We live in a region where there is severe winter for at least three months a year. Our home is our fortress, which should protect us from all external adverse natural phenomena, including cold. But it happens that you come to your home, hoping to warm up after walking through snowy or wet streets, but the heating is turned off. And it is not clear whether regular unplanned repairs are taking place, or whether the utility workers simply decided that the heating season has come to an end. And again you have to wear a warm sweater and woolen socks, additionally turn on the heaters, consuming expensive electricity, and all this in our advanced century.

That is why more and more people are moving away from central heating, looking for alternative, more reliable and stable sources of heat. Of course, gas heating is a good option , however, it is only relevant in places where there is a gas pipeline, and the price of such heating in the winter season is quite high.

DIY pyrolysis oven

Those who own a country house, a bathhouse, a country house, or simply want to heat their home in a natural, inexpensive way will undoubtedly like a pyrolysis stove.

You say: “What, for example, is worse than a fireplace or a stone stove?”

Of course, stone stoves are very romantic and beautiful. However, in order to install such a structure in a house, you will need quite a lot of space, with a foundation prepared for it. Another drawback of fireplaces and heaters is that to maintain their combustion, you need to continuously add an impressive amount of kindling material .

Therefore, the most convenient option for accessible heat in a bathhouse or home is a pyrolysis oven.

Of course, such a stove has its advantages and some disadvantages, the latter, however, are quite insignificant.

Advantages of a pyrolysis oven.

- Very economical fuel consumption. This is achieved due to the fact that such a stove operates not only on fuel, but also on gases released during its combustion. For this property, the pyrolysis furnace received a “second name” - a gas generator.

- Almost any material can be used as fuel for the gas generator: from wood waste and old magazines, to recycled engine oil and plastic.

- Minimum amount of soot produced. Due to the fact that the pyrolysis furnace processes the materials it has already processed several times, there is practically no residue left in the form of burnt fuel . This is a very environmentally friendly home heating solution.

- High utility rate, up to 80%. Even if your entire house is heated by one steam generator, you can wear one T-shirt in all rooms, even in the most severe frosts.

- Easy to control the oven system. Without a doubt, any household member can cope with the principle of controlling this equipment. Moreover, it does not require close attention; you just need to set the heating power and occasionally load fuel.

- You don’t have to spend money on fuel or think about where to throw away household waste without harming the environment. Your waste is the fuel for the pyrolysis furnace.

Although this alternative type of heating has many advantages, of course, it is not without several disadvantages.

- If you buy a ready-made boiler in specialized stores, it will cost you a pretty penny.

- Fuel that is too wet cannot be used in any way for such a stove.

- The gas generator must be permanently connected to the electrical network.

As you can see, in the lists we have given, pyrolysis furnaces still have more advantages than disadvantages.

Methods for supplying secondary air to the furnace:

- Secondary air supply through the firebox door.

- Supply of secondary air through a special hole in the furnace body.

- Supply of secondary air through the silo.

- Secondary air supply through a special brick channel inside the furnace.

1.Supply of secondary air through the firebox door.

The most common method of supplying secondary air to the furnace.

Many modern stove doors have special openings on their body to allow air to pass into the firebox. Usually these holes are conveniently closed with a gate. This damper regulates the amount of air supplied.

Supply of secondary air through a special hole in the furnace body.

The advantage of this method is that it can be delivered exactly to the place where unburned substances accumulate.

The difficulty is that it is not easy to determine such a magical place in the oven.

And the biggest difficulty is that the hole in the stove does not comply with fire safety standards.

Supply of secondary air through the silo.

A silo is a channel for the passage of air from the furnace ash to the secondary air supply area. The silo is made of stainless steel and installed in the oven with expansion gaps for possible expansion.

Arranging the supply of secondary air through a silo is a fairly technical and modern solution in the construction of furnaces.

To properly install silos in a furnace, it is important to understand the combustion processes in the furnace and the consequences of fire on the materials.

In fact, few stove makers use this method, because... This is a rather complex undertaking that requires clarity of design and good quality silo material.

Secondary air supply through a special brick channel inside the furnace.

A good way to supply secondary air, provided there is enough space inside the oven.

I usually have trouble placing another secondary air duct inside the furnace.

Usually you design a furnace with maximum power in a minimum size and there is simply no room left for an air channel, but if you are not limited by size, then making a secondary air channel out of brick would be a good solution.

Perhaps there are some other more exotic methods for supplying secondary air to the furnace.

Heating fireplace stove

Operating principle of a pyrolysis oven

Let's understand the principle of operation of a gas generator boiler, and understand how it differs from other furnaces.

For all types of furnaces, except for the option we are considering, full access to oxygen is necessary , otherwise the combustion process will not occur intensively enough. In pyrolysis furnaces, the loaded fuel undergoes slow smoldering with a lack of oxygen.

You ask: “What are the advantages of this method?”

With the standard method of combustion of any carbon material, energy is released, which provides the necessary heat , oxidation processes occur, unburned gases escape into the atmosphere, and unburned residues are thrown away.

In a pyrolysis furnace, due to the lack of oxygen, a lot of flammable gases and coal are released. The gases released during such combustion are called pyrolysis , hence the name of the furnace. This furnace has two combustion sections; fuel is loaded into one, where it slowly smolders in a small amount of oxygen. Then, due to draft, the resulting combustible gases move into the second chamber and burn there together with a sufficient amount of oxygen, and the remaining coke or coal burns out in the first section.

Thanks to this boiler design, the time of one pyrolysis cycle can reach 30 hours.

So, let's go over the stages of operation of a pyrolysis furnace.

- The fuel you select is supplied to the gasification chamber.

- Smoldering, it gradually begins to release flammable gases.

- Oxygen begins to flow into the section where the fuel burns out.

- Due to the strong increase in pressure, the gas moves to the second afterburning section.

- Next, air enters this chamber and mixes with the pyrolysis gas and begins to burn. At the same time releasing a large amount of heat.

- All these processes heat the water, which is located in a special section and it is sent through a pipeline through the entire heating system, simultaneously cooling the furnace system.

The combustion process of solid fuel is divided into three stages:

- ignition (ignition),

- active combustion

- afterburning.

- In the first stage, solid fuel is first heated and dried and at a temperature of 105 - 110 ° C loses its moisture.

- Then, at a temperature of 300 – 400 °C, it begins to decompose into volatile substances and a solid residue.

- With further heating, when its temperature becomes equal to the ignition temperature, the fuel ignites. The ignition temperature (approximate) of various fuels is as follows, °C: firewood - 300; brown coal – 300 – 400; coal – 450 – 500; anthracite – 700 – 750; liquid fuel 500 – 600; about 600 gas.

- The active combustion stage is characterized by high temperature (more than 1000 °C) with maximum heat release and the highest consumption of air (oxygen) spent on the combustion of coke and volatile substances.

- Afterburning of solid fuel is characterized by decreasing heat release and decreasing demand for air.

How to make a pyrolysis oven with your own hands

Of course, you can buy a pyrolysis oven at a specialized store, however, it will be quite expensive. To avoid spending a rather impressive amount of money, we suggest assembling a gas generator with your own hands.

Don’t be fooled into thinking that a homemade boiler doesn’t require any special expenses. After all, if you want it to please you with its work for many years, you need to purchase only high-quality materials .

The boiler body requires particularly strong metal. Alloy steel is best suited for these purposes.

Well, you need to have at least basic welding skills.

So, if you decide to make a pyrolysis oven with your own hands, we suggest you look at the list of tools and materials that will be useful to you.

- Welding machine.

- Approximately 15 fire bricks.

- 5 packs of electrodes.

- Drill.

- Angle grinder with a diameter of 230.

- Sheet of metal measuring 7.5 square meters. m. and 4mm thick.

- Sensor for measuring temperature.

- Grate bars.

- 10 discs for a grinding machine with a diameter of 230.

- Fan.

- 2 doors.

- Pipes with a cross-section of 57x3.5 mm and a length of 8 meters, a cross-section of 15.9x4.5 mm and a length of 0.5 meters, a cross-section of 32x3.2 mm and a length of 1 meter.

- Profiled pipes with a cross-section of 2.0x30x60 mm and a length of 1.5 meters, a cross-section of 2.0x40x80 mm and a length of 1 meter.

- Steel strips with a section of 80x5 mm and a length of 1 meter, a section of 20x4 mm and a length of 7.5 meters, a section of 30x4 mm and a length of 1.5 meters.

DIY metal stove, method one

To accurately calculate the dimensions of the furnace, you need to either understand diagrams and have a mathematical mind, or contact a person with an engineering or at least technical education.

Niche for “homemade products”

Is everything really that complicated and bad? Are homemade pyrolysis furnaces really a dead-end option for the development of homemade furnace construction? Of course not.

As mentioned earlier, a homemade pyrolysis furnace for constant heating of a residential building requires the installation of a complex control system, which not every craftsman can do.

But there are household objects that also require heating, and at the same time, requirements, standards and GOSTs allow the installation of stoves, the operation of which can be successfully controlled manually. The only thing that is required of them is to generate a sufficient amount of heat at minimal fuel costs.

A simple pyrolysis oven is suitable for such objects.

The list of such objects is quite long:

- workshops;

- garages;

- baths;

- greenhouses;

- buildings for keeping livestock and poultry.

Agree, having a garage oven will greatly simplify car maintenance. An efficiently operating long-burning unit in a bathhouse wouldn’t hurt either. Homemade pyrolysis ovens will come in handy here more than ever.

Spent disadvantage into profit

A long-burning pyrolysis furnace powered by waste oil is perfect for a garage or bathhouse. Not only will heating cost you virtually nothing, but you will also be spared the need to dispose of your own car's waste.

- The design of a pyrolysis furnace is simple and complex in its own way. The simplicity lies in the fact that a pyrolysis furnace can be made practically from scrap materials, for example, from an empty gas cylinder.

- The difficulty lies in the fact that individual components require the use of special materials. But again, this is not always the case.

- The operating principle of long-burning furnaces is that in addition to the main fuel, gases produced by heating the fuel are burned.

Waste oil pyrolysis furnace

A little skill turns into a net profit

A metal waste oil pyrolysis oven for a garage is a good example of this. Its manufacture does not require the installation of nozzles and a complex control system.

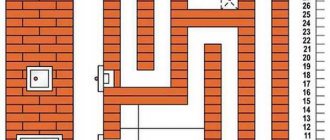

The figure shows a drawing of a pyrolysis furnace for a garage, the manufacture of which will require a minimum of funds, materials and labor.

Scheme of the furnace in production

Pipes, boxes, iron - everything comes into play

We have already described long-burning stoves in the article about stoves for greenhouses. Attentive readers will immediately notice that. Unlike the previous stove, the fuel tank is made in the form of a square box. This is no coincidence; an ordinary metal box is actually used here.

Disassembled oven

As can be seen from the figure, the oven consists of two parts:

- fuel tank - firebox;

- afterburner chamber, temperature chamber and chimney.

All that was required for the metal box was the manufacture of four legs from a steel strip. They are attached to the box by welding.

What you need to know when choosing a long-burning wood-burning sauna stove

When choosing a sauna stove, an important criterion is the duration of combustion without adding firewood: the longer it is, the more convenient it is to use such a device. Ideally, the duration of combustion should be equal to the time required for a steaming session in a sauna. For a procedure that lasts 3-5 hours, one addition of fuel is usually sufficient.

There are certain nuances that should be taken into account to make using a sauna stove as efficient and comfortable as possible. Among them the following are noted:

- Firewood from coniferous and soft-leaved trees burns out quickly and immediately turns to ash, without leaving smoldering coals for a long time. Accordingly, reserves of such fuel have to be replenished more often than usual.

- The process of burning wood is accelerated by strong draft in the stove. To eliminate this, just adjust the draft using the blower valve. If the problem persists, you should check the fit of the stove door and possibly replace it or seal the frame.

Among domestic manufacturers of stoves and fireplaces, the products have proven themselves well. The assortment also includes high-quality wood-burning sauna stoves, designed to quickly heat the steam room to the required temperature and maintain it at the same level for a long time. At the same time, the design of the furnace boiler allows reducing fuel consumption to a minimum.

uses only high-quality materials, which ensures efficient operation of products and a long service life. Steel for boilers and furnace walls contains chromium impurities, has increased strength and resistance to high temperatures, due to which the furnace walls are quite strong, having a smaller thickness than some similar models. This in turn made it possible to improve heat transfer and lighten the entire structure.

The heating rate of the furnace is also affected by the double combustion system. Convection currents ensure uniform heat distribution inside the steam room.

Adjustment is very simple

In the upper part of the furnace there is a hole for pouring waste. This is not exactly a simple hole. As you can see in the picture, a metal shutter is installed on it using a hinge connection.

Damper - draft regulator

Since during operation of the furnace the filler hole acts as a blower, the damper is used to regulate the draft and, accordingly, the temperature regime of the furnace.

The oven works as follows. The upper part of the furnace is inserted into the lower part with a slight tension; tapping with a hammer may be required. It is worth noting that when operating these stoves, the chimney must have a strictly vertical shape.

Rules for starting a furnace during development

The furnace is started as follows:

- The waste is poured into the filler hole in the amount of 2/3 of the tank volume .

- To make the stove start faster, you can splash a little gasoline.

- A wick twisted from oiled paper is ignited and inserted through the filler hole into the firebox - the tank.

- The damper is installed so that the filler hole gap is no more than 10-15 mm .

- A few minutes later, after the burnout flares up, the stove will return to operating mode.

- The damper regulates the draft.

Ready-to-use oven

As can be seen from the figure, heating occurs in the upper part of the stove, where the thermal chamber is located. The secondary air entering through the openings of the afterburning chamber, connecting with waste vapors, burns at a very high temperature. Pyrolysis system in action.

Article: Supply of secondary air without combustion - Afterburning of flue gases

Hello, dear friends!

Secondary air supply does not burn.

Afterburning of flue gases.

When fuel combustion occurs in the TGA furnace (oxidation of organic substances in the fuel in the presence of oxygen contained in the air), the flue gases released during heating (pyrolysis) ignite, releasing a large amount of heat.

However, in flue gases there almost always remains a fairly large amount of unburned substances that are still capable of burning, but which did not have enough oxygen and (or) quickly left the combustion zone.

In order for flammable gases to ignite again, they must be mixed with additional air. Most often this is done in the upper part of the combustion chamber or behind the deflector (smoke tooth), where the temperatures are high, where secondary ignition of the flue gases occurs.

This zone is often also called the “Secondary combustion chamber of flue gases”

Secondary air inflow channels are most often located between the lining and the furnace body, or in special pipes - air ducts. Thanks to this, the air is heated before entering the combustion chamber, and the temperature of the firebox body and lining is slightly reduced, which extends the service life of the product.

Thanks to this effect, we can obtain better combustion of fuel, which means an additional amount of heat released and a reduction in the content of harmful substances in emitted gases, which has a positive effect on fuel economy and the environment.

According to European environmental safety standards , the production and sale of fireplaces and stoves with a high content of CO, CH in flue gases in Europe is prohibited. This means that only the fireboxes of those fireplaces and stoves meet the requirements of the standards that are equipped with a secondary air supply and a secondary combustion system for flue gases.

Also, by switching the firebox to smoldering mode, we can get a long burning process , in which the firewood smolders on the grate, and the flue gases released during pyrolysis ignite in the afterburning chamber in the presence of secondary air.

This also allows you to increase the combustion time of one portion (fill) of fuel without additional lining to 6-8 hours, which means it can provide restful sleep in a warm room for 8-10 hours.

To increase the thermal efficiency of sealed furnaces, it is recommended to connect an air supply from outside the building.

Best regards, Alexey Telegin.

Rules for starting a waste furnace

How does it work?

- Fuel is placed in the barrel. Various wood waste is suitable - tree trimmings, cardboard, paper, rags and other household waste.

Our information. We tried burning plastic drink bottles. There was absolutely no burning or acrid smoke coming out of the chimney. Since we do not have reliable data on the composition of exhaust gases from such fuel, we cannot recommend you to use it; it is better to use wood waste.

Everything is at your discretion. The only thing I would like to note is that everything burns without a trace, leaving a small pile of ash at the end.

- The oven is loaded to approximately 2/3 of its volume. To make the fuel burn faster, you can splash a little gasoline, or you can do without it.

- The fuel is ignited from the very center from the top. After the fuel ignites, you can install the piston directly on it and close the lid.

Oven in working order

As can be seen in the figure, when the furnace is fully loaded, the piston tube extends to a considerable height. As the fuel burns, the piston, and with it the air draft pipe, will move down.

Oven after stop

When the piston drops to the very bottom, this will be a signal that the oven requires recharging.

Operating principle of the furnace

The furnace operates as follows:

- The piston presses on the burning fuel, and at the same time fresh air is supplied through its pipe.

- Pyrolysis gases collect in the upper chamber above the piston and burn at high temperatures.

- Due to this, the room is heated.

- Exhaust gases are removed through the chimney.

If anyone is worried that carbon monoxide will enter the room through the gap between the lid and the piston, we can assure you that these fears are completely in vain.

Real pyrolysis

The draft arising in the furnace will, on the contrary, suck in fresh air from outside through this gap, which acts as secondary air necessary for afterburning.

As previously mentioned, at the end of work, a small amount of ash remains inside the furnace, and the fuel burns completely.

If you look into the hole in the piston tube while the furnace is operating, you can see how cleanly the furnace operates. Combustion occurs at a very high temperature. The functionality and efficiency of this furnace lies in the fact that, in addition to fuel, pyrolysis gases are burned in it. Maximum efficiency at minimum costs.

Our information: long-burning pyrolysis furnaces made from 200-liter barrels are capable of operating on one refill for 30 hours or more. It all depends on the intensity of combustion, which is set by adjusting the draft using a damper installed in the chimney.

Causes and conditions for the occurrence of the afterburning process in a wood-burning stove:

Unburned fuel (volatile substances) drawn deep into the furnace can ignite.

Under conditions of high temperature and presence of oxygen, secondary combustion occurs.

Because secondary ignition occurs inside the furnace, and not in the firebox; this significantly increases the temperature of the gases in the channels.

Secondary afterburning occurs in a specially organized afterburning chamber.