Distinctive features

The blockhouse is made from coniferous and deciduous wood. During manufacturing, the boards undergo chamber drying, which prevents their subsequent deformation. The blockhouse production technology is a “square in a circle”. That is, four boards are cut from a log along the edges for a blockhouse, and ordinary boards are made from the central part of the log.

The appearance of this material “like a log” looks very attractive and largely depends on:

- type of wood used;

- processing technologies.

Wood has the ability to “breathe” - absorb moisture from the air when there is excessive humidity, and release it when it is too dry. Thus, interior walls lined with wood help maintain a balanced indoor microclimate.

At the same time, the blockhouse has good performance properties:

- does not crack or deform;

- does not rot and is not affected by fungus;

- has high strength and lightness.

Dressing the dressing room: rules and methods of design

The dressing room is the second most important place in the bathhouse after the steam room. Here a person relaxes and his good mood will depend on how comfortable he is. Finishing the dressing room is a crucial moment; here you need to take into account many nuances, from the right choice of materials to interior design.

The main, but not the only function of the dressing room is to prevent cold street air from entering the steam room. In addition, it serves as a storage place for bath utensils, and if space allows, then for a certain supply of firewood.

To relax after the bath procedures in a good and comfortable way, again, you cannot do without a dressing room with installed benches, a table and clothes hangers.

Material for interior decoration of the dressing room: selection rules

The dressing room is not a simple room and has special requirements. And it is these that you should focus on when starting finishing. The slightest mistake can reduce the quality of the effect of bath procedures and reduce the service life of the bath as a whole. More frequent repairs will be required.

Requirements:

- The width of the room should not be less than 1 m, and there should be at least 1.3 square meters of area per visitor;

- The design of the dressing room begins with its insulation and lining to prevent the occurrence of through wind;

- The room should have good natural light, the windows can be wide. But they should be done as high as possible from the floor of the dressing room. This will allow you to avoid hanging curtains to create a private environment. And it will prevent the air from cooling at floor level;

- The interior of the room must include benches or sofas, and, if possible, a table. You can’t do without a closet or several hangers.

Note! If the dressing area is small, then it is better to choose wood as the material for furniture. As a last resort, a leatherette sofa will do. Interior items made of fabric will not last long due to high humidity.

What material is suitable for finishing the dressing room?

The design of the dressing room begins with the choice of finishing materials, and this is not so easy to do. The room is exposed to moisture for a long time, but must remain warm, so tiles are not acceptable for it. It gives a feeling of coolness, which is inappropriate here.

Traditionally, wood of various species was used to cover the rest room in the bathhouse. Paint treatment is undesirable - naturalness is the basis of the bath interior. It is not only beautiful, but also practical:

- wood has an attractive appearance;

- this is a warm material - it heats up quickly and maintains the desired temperature level for a long time;

- a pleasant aroma has a beneficial effect on human health;

- properly selected wood does not rot for a long time without additional processing.

How and how to decorate the dressing room - preference should be given to hardwood, as it is more durable and dense in structure - linden, aspen, birch, alder.

Conifers - pine or spruce will have to be treated with water-repellent, odorless paint, which is absorbed into the thickness of the tree. Suitable finishing materials include planed logs, lining, tongue and groove boards.

Particular attention is paid to the floor. It is made waterproof and non-slip by dry wide boards. Porcelain tiles are less common, but such a floor can only be walked on with special shoes - it is not too warm.

How to decorate a dressing room

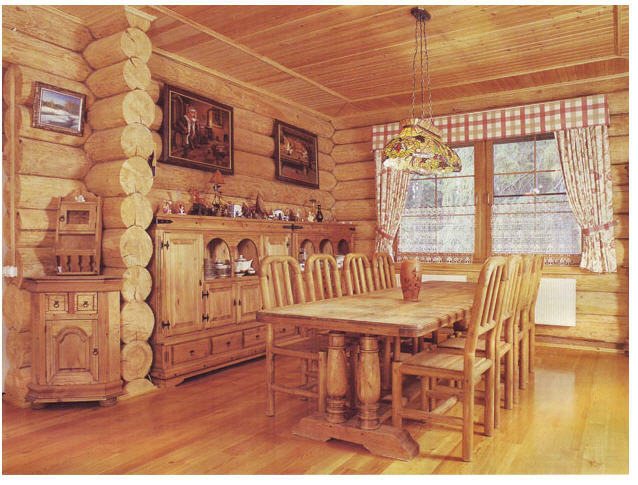

Finishing is not limited to a set of technical actions for insulating and covering the walls, floor and ceiling of the bathhouse. To make it pleasant to relax and convenient to care for the bathhouse, the interior of the dressing room is thought out to the smallest detail. Traditionally, the Russian bathhouse style is used for interior decoration - it creates a special atmosphere and comfort.

The walls are lined with clapboard - the direction is not of fundamental importance. It can be vertical, horizontal and even oblique. The ceiling is covered with boards with a mandatory vapor barrier underneath. But this is not all; it is not enough to comply with all the rules and regulations. We also need to arrange the situation.

Furnishing the room

If the room is small, then you can limit yourself to a few stools and clothes hangers, but you shouldn’t forget about the aesthetic component - it’s good to hang thematic paintings, brooms, and bath paraphernalia on the walls.

When the area of the room exceeds the minimum dimensions, it will not be difficult to expand on the design. It’s interesting to create an unusual and beautiful interior with your own hands. The choice of furniture should be done at the stage of construction of the bathhouse. These can be large sofas with faux leather trim, wooden benches or chairs.

The furnishings of the room should be ergonomic and functional. Before sheathing the dressing room, you need to decide on the style; perhaps, finishing with timber imitation logs is more suitable. All elements of the environment are subject to certain requirements:

- safety from fire - sufficient distance from the furnace firebox; if this is excluded, then cover the area nearby with metal to protect against sparks;

- environmental friendliness of all materials - exclude plastic from the interior;

- compliance with the chosen design direction to create harmony.

The organization of the dressing room includes the presence of structural parts - a wardrobe, bedside tables or even a sideboard for dishes, if cooking and eating food is expected there.

If you move away from the classics and add a little luxury, then furniture with curved legs and carved backs will come in handy. Decorating a dressing room, if done in compliance with all requirements, will be a pleasant experience. The instructions for many decorative materials allow their installation in a bathhouse.

Conclusion

The design of the dressing room begins with its lining and insulation. This cannot be avoided even if the walls are built from thick logs 200 mm in diameter.

The interior decoration of the room is to create a comfortable environment combined with practicality - non-slip heated floors, walls and ceilings made of natural breathable wood. The video in this article will tell you in detail about the process and types of dressing room finishing.

Source: https://9ban.ru/planirovki/predbannick/176-otdelka-predbannika

Technical qualities

Blockhouse is a natural material (see blockhouse - what is it), so it is used for finishing both outside and inside the premises.

For the convenience of consumers, it is produced in different widths:

- for interior decoration 80-90 mm;

- for external finishing 130-230 mm.

The length of the blockhouse can be from 1.5 to 4 m.

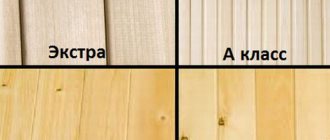

Depending on the surface of the wood, this finishing material is divided into 4 grades:

- Extra grade – ideal surface without knots or damage;

- grade A – small knots up to 3 mm are possible, no more than two per linear meter;

- grade B – possible knots measuring no more than 30 mm and no more than four per meter;

- grade C – the size and number of light knots is not limited.

The division into grades occurs during the sorting of finished products. The price of a blockhouse depends on the type, type of wood, length, width and thickness of the material.

Vinyl block house

This finishing material is relatively new, but has already become very popular on the market. Just like a wooden block house, it has its own advantages, and in appearance it is practically indistinguishable from natural wood, and is in no way inferior in environmental friendliness. Vinyl block house (siding) also has a wide range of color shades.

The advantages of vinyl are as follows:

- it is not susceptible to moisture absorption;

- fire resistant;

- can be stored for a long time;

- much lighter than a block house made of wood;

- without additional processing, withstands temperature changes from -50 to +50 degrees;

- does not fade in the sun;

- no additional special processing or care of the material is required;

- the cost of a vinyl block house and its installation is lower than a wooden one;

- Insulation of walls sheathed on the outside with a vinyl block house can be carried out using any materials.

In addition, installation of siding is very simple, does not require special knowledge and does not take much time. Caring for it consists only of washing it with water from a hose from time to time.

Application

Most often, blockhouses are used for finishing dachas, summer houses, gazebos, verandas, baths, saunas, and frame houses. Gazebos made from blockhouses are very popular for gardens and summer cottages. They are easy to install and look very nice.

Gazebo from the blockhouse - beautiful view

Increasingly, blockhouses began to be used for external and internal decoration of baths. If you decide to build a sauna with your own hands, then the best option is a frame sauna.

Its advantages are obvious:

- easy and quick to build - a frame is erected from timber, covered with wood boards with insulation;

- economically beneficial - these “sandwiches” will cost you much less than a wooden or brick bathhouse.

Is it worth treating wooden surfaces?

Today, experts do not have a clear opinion on this issue. While some point out that after impregnation of wood with special compounds, its service life increases, others note that fumes from chemical compounds negatively affect human health.

Whether or not to process wooden finishing elements, each owner must decide for himself. Most often, the wood in the steam room is not treated in any way, but special compounds are used for this in the dressing room.

Such impregnations allow the formation of a film on the surface of the wood, which prevents the growth of fungus and mold, and thus increases the service life of wooden elements.

If you decide to process the lining, then you need to do this once before installing the panels, and a second time after their installation. To ensure maximum protection of the wooden surface, treatment with such compounds should be carried out 2 times a year.

Since people go to the bathhouse not only to wash themselves, but also to gain health, one must approach the arrangement of all its premises responsibly and carefully. At the same time, it is necessary to choose a material not only on the basis of price, but also taking into account quality and environmental safety. Only in this case, after visiting the bathhouse, you will gain health, vigor and strength.

Bath decoration

After the frame base is ready, it needs to be sheathed with finishing material for the facade. It is best to sheathe the bathhouse with a blockhouse outside and inside. A bathhouse made from a blockhouse will look no different from a log house, and will cost you much less.

To properly install the blockhouse, you will need assembly instructions and videos from the Internet. First of all, you need to choose the right block house for the bathhouse.

Exterior decoration

For external installation, finishing panels made of pine, spruce or larch with a width of 130-230 mm are more suitable.

The installation process can be divided into stages:

- preparatory – you need to give the wooden blockhouse time to acclimatize for several days;

- treatment of wall surfaces with waterproofing;

- installation of vertical sheathing in increments of approximately 70 cm;

- installation of thermal insulation approximately 5 cm thick;

- installation of wind and moisture protection film;

- installation of another thin layer of sheathing - to create ventilation in the blockhouse from the inside. It is attached with self-tapping screws to the first sheathing;

- blockhouse installation.

Blockhouse installation

You can start attaching the blockhouse from below or from above, but make sure that the tenon is on top, because moisture can accumulate in the grooves.

Important! It is necessary to make a gap of 1-3 mm between the boards of the blockhouse so that the surface does not become deformed due to temperature changes.

The process of attaching the blockhouse itself is as follows:

- holes are drilled in the boards of the blockhouse;

- using self-tapping screws, the blockhouse is attached to the vertical sheathing;

- The boards are fastened together with a tongue-and-groove connection.

The screw fastening must be positioned so that it is hidden by the next board.

Fastening the blockhouse using self-tapping screws

When the Block House bathhouse is assembled, you need to process the base of the wood. The surface must be primed and covered with a layer of wax varnish or colorless paint.

Advice: If you are going to tint the blockhouse after finishing, then be sure to paint the tongue and groove of the board, since unpainted areas may appear over time.

The dried surface should be sanded with sandpaper and then another 1-2 layers of varnish or paint should be applied. Frame baths covered with blockhouse have very good thermal insulation and energy saving.

Types of finishing material

If the bathhouse is built from logs, then finishing it will only spoil it.

We invite you to familiarize yourself with the unusually beautiful flowering cactus Echinopsis, variety of species and care at home

Option for finishing a log bath

You can insulate a brick facade from the outside, but the inside is left unchanged. The only thing that can be applied is to cover it with protective compounds against mold and fire. The use of varnishes and paints is contraindicated. Due to elevated temperatures, they can release harmful substances into the atmosphere of the steam room and dressing room.

The finishing in the bathhouse must meet the following characteristics:

- Environmental friendliness. At elevated temperatures, no harmful odors should be released into the room;

- Practicality. Easy to ventilate, wash, repair;

- Heat capacity. During operation, the finish must maintain optimal temperature conditions;

- Fire properties. Particularly relevant for the wall adjacent to the steam room;

- Aesthetics. Not only the body, but also the soul should rest, and therefore the interior is not the last factor for a good rest.

Stylish finishing of the waiting room with clapboard

If we consider popular finishing materials, we can highlight several main ones:

- Wood is the most common option. Can be used for floors, walls, ceilings. Finishing the dressing room with wood meets all of the listed properties. Fire characteristics are added through the use of special protective equipment. The lining, block house is mounted on a frame, which also allows you to insulate the dressing room. If such interior decoration has lost its appearance, it can be restored by sanding the surface and re-coating it with protective compounds.

- Stone. Gives a rugged elegance. A special color is achieved by combining wood and stone. Its use for finishing the wall adjacent to the steam room is more than justified. Once heated, the stone accumulates heat in the dressing room for a long time, which creates an ideal microclimate for comfortable rest.

An example of finishing a dressing room with stone - Tile. The heated floor system plus ceramic cladding is a guarantee of comfort. In addition, tiling is excellent waterproofing. With such a floor covering, an additional source of condensation from the underground space disappears. Often the adjacent wall with the steam room is also covered with ceramics. The heat transfer effect is lower than that of stone, but all fire safety rules are met.

Finishing the bathhouse with the listed materials will create comfort and a healthy microclimate, which is so necessary for proper rest and restoration of health. The ideal option would be to finish the ceiling and walls with wood; floors – ceramic tiles with a warm floor system or wood; the wall adjacent to the steam room is tiled or stone.