The construction of a bathhouse from timber is a full-fledged process of erecting stationary structures. Such structures require a foundation, walls, a roof and a host of other systems necessary for proper functioning. That is why modern builders are often interested in the question of how to make quality bathhouse projects from timber with their own hands.

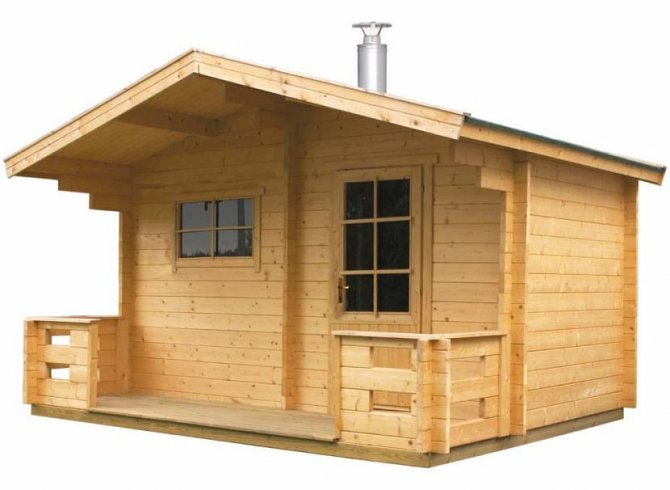

Amateur photo of a finished bathhouse made from timber

>

Bathhouse projects

Number of projects 683

Mini square barrel bath project

- To favorites

- 4.2² Total area

- 2 x 2m Building area

from 80,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bani Elena project

- To favorites

- 42² Total area

- 6 x 8m Construction area

individual calculation

Construction period individually

Amazon Baths Project

- To favorites

- 43² Total area

- 8 x 8m Construction area

from 580,500 rub.

Construction period 35 days

- 1 room

- 2 bathrooms

Project Baths Gloria 7*13

- To favorites

- 68.4² Total area

- 7 x 13m Construction area

from RUR 813,857

Construction time individually

- 1 room

- 2 bathrooms

Bathhouse project "Riga"

- To favorites

- 81.5² Total area

- 12 x 10m Construction area

from 1,630,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Project Baths Jupiter

- To favorites

- 30² Total area

- 6 x 6m Construction area

from 405,000 rub.

Construction period 24 days

- 2 rooms

- 2 bathrooms

Bani Vasilek project

- To favorites

- 60.62² Total area

- 8 x 5m Construction area

from 818,370 rub.

Construction period 37 days

- 3 rooms

- 2 bathrooms

Russian Steam Bath Project

- To favorites

- 108² Total area

- 8 x 9m Construction area

from 1,458,000 rub.

Construction period 45 days

Quad bathhouse project “Standard”

- To favorites

- 2 x 4m Building area

from RUB 179,900

Construction time 1 day

- 1 room

- 2 bathrooms

Project of a garden house-sauna "Vasto"

- To favorites

- 25.5² Total area

- 6 x 5m Construction area

from RUR 344,250

Construction time 3 days

Bathhouse project “Russian Steam”

- To favorites

- 36² Total area

- 6 x 6m Construction area

from RUB 420,968

Construction time individually

- 1 room

Bathhouse project "Nega"

- To favorites

- 16² Total area

- 4 x 4m Building area

from RUB 178,550

Construction time 1 day

- 2 rooms

- 2 bathrooms

Project Baths Wave 9.5*6.5

- To favorites

- 85² Total area

- 10 x 7m Construction area

from RUR 1,031,442

Construction time individually

- 1 room

- 2 bathrooms

Yantarnaya Baths Project

- To favorites

- 55.1² Total area

- 9 x 7m Construction area

from RUR 743,850

Construction period 35 days

- 1 room

- 1 bathroom

Oval sauna project “4x4”

- To favorites

- 4 x 4m Building area

from RUB 319,900

Construction time 1 day

- 1 room

- 1 bathroom

Bani B-10 project

- To favorites

- 5 x 4m Building area

from 325,000 rub.

Construction time 10 days

- 1 room

- 2 bathrooms

Bath Pagoda Project

- To favorites

- 123² Total area

- 15 x 9m Construction area

from 1,660,500 rub.

Construction period 30 days

- 1 room

- 1 bathroom

Project Baths Cozy

- To favorites

- 29.3² Total area

- 7 x 5m Building area

from RUR 395,550

Construction time 23 days

- 2 rooms

- 2 bathrooms

Bath Capella project with attic

- To favorites

- 71.72² Total area

- 6 x 7m Construction area

from 968,220 rub.

Construction time 42 days

- 1 room

- 1 bathroom

Project of a garden house-bath "Theano"

- To favorites

- 45.5² Total area

- 6 x 9m Construction area

from 614,250 rub.

Construction time 3 days

View all projects

A bathhouse in a summer cottage is an attribute of comfort and regular relaxation in close, friendly company. Capital construction of a bathhouse complex requires time, finances and building materials, so many people prefer to buy a ready-made bathhouse, which can be used immediately after installation.

Ready-made sauna made of wooden beams with an installed stove and pipe Source enotes.info

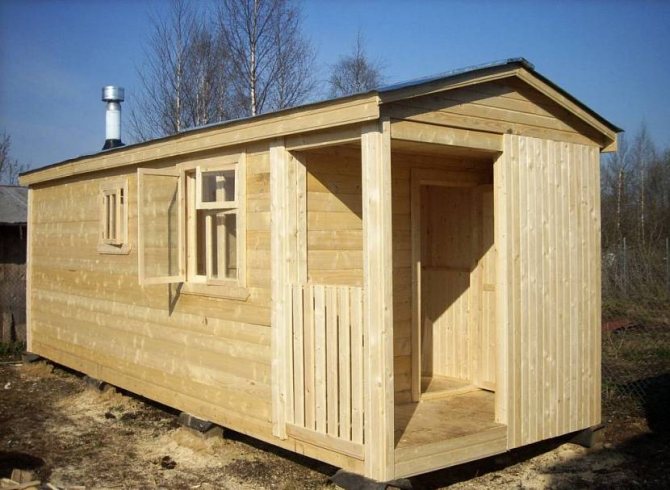

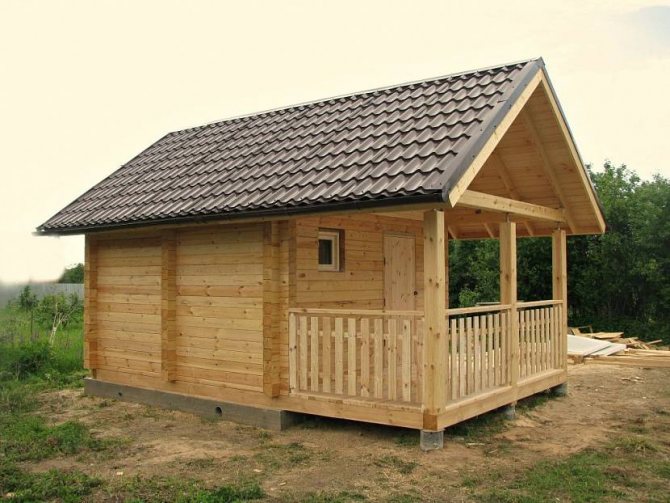

An alternative to traditional projects is prefabricated or mobile baths, which take up less space and are ready for use immediately after delivery. Owners of compact summer cottages and limited budgets will appreciate such projects presented in the portfolio of many developers.

Technology of prefabricated or mobile baths

Ready-made baths are modest structures made of timber, assembled in a factory. Craftsmen make a small-sized body, carry out interior finishing at the client’s request, and then deliver the assembled bathhouse to the installation site.

The owner of a suburban area, using the help of craftsmen, installs the structure on a prepared flat area, installs communications, and after that the bathhouse is immediately ready for use. Some manufacturers provide complete concrete slabs on which the entire structure is installed.

Mini-sauna on a concrete foundation Source m.2gis.kz

The nuances of the technology depend on the specific manufacturer: some offer installation of electrical wiring and carry out interior finishing, others leave this issue to the client to decide independently.

The cost of a ready-made prefabricated bathhouse may not always include installation of a foundation, installation of a stove, and lining of internal partitions with clapboard. But on the other hand, this allows you to independently select these design elements and get a bathhouse with minimal financial costs.

Assembly

A bathhouse made of lumber does not require a foundation of increased strength, since the material is light. It will be possible to save money on the foundation, which would not be possible with a brick building.

Before purchasing beams, you need to calculate the number of cubic meters required for construction.

This is done as follows: the total perimeter is taken, taking into account all the partitions, then this number is multiplied by the thickness and height of the product. The cross section that is often chosen in our winter conditions is 150x150.

Also, you should not choose a wall thickness less than 150 mm if you are building a two-story bathhouse from laminated veneer lumber.

Information. 1 m³ of wood with this section and a length of each product of 6 m is equal to 7.41 units of timber. For example, a bathhouse made of 6x6 profiled timber will require 20 m3 of such timber.

If you are planning a bathhouse with an attic made of profiled timber, do not forget to calculate the material for the gables.

Wood regulates the indoor microclimate well, but when building with laminated lumber, a well-thought-out ventilation system is required. When designing the foundation, ventilation vents are required to install a functional bathhouse ventilation system and dry the floors.

After installing the foundation, the construction of walls begins in about 2.5 months. On the base, waterproofing made of roofing felt in several layers is required, which should protect the future structure from moisture. Despite this stage of work, when laying the first crown, the lumber must additionally be treated with an antiseptic composition.

For even more reliable protection from the destructive effects of moisture, you can lay boards treated with a salt-bitumen solution after the waterproofing layer.

Laying crowns

The beams for the first crown may have a larger cross-section than the products for the remaining crowns, for example, 150x200 mm. They are fixed on the foundation of the bathhouse, in which special spikes (reinforcement) are pre-installed. Then slats (joists) are attached to the base, on which the subfloor will be laid. When laying these slats, places for draining water and the stove are designated.

Next, the box is assembled, all fastenings are carried out using wooden dowels 14 cm long at a distance of 1 m from each other. A jute tape insulation or made of flax is placed between the crowns - it is wound into special grooves in the corners of the beams at the point of the locking connection.

It takes a little time to build walls made of lumber, but it will be needed after the walls are built so that the wood acclimatizes, especially if profiled timber of normal humidity was used. When the material is pre-dried or when using laminated veneer lumber, there is practically no shrinkage, and cracks do not occur, since such material is immediately rejected by the manufacturer.

Openings and openings

During the process of laying wooden products, grooves for electrical wiring are drilled into them. A high-pressure metal flexible pipeline made of galvanized tape (metal hose) is laid through the drilled holes.

Installation of door and window openings is carried out in several ways. The first involves installation during the construction of walls, by cutting each beam, or the second method is cutting out openings with a chainsaw after installing the walls and shrinking the wood. If the bathhouse is built strictly according to the project, then there is no need to trim or saw anything.

Important! Installation of wooden windows can begin only 8 months after the construction of the bathhouse, and plastic windows - after two years due to shrinkage.

Due to possible deformation or sagging, the wooden partitions may sag and large gaps will appear between the top and covering beams, so the openings must be cut out immediately.

Windows and doors must be floating so that the lumber can easily change in size during the shrinkage process; for this, tenons are installed on the sides and bottom of the opening.

Attention! If the openings are too large, it is better to secure the upper beam in the opening with staples or screws to avoid possible sagging.

After erecting the walls, you need to cover the entire structure with a special antiseptic and you can begin laying the floor. When planning a bathhouse made of profiled timber with a terrace, you can plan the upper frame of the terrace from the upper crowns of the beams - simply make overhangs according to the size of the terrace, and install wooden support pillars under their edges.

Bathroom floor installation

Before laying it, a sewerage system, drain holes or a drain with a slope towards the drainage hole are first installed under the required premises. If you plan to build a sauna from laminated timber with a swimming pool, it will require a separate system for supplying, draining and heating water.

A moisture-proof membrane is attached to the subfloor with overlaps on the walls, thermal insulation is laid in the gaps of the floor boards, and a finished floor of boards is laid on top. It is better to purchase larch boards for the floor. It is considered the most suitable in terms of its characteristics. Their width should be up to 4 cm; thicker boards are more susceptible to deformation.

Building a house and a bathhouse from profiled timber with your own hands is quite feasible, but you need to have a project according to which you will prepare all the necessary material. Then waste will be minimal and the process will not take much time.

Glued laminated timber is more suitable for the construction of a bathhouse due to its characteristics.

The most important of them is excellent tolerance to changes in humidity, and due to the lack of shrinkage.

According to these properties, such a bathhouse will be similar to a chamber-drying bathhouse made of profiled timber.

The room does not need finishing, including the outside, and the heat-insulating properties of bathhouses and steam rooms made from such lumber are excellent.

Advantages of ready-made baths

The main advantage of such projects is the speed of production. The bath complex is assembled in a factory; most companies install stoves and install electrical wiring, so the customer does not have to search for a team of carpenters and spend money on electrician services.

This modest-sized design is ready for use immediately after installation Source emupauto.ru

The ratio of price and work provided will please thrifty customers: on average, a turnkey bathhouse on a high foundation of concrete pillars will cost about 240 thousand rubles. The complex includes a recreation room, a shower room and a steam room, each room measuring 2x2.3 meters. The project is equipped with interior finishing, a stove with pipes and a shower tray, the walls are made of timber.

The production of such structures is carried out on a turnkey basis, so the customer does not have to look for a team of builders, electricians, independently select the wood for construction, or delve into the details of the foundation structure. It is enough to contact a specialized organization, select a project, materials, agree on deadlines and pay for the work.

Prefabricated baths are installed on the site at any time of the year, regardless of weather conditions and the depth of soil freezing. This allows you to install a bathhouse in areas located in different climatic zones.

Installation of a prefabricated bathhouse is also possible in winter frosts Source krsk.au.ru

Prefabricated baths are compact, containing only the necessary premises with a minimalist finish. This approach to design saves free space on the site and the financial resources of clients. In general, this design is a temporary option for steam room connoisseurs, or a budget solution for construction in conditions of economy or limited space.

Materials for creating ready-made baths

A common option for building baths is wooden beams. This means that if ready-made turnkey baths are inexpensive, then there is a possibility that the beams were not dried, which leads to the need to carry out “shrinkage” before finishing work. Mobile buildings made of natural timber provide a pleasant indoor microclimate, as well as durability and quick heating of the steam room. When heated, coniferous wood at the base of profiled timber becomes a source of phytoncides that are beneficial for the respiratory tract.

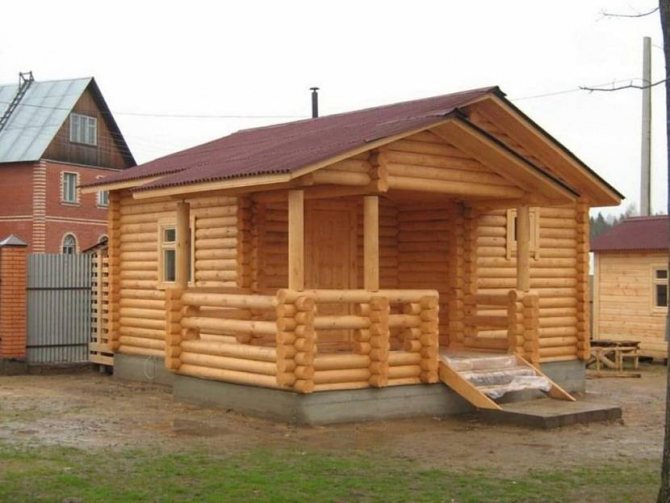

A bathhouse made of timber - a classic construction option Source izhevsk.stroyportal.ru

A prefabricated sauna made of sip panels is a structure based on two particle boards separated by insulation. This option has less weight and is ready for finishing work immediately after installation. Such designs look more modern than traditional bathhouses made of timber; the external façade is finished with vinyl siding.

Owners of spacious country estates, as well as connoisseurs of unusual decoration, will like the ready-made log houses offered by companies for creating baths. Such designs already require laying a foundation and large-scale interior finishing, but they also save the customer’s time and effort by providing ready-made “walls” as an intermediate option between a turnkey bathhouse and standard capital construction.

Prefabricated bathhouse based on a log frame, finished with metal tiles Source banja-aus-russland.de

On our website you can find contacts of construction companies that offer bathhouse construction services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Ready-made complexes made from blocks (foam concrete, expanded clay concrete) are distinguished by high thermal insulation properties, as well as a long service life. The disadvantage of the material is the need to install a foundation, which increases the construction period of the entire bath complex. The external finishing of such buildings is carried out using facing bricks, lining, as well as siding or decorative plaster.

Foam block bathhouse under construction Source et.aviarydecor.com

What are the turnkey prices for log houses and bathhouses made of calibrated logs?

The cost of a house or bathhouse made of calibrated timber is influenced by several factors: – The type of wood from which the material was made; – Number of floors and area of the structure; – Architectural features.

Finishing rounding machine Taiga OS 1

In addition, the price of a house or bathhouse will depend on whether the client orders a foundation from a contractor or builds it on his own; will he need interior finishing or not, and so on. Despite the fact that independent construction of houses and baths seems less expensive financially, experts recommend ordering houses and baths from calibrated logs on a turnkey basis. This is due to several reasons: – The vast experience of professionals allows us to erect buildings in the shortest possible time; – Independent work with calibrated timber can lead to accidental damage to the material; – The contractor immediately names the final price of the work, so no additional costs will arise during the construction process, as often happens when building with your own hands; When ordering a house from professionals, you don’t have to worry about communications – gas pipelines, water supply, electricity, ventilation. The same applies to interior finishing. The customer only indicates his desires and preferences in order to get the home of his dreams without any effort, with high-quality, impeccable renovation, ideal for living.

Mobile sauna equipment

Depending on the final price, construction materials and the specific approach of each manufacturer, the complete set of the bathhouse may vary.

A sauna stove is a mandatory attribute of a finished building; a water tank is usually provided with it. Some manufacturers offer installation of ovens to suit customers' tastes for an additional fee. This approach makes it possible to choose the model that best suits the customer, but at the same time, the final cost increases, sometimes quite significantly.

Traditional stove with a pipe for a bath Source nd-dom.ru

The solution in this case would be to buy a ready-made bathhouse on a turnkey basis: it will not cost much, especially since the total amount of the project is approved before it is handed over to work. The presence and design of the stove, shower tray, shelves in the steam room, as well as interior wall decoration are agreed upon before starting work; all elements are precisely calculated to fit the parameters of the bath.

The foundation on which the structure is built can be prepared by the customer or the manufacturer. In the second case, solutions made from concrete blocks are most often used; piles are also in demand.

These types of foundations do not require lengthy soil preparation, can withstand light weight of the structure, and are suitable for various climatic zones.

Walls, rough and finished floors are made from materials chosen by the customer. In most cases, these are profiled timber and edged boards.

The process of floor insulation in a prefabricated log bathhouse Source e-brus.ru

Mineral wool and flax-jute fabric are used as insulation; the steam room is finished with foil-based materials.

The windows have double glazing, and the door panels are finished with clapboard, while the wood is carefully treated with an antiseptic.

The roof of the building is finished with corrugated sheeting (analogous to metal tiles), ondulin (soft tiles), and roofing felt (an economical option).

Material selection

This product is made from coniferous and deciduous wood: pine, spruce, cedar, larch, oak, aspen.

Cedar and larch are more expensive than others.

These rocks tolerate moisture well and will not lose their qualities over time.

The sauna logs, made of profiled timber from cedar and larch, emit antiseptic vapors, and inside the steam room there will be a subtle and healing aroma.

Pine and spruce are quite an economical option, which has its pros and cons.

The disadvantages are:

- when the temperature is too high, resins are released;

- always requires additional antiseptic treatment;

Pros:

- mildew resistant;

- easy to cut;

- high moisture resistance;

- resistance to cracks and deformation.

Also, a bathhouse made of planed timber does not require finishing either inside or outside.

Information. Pine is more resistant than spruce to all possible unfavorable processes, for example, rotting and the appearance of fungus.

In all cases, if high-quality wood was used in the production of building materials and it was well processed, the constructed bathhouse will serve reliably and for a long time. The resinousness of a plant depends on where it grew, on the time of cutting and processing. With modern manufacturing and processing technologies, this indicator is brought to a minimum. To ensure that the structure has minimal shrinkage, you can choose to build a bathhouse from dry profiled timber.

Features of delivery of mobile baths

Affordable prices, a variety of turnkey projects and natural materials lead to the popularity of prefabricated baths. Unfortunately, the construction market consists not only of conscientious businessmen who value their reputation, so there is a risk of delivering a low-quality bathhouse or losing money when ordering it. Simple steps will help you avoid scammers.

It is worth carefully inspecting the place of sale before deciding to work with the company Source tr.skopelitissa.com

The choice of a developer should be made based on reviews from friends, and carefully check the information about the company. Conscientious sellers are always ready to provide additional photos of their transportable bathhouses - ready-made projects; they do not hide the legal and physical addresses of warehouses, production facilities and offices, so that customers can get acquainted with the assortment live. The absence of a group on social networks and an official website is a reason to think about finding another artist.

The price of a finished bathhouse may differ from competitors by 10-15% in both directions; too low prices are a reason to think about the integrity of the developer in terms of the quality of the materials used and the services provided in general.

Delivery of a mobile bathhouse in disassembled form involves installation on site using a manipulator, and it is necessary to clarify whether the rental cost of the equipment is included in the invoice. Finished buildings are brought to the site, fixed on a foundation or level ground, after which the craftsmen connect the communications. To avoid fraud, you must carefully discuss with the sales manager the list of works included in the price.

Prefabricated structure before installation Source remontik.org

Some manufacturers allow themselves to use raw wood for the production of prefabricated baths to save time. Therefore, it is better to buy a finished log bathhouse without interior finishing and leave it on the site to “settle” for a year so that the structure does not deform.

This might be interesting!

In the article at the following link, read about a 6x8 bathhouse with an attic.

Selection of glued

Glulam beams made from wooden strips-lamellas in terms of the choice of wood do not differ from the choice of solid beams. When making a visual selection, you will notice that such products are carefully processed and do not contain flaws that can be observed in ordinary beams. That is, knots, wormholes, dark spots, etc. are excluded from its structure.

Also, when gluing boards, they are positioned so that the annual rings face in different directions, this provides additional strength.

Attention! When purchasing, you need to make sure that the adhesive composition used to connect individual boards meets all standards and is not subject to degradation at elevated temperatures, humidity, etc.

When building bathhouses from laminated veneer lumber, each individual row of lumber is called a crown; it is recommended to use larch lumber for the lower crowns, and to stock up on coniferous wood for subsequent ones.

Advantages of larch products:

- low thermal conductivity, which means guaranteed heat retention in the room;

- is not afraid of moisture and this property increases over the years;

- light weight;

- high strength;

- essential oils release an antiseptic aroma.

As already mentioned, this is an expensive building material, but its advantages are obvious.

Comparison of wood by thermal conductivity coefficients

| Lumber | Thermal conductivity |

| Pine across and along the grain | 140 and 400 mW |

| Spruce | 110 mW |

| Larch | 130 mW |

| Cedar | 95 mW |

Attention! Oak, maple and poplar are among the coldest trees, so it is preferable not to use them to build a bathhouse.

The dimensions of glued beams are presented in the table

| Height | Section width |

| 140 and 180 | 120 160 200 240 |

| 210 and 260 | 120 160 200 240 |

Video description

The video shows an example of a budget solution:

And several interesting projects of turnkey bathhouses in the photo

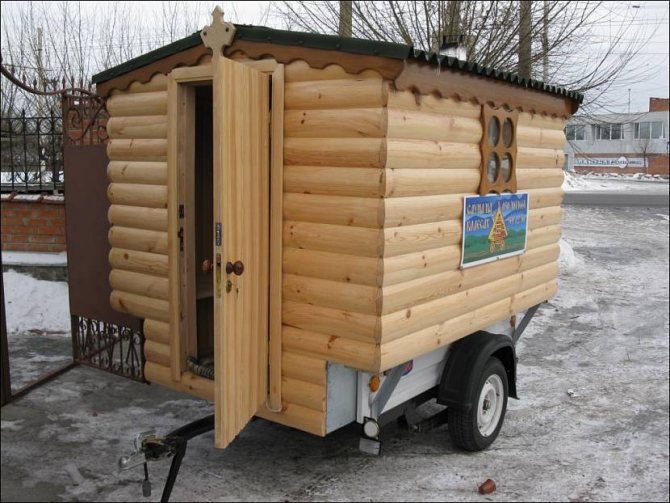

Mobile round-shaped barrel sauna for a comfortable stay for a couple of people Source drive2.ru

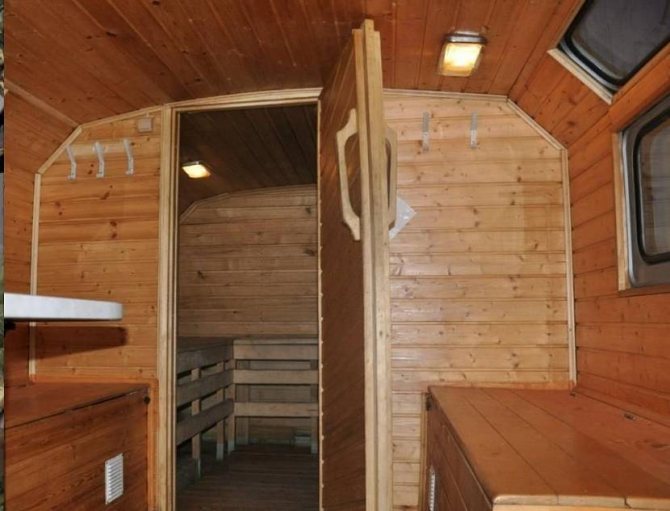

Interior of a steam room in a compact prefabricated bathhouse Source remontik.org

Interior of a prefabricated bathhouse on wheels Source uk.blog-oremonte.ru

A sauna on wheels is an option for lovers of active recreation Source hodor.lol

Compact does not mean boring. Traditional wooden finishing of window and door openings of a finished bath Source brus-dacha.ru

Schematic diagram of the internal structure of a finished bath Source banyaportal.ru

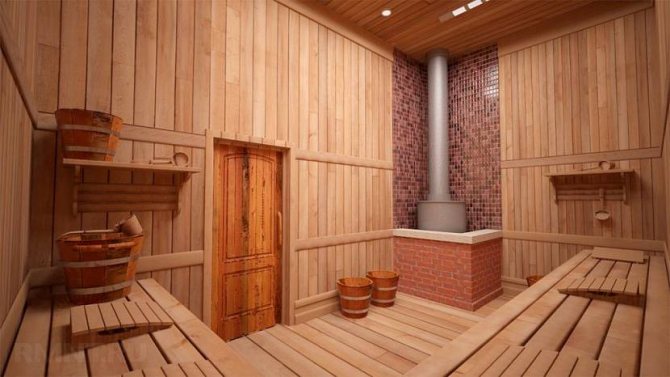

Traditional design of a steam room: a combination of lining and brick Source bg.aviarydecor.com

Traditional design of a relaxation room in a finished bathhouse using the “Russian style” Source sl.aviarydecor.com

This might be interesting!

In the article at the following link, read about the chimney for a bathhouse.