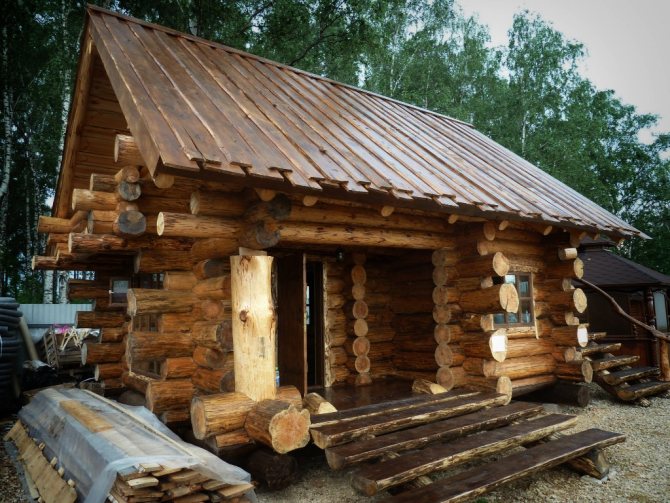

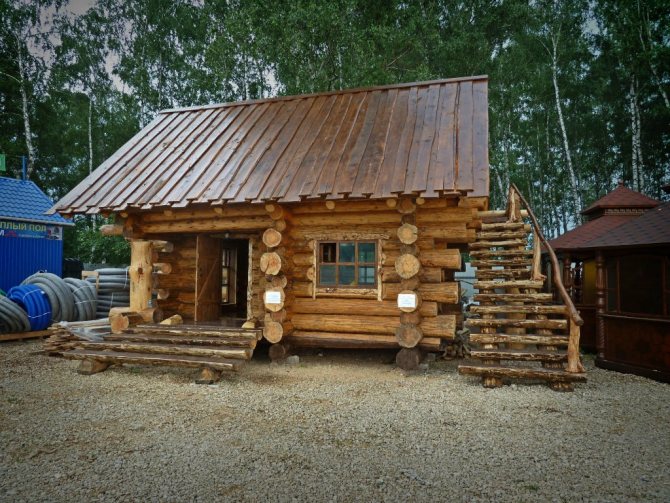

When constructing bath buildings, linden or pine wood is most often used. This is due to the excellent technical characteristics of these building materials. However, the following question naturally arises: “Which bathhouse is better - linden or pine?” Let's try to find the answer together.

Linden bathhouse.

>

Pine (photo), as a building material, is highly valued by bathhouse attendants for its softness and fairly low density, making it easy to process. Along with this, pine tolerates humidity quite calmly, which is a definite plus, because the atmosphere of bath rooms is almost constantly filled with hot and humid air.

Pine is well known to bathhouse builders.

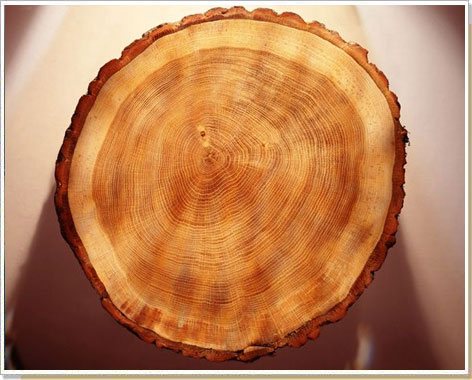

Pine is highly valued for its characteristic pattern, which is created by clearly visible annual rings.

However, this wood has one very serious drawback - under the influence of a high-temperature environment, it abundantly releases resin, which, in turn, emits a rather strong odor. Moreover, if it comes into contact with the skin, these secretions can cause burns.

Linden has the same positive qualities that are inherent in pine. Moreover, it is not capable of releasing resin, which makes it absolutely safe in a steamy bathhouse. Thus, the advantage of linden for a bath becomes clear.

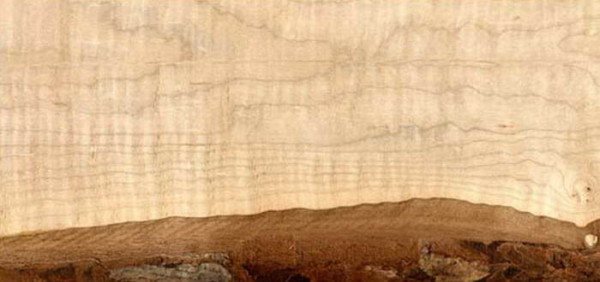

Characteristic pattern of linden wood.

In this article we invite you to take a closer look at linden building materials. You will be provided with the characteristics of the specified wood, as well as instructions for choosing linden products.

Characteristics of building materials

The pros and cons of a linden bath are determined, of course, by the operational and technical characteristics of the material used in construction.

Advantages

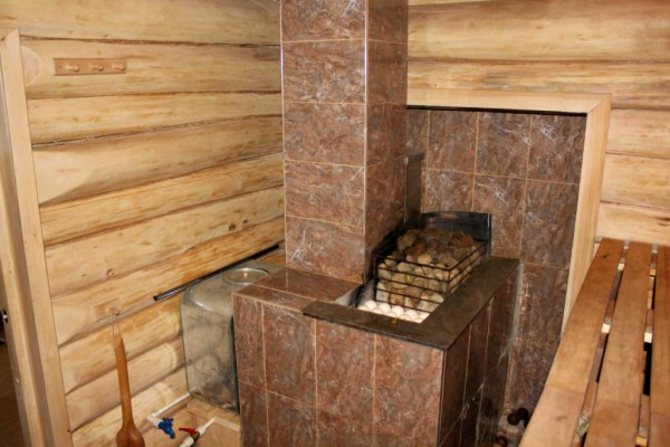

- As a cladding, linden is good because it does not emit resin at all, so you don’t have to worry about the presence of various impurities in the hot air of the steam room. This determines the high safety of using linden for interior cladding of bathhouses.

- Linden wood can breathe, which has a positive effect on the entire structure as a whole. Indeed, in this case, the building material retains its natural qualities for quite a long time. This means that linden can be used not only for interior decoration, but also for the construction of various elements of a bath interior, as well as as a building material for the construction of walls and roofs.

- The fact that linden wood is excellent for constructing a bathhouse is evidenced by its pliability to various types of processing. Consequently, all preparatory manipulations, along with subsequent installation, can easily be done with your own hands.

- Linden in a bathhouse, when heated, can fill the atmosphere of a steam room with an amazing smell. Moreover, hot air does not deprive linden wood of its healing and performance qualities.

Flaws

However, linden also has disadvantages.

- The most important thing is that it is not durable. In order to extend the service life of this building material, the interior of the bathhouse must be ventilated after each use of the steam room. This will make it possible to avoid the rapid occurrence of rotting processes.

- By the way, it will be said that linden begins to rot from the inside, which quite often does not allow us to detect the problem in time and promptly replace the element that has begun to deteriorate.

- Separately, it is necessary to say about the cost of linden wood. This indicator depends on the method of procurement of building materials. If drying was carried out artificially, the price of linden products will be slightly higher than in the case of a natural occurrence of this process.

Linden baths

Cool in the summer in the linden forest. Linden is a shade-tolerant tree. But sometimes the linden thicket becomes so crowded and the young stickies stretch up so high that they are unable to hold the thin trunk in an upright position. Their sparse crowns bend almost to the ground. And when you walk through such a linden forest, sticky trees bent into arcs, like barriers, block the way. But somewhere out in the open, on the edge of a forest, in a bright forest clearing, in a large park or near a village outskirt, you won’t recognize a linden tree. It is stocky and spreading, like a mighty oak tree, its foliage is thick and juicy. While the linden tree is still young, it attracts little attention and hardly stands out among the trees around it. And only after living for dozens or even hundreds of years does the linden emerge as the first beauties of a forest or park.

More than ten species of linden grow in our country, but the most common linden in the middle zone is small-leaved linden. She lives on average 300-400 years, but some centenarians sometimes live twice as long. Reaching a trunk diameter of more than a meter, small-leaved linden rises to a height of up to thirty meters.

At the height of summer, in forests, parks and gardens, the hot dry air is filled with a honey aroma - linden trees are blooming. “The linden honey plant is in bloom, haymaking is in full swing,” people say. Linden flowers are unusual - each of them looks like gold jewelry of very fine workmanship. From early morning until late evening, bees are busy on the golden flowers. They are in a hurry, because flowering will continue for a little more than a week, and during this time they need to collect as much healing nectar as possible. From one large tree, bees collect as much honey as from one hectare of buckwheat, and what kind of honey - golden and fragrant “lime tree”!

Linden flowers, dried in the shade in the attic or in a Russian oven, are a pleasant and healthy tea leaves. Since ancient times, people have used hot flower tea with Lipetsk honey as a reliable remedy for colds.

In ancient times, healing powers were attributed not only to flowers, but even to entire trees, especially the old mighty lindens. The ancient Germans, in the hope of healing, brought their sick children under the branches of spreading linden trees.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In Sweden, where people believed in their kinship with trees, old linden trees, considered the ancestors of ancient families, were carefully protected. One of the linden trees, which had three trunks extending from the root, was considered the ancestor of three related families, one of which belonged to the famous botanist of the 18th century. Carl Linnaeus. Legend has it that after one of the three families died out, one of the trunks dried up.

Among many peoples, the linden tree was revered as a symbol of kindness and generosity. In Greek mythology, the king of the gods Zeus, for his cordiality and hospitality, turned the Greek woman Baucis into a linden tree after his death, and her husband Philemon into an oak tree. In oral folk art, linden and oak are often contrasted with each other, and perhaps one of the reasons for this is the softness of linden wood and the hardness of oak. “Girls are fake, and guys are fake,” says a Russian proverb. And it is not at all by chance that in the Baltic states in the old days there was a custom of cutting down a ochep in the forest, a pole on which a cradle with a newborn was hung, for a girl from linden, and for a boy from oak.

Linden is one of those trees, parts of which are used by humans in one way or another. In many places, fresh branches with leaves were used to feed domestic animals. Juicy and soft, devoid of bitterness, young spring leaves were eaten in some places, and even now they are used to prepare vitamin-rich salads.

Forest workers call linden leaves that fall in autumn as forest fertilizer. After all, linden leaves contain quite a lot of calcium and rot quickly. If in the spring under the oak tree there are still last year's browned leaves, then you will no longer find the leaves under the linden tree.

In autumn, small nuts appear on the linden tree, which remain on the branches almost all winter. They contain up to 12% fatty oil, similar to almond oil. In winter, when nuts plucked from a tree by the wind fall onto the snow crust, mice readily collect them. Anyone who had to feast on linden nuts in the winter would remember their special, unique taste for a long time.

Everyone knows the little rhyme about the “white hare” who picked a bast in the forest and put it under a log. In fact, the hare does not prepare bast, but simply feasts on the sweet and juicy bark. But squirrels, crows and rooks actually harvest bast. They pluck it from dried branches without causing any harm to the tree. The dry crust covering the bast fibers crumbles, but the flexible soft fibers remain. This is what squirrels and birds line their nests with. Durable bast fibers of old and young linden trees have found a wide variety of uses in human economic activities. For basting, the bark was removed from large trees. Longitudinal cuts were made on the trunk on both sides. Then, using a wooden wedge, two half-cylinder grooves were separated from the trunk. The bark removed in this way was called bast. Dried bast was used as roofing material for outbuildings, and simple utensils for dry food were made from it. But the main part of the bast was used for the production of bast, the use of which was very diverse. To obtain bast, bast was soaked in mochila - ditches dug in the forest near a stream or lake. Bast harvested in spring or early summer was loaded into soaking ditches. Well-soaked bast was hung out to dry, and in winter it was brought to the village and put into use. Soaked bast fibers tied into a bundle instantly turned into a bath sponge, which is well known to modern people. They knitted brushes from bast for whitewashing stoves, made brushes and brushes for washing dishes, wove quite strong ropes and even threads for fishing nets. Archaeological excavations confirm that fishing nets were woven from bast back in the Neolithic era. The strength of ropes made from moss can be judged by the fact that they were used to make harnesses and fetters for horses. On simple wooden looms, village craftsmen wove matting, from which they made coolies, capes for horses, and much more. The ancient Germans wove clothes from bast - mainly cloaks and belts. In Russia in the last century, Ryazan lamplighters made raincoats from bast bags. One corner of the sack-bag was inserted into the other - and the cloak was ready. In the old days, sponge was widely used by carpenters as padding material for upholstered furniture. The mop was also used for polishing wooden furniture. Moreover, it was used so widely that the polishing process itself began to be called basting.

Once upon a time the linden tree covered almost all of Rus'. Bast fibers from linden bark were used to make bast shoes, feet, shoe covers, boots and sandals. One shoe was worn during long journeys, another during commercial hunting and fishing, and the third was simply used as house shoes, similar to modern slippers. For Russian people, wicker bast shoes were as traditional as wooden shoes for the peasants of Western Europe.

Bast for weaving shoes was removed from trees no older than ten years old. After making longitudinal cuts on the trunk with a knife, the harvesters removed four narrow strips from each tree. After removing the top crust, the bast ribbons were soaked and weaving began.

The most common shoes were bast shoes. There are many beliefs and customs associated with them. Thus, in the Oryol province, sprouted cucumber seeds were carried into the garden for planting in bast shoes. The peasants believed that the cucumber lashes would be as long as the frills of bast shoes, and that the cucumbers themselves would be strong and juicy. In the Kaluga province, bast shoes acted as the “chicken god”. It was hung on a roost to prevent chickens from walking around other people's yards, and to lay eggs not in burdocks, but in their own nests. In the Kursk province, a guy presented bast shoes as a gift to his chosen one. If the girl did not like the guy, then the gift was rejected, but if the gift was accepted, the groom could safely send matchmakers. The Ural Old Believers considered bast shoes to be God's shoes. They buried their dead only in bast shoes, apparently believing that these were the only worthy shoes in which to appear before God.

The time for bast shoes has long passed, and now only in the souvenir shop you can buy small souvenir bast shoes. Every peasant family has enough leather and rubber shoes, but no, no, somewhere in the outback you will meet a stubborn old man walking in bast shoes to mow and claiming that the best shoes for mowing work cannot be found. It is these old people who still keep the secrets of weaving bast shoes.

During the Great Patriotic War, bast shoes served the partisans well. For example, the partisans of the Chernihiv region went out on important missions only wearing bast shoes, which were specially woven by a local craftsman. It turns out that they had great advantages over other shoes. They did not leave a clear trace, and most importantly, the bast dogs did not take the trace of the bast shoes. These are the wonderful properties of linden bark. Only birch bark can compare with it.

But linden wood is no less wonderful. Peeled linden logs were placed in a stack under a canopy, where they dried all summer until winter. In the winter, when the peasant had a lot of free time, he would bring tins into the house and start making things. From wood that had turned black over the summer, the village craftsman cut toys, dishes and other household utensils. Beneath the cutter, pure white wood was exposed. Some peasants sent the finished products sparkling white to the market. And perhaps the village treemakers came up with a riddle that once existed: “Into the hut as a raven, out of the hut as a white swan.” It wasn't that hard to figure it out. Of course, this is a lutoshka - a linden log that has undergone miraculous transformations in the skillful hands of a craftsman.

Linden is a mature wood species. The color of the wood is white with a slight pink tint. When looking at turned or carved linden products, we hardly notice its texture. They seem to be made of a homogeneous wood pulp, devoid of layering. This idea arises because linden products are polished very rarely. No matter how sharp the cutter is, it still crushes the wood fibers, making the wood slightly velvety in cross sections and glossy in longitudinal sections, which is why it seems that linden does not have any specific texture pattern. But that's not true. To make sure of this, carefully sand the lime wood and the texture will immediately appear. You will find wavy, clearly demarcated growth layers, especially in end and tangential sections. This clarity is explained by the fact that each annual 76 layer is separated from the other by a light, very narrow strip.

In a radial section, the annual layers are almost invisible, the wood seems homogeneous, and only if you look closely, you can notice numerous small lines - the pith rays. In an end section, the medullary rays are visible in the form of numerous narrow stripes extending from the core. But you can only see them with a magnifying glass. Linden wood is diffusely vascular. The vessels are very small, although numerous. Through a magnifying glass they are visible as light dots on the end section.

Linden wood is soft, especially when freshly cut or steamed, but when dried, it becomes quite hard. Therefore, craftsmen carved various tableware from linden wood: ladles, scoops, bowls and spoons. They sharpened bowls, dishes and turning toys on lathes, including the famous matryoshka dolls.

In the southern regions of Russia, even houses and various outbuildings were built from linden. Where linden grew a lot, it was used very widely. Lithuanians laid linden floors. Such floors were considered warmer and softer than pine. Their only drawback was that they were more quickly affected by wood fungi than pine trees. For this reason, they tried to lay linden floors not on the first, but on the second floor. Carpenters made richly carved furniture from linden.

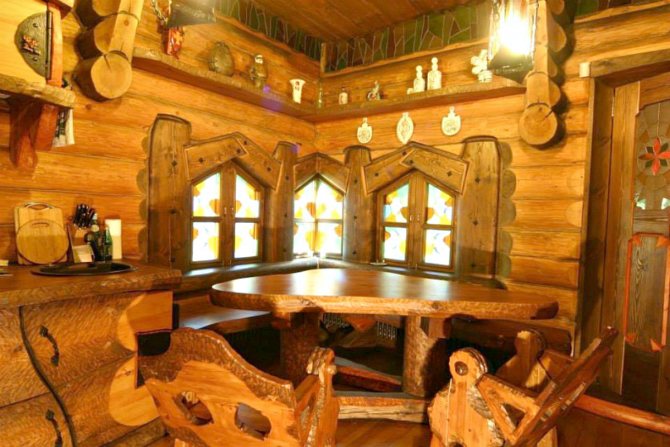

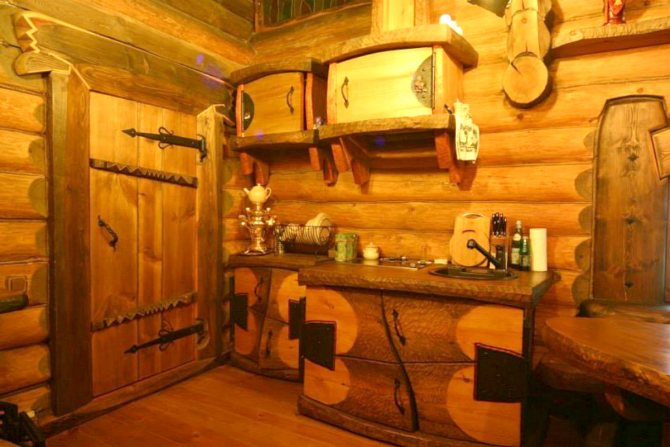

Linden wood has a unique smell, this smell is persistent and lasts for many years. Go into the barn, where debarked linden ridges lie in stacks, laid out to dry. You will immediately notice a familiar smell - it smells like loofah and maybe a little linden blossom. In some areas, peasants believe that a light honey scent always lingers in a bathhouse built from linden ridges, because wet wood smells even stronger. There are also bathhouses in which everything is made of linden: walls, floor, ceiling, shelves and benches. And on the shelves and benches are linden clumps, brooms made from leafy linden branches - some steamers prefer them to birch ones. And of course, you can’t do a bath without a washcloth, which can only be made from the bast fibers of linden bark.

Linden not only cuts well, but also bends and polishes well. Folk craftsmen bent the sides of sieves and boxes from thin linden boards. Master carriage makers upholstered carriage bodies with complex curved surfaces with thin linden planks. Linden was also used to make wooden parts of accordions. And what shoemaker could do without linden! A kind of stool—a linden block—on which the shoemaker sat was called a “sticky.” The tabletop at which he worked was also fake. They also made shoe lasts from linden. Veliky Ustyug craftsmen always cut the finest birch bark patterns on a linden cutting board. And the Bogorodsk carver did rough processing of the linden workpiece with an ax on a linden block, the so-called work chair. And this is no coincidence - after all, on soft and viscous linden wood, tools become less blunt, they can be easily moved in any direction, and their marks are quickly smoothed out, leaving the working surface relatively flat. For the same reason, drawing boards are made from linden. The pencil moves equally well across the paper in all directions, and the buttons fit easily and hold firmly in soft and sticky wood. You can’t do without linden in a modern model workshop. What is valued here is the relatively low shrinkage of wood, the ease of processing and the ability to maintain its original shape unchanged. Linden is easy to stamp. This property is used in mechanical engineering. Impregnated with resins and pressed under high pressure, it becomes stronger than metal. Bearings and other critical parts are made from this material.

Oil, caviar and grape juice are well preserved in linden containers. In the Caucasus, huge vats for squeezing grape juice and churns were made from linden trees. In modern cooperage, linden staves are used to make dishes intended for storing and transporting granular caviar.

Craftsmen carve wooden parts of special hand tools from linden. The engravers of the village of Kubachi make the handles of gravers from linden, and the woodcarvers of Bogorodsk make the handles of knives and chisels. Craftsmen explain this preference given to linden by the fact that its soft wood is less irritating than the wood of hard trees. Moreover, the Kubachi residents try to use old linden wood for these purposes, since its wood is more porous and loose. While working, it easily absorbs the sweat that accumulates on the palm.

In old bazaars, next to toy shops, one could meet sellers of popular prints. But why popular prints? Were they really painted on bast? Of course not. The fact is that in some places in Russia linden, as well as its wood, was called bast. It is believed that it was wood that gave the name to folk pictures. Popular prints were printed from clichés cut from linden boards. Before applying the design, the board was carefully sanded. Then the wood around the marked lines was cut to a shallow depth with a knife, and the space between them was selected with chisels. Thus, the contour lines became embossed. Before printing, ink consisting of furnace soot and linseed oil was applied to them with a leather swab. Then moistened paper was placed on the cliché and pressed in a press. Only the outline drawing and dashed lines were printed on the paper. The print was hand-painted with rich and bright colors. There is a legend that Lubyanka Street in Moscow was named so because once upon a time, artists who printed and sold popular prints lived on it.

Source: “The Magic World of Wood” Gennady Yakovlevich Fedotov. Enlightenment, 1987

A little about construction

timber

Linden timber is an excellent material for building a bathhouse.

Advice! When choosing linden timber for building a bathhouse, you must carefully ensure that the surface of these elements is clean. That is, the presence of cracks, chips and other unwanted inclusions should be completely excluded. In addition, the color of the product should be evenly distributed over its entire surface.

Before installing the timber, the foundation must be insulated, and special slats must be laid on top of the thermal insulation, which will prevent the beams from touching the base, and will also ensure ventilation of the building material.

Next, the beam itself is mounted on the mentioned slats. The first crown must be carefully checked for the evenness of all planes.

As for fixing this row, this manipulation is not required for two reasons:

- The weight of the structure will reliably fix the lower crown without corresponding elements.

- If such a need arises, loose beams will be easier to remove.

The lower crown of the beam does not require additional fixation.

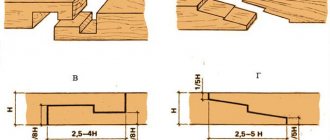

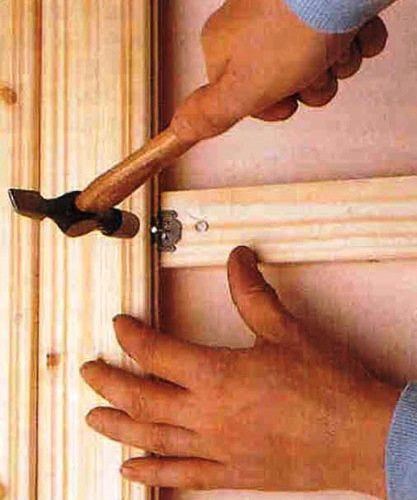

After the lower beams are in place and are perfectly aligned using special tools, you can begin laying the second row. Here you can no longer do without fastening elements, which are metal pins or wooden dowels.

To carry out the installation operation, holes are made at the ends of each beam through which the building material is placed on the fasteners. It is important that these perforations exactly match the size of the pins.

It is necessary to lay a heat-insulating layer between the crowns in order to additionally protect the structure from the influence of various negative factors related to the environment.

A linden bathhouse has one feature that distinguishes it qualitatively from its sisters, built using other types of wood. We are talking about two upper crowns, which are usually not fixed until the structure shrinks.

The upper rims are fixed after the structure shrinks.

This is due to the fact that the upper beams, after the bathhouse shrinks, must be dismantled in order to lay the ceilings. In the case of linden, everything is different, since a linden structure is not subject to such a phenomenon as shrinkage. It is for this reason that the upper crowns are fixed immediately, after which the roof is installed.

Lining

Before installing the lining, you need to build a frame. To do this, guide bars are nailed to the wall, between which additional slats are attached.

Then thermal and waterproofing is laid. Lining is sewn on top of these elements (photo).

The lining is fixed on the sheathing, which serves as a frame for thermal insulation.

Advice! The direction of fastening the cladding should be foreseen in advance, since the method of installation of the guide bars, which are always installed perpendicular to the lining boards, depends on this.