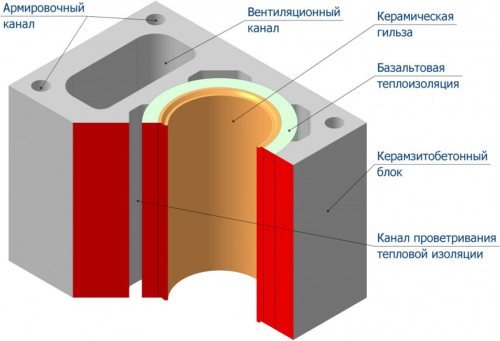

Increasingly, modern bathhouses are equipped with ceramic pipes. Why are they so popular? Brick is subject to a number of external influences: moisture destroys it, over time the masonry crumbles, and temperature changes cause deep cracks. Ceramic pipes are stronger and less capricious.

Chimney made of ceramic pipe

Design features of a chimney for a steam room

- The chimney is a vertical structure mounted inside the bathhouse or on the facade of the building. Its main task is to remove fuel combustion products at a speed sufficient to maintain natural draft in the furnace.

- A well-designed design ensures quick heating of the bath, maintaining the necessary microclimate in the steam room and economical fuel consumption.

- The most common problems with smoke exhaust ducts: Extremely strong draft, which will lead to rapid burning of fuel without adequate heating of the steam room. Traction too weak. An inadequate amount of oxygen enters the firebox, as a result of which the combustion process is interrupted and the thermal conductivity of the stove decreases.

- Proper installation of the chimney is a guarantee of your own safety and the longest possible service life.

How to calculate a chimney

The optimal shape of a chimney is considered to be cylindrical, since it is the most streamlined.

There are no corners in the cylinder, which means smoke moves through it without obstacles, while soot settles on the walls in a minimal amount. The main parameters of the chimney are the internal cross-sectional area and height. They must be calculated to ensure the following:

- optimal amount of traction;

- high furnace efficiency;

- fire safety of the building.

Experts offer the following algorithm for calculating the cross-sectional area of a chimney:

- Determination of the volume of flue gases during fuel combustion: Vgas=b*Vtop*(1 t/273)/3600, where b is the amount of fuel burned in the furnace in 1 hour (kg); Vtop is the flue gas volume coefficient for a specific type of fuel (for firewood it is 10 m3/kg); t – temperature of flue gases at the outlet (110-160°C).

- Determination of the cross-sectional area of the chimney: S smoke = Vgas / w, where W is the speed of movement of flue gases in the chimney (assumed 2 m/sec).

- Determination of diameter (if the chimney is round): D = √ 4 * Ssmoke/ π.

For example, the calculation of the simplest stove-heater, in which 6 kg of dry firewood burns in 1 hour (Vtop = 10 m3/kg), and the temperature of the flue gases at the outlet is 120 degrees looks like this:

- Flue gas volume: Vgas=b*Vtop*(1 t/273)/3600= 6*10*(1,120/273)/3600=0.024 m3/sec.

- Cross-sectional area of the chimney: Ssmoke= Vgas /w=0.024/2=0.012 m2.

- Pipe diameter: D = √ 4 * 0.012 / 3.14 = 0.125 m (i.e. you need to take a pipe with a diameter of at least 130 mm).

| Thermal power of the furnace, kW | Dimensions, mm |

| less than 3.5 | 140x140 |

| from 3.5 to 5.2 | 140x200 |

| from 5.2 to 7.2 | 140x270 |

For a cylindrical chimney, the diameter must necessarily be larger than the stove outlet.

The general rule is: for every kilowatt of furnace power there is 8 cm² of chimney cross-section. Those. if the thermal power of a sauna stove is 20 kW, then the chimney area should be 160 cm². Accordingly, its diameter is at least 140 mm.

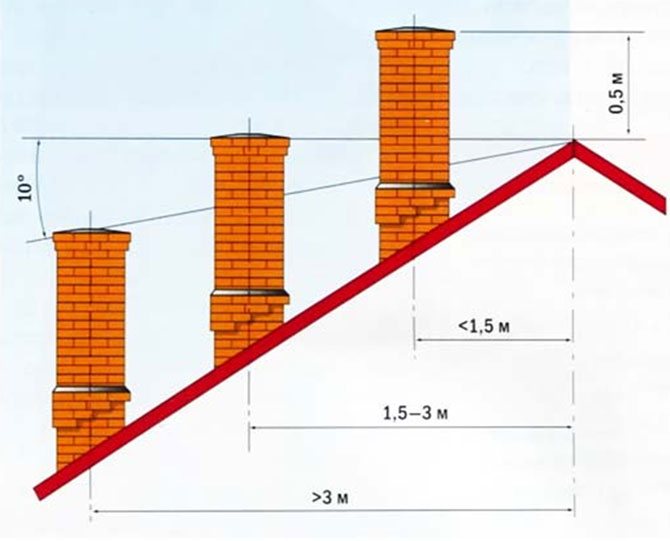

When calculating the height of the chimney, the height of the building, the type of roof, the presence and size of adjacent buildings are taken into account.

| Distance to roof ridge, m | Pipe height |

| less than 1.5 | 0.5 m above the ridge |

| from 1.5 to 3.0 | flush with the ridge |

| more than 3.0 | at the level of a line drawn down from the ridge at an angle of 10° to the horizontal |

If the pipe rises above the roof by more than 1.5 m, it requires additional fixation.

Choosing material for a chimney in a bathhouse

The market offers a wide range of raw materials for the production of smoke exhaust structures; let’s briefly name each of them.

It is low cost and easy to install, however, due to its porous structure it can accumulate condensate.

It conducts heat very well and heats up quickly, but lacks corrosion resistance. It has a large mass, which complicates the installation process and requires the construction of a foundation.

The model is quite expensive and difficult to install, although its appearance is very pleasant. If you do not line the inside, the structure becomes clogged with soot, susceptible to condensation, dampness, and subsequently cracking and allowing carbon monoxide to leak.

Due to its strength, ceramics can withstand high temperatures, are durable and can be used with any type of boiler. However, the installation of such a chimney is very expensive, and the design itself is poorly maintainable. Therefore, installation should only be carried out by a qualified technician, and the owners will have to treat this ventilation system with care.

Most bath complexes - home or commercial - use this option. This is due to excellent resistance to atmospheric agents; soot virtually does not accumulate, and the installation will last for many years. The appearance fits well with any bathhouse exterior; the shiny surface is pleasing to the eye. In addition, this design is quite easy to maintain.

Our production

Single wall chimneys

Double wall chimneys

Mounting elements

A glass smoke duct is a good choice, since this material has minimal inertness and is resistant to moisture and corrosion. The constant increase in the cost of installing such a structure is due to the complexity of the process and the high cost of fire-resistant glass in general. Therefore, such chimneys are the most expensive systems these days, although the cost is fully justified by the advantages of this option.

Chimney classification

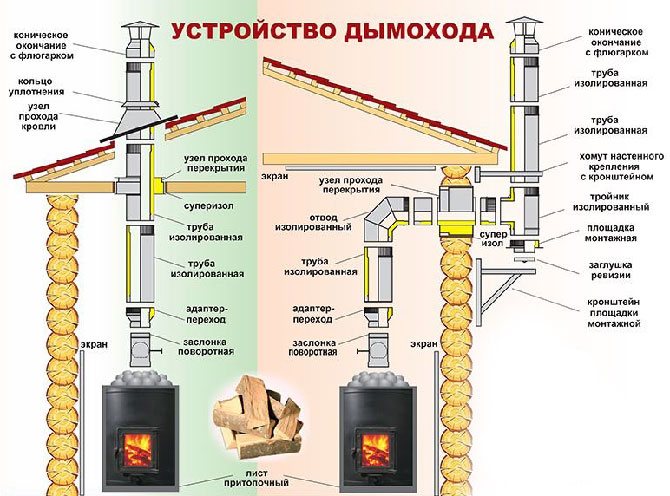

After completing the calculation part, you need to decide on the type of sauna chimney. It can be internal or external, each of them has its own advantages and disadvantages.

- The external one is easier to install and secure, and has a much lower fire hazard. However, the heat loss from such a chimney will be very significant.

- The internal chimney transfers all its heat to the room, but its installation is more difficult (you need to go through the ceiling and roof). Its main drawback is the increased fire hazard.

But in principle, all disadvantages are minimized when non-combustible materials and high-quality insulation are used during the installation process.

Brick, metal and ceramics are usually used as materials for the manufacture of chimneys.

We invite you to familiarize yourself with: Do-it-yourself barrel sauna - we study the varieties, choose the best wood for manufacturing

| Name | Advantages | Flaws |

| Brick | the possibility of embedding into an array of walls, additional heat radiation into adjacent rooms; | highly qualified masons are required, the rectangular cross-section and rough walls create additional resistance to the movement of flue gases and contribute to clogging with soot; |

| Steel pipes (black) | low price, ease of assembly, satisfactory weight characteristics, fire safety | short service life, susceptibility to corrosion, the need for thermal insulation to prevent the formation of condensation; |

| Steel pipes with stainless coating | low price, ease of assembly, satisfactory weight characteristics, fire safety | high price, the need for thermal insulation to prevent condensation; |

| Ceramics | durability, aesthetic appearance, no condensation | heavy weight, high price, need for qualified specialists; |

| Sandwich pipes | light weight, compactness, convenience and ease of installation, resistance to high temperatures and aggressive environments | high price |

Obviously, a chimney made of sandwich pipes is the most preferable, the only thing for which it is “scold” (except for the price) is its service life of 15 years, which is much lower than that of a brick one.

Types of stove chimneys

Chimneys for baths are different:

- according to the material of manufacture;

- according to design features and installation location.

For many years, sauna stove chimneys were traditionally made from baked bricks. Nowadays, metal products are becoming increasingly popular.

Depending on their location and design, they come in two types:

- chimneys installed indoors and passing through the ceiling and roof;

- structures brought out through the wall and rising along it from the outside of the building (read: “How to make a chimney in a bathhouse through a wall - device options”).

The best option is selected taking into account the advantages and disadvantages of each type of smoke exhaust pipe.

Types of chimney pipes by location

Chimney pipes differ in external and internal ones; the bathhouse owner should decide on this issue in advance.

External installations are not adjacent to the fireplace stove; they are mounted outside, along the facade of the room, and ensure fire safety. In this case, you will not have to make holes in the roof and wall, but the heat transfer consumption will be significant.

Internal installations are mounted above the furnace. If the implementation of this type of pipe takes a little longer, this pays off with the advantage of stable heat retention in the room.

Types of chimney pipes depending on material

Every bathhouse owner wants to experience comfort and enjoy health-improving treatments. To do this, you need to choose the right modern materials for the structure, so brickwork will not work. Ceramic pipes show excellent heat transfer results, but their use for a bathhouse is impractical.

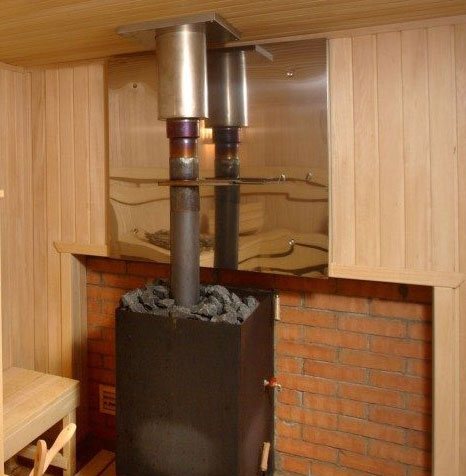

Stainless steel sandwich pipes are double-circuit modules made of stainless steel types, which are supplemented with special materials for thermal insulation. They show high performance and do not accumulate condensation. Installation work does not involve large costs due to the lightness of the design. Another advantage of steel pipes is their ability to be painted in any color, with a steel thickness of 1 mm considered optimal.

Types of smoke exhaust structures

The chimney for a steam room can be external or internal. In our country, you can often find internal options. Among their advantages is the absence of violation of the architectural style, as well as saving heat in the room. Which chimney is better for a bath? All the heat remains inside the steam room. Internal systems are good because they have better traction. They are also easier to care for. The internal structure also does not require insulation.

External chimneys are not entirely traditional for use in our country; they have an original appearance, and there is no need to make a hole in the ceiling. Internal chimneys do not interfere with design elements and retain heat with high efficiency. They have better traction and are easy to maintain.

Which pipe is best for a sauna stove?

Almost always, the choice of chimney depends on the size and layout of the stove and the bathhouse itself. The most affordable in terms of price and installation cost is considered to be a stainless steel pipe. If you buy a ready-made passage unit, then it is quite possible to install the chimney yourself. But despite all their advantages, sandwich chimney pipes are considered the most suitable for small steam rooms, for a country bathhouse or a temporary bathhouse with a metal stove.

If you build a full-fledged steam room, then it is best to use ceramic or brick chimneys for a bath.

The metal channel is advantageous in that, regardless of the type of bathhouse, the structure does not rust from condensation and moisture. The beautiful nickel-plated surface organically complements the interior of the room, decorated with wood. The price for a sandwich is about $10 per meter. The chimney itself is made up of separate sections connected by clamps, which also secure the pipe to the wall.

Important! From ready-made parts, you can assemble a pipe of the most complex shape, bend and tilt it in an almost arbitrary manner. This means that the stove in the bathhouse can be placed in any place where the power elements of the roof do not interfere.

A stainless steel chimney is better suited for a small bathhouse

In addition, the metal warms up faster, which means that draft will appear in the furnace, and accordingly, the time to warm up the steam room will be halved.

This is where the advantages of using a steel pipe for a stove end; then there are only disappointments:

- Hot metal in the humid atmosphere of a bathhouse is susceptible to gas corrosion. This means that in a year or two, depending on the intensity of use of the steam room, fistulas will appear in the chimney, and some sections will need to be replaced;

- When heated, stainless steel emits a specific “metallic” smell, which is very difficult to remove from the steam room;

- There are a huge number of fakes on the metal chimney market.

Most often, sellers boast that the sandwich body does not rot even in sea water, and the internal flame tube is made of stainless steel with a high nickel content. In fact, the outer part is made of galvanized, and the inner part is made of food-grade stainless steel. As a result, zinc vapor appears in the air of the steam room and the entire bath, which can easily be poisoned. A heat-resistant metal with a high content of silicon and manganese should be used for the inner pipe.

It is difficult to build a pipe out of brick. Moreover, the chimney will need to be built together with the stove, and before work begins, a foundation will need to be made. Otherwise, the slightest deviation from the vertical can cause cracks in the masonry.

. It takes a long time to build a chimney; a full-fledged chimney on good brick and masonry mortar can be built in no faster than a week. In this case, you will have to wait the same amount of time until the solution sets and the structure gives the planned shrinkage. The standard pipe cross-section is 10x12 cm and 15x15 cm; in practice, preference is given to a larger size due to the possible overgrowing of the surface with soot.

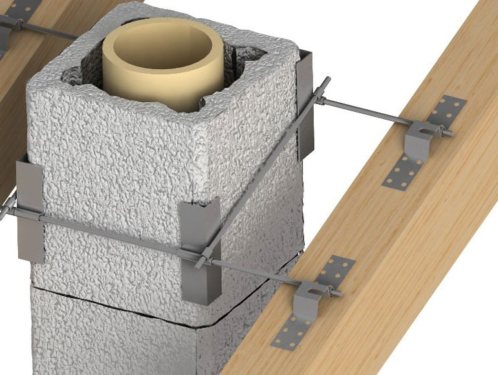

Brick is considered the safest option for arranging a passage through floors. Sometimes a casing for a metal pipe is even made from brick; this guarantees protection of the wooden ceiling and no burns through the wood, which often happens with metal structures.

Brick passage for stainless steel pipe

The most progressive and convenient option for making a chimney pipe. We can say that this is the best thing you can do with your own hands without having the qualifications of a stove maker. The range of ceramic diameters is quite large, from 14 cm to 30 cm, it is clear that for an ordinary home steam room the diameter of the pipe for the stove in the bathhouse is taken to be minimal.

Sections 500 mm high

The chimney is assembled from sections cast from special heat-resistant clay and fired in a kiln at 1100°C. A ceramic chimney is not afraid of moisture, like a brick, does not rot or burn out, like metal, and at the same time has a relatively low weight.

Significant disadvantages include:

- High price for sections and components;

- The need for certain qualifications and knowledge for proper assembly.

The ceramic pipe has a low coefficient of thermal expansion, so there are no problems with shrinkage and breakage of the apron covering the pipe body on the roof. The ceramic chimney technology itself involves installing a channel inside a brick casing. To reduce losses and overheating, the ceramic channel must be sealed with basalt cloth.

An interesting solution is to install a chimney from two ceramic channels. Typically, this scheme is used for a large bathhouse with a huge brick stove. The ability to block one of the channels ensures quick ignition of the firebox even in extreme cold.

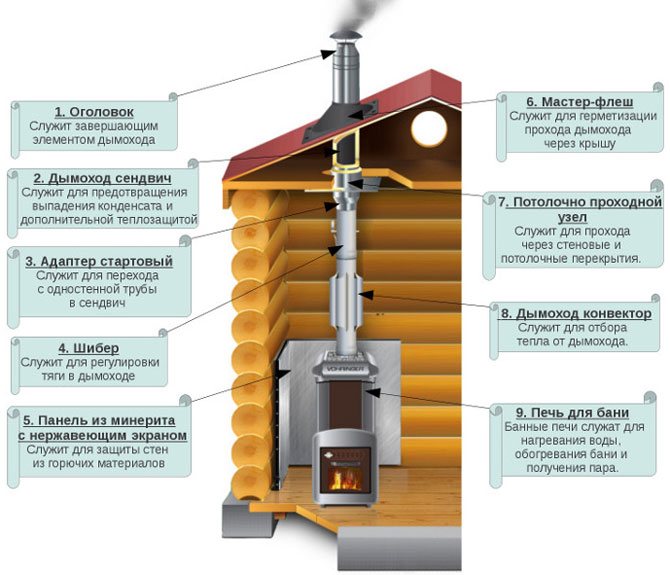

Chimney assembly diagram for a bathhouse

You need to know that the likelihood of using the sauna without a threat to your health depends on how the chimney of the sauna stove is installed.

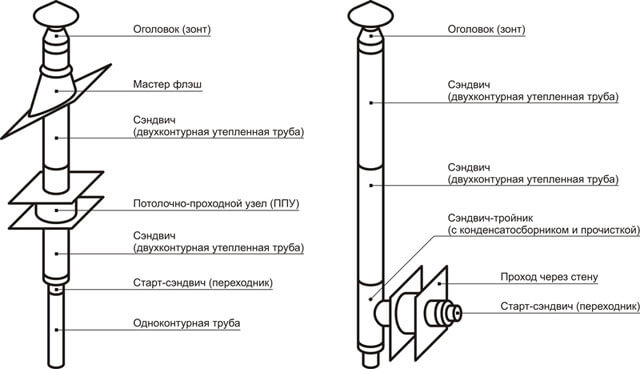

The chimney installation scheme comes in two configurations: internal and external. Depending on this, the chimney elements are selected.

Types of installation

Installation can take place on brackets through the wall or straight through the roof.

In the first case, the entire system is carried into the wall, and then rises, adjacent to the bathhouse, but without passing through it. This looks more aesthetically pleasing, and has the following advantages:

- the free space of the steam room is not used;

- there is no risk of getting burned on steel or stone;

- less chance of fire;

- It’s easier - you don’t have to make a hole through the entire attic.

- cases of smoke are easier to detect, as well as to track the general condition.

We suggest you read: How to cut tiles with a manual tile cutter

But at the same time:

- heat loss increases, since steam actually immediately enters the outside;

- the installation itself is more difficult due to the need to comply with the dimensions of the connection between the hole in the wall and the parts of the product;

- The heating of the pipe is greater due to the fact that the gases escape in the horizontal direction. With this arrangement, the resistance of the flue gases when moving through the channel increases;

- In terms of the number of elements, this option is 10% more expensive than the usual one.

When installing smoke exhaust systems in a straight line through the roof, the chimney is located straight, without bends, it departs from the boiler and goes upward, where it crosses the ceiling and exits on the back side of the roof. Advantages of such a connection:

- Stable draft due to the location of the chimney closer to the roof ridge.

- The condensate container is kept warm, so its cleaning pocket is dry and clean. This extends the service life.

- Cold bridges do not form in the walls, and thermal insulation is not compromised.

- The stability of the smoke exhaust duct is higher due to the fastenings to the roof. The fasteners themselves can be chosen cheaper than for the option on the facade.

- The aesthetics of the structure are not spoiled by side smoke outlets.

- Only a small part of the structure is located outside, which deteriorates over time from snow and rain. You can inspect and clean most of it without leaving the building.

- You can use non-insulated parts of the chimney that are located inside the bathhouse.

- This option is easier and 10% cheaper to install than when outputting through a wall.

- Flue gases go up, there is no obstacle to their exit. Heating is less than with a horizontal connection, since the resistance to smoke flow is minimal.

However, there are also weaknesses:

- The probability of “missing” the occurrence of a fire is higher, since smoke occurs in the ceilings that are located in the attic and on the roof, and they are simply not visible until the fire appears.

- Heat loss through the roof. Tightness is restored when waterproofing is installed before coating.

- Reduction of usable area, since according to safety requirements there should be nothing around the stove pipe for a bath.

- Increased costs for changing the roof and ceiling of the steam room, in particular, after finishing the final finishing.

- If the integrity of the smoke exhaust structure is damaged, the bathhouse begins to smoke.

- Condensation leaks and accumulated soot spoil the appearance of the roof.

- Burns from heated parts are possible in emergency situations.

When deciding on the installation method, the following nuances must be taken into account:

- dimensions of the building - if it is very small, then it is logical to make an external structure;

- the steam room is built from scratch or in an old room - in the first case, you can immediately think about the issue of insulation;

- Do you need to heat adjacent rooms?

External placement

An external smoke channel device is more expensive and difficult to install. This is due to increased requirements for compliance with the dimensions of the connection between the hole in the wall and parts of the product. For external installation, it is necessary to use double-walled chimneys to avoid the formation of condensation and fire.

It is external structures that are the least flammable, since the smoke is instantly directed outside, rather than circulating through a pipe located in the building. The advantage of such a system is the absence of the need to make a hole in the ceiling and roof and saving of internal space. This reduces the risk of carbon monoxide poisoning.

The main advantage of the internal location of the chimney is the easy provision of draft in the chimney structure, which is achieved by the vertical direction of the exhaust gases. In this design, the main part will be located in the interior of the building, which allows the bath room to heat up much faster.

Stainless steel design features

Concept

A chimney is a device that is made of different materials and is designed to provide draft to maintain combustion and remove smoke generated as a result of fuel combustion from the home.

Steel pipes are made with a round or oval cross-section without corners to prevent turbulence of combustion products. They are distinguished by extremely smooth walls, which does not allow soot to accumulate. But a stainless steel chimney is rich in more than just pipes! For example, the structure consists of the following elements:

- spark arresters;

- tees;

- deflectors;

- knees;

- audits;

- stubs;

- cones;

- adapters;

- condensate collectors;

- mouths;

- wall clamps;

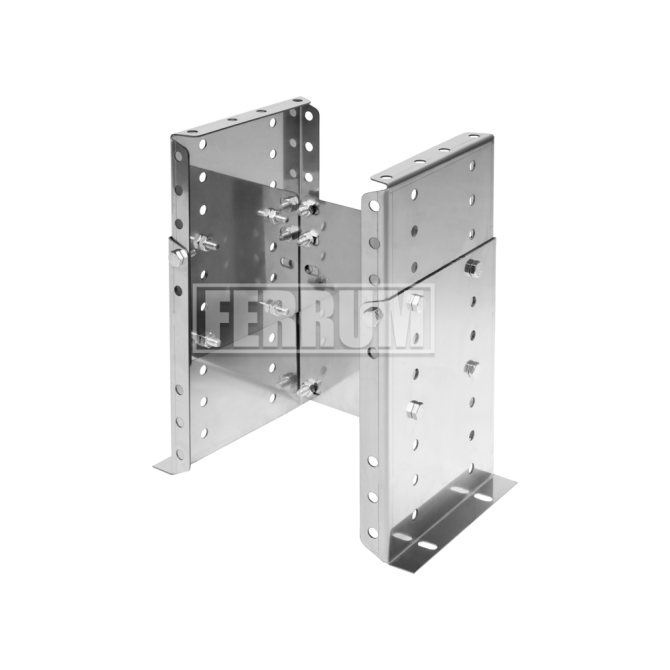

- support consoles.

Thus, a chimney is not a piece of cake, but a rather complex structure that requires serious attention and increased attention not only to construction, but also to maintenance.

Today, the market proudly displays chimneys made from various raw materials. Each type of “stove gadget” has both supporters and opponents. But stainless steel chimneys have the most supporters and the fewest haters. Why? Let's find out now.

Advantages

It is no coincidence that the product, made of stainless steel, has acquired a huge army of fans. Adherents value it for its colossal number of recognized merits.

- Long service life. The device can last 8-10 years with proper installation and careful care (of course, it cannot be compared with brickwork).

- Resistance to the harmful effects of thermal factors. The “stove gadget” is heat resistant.

- Resistance to the negative influence of climatic factors. The stainless steel product is not afraid of rain, snow, hail, drizzle, cereals, frost and dew. Besides, he doesn’t care about frost or heat.

- Resistance to the harmful effects of biological factors. The device does not attract “uninvited guests”.

- Resistance to the negative influence of chemical factors. "Gadget" is not afraid of compounds that contain aggressive substances.

- Resistance to the negative effects of mechanical factors (within reasonable limits). The metal device does not crack, is not scratched, and is not deformed.

- Patency. The stainless steel product is known for its high degree of permeability of combustion products, since it has extremely smooth walls.

- Versatility. The metal chimney goes well with any heating systems.

- Practicality. The stainless steel device is ideal for structures built from any raw material.

- Ease of installation. Installation of the product is simple due to its sleek design. In addition, it can be installed at any time of the year.

- Acceptable price. The chimney has a relatively low price (however, the same cannot be said about the sandwich option).

- Easy to maintain. The device requires minimal maintenance. It can be cleaned once a year as it does not accumulate soot.

- Maintainability. If one or another element of the chimney fails, there is no need to dismantle the entire structure, since all parts can be easily changed.

- Light weight. Due to the ease of the device, there is no need to build a solid foundation for the stove, as is, for example, the case with brick chimneys.

- Variety of models. There are several types of stainless steel chimneys (we will look at them a little later).

- Safety. The metal device does not harm people and the environment.

- Availability. The product can be purchased in an online store, in specialized retail outlets or on the market.

- Aesthetics. The chimney has an attractive appearance.

We recommend: Draft regulator for the boiler - how to install, do-it-yourself setup

The benefits are impressive. Let's look at the disadvantages.

Flaws

Well, well, well, why do opponents of metal chimneys wrinkle their noses at the mere mention of stainless steel fixtures?

- The need for a supporting structure when installing a high chimney.

- Inconsistency between the appearance of the product and the architecture of the building.

- The need for insulation of the structure.

I would say that there are no negative aspects to stainless steel chimneys. Don't want to spend money on thermal insulation materials? Buy a model that is already insulated - sandwich pipes. Do you want the appearance of the structure to match the overall architecture of the house? Cover the chimney with raw materials that match the roofing material.

Installation of a chimney made of sandwich pipes

Sandwich pipes are ready-made double-walled structures consisting of an inner and outer pipe with insulation between them. To seal the joints of the assembled elements, a special heat-resistant sealant is used. The versatility of sandwich pipes allows you to install a chimney of any design with your own hands.

The procedure for installing an internal chimney with a horizontal exit from the stove is as follows:

- The necessary materials are purchased and the workplace is prepared. Openings for the passage of the chimney are marked and opened.

- Using a special clamp and sealant, a stainless steel tee with a tap for draining condensate is installed on the stove chimney. A chimney-convector is inserted into the upper socket of the tee.

- Then a damper is installed in the convector socket to adjust the chimney draft. A starting adapter is installed in the gate socket (for the transition from a single-wall stove pipe to a sandwich pipe), after which the required number of sandwich pipes is assembled to the required level.

- All connections are assembled using sealant and secured with clamps. The coupling scheme is as follows: the inner pipe is “through condensate” (the upper pipe enters the socket of the lower one), the outer shell is “through smoke” (the lower one enters the socket of the upper one).

- To pass through the ceilings, a ceiling-passage assembly is installed on the chimney with expanded clay filled into the gaps. The passage unit performs a dual function: fixing the chimney and preventing the impact of high temperatures on building structures.

- After leaving the roof, a cap is installed on the last sandwich, and the junction of the pipe to the roof covering is sealed with a special elastic element.

Upon completion of the work, it is necessary to test the assembled structure - a test firing of the furnace to ensure the tightness and reliability of all connections.

Organization of passage through the roof

The most critical stage of installation is the passage through the roof. After all, cutting a hole in the roof of the steam room can disrupt the hydro- and thermal insulation of the roofing pie, resulting in leaks and destruction of the rafters of the building. Following these recommendations will help you make the right passage through the roof:

- The hole on the roof must be designed in such a way that the distance between its walls and the pipe is about 10-13 cm.

- Make a wooden box on the roof in the place where you plan to install the chimney.

- Fill the entire space that separates the chimney from the inner duct with non-combustible material. In this case, stone wool is suitable.

- Press the waterproofing layer with sheathing bars.

For proper waterproofing, small cracks in the roof can be sealed with silicone-based sealant. Larger cracks can be sealed by installing a special element - a passage, which is located at the point of exit through the roof.

Chimney passage through the roof

The roof passage is an apron-cap, which consists of a steel base and a rubber tip.

The passage is put on the pipe and securely fixed to the roof. Too much effort when shrinking the apron onto the pipe is not required; it can break the tightness of the connection and cause a roof leak.

Often modern baths are built from pine. This wood sometimes overheats. The process of smoke passage must be created with maximum attention. The wall must be fenced with any non-combustible materials. You can strip steel sheets; mineral wool or brickwork will also work.

Another effective method of protection is a special ceiling-passage assembly.

At the next stage, the pipe is erected above the roof. Its height must be at least 1.5 m. When it passes through the roof covering, it is necessary to apply a sealing cover. Using this operation, you can hermetically connect the chimney pipes.

In order to get good traction and long service life, you need to clean the pipe from accumulated soot and debris once every six months. And then the bathhouse will delight its owner for a very long time.

These are structures for connection to boilers and fireplaces that have an outlet for gases from the combustion chamber in the upper part of the body.

From there, the system is mounted directly onto the roof, which requires partial dismantling of the roof, but requires a minimum of materials for transitions and connections, due to the straight trajectory. To select, it is important to calculate the length of the structure with the elevation above the ridge.

This is the best stainless steel chimney for a home fireplace due to its direct connection and the optimal diameter for connecting to the outlet of 115 mm. Inside there is stainless steel with a sealed weld that will not allow condensation to pass through.

This is followed by a thick layer of mineral wool with a density of 120 kg/m3, which protects the attic floor and roof from fires. The outside of the chimney is wrapped in laser-welded galvanization, which eliminates damage to the galvanic layer.

Pros:

- all parts for installation in the kit, including ceiling elements for the roof;

- the insulating layer is resistant to temperatures of 700 degrees;

- an insulation thickness of 40-50 mm will prevent the surrounding materials from igniting from hot smoke and heat from the pipe;

- suitable for burning wood (rising ash will not damage or burn through the inner layer);

- screws included;

- stainless steel head that protects the outlet from blocking with snow;

- the package comes with a sealant that can withstand 1200 degrees;

- the box contains 7 sheets of basalt wool and 5 clamps for connecting high structures;

- pre-furnace sheet and stainless steel screen;

- AISI 439 steel on both parts of the pipe (on the one in the room and on the one outside on the roof).

Minuses:

- the thickness of the stainless steel connecting to the fireplace is 0.8 mm, and the cross-section of the pipe wall on the street is 0.5 mm;

- the pipe leading from the fireplace is not covered with insulation (protection starts only from the ceiling), so you can get burned on it;

- the cost of the entire set is 27,000 rubles.

This is the best stainless steel chimney at the most affordable price of 11,000 rubles for a complete set. Inside the sandwich structure there is stainless steel with a wall section of 0.5 mm, which is resistant to deformation thanks to the dense winding of Rocwool basalt wool and a galvanized layer on the outside.

The pipe connection is made using TIG welding technology, which provides a strong seam with minimal soot collection on the protrusions.

Pros:

- the price is one of the most attractive 11,000 rubles;

- The set includes an insulated umbrella that protects against precipitation;

- 4 stainless steel clamps for assembling a long pipe into a single unit;

- adapter from single-circuit structure to double-circuit structure;

- roofing adapter (master flush) included;

- 1 m of starting pipe without insulation and 3 m of double-layer pipe for leading to a high roof;

- sandwich thickness 40 mm;

- high quality AISI 439 stainless steel.

Minuses:

- there is no roof insulation, so you will have to purchase additional materials separately;

- only one fastening to vertical structures;

- metal thickness along the entire length of the pipe is 0.5 mm;

- Suitable for burning with coal or gas, but it is better to use wood rarely, so as not to heat up the thin walls too much.

This is the best option for installing a heating system not only in a private home, but also in an office building, because the internal flow diameter is 200 mm, which can satisfy the needs of a serious boiler. The wall thickness of 0.8 mm has sufficient rigidity for long-term performance.

Pros:

- insulator filling density 120 kg/m3;

- high-strength stainless steel;

- withstands temperatures up to 700 degrees;

- simple assembly of the socket system;

- sealed internal seam;

- insulation thickness 50 mm;

- 7 meters of pipe for high reach;

- flange for passage through the ceiling;

- a large head covering not only the inner pipe, but also the outer one;

- 8 basalt wool slabs for attic insulation;

- 2 fasteners and 9 clamps included;

- stainless steel screen 1x1 m.

Minuses:

- the large outer diameter of the pipe 280 mm requires a large hole;

- price 42,000 rubles.

Such designs are suitable for boilers and furnaces that do not have a direct upward outlet of exhaust gases, and the exhaust channel is located on the side. To connect the chimney, you need a kit with a side inlet and the ability to attach a high vertical stand (without loading the boiler).

This is the best option for a stainless chimney for a bath due to the wall cross-section of 1.0 mm, which allows you to transfer high heat from a nearby boiler, where wood burns at high temperatures. The rear connection provides open access to the rock laying area.

The diameter of 120 mm promotes strong draft, which will allow you to heat the bath to the desired maximum level. The upper part has a narrowing and an umbrella that prevent the hole from clogging.

Pros:

- wide insulation board that can easily be adjusted to the contours of slate or tiles to cover a hole in the roof;

- stainless steel stand to hold the side outlet from the boiler and the high mast; adjust the distance from the partition;

- internal flow diameter 120 mm;

- stainless steel wall thickness 1.0 mm for high heat;

- strong connection of all longitudinal joints using argon welding;

- the socket system is easy to assemble with your own hands;

- environmentally friendly insulating material inside;

- can withstand temperatures up to 1000 degrees;

- guarantee of operation with regular use for up to 15 years;

- Includes pre-furnace sheets and passage parts for floors;

- two sealants with a temperature range of 260 and 1200 degrees for high-quality sealing of adjacent parts;

- 8 clamps for assembly;

- tee for collecting condensate;

- The total length of the chimney is 6 m, suitable for outlet to a large height, which will provide good draft even with closely spaced houses.

We suggest you familiarize yourself with Handles for washcloths how to knit

Minuses:

- the cost of the set is 29,000 rubles;

- The insulating fiber is 30 mm thick, which is smaller than similar models.

This is the best stainless steel chimney kit for heating in a country house. The vertical pipe can be placed either outside by fixing the bracket on the outside wall, or running inside the room and out through the roof.

The set includes a tee with a cover and a condensate collector. The diameter of the inner pipe is 120 mm and it is wrapped in a dense insulator. The outside has a mirror cladding made of galvanized steel, which has a presentable appearance.

Pros:

- acid-resistant steel AISI 304 is suitable for copper boilers that produce caustic condensate;

- total length of the chimney is 5 meters;

- condenser collector;

- insulated umbrella;

- large slab 100x120 cm included in the kit for fireproof cutting of the ceiling;

- basalt wool for insulating combustible roofing;

- the sandwich layer inside reaches 50 mm;

- self-tapping screws for fixation and a skirt that prevents sediment from pouring between the roof and the pipe;

- 4 stainless steel clamps;

- pre-furnace sheet;

- complete distribution of the weight of the chimney onto the bracket, without loading the boiler;

- separate flange for the passage of the ceiling in the room.

Minuses:

- cost 50,000 rubles;

- the large outer diameter of 220 mm (due to insulation) requires making a large hole in the roof;

- the thickness of the metal walls at the outer and inner parts is 0.5 mm;

- You can get burned on the starting tube.

Chimney passage through a wooden ceiling

Before installing the internal chimney, it is necessary to calculate the direction of its passage in order to avoid sticking into the rafters. If this is not possible for some reason, you need to use contours, but it is better to immediately choose a place for the boiler so that the chimney is placed strictly vertically.

Passage through the ceilings is done in the following sequence:

- A square hole is drilled in the ceiling with a side 20 cm larger than the cross-section of the pipe.

- A similar hole is made in the roofing. The wooden structures located next to it are protected with mineral wool.

- 2 squares are cut out of a sheet of asbestos cement with sides 10 cm larger than the previously made holes. They are secured to the base using self-tapping screws or heat-resistant glue.

- The chimney is routed through the linings.

- The remaining cracks are sealed using heat-resistant sealant.

- An elastic element is placed on the pipe on top of the roof. It is pressed to the chimney with a plastic tie, and to the roofing with waterproof glue.

Is it possible to install a sandwich chimney in a bathhouse with your own hands?

The use of this design allows you to prevent and protect the room from possible fires. Thanks to the insulation, the heating temperature of the pipe usually does not rise.

There is a certain sequence that accompanies proper self-assembly. Strict compliance with the rules and recommendations of the manufacturer, guaranteeing the uninterrupted operation of the chimney system.

Assembling a furnace gas removal system is in many ways similar to installing a sewer system made of cast iron pipes. Unlike cast iron, ceramics are sold in ready-made sections, and they can only be cut with a diamond cutting wheel, and only at the end sections of the chimney.

First of all, using a construction cord and a level, markings for installing the chimney trunk are applied to the wall of the bathhouse. You can punch a channel in the ceiling of the bathhouse and run a cord with a suspension or use a laser level. Having guidelines along the vertical axis, you can easily assemble a brick shell.

A 30 cm thick foundation is sufficient for ceramics.

The first two sections of the outer body have side windows for connecting to the sauna stove, so the first section of the ceramic pipe should be angular. After laying the thermal insulation and fixing the ceramics, reinforcing bars are placed in the additional channel.

We invite you to familiarize yourself with: Foundation for a bathhouse made of tires

Separate sections of the ceramic pipe are connected mechanically with the obligatory pressing of a sealing mixture prepared from powder glue. The putty hardens quickly, but for final setting you have to wait 4-5 hours.

They are attached to the roof rafters with a wire frame.

After the chimney is assembled and finally leveled, the fittings are tensioned by heating and fixed. After cooling, the sections are filled with heat-resistant cement-sand mortar. If the pipe height is more than three meters, then the reinforcement is sealed and poured in separate sections of 1.5 m.

It is impossible to align a sauna pipe without a level

About the design

What design features should you pay attention to when choosing? The chimney must withstand large temperature changes, and its material must be moisture-repellent. It is ceramic pipes that meet these requirements.

Some sellers are misleading by saying that each element of the circuit is sold separately. The chimney is supplied as a kit. Don't buy this canard. If the issue of maintenance is of particular concern, then the bathhouse is equipped with multi-channel expanded clay blocks. At the same time, ventilation is created. This is useful if you want to reduce the amount of work.

How to avoid problems

Even if the chimney installation is carried out correctly and it is operated according to all the rules, problems may arise, the most important of which is clogging of the pipe.

Along with the smoke, soot, soot, and grains of ash come out through it. Some of them gradually settle on the inner surface of the pipe, reducing its diameter and reducing draft.

If this is not dealt with, then over time the heat transfer of the stove will decrease, the load on the chimney will increase, which can lead to its premature wear. In addition, the resulting thick layer of soot can ignite and cause a fire.

You can identify a clogged pipe by the following signs:

- Smoke color. When the chimney is working normally, it is transparent, but if dark clouds appear, it’s time to clean the chimney.

- Flame color. His tongue should be light orange rather than bright red.

What should you pay attention to when installing a chimney in a bathhouse?

Below are guidelines on what to focus on first.

The small cross-sectional size will prevent the removal of fuel products in the required quantity. The volumetric section, on the contrary, contributes to the movement of smoke too quickly, which will not allow the bathhouse room to be properly heated. This, in turn, will increase fuel costs. You should take this point seriously, since the result will depend on it.

Deciding on the form is easy if you take into account the basic principle of its operation. Chimneys tend to heat up unevenly, as a result of which smoke comes out to the roof surface along the central axis. It follows that the correct shape is a circle. Cylindrical structures heat the room much faster and do not require unnecessary financial costs.

A chimney with a rectangular cross-section provokes turbulence that interferes with the necessary draft. A rectangular configuration is permissible only when we are talking about heating devices that do not require powerful traction.

Pipe diameter

The scale is determined by the degree of power draft of the sauna stove and is located in the intermediate range from 115 to 270 (mm). However, in order to accurately determine the diameter, you need to familiarize yourself with some of the requirements specified by the manufacturer in the instructions. If you do not have a diagram for installing a chimney for a bathhouse with your own hands, then it will be enough to know the ratio of the cross-sectional diameters of different shapes. It looks like this:

- cylindrical – 1 to 10;

- rectangular - 1 to 1.5.

For brick chimneys, the minimum cross-sectional diameter should be 140x140 mm.

The successful operation of a chimney system primarily depends on how accurately the pipe size is determined.

Flue height

According to the standard, its height should be at least 5 meters. The calculation of the height of the chimney is carried out in accordance with the basic technical characteristics of the materials.

The channel should be located at least half a meter above the roof ridge and not below its level. In this case, it is worth taking into account the thickness of the roofing covering and the angle of inclination of the roof slope. The height is selected without taking into account the chimney “umbrella”.

Tips for maintaining chimneys for baths

The most budget-friendly and proven method of cleaning a chimney is mechanical, using a cable, a brush and a weight.

First you need to close all the openings of the stove so that soot does not get into the room, then climb to the roof, providing yourself with insurance.

Using a weight attached to a cable, check the chimney for the absence of foreign objects, then use a brush to clean its inner surface from soot.

Upon completion of work, heat the stove and check the draft.

The second method is chemical, using special briquettes, liquids or powders, which are added to the stove with firewood and set on fire. Combustion products will destroy all deposits on the walls of the chimney and are not harmful to the human body.

If you regularly clean the chimney, inspect its condition, and do not burn wood with high humidity in the stove, as well as plastic and polyethylene, then it will serve its owners faithfully for a long time.

The simplest chimney

This element will be based on a stainless steel pipe. In addition to this, you need to prepare one elbow with a diameter of 20x120 cm from galvanized steel, two elbows of 16x120 cm each, three of stainless steel of 16x10 cm each. You will also need a tee with a diameter of 16 cm and a plug for it. You also need a fungus that is the right size. The diameter of the chimney for the bathhouse in this particular case will be 16 cm.

The prepared pipes should be connected to each other using self-tapping screws.

The section of pipe that will be outside is wrapped with basalt wool. The layer should be approximately 16 cm. You should also additionally wrap the cotton wool with asbestos cord. Then a pipe with a diameter of 20 cm is connected, which is fixed and thoroughly coated with bitumen mastic. An asbestos cord is placed in the gap between the two pipes. This is necessary for protection from rain.

This is how you can independently design and install stainless chimneys for a bathhouse. This is a very affordable solution.

General installation recommendations

It is necessary to study in as much detail as possible the information on how to properly make a chimney pipe in a bathhouse and all the details related to its installation, because reliability, service life, performance and, above all, your safety will depend on its quality. Any seemingly insignificant mistake can provoke irreversible consequences.

First you need to familiarize yourself with the main instructions of specialists and instructions (if available).

The areas where the smoke channel passes through the ceilings must first be protected. The step-by-step guide for this stage of installing a chimney in a bathhouse with your own hands is as follows:

- Preparing the passage pipe. It is required to fill its exterior with basalt wool.

- Next, you need to insulate the inside of the unit - decide on the installation point on the ceiling and prepare a hole of the desired shape.

- In the area where it meets the ceiling, spread another thermal insulation layer and then proceed to the cutting device.

- Be sure to leave a small gap between the passage unit and the smoke channel.

Roof work

Start this stage by dismantling the roof:

- It is necessary to determine the dimensions from both the internal and external areas of the roof, taking into account the roof slope (slope).

- Cut a hole inside the roof. To do this, cover the opening areas with metal sheets on both edges, the thickness of which should be 0.5 (mm). You need to make 4 holes measuring 450 by 450 (mm), using the square section method. The scale depends largely on the adapter.

- A roof flashing or master flash is used to pass the chimney through the roof. Their main task is to seal the passage and protect against moisture.

Please note: the master flush must be placed under the top edge of the roof to avoid leakage. Also, seal the joint with the pipe and secure everything with roofing screws.

Construction of a sauna stove: video

It is worth paying attention to a number of mistakes that are made when building chimneys by non-professionals:

- Use of unsuitable materials such as asbestos and aluminum. This may cause a fire.

- An unauthorized change in the diameter of the chimney can reduce efficiency or destroy the structure of the bathhouse.

- Combining several chimney systems into one.

Several more typical mistakes in chimney construction are shown in the video presented.

Sometimes it seems that you can quickly build a chimney in a bathhouse with your own hands, without anyone’s advice. But the construction of a chimney is quite a responsible procedure, requiring compliance with the rules, the availability of skills and the study of modern techniques. This will save you from mistakes, and the chimney you built in the bathhouse will serve reliably and for a long time.

On the right side, the opening is filled with pieces of bricks to cover the space above the core. The distance between the masonry and the core should be about 3 cm, all voids must be filled with thermal insulation material.

In the next row, the space above the core disappears completely, after which the formation of a displacement of the channels towards the middle begins. In order to prevent the destruction of the masonry in the future, an additional row of bricks is laid above the core. The next row becomes the beginning of the narrowing of the brick pipe.

The cross-section of the pipe should not be larger than permissible, this will slow down the rise of combustion products. The easiest way is to purchase a ready-made structure, however, you also need to be able to install it correctly. When installing a pipe, its end must extend to the street at least 50 cm. At the joints of the chimney and roof, an otter is installed, which will protect the bathhouse from the penetration of precipitation.

Remember that chimney repairs often cost many times more than just installation services. It is for this reason that it is better to follow all the rules and recommendations at the bathhouse design stage.