Types of stairs

The division of stairs into types occurs according to several positions: material of manufacture, design, purpose, location (internal, external).

Metal, wood and reinforced concrete mixtures are used as materials for the manufacture of staircase structures

Most often these materials are combined.

By design there are:

- attached - the simplest and most common structural type. It consists of two parallel supports, to which steps are welded at an angle of 900. They can be both stationary and portable, for example, a stepladder;

- marching - have a more complex design, which involves installing steps on beams installed at a certain angle. Bowstrings or stringers can serve as supporting elements. The owners of a private house can do these things with their own hands;

- screw - The steps are attached on one side to the support beam, and the other side is protected by railings. The steps are made in the shape of a triangle or sector. It is quite difficult to make such a structure yourself;

- bolted stairs - in this case, the steps are attached directly to the wall using special strong bolts (bolts). The other side is connected by railings. A prerequisite for this type of stairs is a strong wall that can withstand the load.

Advantages and disadvantages of stairs made of profile pipes

A DIY staircase made from a profile pipe has a lot of advantages compared to structures

from other materials:

- high strength, which is ensured by a profile pipe;

- long service life, one might even say that this is a staircase that will last for centuries;

- the frame manufacturing process has already been worked out to the smallest detail, so it will not take much time;

- the use of different fasteners, any design ideas can be realized;

- relatively cheap building materials for the frame.

Along with the advantages, there are also some “disadvantages” of stairs made of profile pipes, which must be taken into account before starting work.

Thus, a metal frame is a fairly heavy structure, so for auxiliary elements you need to use lighter materials, such as plastic or glass.

But this nuance allows you to give them a more aesthetic appearance.

The second point: the use of a metal profile implies that all connections must be welded, therefore, the master must be able to use a welding machine.

Stages of manufacturing stairs from profile pipes

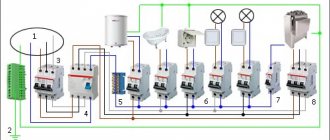

The most commonly used option for making stairs is a frame made of a profile pipe, and the steps are made of wood. For the base, take a pipe with a diameter of about 60 cm and a corner 40x40 cm.

Using this design as an example, we will consider the main stages of work:

- At the first stage, a calculation and drawing of the future structure is made, the number of steps is determined and the length of the stringer is calculated. The most optimal dimensions: staircase width within 80-120 cm, step height – no higher than 20 cm and no less than 12 cm, depth – 30 cm.

- Next, the pipes are marked and cut, and frames for the steps are made.

- It is necessary to concrete the platform, which will serve as the base of the entire structure, and also maintain the angle of inclination. This level is considered to be zero - the first stage will be located on it.

- The profile pipe is installed, secured by welding to the fillers in the concrete platform on one side, and on the other to the anchors that are built into the wall.

- Angles are welded to the metal pipe, the dimensions of which are determined at the initial stage. It should be noted that all dimensions, even if a household stepladder is made, must be observed exactly.

- When the frame is assembled, the railings are welded to it (if they are metal) or secured in another way if wood or other material is used.

How to make a staircase from a profile pipe with your own hands? (video)

Design features

In the process of manufacturing a staircase from a profile pipe, there are nuances, knowledge of which greatly simplifies the work. So, if the railing is installed on the side of the staircase frame, then it is possible to increase the width of the span.

When constructing a staircase, it should be taken into account that during operation the structure may require routine repairs. For this purpose, a gap is left between the wall and the supporting structure.

To prevent vibrations of the staircase when moving along it, the length of the racks in the spans is limited.

A completely metal staircase made of a profile pipe is not very attractive, so auxiliary materials such as glass, durable plastic or sanded wood are often used. This not only facilitates the design, but also makes the appearance of the staircase more beautiful.

Stepladder

In a farmstead, an attached stepladder is an indispensable thing that is useful for performing any work at height.

You can make it yourself. There are stepladders of single-sided or double-sided types. Structurally, a stepladder looks like this - two parallel steps and steps attached to them.

Calculation of the height of a stepladder is done in the process of determining the interval between the base, that is, the floor, and the last step. The optimal interval between them is 20-25 cm.

According to their functional features, there are three types of stepladders: classic, universal or transformable.

The frame of universal stepladders can be folding or telescopic, in which the sections are pulled out gradually, as needed. The sections are secured with latches or hooks.

The folding stepladder works in several positions, and is also compact and lightweight when assembled, which greatly simplifies transportation.

In non-separable stepladders, connections are made by welding,

and transforming structures are joined using bolts. This connection method allows you to quickly dismantle the damaged element and replace it.

Made with your own hands, it has a number of advantages, such as lightness, practicality and ease of use, and a high degree of reliability.

A DIY pool ladder depends on the volume, bowl design and your capabilities.

You can install a pool ladder with your own hands, or for permanent ones. What is the best material to make a staircase from? Let's consider each option separately, their pros and cons.

ADVICE!

The most suitable place to install a ladder is the most illuminated one. A bright place makes it possible to easily climb and descend slippery steps.

It is possible to make a pool ladder from various materials:

- stone,

- concrete,

- wooden,

- metal,

- plastic.

Types of stairs for the pool

The main criterion to be followed when choosing is physical comfort and safety. As a rule, in a family there are people of different ages and physical abilities: children, young men and women, middle-aged, elderly. Focus on the weakest! Or install several different ladders around the perimeter of the bowl.

When choosing a ladder or stepladder for a pool, follow the rules of safety and comfort!

Manufacturers offer many different configurations. For example, there are stairs with easier descent: a large angle of inclination requires less effort when descending and ascending. It is also recommended to choose a distance between steps of at least 25 cm. Please do not forget about handrails and anti-slip devices.

Let's consider these nuances in detail.

Stationary pool

You can build a Roman staircase or install a one-sided metal one, securing it to the side.

The Roman staircase for the pool consists of gentle steps. The shape of the steps is very different - round, rectangular, figured. The standard angle of inclination is no more than 30-45®, which allows you to make the descent as flat as possible. Any color and finishing style, the design looks very aesthetically pleasing, it’s comfortable to stand on and get down.

When building a Roman staircase, take into account the angle of inclination and dimensions of the pool

The Roman staircase is part of a bowl, therefore, it can be plastic, concrete or consist of different materials. If the size of the pool allows, the Roman stairs are made very wide, thus creating “shallow” places for relaxation.

Frame pool

The most convenient are double-sided stairs for a swimming pool: with this design you can climb up and down from both sides. When purchasing a prefabricated pool, it is advisable to immediately take care of a suitable ladder. The assortment includes factory Chinese designs and components for swimming pools of the same brands.

A double-sided stepladder for a frame inflatable pool must be safe for children

Inflatable pool

It’s easy to get by with a little money by adapting a small aluminum stepladder for an inflatable pool with high sides. Since rubber pools are often purchased for children, it is worth paying attention to the width of the steps and the anti-slip coating. Thus, fixed dielectric mats will serve faithfully, protecting children from falling.

The ladder for an inflatable pool has assembly features: it can be installed when the pool is already inflated and completely ready for use. Manufacturers offer a large selection of ready-made structures: with adjustable height, from different materials, with removable steps, railings, etc.

Advice from Chistyuli . Planning to cover your pool at night? Buy a removable ladder. In the evening you can easily remove it to cover the pool. And in the morning you will install it again.

Stone staircase

It is stationary and is usually laid on the outside of the pool bowl; the stone staircase looks very beautiful and will decorate any pool. But if you build a stone staircase inside the bowl, then over time the steps of the pool will become covered with plaque, will slide and pose a danger to vacationers.

ADVICE!

To ensure safety, handrails made of stainless steel or aluminum must be installed on the sides, and the steps themselves are finished with slabs with anti-slip notches.

Concrete staircase

Since it is covered with finishing materials suitable for finishing steps. It has an anti-slip surface, a wide step projection and can serve not only as a descent, but also as a place to rest. The downside is that concrete construction often takes up a lot of space and is not suitable for small pools.

ADVICE!

Approximate proportions for concrete mixture: proportions of M20 concrete 1×2.8×4.8 (cement, sand, crushed stone.). Water is added based on the specific situation.

Wooden staircase

Just like stone, it is often built for the protruding sides of the pool from the outside. But there are exceptions, if the wood is coated with a special varnish for floating ships. In this case, the tree can withstand constant exposure to water and not rot. Unlike stone, wooden is portable and can be removed at inconvenient times.

ADVICE!

To reduce the impact of water on wood, it is best to treat the structure with special impregnations that prevent rotting, or with water-repellent paint.

Various designs

Each type of pool requires a special approach, so there is no universal option that would be suitable for a frame and a regular stationary one. Below we will consider the designs that are most often used.

For inflatable or frame pool

A frame or inflatable pool is purchased due to its mobility and the ability to be stored in a garage or storage room in winter. This means that the ladder that will be used with it must be transportable. Usually it looks like a stepladder; these pool stairs are double-sided. The height will depend on the height of the pool side. Differences between models may lie in the number of steps, as well as in the step between them. If there are children in the family, then it is necessary to take care of more steps with smaller steps.

The price of stairs for frame and inflatable pools also depends on the material used. Most often, a metal frame with plastic steps is used. The front side of each step is covered with a rough pattern or a special rubber pad. This increases safety because it prevents your foot from slipping. It is better to opt for a product with railings. Where there is water, it is always slippery, so it is better to protect yourself and your family. It is easier to store a staircase in which the steps can be dismantled and placed separately from the frame. For older people, it will be easier to enter the pool using stairs that have a platform, since you won’t have to lift your leg high.

Note! It is better to buy a ladder with a frame made of aluminum or stainless steel. These metals are highly resistant to corrosion, so you can leave the ladder in the pool without fear that it will rust.

Stationary option

In stationary pools that are located in a recess, the use of ladders in the form of stepladders is impossible, so other solutions are used. For some pools, the fastening is made directly to the wall; in others, the handles are made in the shape of an arc and they serve as a lock or simply grip the top edge. It doesn't have to reach the bottom. It should be comfortable to swim up to such a ladder and rest your feet on it. The pitch of the steps is selected depending on specific needs. The material for the manufacture of such stairs is stainless steel. It perfectly withstands even significant human weight, and also does not fail from exposure to water and chemicals that are used to clean the pool.

Note! If the pool will be used by elderly family members, then it is worth considering installing an inclined ladder that will rest at the very bottom. It will require additional space, so its installation should be considered during design.

Some pool owners prefer a monolithic ladder. In appearance, it resembles a regular staircase that is used in buildings. It is very easy to handle, but the laid tiles can be quite slippery, making it easy to get injured. To prevent this from happening, stainless steel railings are installed, and anti-slip rubber mats or tiles with a special surface are laid on the steps. This option should also be included in the project, since it can radically change the shape of the finished pool.

Metal staircase

For both large and small pools. Installation of a ladder into a pool can be attached to the bowl, or it can be mounted. They are made of alloy and black steel and have anti-corrosion properties. This staircase is easy to maintain and affordable.

IMPORTANT!

During operation, low-quality metal will begin to rust. Before purchasing, you need to familiarize yourself with its composition. The more nickel it contains, the more reliable and durable the metal.

How to choose?

When choosing a ladder for a pool, pay attention to several factors: price, appearance and technical characteristics. The latter must be studied especially carefully from the point of view of structural safety.

You can usually find stainless steel pool ladders on sale. They are distinguished by their aesthetic appearance, lightness and ease of installation. A stainless steel pool ladder is suitable for stationary in-ground reservoirs. This is due to the fact that this design is very resistant to corrosion, can withstand heavy loads and is characterized by a long service life.

Criteria for choosing a ladder to a stainless steel pool:

- The structure must have reliable fixing fasteners with rubberized elements.

- It will be better if the steps are equipped with rubber pads or have a corrugated surface.

- If the ladder will be used in a children's pool, preference should be given to models with wide treads, often located. The railings should also be low enough.

- In cases with inflatable structures, you can use double-sided ladders for pools of the “stepladder” type. They are not fixed to the sides. When purchasing, you need to consider the height of the bowl. The height of the support post of the stepladder should not be more than 15 cm higher than the sides of the pool.

- If the water in the pool contains chlorine or salt compounds, give preference to models that have improved anti-corrosion properties. This will save the structure from rust and help maintain the aesthetic appearance of the pool.

Types of staircase structures

- Roman ones are divided into stationary and attached.

Stationary ladders are laid immediately when the pool bowl is filled. They may have different appearances, but the size according to GOST must be observed. Namely, the angle of inclination should not exceed 30-45 degrees. Or the stairs will be too steep and dangerous. And the width of the steps for the stairs to the pool should be the length of an adult’s foot or wider. If this is a design for a children's pool, then ideally the width should correspond to the size of the child's foot. Add-on Roman steps are ready-made steps with or without railings, which are easily and simply installed in the pool bowl.

The Roman staircase is the best option for a permanent pool without sides. Its steps are often round, and the descent into the water is smooth and pleasant. You can also use a metal staircase that has steps on only one side. It is attached to the board.

- Metal attachments have a wide selection on the market.

They present all kinds of designs with a pair or several steps, depending on the depth of the pool. They have various types of attachment to the sides, wall and floor of the bowl. For flanges and embedded parts. A more reliable option is to install a chrome ladder while finishing the pool.

- Ladders stepladders

They can be plastic and metal, stationary and portable. Naturally, the advantage of a stationary metal staircase is obvious. But it is desirable that it be an indoor pool, since despite the anti-corrosion weather conditions, over time the stairs will become unusable. As for plastic, this is a lightweight prefabricated structure made of plastic pipes; you can easily assemble it with your own hands for the duration of the use of the frame pool. These stairs are double-sided, which is another advantage.

Design characteristics

Stairs for swimming pools are available in a wide range today, and choosing the best option is not difficult. Of course, if you know what requirements the design must meet. First of all, you should choose a ladder based on the shape and dimensions of the pool itself, and only then look at the appearance and cost.

The most popular are stainless steel stairs equipped with handrails and rubber pads on the steps. They are reliable, durable and look neat in any pool.

Types of stairs

There are many types of stairs, but their shape is determined by the design of the pool itself. So, in a small children's pool it would be unwise to install a spiral staircase or an option with high narrow steps. In this case, a model with wide treads or even a slide for a fun descent into the water would be more suitable.

All designs can be divided into:

- Stationary or Roman - often such stairs are made of the same material as the pool bowl. They are strong, durable, easy to use and safe. Children can play or adults can relax on the wide steps or flight.

- Attached - these stairs are made of stainless steel. They have a lightweight design and take up minimal space. They are easy to carry and, if necessary, install in another place. In addition to the fact that pool ladders are relatively inexpensive, they are durable and beautiful, and can highlight the advantages of the design of a pond or give it your own style. Stainless steel structures can be three-, four- and five-stage. The first is used for pools with a depth of up to 140 cm, the second - for reservoirs with a depth of 140 cm to 180 cm, and the last option - for depths greater than 180 cm.

If the family has small children, an excellent solution would be to install a plastic ladder with a slide for the pool.

How to choose a staircase

When choosing the type of structure and the material from which it is made, you should focus on the installation method. To fasten the stairs, anchors are used (installed at the base of the pool during construction) or special glasses installed after finishing the bowl. It is very important that there are rubber gaskets between the metal parts of the ladder and the surface of the pool. They will protect the metal from corrosion and maintain the integrity of the coating of the reservoir.

Useful tips for choosing a ladder depending on the shape of the pool:

- For non-recessed models, it is better to choose a stepladder, which is used to first climb on board and then descend into the water. As a rule, such products are made of metal pipes, and the steps can be made of polyurethane, stainless steel or other materials. In terms of execution, such models are very simple and can be made with your own hands.

- For pools with recessed bowls, experts advise installing closed Roman staircases with rounded steps and a smooth descent. They can be stationary or attached. Stationary ones are mounted and finished simultaneously with the inner surface of the bowl, using the same building materials and coatings. The advantage of this solution is that you can resort to decorative finishing and make your pool unique, for example, by decorating the stairs and bottom with mosaics, glowing stones or decorative paintings. However, such convenient and large stairs are only suitable for wide swimming pools, as they take up a lot of space. The attached Roman staircase is installed after finishing the bowl. It is a pyramidal structure, which is attached to the sides with special handles. On sale you can find suitable models for all types of pools, even small oval or round ones. Such stairs are installed to a depth of 0.5 m to 1.5 m, but if desired, you can order the production of a version with original parameters.

- A ladder for a frame pool looks like an ordinary stepladder or in combination with an inflatable slide. The stepladder is supported on one side on the ground, and the other on the bottom of the pool. Among all manufacturers of such structures, Intex pool stairs are especially popular.

If you want to make your descent into the pool not only beautiful, comfortable and safe, but also useful, pay attention to balneological stairs. The treads of such models are equipped with special massage jets that stimulate blood circulation in the feet and relax the skin of the legs.

What to look for when choosing a staircase:

- Steps must have a textured or matte surface or rubberized anti-slip pads.

- The dimensions of the ladder must correspond to the depth of the bowl.

- The cost, unfortunately, does not always correspond to the quality, so you should not immediately buy the most expensive model. In some cases, it is better to build the structure yourself.

- If small children will swim in the pool, choose stairs with a small step step so that the child feels comfortable and does not trip.

Making steps from wood

A DIY wooden pool ladder is a stepladder. It is made of beams with a section size of 60 by 40 and strong boards made of durable wood for steps and an upper platform for convenient descent into the water. The main task of such a ladder is stability and mobility. The steps are fixed into the grooves of the beams and secured with metal rods for reliability. The wooden staircase is sanded well so that the wood becomes smooth and covered with stain and varnish. To minimize the impact of water on the material, it is advisable to lay rubberized mats on the steps.

Installation recommendations

Making a ladder for the pool is half the battle. Next, you will need to select the correct location to install it. The place under the stairs should be well lit so as not to trip in the dark. It is advisable to additionally fix the part of the ladder that is not located in the pool to the ground. To do this, you can use metal pins and make loops on the ladder itself. The legs that are in the pool can pierce the canvas, so it is advisable to stick rubber pads on them. In wooden stairs, all self-tapping screws and nails should be well sunk into the wood and preferably covered with wood putty, as it is easy to cut yourself on them. Below is a video about the installation of the factory version:

Making steps from metal

There are a lot of options for chrome stairs, both in terms of external design and functionality; you can buy a ready-made one. Or you can do it yourself using a welding machine and metal. Select a suitable drawing, measure the parts and weld them to each other. Parts can also be secured with galvanized bolts. Typically, such a ladder looks like a stepladder. The metal is treated with anti-corrosion substances. The steps are covered with anti-slip material. A rubber pad is placed on each leg of the metal ladder to prevent damage to the bowl lining. Such a ladder will be reliable and can withstand heavy loads.

The minimum cost of a ladder for a stainless steel pool is 5,000 rubles.

DIY pool ladder

Before you start building a staircase to a stainless steel pool, you should understand the design features and develop a detailed plan.

The most common staircase consists of a frame, handrail and tread. Closed Roman staircases also have risers and sometimes flights. The width of the tread (the platform on which one steps on) should correspond to the length of an adult’s foot or be slightly less. Vertical stairs for inflatable frame pools should be made slightly higher than the side.

To work you will need the following tools and materials:

- stainless steel pipes or channel;

- stainless steel fittings or sheets 4-5 mm thick;

- welding machine;

- Bulgarian;

- rubber pads for anti-slip effect.

The most important thing when assembling a metal pool ladder with your own hands is to weld the seams correctly. For the simplest design, steps can be made from reinforcing bars. In this case, you won’t even need rubber pads, since the corrugated surface of the reinforcement will prevent slipping. The rods are welded at a small equal distance from each other. For one stage, 3-5 pieces are enough. If you want to make solid steps, use steel sheets, but they will need to be covered with rubber to prevent slipping.

The frame of the staircase will consist of profiles in the form of a channel installed edgewise, and the railing will be made of a 45 mm corner. All connections should be welded and then treated with an anti-corrosion compound.

Progress:

- Develop a drawing of the future staircase and prepare the necessary materials. When calculating the height of a double-sided ladder for a frame-type pool, first measure the distance from the bottom to the top of the side and add 30-40 cm to this.

- Cut the metal profile into pieces of the required length. The optimal width of the stairs for a pool can vary from 50 to 70 cm. In accordance with this parameter, make the length of the steps.

- The strongest and most reliable connections are obtained using a welding machine. But if you don’t have one, or you don’t have the relevant work experience, you can use galvanized bolts as fasteners. Place marks on the base pipe in increments of 35-40 cm for the locations of the steps. Remember that if children will use the stairs, the height of the steps should be lower.

- If you will be bolting the pieces together, first drill holes along the edges of the steps and then at the marked points on the base pipe. For a stronger connection, use galvanized metal corners.

- Attach rubber pads to the surface of the steps.

- After assembling the structure, go over it with a grinder or a file, paying special attention to the connection points of the parts. This way you will remove all sharp burrs that could cause you to cut yourself.

- After cleaning, seal all holes in the stairs to prevent water from getting inside. This can be done using a welding machine or special decorative plugs.

- All that remains is to cover the surface with waterproof and anti-corrosion paint to give the staircase a complete and beautiful appearance. Homemade stairs should be treated with protective paint annually, removing the previous layer using a special solvent.

Conclusion

Whatever ladder you choose, it must be reliable and safe first and foremost. This staircase will be convenient and pleasant to use for many years. Even if it is stationary. By the way, a portable wooden or metal ladder, in winter, can serve as an excellent stand for flowers in the winter garden!

Reading time ≈ 4 minutes

The presence of a stepladder on a household is due to many household tasks. It is necessary for repair work, when replacing light bulbs, as well as for cultivating the garden. It doesn’t matter whether you bought it on the market or made it yourself. Moreover, if you follow professional recommendations, a DIY stepladder will last much longer than any other. Therefore, next we will consider the instructions for assembling it.

Features of a homemade stepladder

Before you make a stepladder with your own hands, you should decide on the material. Many are inclined to choose budget wood, while forgetting about its disadvantages. Due to the hygroscopic nature of the material, after some time it will begin to dry out. The design will be unreliable. In addition, the tree will have to be treated regularly to protect it from insects.

This problem can be solved with the help of metal, blanks of which remain after repairs or are purchased in hardware stores. There is a choice: the stepladder can be made from aluminum or from heavier steel. A garden structure made of aluminum will be characterized by low weight, sufficient strength and lack of tendency to corrosion. The latter also means that no painting is required. In the case of steel, the owner can count on the durability of the stepladder and excellent strength. However, the weight of the product will be quite heavy, and the material will require periodic painting. Because real steel is susceptible to corrosion.

Also, a metal stepladder requires some care during manufacture. If the metal profile was cut poorly, there is some risk of injury. It is advisable to treat sharp areas with something.

Conditions for manufacturing a stepladder from a profile pipe

In order for a metal stepladder made from a profile pipe to last as long as possible, the following conditions must be met:

— Since the stepladder principle involves two folding ladders, their dimensions should not be identical. It is important to mark a slight difference between their widths so that the design does not look flimsy; It is important! The result should be the effect of a dense liner.

— So that the steps of the stairs do not impede its folding, they must be placed closer to the outer edge of the profile; — The placement of steps should not be continuous - the upper part of the stepladder is freed from them. A connecting mechanism should be provided here.

Compliance with these fundamental rules will help make the structure durable.

Preparing to assemble a stepladder yourself

The most popular model is a stepladder made from a profile pipe. To make it, you need to cut 4 strips of two meters in length from a metal profile. The size of the steps is determined independently. You will also need a long bolt with nuts and two eyes for the job. It should be noted here that the design will be much more reliable if a welded connection is used. Since fixing with bolts requires an accurate calculation of the permissible load. Otherwise, the owner will not be insured against sudden deformation of fasteners. Therefore, in the photo you see an example of a welded model.

— Tape measure for taking measurements; — Welding machine with protective mask; — Drill for drilling holes; - Angle.

If you plan to cut the profile strips yourself, you should also get safety glasses. Then it is recommended to clean the sections from sharp protrusions. You can use a drill with a special attachment.

It is important! It is advisable to choose a steel profile with a rectangular rather than circular cross-section.

The same should be done with the strips for the steps. Before starting work, it is advisable to make a sketch drawing.

Sequence of work

After all the parts have been prepared for work, the steps are applied to long strips for marking. Here it is recommended to use a square to maintain a right angle. For now, work will be carried out on two of the 4 available profile sections. The sequence of operations will look like this:

1. After correcting the future connection, you can begin making welds. And the first step is to attach the lower support; 2. When the first step is ready, you can weld the rest sequentially; 3. When the installation of the first part of the stepladder is completed, it will be necessary to drill holes for the threaded bolt in the upper part; 4. Then you should weld the ears, as shown in the corresponding photo; 5. Now the second part of the stepladder is assembled in the same way; 6. After securing the two ladders with bolts, it is necessary to conduct a strength test.

The result should be a reliable design. To protect the metal from corrosion, it should be primed and then painted.

PVC pipes have become used in many construction fields. They are used to make stepladders for household needs, garden ladders, and children's ladders. But is this material suitable for creating a staircase to the second floor? Experts have proven that it will do. Although, a few years ago, only handrails or stair railings were made from plastic pipes.

Plastic itself is a soft and flexible material. But with certain processing and modification, PVC acquires sufficient strength. For example, pipes with a round cross-section made of plastic can easily support the average weight of a person.

This material is convenient because it does not require additional decor, like wood, metal or plywood. It doesn't need to be painted. It is enough to remove dust and dirt. In addition, plastic is not expensive in price. Which is also not unimportant for users.

Do-it-yourself wooden ladder for a pool

For frame pools installed on personal plots, it is quite possible to use stairs made of plastic or metal.

However, wood is the most flexible material in terms of processing. Such a staircase will be reliable, comfortable, environmentally friendly and pleasant to the touch.

Before starting work, take all necessary measurements. Determine the height of the pool bowl, the number and parameters of steps.

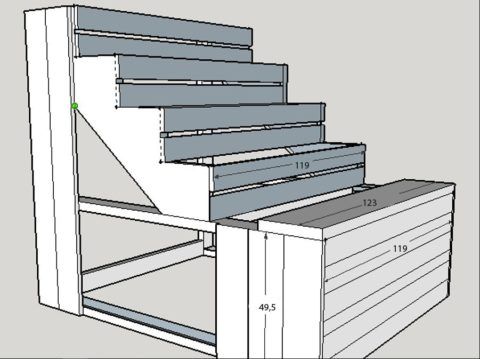

For a staircase with the parameters shown in the figure, you will need bars with a cross section of 50X100 mm:

- 45 cm in length - 2 pieces,

- 5 cm - 2 pieces,

- 143 cm - 2 pieces,

- 102 cm - 4 pieces,

- 135 cm - 2 pieces.

In addition, you need 13 bars 120 cm long with a cross-section of 25X100 mm, as well as 6 pieces 124 cm long and with a cross-section of 50X250 mm.

Cut all boards according to the specified dimensions using a jigsaw. Sand the wood, removing any rough edges, and begin assembly.

You can see the design layout in the photo. Fasten the wooden elements together using self-tapping screws and a screwdriver. Cover the finished structure with varnish or paint. If desired, the steps can be supplemented with carpet. It is nailed down with a furniture stapler.

Assembling such a structure will only take you a couple of hours, but it will delight you all summer, and perhaps even more than one season.

Staircase to the second floor

Manufacturers began to create ready-made designs. The kit includes all stair parts. They only need to be assembled at home. This staircase is made from plastic pipes with your own hands according to the instructions. There are no particular difficulties in assembly.

You can also build the stairs to the second floor yourself. To do this, you need to purchase pipes with a round cross-section and fasteners for them (fittings). Some people still have parts of pipes from construction work. They too are coming into play. To increase the strength of the inter-floor staircase, it is mounted directly on the wall. Or, stepping back from the wall a few centimeters.

The workflow is as follows:

- Layout. This is the most basic and primary part of the work. A staircase made of a round pipe must be made according to a competent drawing. You can use a ready-made diagram and apply your own dimensions to it. If you are good at drawings, make the plan yourself.

- Assembly. The structure is assembled using fittings. The convenience of working with plastic also lies in the fact that you do not need to use glue, screws or other fasteners. First, the base is assembled, that is, the side parts. A mount is mounted on the wall to secure the finished pipes.

- The steps are cut from a pipe of the same size so that the stairs do not “move apart”. The distance between steps should be the same. It is calculated depending on the person's step. If only a child will walk on the structure, his step is taken into account.

- The ladder is attached to the wall after complete assembly. It is not convenient to do this alone. You can call an assistant.

- For interfloor systems, handrails or side rails are required. They are also made from plastic pipes. You can use metal for this case. Metal handrails are stronger.

The plastic pipe staircase to the second floor is ready! You can test and use it.

Metal models

The side ladder is installed to the edge of the pool without any fastenings.

The simplest and most commonly used option for a pool is a metal structure that is installed at the edge. You can assemble such a circuit with your own hands, using only metal pipes and a welding machine. For example, it is not so easy to make Roman steps yourself, unless you purchase a ready-made structure that is carefully selected to fit the shape of the pool bowl.

Metal pool ladders are the most common; with their help you can quickly and easily go down into the water or climb up. Most often they have an emphasis on the upper platform and bottom, but there are options when the structure is attached only to the walls of the pool. In their shape, such structures resemble the letter “A” or “P”.

The first option is a metal stepladder, for which stability is ensured by resting on the walls of the pool. The second option is a ladder, the fastening of which is located on the platform. The structure itself is assembled from metal pipes, which serve as handrails and a frame; pipes or plastic, metal corrugated crossbars are also used as steps. It is quite easy to assemble such a staircase with your own hands from pipes.

For an inflatable pool, a metal ladder must have legs with tips to ensure its stability on the ground. For large pools, mounted models are used. They simply “slide on” to the side and have comfortable handrails. This option is used for pools buried in the ground.

The width of any metal staircase should not exceed half a meter (for most models) to make it convenient and safe to use the structure.

A gymnastic wall made by yourself is approximately 10 times cheaper than a purchased one. Although it is not much different from the store bought one. You don’t need to be a great expert in soldering pipes to assemble it from polypropylene pipes. I made this wall bars for my child. It can withstand up to 80 kilograms, which is quite acceptable for school-age children. It’s not for me to explain to you how useful gymnastics is for children, especially for strengthening the spinal muscles. And the prices for such gymnastic installations leave much to be desired... These criteria pushed me to think and make this wall from polypropylene pipes for my son.

My son drew a picture; he had wanted one for a long time.

Let's get started

What you need:

- Pipes are inch, diameter 33 mm.

- Fitting for pipes.

- Soldering iron for polypropylene pipes.

- Paint if desired.

You will have to calculate everything yourself according to your needs. Take into account the height of the ceiling, etc. things. Once you have calculated everything, we cut the blanks. And we begin to solder the nodes. You can remove the black markings from the pipes with alcohol in advance so that you don’t have to do this later. But you can, of course, erase it in the end - it won’t be any worse.

It took me about an hour to do everything and the wall was ready. I recommend doing soldering in open areas, as it all stinks terribly if you work for a long time. Also, be sure to use work gloves - the soldering iron is very hot and you will definitely get burned if you do not have much experience in welding polypropylene pipes. Please note that all ends of the pipes are sealed with plugs.

I painted the base blue. To ensure smooth transitions, I used masking tape.

The gymnastic wall bars are attached as follows. We make holes in the tees along the entire length on the sides. On the back side we place pre-cut and painted pieces of the same pipe and screw them to the wall with long bolts. Before doing this, we make holes in the wall with plastic inserts.

Gymnastic rings are also made of pipe. To bend them into a ring, you need to heat the pipe along its entire length, and use a wide-diameter pipe like a template to cool it. Next we solder it with a jumper. I bought the ropes, there’s no escape. The child really likes it - he is simply delighted!

Control tests with a mass of 75 kg.

The result met all expectations. It turned out that making something beautiful and necessary is not at all difficult. Thank you all for your attention!