Making a boiler for a bath from a pipe can be done quite easily if the craftsman has the skills to work with plumbing tools and metal. In addition, you will need to have a certain list of working tools in your home workshop.

If you do not have enough funds for the construction and finishing of a bathhouse complex and the purchase of an automatically functioning heating system, then a boiler for a bathhouse complex can be made with your own hands from a piece of pipe of the appropriate diameter and size. This approach makes it possible to save a lot of money when equipping a bath complex. In addition to a pipe of the appropriate diameter and length, a boiler for a bath complex can be made using a metal barrel or metal sheets. Such a boiler does not have an automatic control system, but it provides effective heating of the premises.

The heating devices of the bath complex are its heart. The degree of comfort during the operation of the bath depends on the quality of their functioning.

Nowadays, installing a heating device with a heating system in a bathhouse complex has become very popular. Installing a boiler for heating and a heating system in a bathhouse is labor-intensive and very responsible work. The installed boiler performs the same functions as a sauna stove. It does:

- heating a certain volume of water;

- heating of the bath room;

- heating stones to generate steam in a steam room.

Homemade heating units that perform the full range of functions assigned to them have become very popular in recent years.

Classification

You can find a huge number of different models of boilers for baths, which can be divided into separate groups according to different factors.

By fuel type

Kinds:

- Gas. Compact designs that consume little fuel. To connect the equipment, you need access to the central gas supply system.

- Solid fuel. Popular models of stove equipment that use different types of firewood. The surface of the boilers heats up quickly and releases heat for a long time.

- Boilers running on liquid fuel. To operate them, you can use waste oil, kerosene, and diesel fuel. When burning, liquid fuel emits an unpleasant odor. Therefore, boilers must be installed in separate rooms.

- Electrical. Equipment that does not pollute the environment. There is no need to assemble the chimney during installation. Electric boilers are connected to 220 or 380 V.

Pyrolysis boilers can be classified as a separate group. They have the highest efficiency rate. The design has an additional chamber in which the wood gas released after burning wood is burned.

By material

Modern boilers are made of metal, since this material is reliable, durable, and wear-resistant. Some types of alloys are susceptible to rapid rust formation. Therefore, boilers need to be coated with special protective compounds.

By shape and volume

According to their shape, boilers are divided into two groups:

- Cylindrical - you can find seamless units on sale that are made from large diameter pipes. Suitable for installation in small steam rooms.

- Rectangular - such boilers are easier to find on sale. If you make equipment of this shape yourself, you need to learn how to work with a welding machine.

The volume of the boiler depends on the size of the room that needs to be heated.

Types of boilers

Solid fuel boiler

Depending on the type of fuel used, all known designs of boilers (metal stoves) for baths are currently divided into the following classes:

- gas units;

- electric boilers;

- devices operating on solid fuel;

- pyrolysis boilers;

- boilers running on liquid (diesel) fuel.

Manufacturing a gas boiler, which is the most economical option of all of the above, seems possible only if gas is already supplied to your site.

The peculiarity of such boilers is that during operation they emit almost no odor or burning and do not require the preparation of fuel reserves for the whole year.

The indisputable advantage of electric boilers is the absence of any harmful waste and the ability to do without ventilation systems. Such boilers also remove the worry about having long-term fuel reserves; But with such a choice, one should not forget about the constant increase in the cost of the electricity they consume.

Making a boiler

Solid fuel boilers are capable of maintaining both the combustion process itself and the required heating temperature for a long time. But, unlike their gas and electric counterparts, they cannot operate continuously and require regular loading of new batches of fuel.

Pyrolysis and liquid fuel boilers are made, as a rule, according to complex technological schemes and can hardly be implemented under ordinary domestic conditions. Only the first three of the types of heating structures we have considered are suitable for self-production. We offer for your consideration the most common version of a solid fuel boiler today, powered by conventional wood.

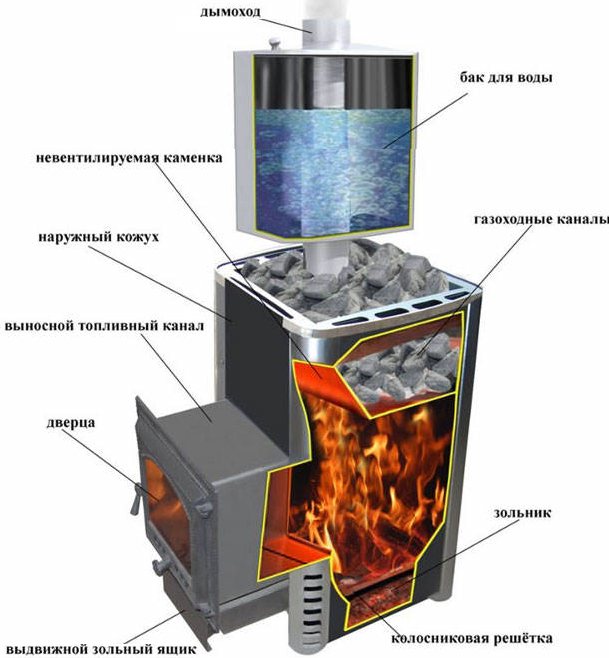

Device

Design elements:

- Kamenka. A container that is filled with stones. To obtain steam, they need to be heated to maximum temperature and doused with water.

- Combustion chamber. Made from thick metal sheets.

- Grate. Separates the combustion chamber from the ash pan.

- Ash box.

- Container for water.

- Blower. Hole for supplying fresh air to the combustion chamber.

- Doors for firebox, ash pan.

Separately, you need to buy a chimney to remove gases remaining from the combustion of fuel from the firebox.

Boiler installation

Protection of walls, ceiling

Installation of the boiler should begin with preparing the foundation; Moreover, the power of the latter will depend on whether you plan to cover the boiler with bricks or not. You will only need such a covering if you are used to steaming in several “passes” and want the heat to stay in the steam room for as long as possible.

The foundation for the boiler is made of refractory bricks, which are laid on a previously prepared site in two rows and then filled with ready-made concrete mixture. The dimensions of the area for the foundation and its distance from the walls of the steam room also depend on whether you are going to cover the boiler with bricks or not.

For safe operation of a metal boiler installed in a steam room, the walls in the area where it is placed must be covered with a layer of fire-resistant material (Izovera, for example). The places where the chimney pipe is laid through the wooden elements of the bath structure must be protected using a special fire-resistant material (asbestos).

DIY making

Anyone can assemble a boiler for a bath with their own hands. To do this, it is enough to prepare a place for its installation, make a drawing of the equipment, collect consumables, tools, and perform the work.

Scheduling and preparation

Before starting work, it is recommended to make a drawing of the future device. On it you need to indicate the dimensions, individual elements, and places of fastening of the boiler parts.

Materials and tools

Consumables:

- metal sheets or large diameter pipe for the body;

- tap for water tank;

- steel pipes for the manufacture of a heat exchanger;

- doors for the firebox, blower;

- fittings for the grate;

- channel, fireclay brick;

- clay mortar;

- pipes for chimney assembly.

Tools:

- drill with drills;

- hammer, pliers;

- welding equipment;

- grinder with metal discs;

- tape measure, building level.

Additionally, you need to prepare protective equipment.

Carrying out work

It is easier to assemble the boiler not from individual metal sheets, but from a large diameter pipe. It needs to be divided into parts:

- The bottom is an ash box. Height - 10 cm.

- The middle one is the combustion chamber. Height - 30–40 cm.

- The top one is a heater. Height - 40 cm.

The water tank must be mounted around the chimney.

Execution of work:

- Fix the fittings inside the pipe along the intended sections to create separate demarcation grids.

- Fix a thick sheet of metal between the combustion chamber and the heater.

- Make a hole on the back side of the combustion chamber on which to secure the initial elbow of the future chimney.

- On the front side, cut three rectangular holes for the ash pan, firebox, and heater.

Basalt slabs must be fixed to the walls surrounding the boiler. Screw stainless steel sheets on top of them. You can make a water tank yourself. To do this you will need several metal sheets. Make a hole in the bottom of the container to attach the tap. In the upper part - for filling with water.

Design

Diagram of a boiler for a bath First, you should stock up on all the equipment and tools necessary to assemble such a boiler.

The tools you will need are a welding machine and a grinder, and as the initial workpiece you can use a metal barrel with a volume of 200 liters (horizontal design). Let's consider this option in more detail.

The entire pipe is divided into three parts, each of which represents a specific functional unit of the furnace, used for its intended purpose. The lowest part of the pipe space and located above it are used for the firebox and stone. They provide the required operating mode of the boiler and create conditions for its normal functioning.

The lowest sections of the pipe (blower, firebox and heater) are equipped with partitions on which special grates are hung - grates, which are freely sold in specialized furnace casting stores. The heater compartment is filled with small oval-shaped stones, the structure of which allows you to “keep” heat for a long time.

In a vertical stove, a compartment serving as a container for hot water is installed directly above the heater. To do this, another partition is mounted directly above it, which is the bottom of this compartment.

The boiler, like any other sauna stove, must necessarily consist of the following structural parts:

- The furnace in which fuel combustion occurs;

- A chimney through which smoke from burnt fuel is removed;

- Ash pan for ash extraction;

- A heater that allows you to redistribute and remove heat;

- Water tank.

You can make a boiler without a heater, in this case the bath will be heated only from the walls of the boiler and the tank, but the steam in such a bath will be heavy, because the heat from the firebox will only be used to heat the water, while it will quickly boil and fill the bath with thick steam .

The boiler firebox is made of thick-walled metal - it carries the greatest thermal load, and thin metal will quickly burn out. The bottom of the firebox must be equipped with a grate through which the ash from the firewood is poured into the ash pan. The thickness of the grate must be at least 5 mm.

An ash pan is a space under the firebox, the purpose of which is to collect ash and conveniently remove it. Through the ash pan door, air is drawn into the firebox, causing fuel to burn.

The chimney is part of the combustion system. It must be equipped with a valve or gate, the degree of opening of which can be adjusted to the draft. The chimney passes through the tank or heater, heats it and ends in a chimney.

A heater is a built-in or mounted container in a boiler in which special stones for a bath are placed. The volume of the heater depends on the size of the boiler and the sauna itself: a heater that is too small will not be able to warm up the room, and a heater that is too large will require prolonged heating of the stones, during which time the water in the tank will boil and the sauna will be filled with water vapor, making it hot and uncomfortable. Therefore, you should adhere to the rule: the volumes of the heater, water tank and firebox should not differ much.

Heater sample

1 – lining with refractory bricks; 2 – steel barrel; 3 – metal pipe; 4 – water tank; 6 – partition between the heater and the firebox made of channel or reinforcement; 7 – combustion chamber.

Necessary tools, materials

To make a sauna boiler you will need the following tool:

- Welding machine;

- Grinder with cutting wheel.

In addition to sheet metal or barrels, you will also need:

- trimmings of reinforcement and channel for the manufacture of internal through partitions;

- sheet of thick-walled (minimum 5 mm) metal for the grate;

- pipe with a diameter of about 100 mm;

- metal hinges for the door;

- tank tap.

To create a screen that allows for better heat distribution throughout the steam room, fire-resistant bricks are used. It is laid out on the outer side of the walls closely or at some distance, or the inner walls of the firebox are lined with it.

Boiler for sauna from a barrel

The simplest design that allows you to make a boiler from scrap materials. Such a boiler is made from a metal barrel with a wall thickness of at least 3 mm - thinner walls will quickly burn out.

- The bottom of the barrel is cut out and instead, a bottom made of metal with a thickness of at least 5 mm is installed with legs welded to it from scraps of a channel or I-beam.

- At a distance of 3-5 cm from the bottom, use a grinder to cut out a window measuring 15x10 cm - this will be the door of the ash pan and ash pit. The door itself is made from a sawn piece of metal. Weld hinges and a latch handle to the door. Fasten the door in place.

- Above the ash pit, 5-7 cm, a grate is welded into the barrel - a sheet of metal cut to the shape of a barrel, with holes for air intake and ash discharge. The holes are usually made longitudinal, in the center, 1/2 the diameter of the grate. You can simply weld a row of thick reinforcement rods inside the grate.

- 5-10 cm above the grate, by analogy with the ash door, cut out the firebox door, measuring at least 25x40 cm, otherwise it will be inconvenient to put firewood into it. They also weld the latch handle and hinges, and put the door in place. The walls of the firebox are lined with refractory bricks.

- A heater is located above the firebox, and the height of the firebox is selected as 1/3 of the height of the barrel minus the ash pan. The partition between the firebox and the heater is not solid; it is made from channel scraps, and the holes between them should not exceed the size of the stones. The height of the heater is approximately equal to the height of the firebox. In the middle part of the heater it is necessary to make a window with a door - through it stones are placed inside the boiler, and water is added into it when steaming.

- The top of the barrel acts as a water tank. The partition between the heater and the tank must be solid, the seams are well welded, and in the center of the partition there is a hole with a diameter of about 100 mm, to which a piece of pipe is welded with a height twice as large as the height of the water tank. The water in such a tank is heated due to hot smoke passing through the pipe, as well as thermal radiation from the stones in the heater.

- The upper part of the tank is made in the form of a lid through which water is poured. You can just make a hole, but then the tank will be inconvenient to wash. A piece of half-inch pipe is welded into the lower part of the tank, and a tap is attached to it using a thread.

We suggest you familiarize yourself with Bathhouse on stilts, how to drain water

The resulting boiler is cleaned of scale and rust and, if desired, coated with heat-resistant polymer paint - it is sold in stores that sell sauna stoves.

Sample of a finished boiler

Despite the fact that the boiler, unlike the furnace, has a completely different device, these units are intended for heating the room. The main feature of these products is the construction of the heater. It is attached to the side of the boiler and heats up on its own, heating up the stones in the steam room. Of course, the body can be made without a heater, but then the room will warm up due to the heating of the structure itself.

It is the firebox that receives the maximum temperature load. Therefore, it must be made of thick sheets of metal. A grate is installed at the bottom of the combustion chamber through which burnt particles will fall out. They end up in the ash pan, which is designed to collect fallen ash. In addition, this compartment, located below the firebox, is needed for air intake. It is thanks to oxygen entering the firebox that the fuel begins to burn.

Another element of the boiler is the chimney. It must be equipped with a valve that will regulate the exhaust of smoke. But the heater can be made either mounted or built-in. It all depends on your desires and skill.

Boiler for a bath: reasons for construction

Today, a wide variety of solid fuel boilers are on sale. You can, of course, put a brick oven in the bathhouse. But remember, this is a rather complicated process, especially without the experience of a mason.

And the price of such construction will be much higher than the cost of a boiler for a steam room, since it entails the cost of purchasing clay and brick, as well as a thorough study of production technology. The result is considerable additional costs.

Note! What to choose is up to you as the owner. The main thing to remember is that for a small-sized steam room somewhere in the country, a boiler is quite suitable; it can be made from simple improvised means. In addition, such installation of a boiler in a bathhouse will be cheap.

Plus, it’s fun to make it yourself. Construction is, of course, a responsible and important process, so you shouldn’t be afraid of difficulties, you need to get to work with readiness.

Types of boilers by fuel type

When preparing for the manufacture of the unit, you need to proceed not only from the available material, but also take into account what exactly will be used for heating. You can make boilers for the bathhouse that operate using gas. Other options are diesel or solid fuel (wood, coal).

Homemade boilers can be like this

| Types | Characteristics |

| Gas. | This type of equipment does not emit fumes, is odorless and is quite simple and easy to use. |

| Electrical. | The boilers are environmentally friendly and do not require ventilation or periodic addition of fuel. But they are quite expensive financially. |

| Running on liquid fuel - diesel. | In terms of convenience, they are considered second only to gas units. But the disadvantage of this design will be the storage of fuel, which deteriorates over time, losing its physical properties. |

| Solid fuel. | These wood-burning units are environmentally friendly; they make it possible to maintain the desired temperature in the room for a long time due to the relatively slow combustion of wood. |

Nowadays you can find combined types of boilers on the market, but they are not particularly popular. In application, the best performance is achieved by units configured for one type of fuel. And if you choose among the existing options, then gas or solid fuel equipment will be optimal.

https://www.youtube.com/watch?v=9iO1yuYXCu8

The simplest and most inexpensive option for a heating unit is a pipe bath boiler. This cylindrical shape can be installed in two ways - vertically and horizontally. If we consider the first option, then to make it you will need to close the pipe on one side and install a door on the other.

The vertical boiler design also provides for a plug on one (lower) side of the pipe. A hole with a door is made at the bottom, which will become a firebox. The heater can be made in the same way as in the previous version, by welding a sheet of metal on the side. At the top of the product there will be a water tank, which is obtained by creating another plug in the middle of the pipe.

We invite you to familiarize yourself with Fireproof materials for walls around furnaces

From sheets of metal

First you need to create a drawing with exact calculations of each boiler compartment. Then, based on the calculations, the required sheet sizes are cut out and joined by welding. You should have a solid structure with several holes for the firebox and chimney installation. The next step is to join the remaining prepared sheets of metal to create a water tank. After this, we install the door for the firebox and a small pipe for connecting the water.

Having installed such a boiler in a steam room, you can line it with bricks. This will give a more aesthetic appearance to the heating structure. The brick box must have ventilation holes.