Waste oil is used engine oil, considerable reserves of which can be found in the garage of every car enthusiast. As a rule, they are simply disposed of during the next general cleaning. But there is a better way: waste is an excellent fuel for a potbelly stove, with which you can heat not only a garage, but also a small country house.

A waste oil stove is quite easy to make with your own hands. Then the oil deposits will be used, and heating the garage in winter will not cost a penny.

History of creation

The first stoves running on waste oil appeared back in the days of the USSR - it was under Nikita Sergeevich Khrushchev that people began to be given land for summer cottages. Naturally, the houses at the dachas had to be heated with something in the spring and autumn. It would be possible to use a potbelly stove with wood, which some did, but firewood was expensive even then, and unauthorized cutting could be punished to the fullest extent of the law. Gasoline also cost money, so the idea of using stoves similar to kerosene gas, which can be used to cook, but cannot heat the premises, came to the minds of summer residents.

Advantages of exhaust furnaces

Such stoves have a lot of advantages, let's try to summarize them:

- As you understand, the price of used oil is low, therefore, such a stove will be a very economical heating option. Any type of oil is suitable: transformer, motor, shock-absorbing, transmission, and it can even be very dirty. And, if you consider that this stove will not require any more energy sources (coal, firewood, gas, electricity, without which an ordinary fireplace cannot do), then the savings for its owner are significant. By the way, the heat output of such a stove is 13-15 kW/hour - compare with an electric radiator!

- Surprisingly, but true: a furnace running on waste oil is environmentally friendly. Try using it on the territory of a garage cooperative - none of the neighbors will complain about smoke, because the oil burns completely without smoke or residue. You can operate such a stove in any crowded place, because people are not threatened by toxic emissions, and the surrounding area is not afraid of pollution from it.

- The design of the exhaust furnace is very simple. Its dimensions are small, it can be easily disassembled for transportation from one place to another. You will not find any regulating nozzles or drippers that complicate the operation of the stove here. It is regulated without any automation - simply by a lid moving over the pipe for filling oil. This simple miracle stove will quickly raise the room temperature to room temperature, since at a combustion temperature of 800-900 degrees, it creates an outlet air temperature of up to 95 degrees.

- But the most important thing is that everyone can make such a “helper” independently according to the drawing below.

Fuel

For such a stove, so-called waste is used - that is, used transmission or motor oil, which is drained from car engines and gearboxes at service stations. You can also use industrial oil. For organizations, it will be quite expensive to dispose of this waste, which has a high-hazard class, so they will willingly meet halfway by selling the waste at the lowest price or even giving it away for free.

This type of fuel, when burned correctly, does not smoke or form a burn; it can be found at almost any service station. But modern oil may contain various alcohols, additives, additives, as well as moisture, so the oil must be filtered and purified. In addition, in cold weather you will have to store it in a warm room, as it will freeze. If there is no warm room, then the oil in the barrel can be placed in a deep hole, below the freezing level.

Principle of operation

A homemade stove operates using waste oil on the principle of pyrolysis - the decomposition of fuel molecules into elementary components. These substances are oxidized under the influence of oxygen molecules, giving off heat to the environment. The combustion process of oil vapors is self-regulating and is maintained at the same temperature level. In principle, you can change this temperature by increasing or decreasing the flow of oxygen, but it will not be possible to maintain the same value, and in addition, the amount of exhaust gases and soot in the chimney will increase. After the combustion process is completed, cooling occurs and water vapor, nitrogen oxide and other combustion products are released into the atmosphere.

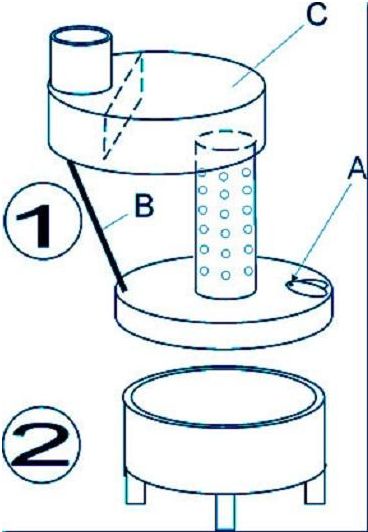

Let's consider the process of fuel combustion using the example of the simplest design of a stove during testing. The diagram of the stove is as follows - lower tank, pipe with holes, upper tank.

Fuel is poured into the lower tank, and a small amount of gasoline or other solvent is poured onto its surface. Gasoline is set on fire using a wick on a long wire.

The substance on the surface of the oil ignites, releasing thermal energy that heats the oil. The oil boils, volatile vapors are formed, which enter the middle part of the stove. There, under the influence of air flow, the vapors ignite, forming a stable flame. After ten minutes the stove starts working in constant mode.

How to make a furnace for testing with your own hands according to the drawings, construction from a gas cylinder

The tank is made collapsible and consists of two parts for easy cleaning of carbon deposits. Next, we assemble the tank lid from a piece of pipe and a cut out circle of metal with two holes for the filling hole and the afterburner.

The outer diameter of the pipe section for the lid should be slightly smaller than the inner diameter of the tank, thanks to this the lid will close it freely. All that remains is to weld the pipe for the chimney outlet. A piece of pipe with a diameter of 10-12 cm is perfect for its role.

To complete the entire structure, a steel bar must be welded between the upper and lower tanks, thus providing additional rigidity to the structure. After completing all welding work, the welded seams must be cleaned with a grinder with a cleaning disk to remove burrs and sharp edges, so as not to get injured during further operation of the furnace.

The upper part can also be made collapsible by making it by analogy with an oil tank. Upon completion of assembly, be sure to check all welds for leaks using a soap solution and supplying compressed air to the cavity of the stove. By analogy, you can make a furnace from sheet steel with the only difference being that the number of parts and welding operations will slightly increase. Therefore, describing it separately does not make practical sense.

Re: Waste oil stove for sauna

Before igniting the stove, you first need to fill it with at least half a tank of waste and add a few grams of gasoline or solvent on top. Typically, heating to operating temperature takes no more than five minutes. You need to wrap a piece of paper on a piece of long wire to make a kind of wick, set it on fire, and carefully ignite the gasoline through the hole for filling the waste.

Gasoline heats the oil to the temperature of evaporation of flammable substances, where they then ignite. A stable combustion of oil vapor is formed in the perforated pipe. The intensity of combustion is regulated by covering or opening the filling hole, from where air is blown directly. No matter how reliable your stove may seem, you should not forget and always follow the basic fire safety rules:

Waste oil stove diagram

In general, any oil stove is structurally composed of three parts:

- The lower part or evaporator chamber, where the pyrolysis process occurs,

- The middle part, in which combustion of pyrolysis products occurs,

- The upper part, where the split fuel fractions are burned and cooled.

Waste oil stove diagram

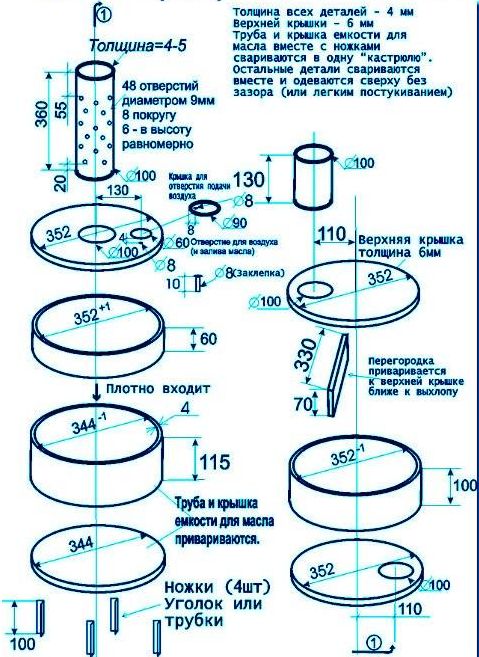

The lower part is a wide closed tank with a fuel reservoir. The tank can be either square or round. Wall thickness – 4 mm. The upper part, the tank itself and legs from corners or thick tubes are welded into a one-piece structure. The throttle opening at the fuel tank is usually not closed by anything. Ignition occurs just through it using a torch.

The middle part is a vertical pipe with holes for oxygen supply. The pipe should have a thickness of 4-5 mm. According to the design of the holes on the pipe there should be 48 pieces with a diameter of 9 mm. They should be arranged in horizontal rows of 8 holes each - a total of 6 even rows.

The upper part or afterburning chamber is equipped with a pipe welded into it with a diameter of 100 mm and a height of 130 mm, intended for mounting a chimney. The shape of the upper part is similar to the lower one, but a partition is welded inside it on top, which helps not immediately release the heated combustion products of oil vapor into the chimney. The thickness of the top cover of the afterburning chamber should be greater than that of the other parts of the furnace - 6 mm.

The dimensions of the waste oil stove must correspond to already developed projects - deviation from the specified values is fraught with a decrease in the efficiency of the stove and a deterioration in its performance.

For convenience, you can equip the furnace during mining with a continuous fuel supply system. The principle of its operation is the principle of communicating vessels, known to everyone since school days. A steel container for oil is placed at the same level as the evaporator chamber, connecting them to each other with a fuel supply pipe. The distance between two tanks should be at least half a meter.

A waste oil stove must have a chimney at least 4 meters high. It should not be vertical everywhere - in the room it is necessary to make elbows at an angle of 45º so that most of the heat does not go directly into the pipe, but remains inside the room. Naturally, the street part of the chimney is vertical as standard.

The sludge reservoir should not be collapsible, otherwise the hot sludge will definitely find a hole to escape.

Manufacturing instructions

A do-it-yourself waste oil stove is made from two tanks, a connecting pipe, and a chimney . Its structure is welded from metal, 4 mm thick. But for the top cover of the upper tank, the metal thickness should be greater - 6 mm, since this cover burns out much faster than other parts of the furnace.

The requirements for the connecting pipe are:

- Its diameter must be at least 100 mm.

- The length of the pipe should exceed its diameter by four times, having a length of 35-40 cm. Holes with a diameter of 9 mm in the amount of 48-50 pieces are drilled throughout the pipe.

- The location of these holes can be as follows: in a circle - 8 pcs., and in a row (along the pipe) - 6 pcs.

As can be seen in the diagram, the smoke exhaust pipe is placed above the upper tank. It is made of heat-resistant material, for example steel. But the final section of the pipe, which will withstand a lower temperature load, can be made from materials such as tin, galvanized or ceramic. The chimney must have a height of at least 4 meters, and best of all – 5-7 meters.

The heat transfer of the stove will be better if the section of the chimney pipe is made at an angle. Only its final section should be vertical to prevent wind from blowing. The chimney is covered with a special cover to protect it from rainwater flowing into it. It is advisable to design the chimney pipe so that it can be easily removed to clean the chimney from soot and soot.

The lower part of the tank is welded to the legs, tightly (without gaps) placing a lid on top of it, which has a hole for air and oil. Then the lid with the hole, the pipe on which 48 holes are drilled and the upper tank are welded together.

The hole for air and oil should be adjusted and closed easily using a special cap mounted for this purpose. The combustion power directly depends on the size of the gap left.

A do-it-yourself waste oil furnace made in this way is ready for use. It will not only effectively heat the room during the cold season. On the hot surface of its upper reservoir you can warm up food you bring with you to the garage or boil water.

This stove can also be used as water heating. On the hottest upper tank, you can mount a container of water, from the top of which a pipe comes out, connecting to a water heating radiator. The cooled water will return again to the same container through the return pipe. A water circuit arranged in this way will give you relatively inexpensive heating, which, moreover, can be adjusted.

How to make a waste oil stove

You can make an oil stove using a simple project that has been tested by time and years of operation. It will require 4 and 6 mm thick metal, corners for the legs, as well as a chimney pipe. Naturally, you will need a grinder for cutting metal and a welding machine.

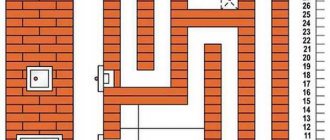

For the evaporator chamber, a circle with a diameter of 344 mm and a sheet for the side walls with a height of 115 mm are cut out. The sheet is rolled into a ring with a diameter of 344 mm and welded. Then the ring and circle are welded together. The legs are welded onto the oil fill tank made in this way. The lid for the tank is made of a circle with a diameter of 352 mm with two holes drilled in it - for a pipe with a diameter of 100 mm and an oil fill with a diameter of 60 mm. It should fit tightly onto the oil tank.

The gasifier pipe is made of a steel sheet 360 mm wide, which is welded into a ring. The diameter of the pipe should be 100 mm. Holes are drilled in it according to the drawings. The pipe is welded to the fuel tank cap.

Stoves running on waste oil

The upper part consists of three parts - the top cover, side walls and bottom. The diameter of the bottom and lid is 352 mm, and the height of the ring-shaped middle part is 100 mm. A partition measuring 330x70 mm needs to be welded to the top cover, closer to the exhaust hole. In the bottom you need to drill a hole with a diameter of 100 mm for a gasifier pipe, located at a distance of 110 mm from its center to the right side, and in the lid - for a chimney pipe with the same diameter, at the same distance from the center, but to the left. A small pipe with a height of 130 mm is welded onto the lid.

The fuel tank cap, gasifier and afterburner are welded together. The chimney pipe is mounted on the branch pipe. Additionally, you need to weld several parts of the pipe at an angle of 45º for the room, and take a vertical pipe 4 m long outside.

Potbelly stove using waste oil

The craftsmen also modified the well-known design of the potbelly stove so that it could run on waste fuel. In general, the potbelly stove was originally designed for use with solid fuels, but, as you know, engineering always goes beyond stereotypes and boundaries.

A potbelly stove using waste oil is obtained as follows - an oil reservoir located under the bottom of the stove is added to the structure. A gasifier pipe with holes, bent at a right angle, goes from this reservoir to the stove vent. Thus, the space under the grate becomes a fuel afterburning chamber.

Everything seems simple, but there are some nuances. The holes in the gasifier should be located according to a slightly different principle than in conventional oil furnaces. Some of them - up to one third - should be located evenly on the horizontal part of the pipe. The remaining holes are made in a row on both sides of the pipe. They should be located symmetrically over the entire surface of the gasifier - along the curved part and along the horizontal section of the pipe.

The fuel filling port should not be located near the gasifier to prevent oil from escaping through the openings. It is better to do it in the far corner of the fuel tank. You need to pour the waste into the hole very carefully, using a funnel with a long, preferably curved spout.

There is also a stove design made from an old gas cylinder. It is better to use a household cylinder, since industrial analogues are too tall and narrow. Some sources recommend making such a stove vertical, while others recommend laying the cylinder on its side. But, in both cases, a stable slow combustion process cannot be achieved.

In order for the gas vortex inside a vertical furnace to form correctly, it is necessary that the depth of the firebox be twice its width, but due to the size of the cylinder, you will have to make the blower too high, which will ultimately lead to excessive heat intake from the combustion part.

A stove with a side-mounted cylinder has other problems - its upper spherical part will not allow the gas vortex to spread over the entire plane. The vortex will eventually take the form of a narrow rope, which, without burning out completely, will evaporate into the chimney, taking the heat with it.

Waste oil furnaces: restrictions and prohibitions

Installation, operation and maintenance of a waste oil furnace

are associated with certain restrictions and prohibitions aimed at the efficient and, most importantly, safe use of liquid fuel heating equipment. Note! All air furnaces using waste oil are designed for heating industrial premises. The use of equipment other than its intended purpose is strictly prohibited.

General recommendations.

1. Do not use liquid fuel stoves for heating residential premises, cabins for builders, summer cottages and houses and administrative facilities. 2. Despite the seemingly simple operation and design of an oil heating stove at first glance, it is a source of increased danger. Therefore, when carrying out any work related to the heater, it is necessary to strictly comply with the requirements specified in the operating instructions.

3. Liquid fuel heaters operate on waste oil, diesel fuel, kerosene, and heating oil. The use of other types of fuel is excluded. It is also prohibited to burn transformer oil, heavily contaminated fuel, with mechanical impurities, water, antifreeze, paints and varnishes, gasoline, solvents, acetone and lubricants.

4. It is prohibited to operate waste oil stoves in places with high humidity, in dusty and cluttered rooms, in the open air and in places where flammable liquids, toxic or chemically active substances are stored or placed.

5. If in a heated room there is only an exhaust hood (the presence of powerful fans, paint booths, etc.), and there is no influx of fresh air, then a reverse draft effect is possible, that is, combustion products can enter the room. Therefore, the presence of supply and exhaust ventilation is mandatory when using liquid fuel heaters!

6. It is strictly prohibited to independently make any changes to the design or settings of the stove using waste oil or other liquid fuel.

7. Grounding when operating liquid fuel stoves is mandatory.

8. We recommend that you do not leave the oven running without long-term supervision. Monitor work every 2-3 hours.

9. Do not operate a faulty heater.

10. Do not install an oil furnace into an air box system - they are not designed for this. With the exception of those models whose manufacturer gives permission for use with air ducts.

11. Do not try to dry clothes or shoes on a working stove, or use it as a stove for cooking.

Tips for transportation and storage.

12. Delivery of liquid fuel heating equipment to the site must be carried out in a strictly vertical position. Other options are excluded. 13. When loading and unloading, avoid sudden shocks and impacts —

The heater attachments may fail.

14. During transportation, protect your waste oil furnace from precipitation.

15. When accepting heating equipment, make sure that it is not damaged. If the heater is damaged, then additional approval is required for its further operation, based on the current damage.

16. Do not store the liquid fuel stove outdoors, or in very dusty or dirty areas.

Installation of a waste oil furnace.

17. Installation of a liquid fuel heater and its components must be carried out by specialists with the proper experience and approval, in accordance with current SNiP and SanPiN standards, while strictly observing the requirements of the operating instructions, current technical standards and regulations, as well as fire safety rules.

18. The waste oil furnace must be installed on an absolutely flat surface. If the surface has unevenness or differences, the distribution of waste oil on the plate will be uneven, which can lead to poor combustion.

19. Do not run liquid fuel equipment without a chimney or in the open air.

20. The chimney must be folded in full accordance with the requirements of the operating instructions for the equipment.

21. Connecting a chimney of reduced or increased diameter, as well as a general chimney system, is strictly not recommended.

22. To normalize traction, we definitely recommend using a knee with a traction regulator.

23. Use a voltage stabilizer if there are frequent power surges.

Operating a furnace using waste oil.

24. Ignition of the liquid fuel heater during testing is carried out exclusively in a cold state. Failure to comply with this condition may result in uncontrolled ignition of waste oil vapors and burns. When restarting, be sure to wait until the device has completely cooled down.

25. We recommend heating the combustion bowl using diesel fuel. Heating the bowl with gasoline, alcohol-containing liquids, paints and solvents is strictly prohibited.

26. Do not add diesel fuel to a hot plate, or after the flame has started to burn.

27. Do not disconnect the waste oil furnace from the mains while the fan is running. This can lead to breakdown of the fan itself, as well as overheating of the combustion chamber with its subsequent failure.

28. We do not recommend opening the top cover of the combustion chamber or touching it while the oil stove is operating.

29. The efficiency of a waste oil furnace depends on many factors, one of which is timely cleaning of the combustion chamber. We recommend carrying out maintenance of the combustion chamber and bowl until the performance of the liquid fuel heating unit deteriorates. Dirty devices work and heat much worse than cleaned ones.

30. When starting maintenance on the liquid fuel stove, wait until it has completely cooled down.

31. When daily servicing a plate on which waste was burned, we recommend not throwing a hot plate into the snow, or trying to “beat off” unburned residues by banging the plate on the asphalt. All this can lead to premature failure of the plate.

32. If a lot of water/antifreeze collects in the fuel storage tank, be sure to remove these fluids. If they get on the combustion bowl together with waste oil, it can cause uneven combustion and strong hissing of the flame, which is incorrect and unsafe operation.

We wish you safe, long and efficient operation of your waste oil furnace!

No part of this article may be reproduced in any form or by any means, electronic or mechanical, or published on the Internet without the written permission of the copyright owner. © ThermoAlliance, 2014.

Features of furnaces during mining

The exhaust stoves are very economical - from 0.5 to 2 liters are consumed per hour, while the heat release reaches a value of about 15 kW, which is equal to the heat transfer of an electric heater. They are small in size and weight - they are easy to bring and take away. You can additionally weld a steel sheet onto the top of the stove and use it to heat a kettle, pan and other containers with liquid.

But there are also disadvantages. The stove must be made strictly according to the design, since dangerous chemical processes occur inside it - nitrogen oxides are formed, which are dangerous to human health.

The chimney will become contaminated with oil combustion products quite quickly, so it will have to be cleaned at least once a week.

In stoves of this type, complete combustion of oil does not occur - the heaviest fractions cannot evaporate completely due to insufficient combustion temperature. Therefore, they settle over and over again in the form of oily sludge in the tank. It's not easy to clean all of this.

Ways to increase heat transfer

It is possible to increase the efficiency of heating a room with a furnace during mining. Any furnace has a reserve of mode stability, including oil ones. Therefore, by using some methods, you can achieve an increase in heat transfer by 15-20%.

- The first method is to use a simple fan, which should be located a couple of meters from the stove. He still won’t be able to cool the oven, but he will be able to distribute the heat evenly throughout the room.

- The second method is to add a water circuit. It is recommended to extract heat from the upper part of the furnace, where the heating temperature is maximum. But if you place a water tank there, the temperature regime will be disrupted. Therefore, around the upper third of the combustion chamber it is recommended to make a heat absorber in the form of a coil or water jacket connected to a water circuit. Another feature is that water heated in this way will not move along the circuit itself; you need to use a water pump.

Pros and cons of metal sauna stoves

Most often, metal is used . Its advantages include:

- Long service life and wear resistance.

- Resistant to high temperatures.

- Possibility of using most types of fuel, including waste fuel.

- Possibility of quickly heating the bath. Even the simplest stove can completely warm up a room in an hour.

- Possibility of assembly from improvised means. For example, if you make a furnace during mining, then the cost of materials for its manufacture will be minimal.

- Easy to assemble by yourself.

- Little weight. If a metal stove is made, then it will not be necessary to build a foundation for it, as is done for a heater.

Metal stoves also have certain disadvantages. For example, compared to a stone stove, a metal stove will cool much faster , which is why it needs to be constantly heated. But in this case, you will only need to adjust the volume of waste entering the heating device.

Safety precautions

Perhaps the most important piece of information regarding a waste oil stove is its proper operation and compliance with fire safety rules.

- Since the heating temperature in the stove is quite high, there should be no flammable objects nearby,

- While fuel is burning, the stove must not be left unattended to prevent boiling oil from spilling out, nearby objects catching fire, and other unpleasant events.

- Do not install the stove in a draft,

- Gasoline or other flammable substance is used solely as a lighter fluid and not as a fuel. It should be used in small quantities,

- The fuel for the stove is used oil, preferably technical and purified. You should not use heavily watered fuel in stoves of simple designs - there is a risk of explosion,

- Do not allow water to get into the oil,

- It is vitally important to ensure that there are no holes in the chimney, otherwise all toxic compounds will enter the room along with the smoke.

- If a fire does occur, then water will not help - you must use a carbon dioxide fire extinguisher. Ordinary powder will not work - if the substance comes into contact with hot metal, an explosion will occur. It is better to keep the fire extinguisher in the room where the stove is located.