parameters for the final design can be found in the manufacturer’s documentation. A relatively compact bathhouse with an area of 9 square meters. m. is built on one floor and is usually divided into three sections:

- 50% is given to the leisure room;

- 25% washable;

- another 25% is occupied by the steam room.

The problem with this design is that it does not provide adequate comfort. If you have sufficient funds, you should definitely build a bathhouse of expanded clay parts on 2 floors, with a full-size steam room located below. There it will be possible to lie down on the shelf, and it will be easier for the assistant to move around. In addition, it becomes possible to supplement the leisure room with an insulated vestibule, which reduces heat loss.

A bathhouse with a pitched roof is easier to build than one with a gable roof, but then it will not be possible to organize a full-fledged attic or attic.

Foundation

The opinion that is sometimes found that outbuildings and ancillary buildings can be placed directly on the ground is incorrect. After all, the properties of the soil can change; they change under the influence of precipitation and other factors that are unpredictable in advance. When building baths from expanded clay concrete, strip foundations are most often used, which are very simple to construct and unpretentious to use. Many even build such foundations on their own, without using expensive special equipment.

Small baths are sometimes built on columnar foundations supplemented by rand beams, but if the soil tends to swell greatly, this idea is unsuitable.

Construction on difficult soils is mainly carried out using the screw method. Such foundations can be installed in a matter of days and are equally effective in swamps and hills. The only serious limitation is incompatibility with rocky soil. It is important to choose structures with the strongest possible welds, since it is corrosion in them that causes many problems. The pile-screw version, reinforced with a grillage, turns out to be much stronger.

A monolithic foundation under bathhouses made of expanded clay blocks is extremely rare; even if there are problems with the geological substrate, it is advisable to limit yourself to piles. If you choose properly processed pile elements, you can increase the service life of the structure to at least 100 years. Preparation for the formation of the foundation involves clearing the site and marking it in accordance with the project.

Advantages and disadvantages

Before you start building a bathhouse using expanded clay concrete, you should familiarize yourself with the main advantages and disadvantages of the structure. The advantages include:

- environmental friendliness and safety of the material;

- high level of thermal insulation;

- light weight of the blocks, which greatly facilitates the installation of the structure;

- possibility of using standard fastening solutions;

- evenness of the walls being erected;

- saving money;

- simplicity of interior and exterior decoration.

Despite many positive aspects, a bathhouse made of expanded clay concrete has disadvantages. The disadvantages include:

The porosity of a building material affects its strength, significantly reducing it.

- It is impossible to erect a structure higher than 2-3 floors, since the blocks are characterized by increased porosity and instability to mechanical stress.

- The need for external and internal cladding, otherwise the walls will begin to crack.

The main advantages of bathhouses made of expanded clay concrete blocks

• Construction will be inexpensive compared to the use of other building elements. If, for example, we compare turnkey log baths with expanded clay block baths, then the final amount will be three times higher. Moreover, the advantage is that you can lay the blocks yourself, but the log house does not tolerate amateurs. After construction, wood requires the use of impregnations, and expanded clay block requires only finishing;

• Quick construction of the box saves time, and ease of installation saves the family budget on the work of masons;

• The blocks are lightweight (up to 15 kg), so the foundation can be cast at minimal cost without additional reinforcement;

• Expanded clay concrete holds up well to any finishing materials; if a residential building requires the use of high-quality construction technologies, then a simple bathhouse will look great even with the usual plaster;

• Budget building materials have a high level of thermal insulation, so you can build a high-quality steam room at a low cost;

How to build: stages

How to draw up a project and drawings?

If you want to build a small bathhouse at home or in your country house with simple equipment, you can draw up a plan yourself. It is important to determine the main stages of construction, calculate the amount of material, and determine which foundation is suitable for a particular type of soil. A two- or three-story steam room with a swimming pool, a gazebo and a separate utility room will be more difficult for a person who does not have construction experience to think through. Then it is better to order a bathhouse project made of expanded clay concrete blocks from a specialist, and if funds allow, hire a team of builders who will build a turnkey steam room.

A one-story building can be developed without outside help.

If there is a lot of space on the site, you should think about additional construction of a cozy guest house. You can organize a mini-cafe inside the room so that you can continue your pleasant rest and pastime immediately after the bath.

Pouring the foundation

The primary and important task is to create a solid and reliable foundation. The type of foundation is determined based on the characteristics of the soil over which the structure will be erected. The supporting structure can be of the following types:

- tape;

- columnar;

- concrete;

- brick;

- monolithic.

The optimal base option for this design is a strip one.

It is best to build a bathhouse from expanded clay concrete on a strip foundation. Before laying the foundation, the area is cleared of debris and vegetation. Then, along the perimeter, observing the dimensions, pegs are installed on which the twine is stretched. At the next stage, a ditch 50-70 cm deep is formed, the bottom of which is covered with a sand cushion. The surface is well compacted, after which formwork made of boards or plywood is installed on the sides. For the strength and reliability of the foundation, it is recommended to lay reinforcement. Also at this stage, drain pipes are removed. Next, the trench is filled with concrete mixture, after which the base is allowed to dry. Before erecting walls, waterproofing must be carried out. To do this, it is recommended to use roofing felt laid on the base in 2 layers.

Block laying

The construction of a bathhouse from expanded clay concrete blocks begins from the corner, focusing on pre-installed beacons and string stretched around the perimeter. When the first row is ready, the evenness of the masonry is checked using a level and plumb line. For better adhesion of the block to the mortar, the surface is tapped with a mallet, and excess cement mixture is removed immediately. To keep the walls strong, reinforcement is carried out every 3-4 rows. Do not forget about the correct design of door and window openings. Concrete or metal floors are laid above them.

Do not forget about laying reinforcement through a certain number of rows of masonry.

Window openings in the future premises must be designed correctly.

Pockets are left at the bottom and top of the masonry for floor and ceiling beams. Wooden bases are secured with metal corners and treated with an antiseptic. Ventilation in a bathhouse is often located behind the stove. The inlet opening is formed at a height of 1.5 m from the floor, and the outlet opening is on the opposite wall, with a distance of 30 cm from the bottom. When the load-bearing walls are ready, you can begin to build partitions separating the steam room from the guest room, utility room, and other areas.

Roof installation

If the bathhouse is built as a separate structure, a gable roof is erected, but other options are also used, it all depends on the size of the structure and the taste preferences of the owner. The Mauerlat is attached to the anchor bolts pre-installed in the blocks. Then the rafter legs are installed, the support for which is the ridge beam, Mauerlat and additional fastening systems. At this stage it is necessary to insulate the ceiling and make waterproofing. After the roof is sheathed, the selected roofing material is mounted on top of it. Preference is given to corrugated sheets, metal tiles, and bitumen shingles.

To cover the building, you need to fix the Mauerlat.

Next, you need to build a rafter system for the building.

Insulation and finishing

If the steam room is intended only for summer use, the walls of the bath may not be insulated. Otherwise, it is necessary to additionally install insulation, which will retain heat in winter and maintain a comfortable climate in the room. The optimal materials are:

- mineral or basalt wool;

- Styrofoam;

- polystyrene foam.

It is preferable that the installation of insulating material be carried out from the inside of the finished building.

As reviews from the owners show, it is best to insulate a bathhouse from expanded clay concrete blocks from the inside. This will help quickly warm up the room and prevent sudden temperature fluctuations in the masonry. The insulation is mounted on pre-installed wooden planks. Then the interior decorative finishing of the walls is carried out. The design of the steam room can be any, but most preference is given to wooden lining, which is environmentally friendly. To decorate the walls of the steam room, it is recommended to use linden, aspen or pine wood. The floor is tiled; in the recreation area, the floor covering can be anything. It is recommended to finish the outside of the masonry with decorative “Bark Beetle” plaster. More expensive options are facing bricks, siding, facade cassettes, clinker tiles.

How to make a stove in a steam room?

To maintain a comfortable microclimate, a classic Russian stove is installed in the bathhouse. Before its construction, it is necessary to separately lay the foundation, carry out waterproofing, and at the next stage the laying of the order and installation of the chimney is carried out. When the stove is ready, you need to let it dry for a while, and then start putting it into operation. The first fire is performed at minimum power. If the structure is not cracked or deformed, the next time the combustion material is laid at half power. The last fire is carried out at full capacity.

The Russian stove is decorated with red clinker bricks, decorative plaster, ceramic tiles, or decorated with classic whitewash. It is important that the facing material is resistant to high temperatures, otherwise the finish will not hold up. In a bath made of expanded clay concrete, heat is retained for a long time, so on a cold washing day, 1 heating will be enough.