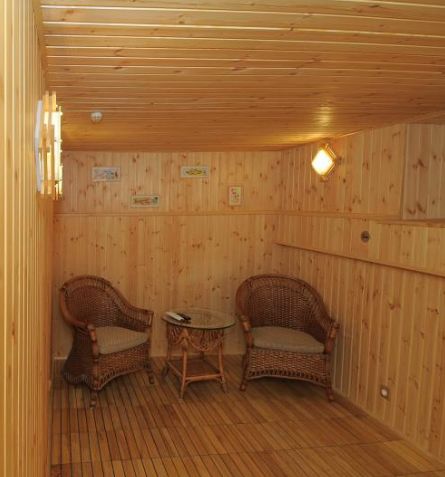

Bathhouse cladding

Before talking about internal processing, I would like to note that for the classical decoration of the premises of both Russian and Finnish baths, natural materials in the form of wood are used. This is due to the fact that this material has high aesthetic values and also fully complies with environmental standards. At the same time, not every tree can be used for cladding a sauna. So, the following types of wood are better suited for this:

- Linden. This tree has a structure that can perfectly withstand high levels of moisture; it does not delaminate when exposed to high temperatures. This wood is also easy to process, it is distinguished by its softness and light color.

- Aspen. This tree is widely popular due to the fact that it is quite easy to process, and its cost is relatively low. This material is excellent for wall cladding in bathhouses; you can also use this material to make wonderful benches and other furniture inside saunas.

- Alder. If we talk about alder, then first of all, it is important to note that it is the most aesthetically pleasing domestic wood species. This wood has a rather bright and expressive texture. That is why, if you want to build not only a functional, but also a beautiful bathhouse, then this material is best suited for you.

Choose the right wood for sauna cladding; not all materials are equally good.

It is important to note that only sheet wood is considered for the construction of saunas. This is due to the fact that it is from these rocks that it is best to build a steam room. Coniferous types of wood tend to release various substances in the form of resins during heating, which can negatively affect your health.

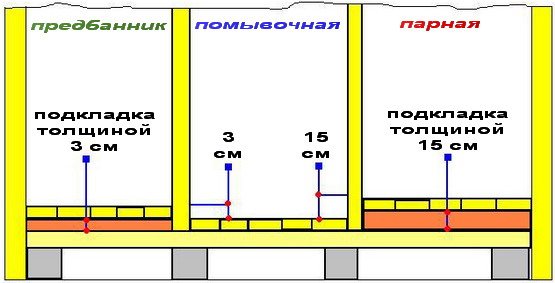

Arrangement of the floor in the dressing room

Dirt floors in this area are the easiest option, but water can turn them into dirt. Regardless of the composition of the soil, such a floor will still allow water to pass through.

As for the clay floor, it practically does not allow water to pass through, or it does, but in small quantities.

Floors at different levels

- Boards laid on such a covering are most often below the water level, which will accumulate during the washing process, and this is not entirely correct in terms of hygiene. Since water after taking water procedures will deteriorate over time, resulting in an unpleasant odor;

Advice! To improve the quality of earthen floors, when arranging them, you will need to step back from the foundation 50 cm, select soil to a depth of 50 cm and fill the hole that is formed as a result with gravel or sand. Then put boards on top of this. In this case, the water in this room will not linger, but will flow into this hole and then enter the ground, which will eliminate the possibility of the spread of an unpleasant odor.

- When arranging the covering in the dressing room, it is best to divert the water as far as possible outside the bathhouse, then the floors in this room can be made concrete by laying tiles on them, and removable wooden gratings on top of them. You can easily dry this design during its operation. To do this, you just need to take it outside to ventilate;

These floorings are easy to dry

- Sometimes it is possible to lay the boards directly on gravel or sand, but it is best to make the floors in the dressing room on logs that will be raised from the sand or gravel by 10 cm. In this case, the logs will be placed on concrete or brick pillars or simply on large stones;

Advice! The boards on the floor should be laid with the convex side up with a small gap of no more than 1 cm. They will need to be secured with nails. Boards should not be laid close to each other, as they may swell and swell when wet.

Floor joists

- It will be very good if you impregnate the gutter and joists with any type of agent that prevents the process of rotting;

- The rough covering in the dressing room does not have to be made of wood, but it is imperative that it be waterproof;

- When installing floors in this room, you should not use linoleum, as this material has a specific odor.

Before covering and before painting the floors in the bathhouse and dressing room, you will need to decide on the material that you will use to finish the floors. The heat capacity of this material for finishing flooring will no longer be of particular importance. Since the temperature at floor level will rarely rise higher than 300 C.

After installing the logs, you can lay the boards

For the same reason, the quality of the thermal insulation material will not affect the performance properties of your building. But if the bathhouse has several floors, the reliability of thermal insulation in this case will be of great importance.

When arranging the flooring in the dressing room, you should also take care of its insulation. We will tell you below how to properly insulate a dressing room.

Insulation

Speaking about how to insulate a dressing room, it is worth saying that this process is quite labor-intensive and multifaceted. Its implementation begins from the construction of the foundation and ends with the interior decoration of the room.

Dry and warm in the dressing room

As a rule, foil-coated polyethylene is used as bath insulation in this case, but it is also possible to use liquid nails. You can also use a special type of material to insulate the dressing room, which is called “dressing room insulation.” Thanks to the use of such material, you will significantly increase the temperature in this room, making it more comfortable.

We insulate the floor

Also, do not forget that the insulation for the bath should not interfere with the free circulation of air in the dressing room. This is necessary both to allow fresh air to enter the room and to prevent condensation from accumulating in it.

Working with walls

Advice! When building a bathhouse with your own hands, special attention should be paid to ventilation. Because thanks to it, the level of humidity in this building is reduced and the wooden parts of the bathhouse are fully cooled, thereby minimizing the risk of fire.

Construction of the floor in the dressing room

As you already understood, when arranging the flooring in the dressing room, the main thing is to choose the right material, since this room will always be exposed to moisture during operation. Water will constantly drip onto the floor, which will then seep into holes and cracks in the floor.

Floors should be thoroughly treated

The selection criteria are:

- When choosing material for the floor in the dressing room, the last thing you should look at is its price. It is important to ensure that the floors in this room are warm and of high quality. Judge for yourself, coming out of the steam room hot, will you like stepping on a cold base;

- You need to select materials for the floor that will not cool quickly enough and that at the same time will heat up quickly.

Ready-made finishing option

The best option is to use wood, but in this case it is advisable to use some additional coating. As you can see, building floors in a dressing room is not such a difficult task, so you can do all the necessary work yourself; the instructions in the article will help you do everything correctly.

Protecting the steam room finish

So, when we have figured out what materials we need to use inside the bathhouse, it is important to understand how they can be protected. As mentioned earlier, wood tends to wear out and be subject to various damages during use, and especially in a steam room. This is due to the fact that extreme temperature conditions are created for the tree in the steam room, which negatively affect its condition.

It is important to note that using simple wood varnishes in a steam room is strictly prohibited. This is due to the fact that such varnishes are not designed to withstand high temperatures, and also have a rather unpleasant aroma. Such varnishes emit many toxic substances that are harmful to human health.

It should be noted that we can divide all varnishes that are presented on the domestic market into:

- varnish designed to protect the ceilings of baths and saunas;

- a varnish designed to protect walls and treat floors, benches and other elements that have direct contact with your body.

Varnishes can also be divided into:

- Imported copies, which are presented in the form of such companies as: Teknos, Akzo Nobel (Dulux trademark), Tikkurila, Belinka and others.

- Domestic specimens, which are presented in the form of “Rogneda”, “Senezh” and others.

Use only special varnishes for saunas and baths

Faktura / Texture varnish for baths and saunas, heat-resistant with silver ions and natural wax

Water-borne acrylic varnish FAKTURA™ for baths and saunas protects the wooden surfaces of walls, ceilings, partitions, doors (except floors and shelves) of baths, saunas, steam rooms, and washing rooms from moderate and high humidity and high temperatures (up to +120°C). Without smell. Quick drying. Colorless. Prevents wood from darkening.

- Natural wax effectively prevents the penetration of moisture, microorganisms, sedimentation and accumulation of dirt, forms a water-repellent coating, and inhibits cracking of wood.

- Fungicide ROCIMA (Switzerland) protects wood from blue staining, mold, fungi and other biological damage; does not separate from the coating even at high temperatures.

- The varnish does not contain lead, cadmium, or arsenic that are harmful to humans.

- Silver (Ag+) – a natural antiseptic friendly to the human body – ensures a healthy microclimate in the house, because Silver ions suppress the development of pathogens.

Frost resistance:

withstands 5 cycles of short-term freezing/thawing down to -30°C during transportation. Thaw without additional heating.

Precautionary measures:

transport and store in tightly closed containers away from heating devices at temperatures from +5ºС to +30ºС. Protect from moisture and direct sunlight. Keep out of the reach of children. Carry out painting work in a well-ventilated area. Use personal protective equipment for the respiratory system, eyes, and skin. Use rubber gloves to protect your hands. In case of contact with skin or eyes, rinse with water. After finishing work, ventilate the room. Dispose of empty containers as household waste.

Fire and explosion proof.

Guarantee period:

24 months from the date of manufacture without opening the container.

Compound:

heat-resistant acrylic dispersion, high-temperature microwax, functional additives, water.

Application

Thoroughly clean the new surface from dirt, dust, grease and other contaminants, completely remove any coating with solvent-based varnishes/impregnations. Clean the surface previously painted with water-based varnishes with sandpaper to a matte state or sand it off, remove dust. The surface to be painted must be dry (wood moisture content no more than 20%), clean, durable. Before use, mix the varnish thoroughly; diluting is not recommended.

Apply with a special brush, paint sprayer or roller for water-based varnishes in a thin, uniform layer in the direction of the wood pile with calm movements in 2 or more layers. During painting work, stir the varnish periodically. To obtain an ideal result, after the first layer of varnish has dried, lightly sand the surface with fine-grained sandpaper and remove dust. Apply at temperatures above +5°C and air humidity no more than 80%.

In the steam room, apply varnish in 1 layer without dilution and use only colorless. In other rooms, apply in 2 or more layers; if necessary, apply the first layer with varnish diluted 10% with water.

Means for treating walls and ceilings

In order to choose the right protective agent for baths and saunas, you should first of all understand the composition of the varnish. It's actually quite simple; to do this, you should read the instructions from each manufacturer. First of all, varnishes with an acrylic base are suitable for this.

For example, when using the water-borne antiseptic “Sauna” (“Senezh”), which has an acrylic base, a transparent heat-resistant polymer coating appears on the wood. This product can protect the surface from dirt and water. Plus, it has the ability to pass air through itself, which is an important fact in this matter.

This coating can not only protect the tree from biological damage, but also has an antimicrobial effect. This product is capable of destroying pathogenic household microorganisms that cause various diseases in people.

If you decide to build a sauna or bathhouse that will last forever, then Sauna will come to your aid. This water-borne acrylic-based product has an excellent protective effect and also has high decorative properties.

Natura (Teknos) on an acrylic base. Initially it acted as a colorless composition that does not change the color of the wood. Using the Teknomix system, you can easily tint a tree in any shade.

If you want to give your steam room an unusual, spectacular shine, you can achieve it using an acrylic-based composition Supi Arctic (Tikkurila). It should be noted that in addition to shine, you will get wonderful dirt- and water-repellent properties.

Supi Arctic varnish (Tikkurila) will transform your steam room with an unusual shine