The impact of groundwater and precipitation negatively affects the strength of all structural elements of the building.

Comprehensive protection of structures from moisture penetration includes mandatory waterproofing and vapor barrier of walls.

It is important to carry out the specified work in accordance with the technology requirements. Otherwise, vertical insulation will not fulfill its purpose, but will only aggravate the problem. Water penetrating through an unsealed layer of film will cause the rapid development of mold and mildew, which will lead to the destruction of the structure of the wall material.

Types of vapor barrier materials

The primary issue is the choice of material that will protect the insulation from moisture. Classic roofing felt and glassine, which were used for water vapor barrier, have given way to modern polymer films with different performance parameters. Membranes used in construction are divided according to vapor permeability into completely impermeable films and partially permeable (diffusion) films.

Manufacturers offer the following types of vapor barrier membranes:

:

- polyethylene film (can be used to insulate a roof or floor, the barrier is vapor and waterproof);

- reinforced polyethylene film (higher strength);

- aluminum foil film (used for internal insulation, mounted with the reflective side facing the room - additionally helps to retain heat, primarily designed for use in saunas and baths);

- film with anti-condensation coating (prevents moisture condensation, intended for installation in structures with metal elements prone to corrosion - corrugated sheets, metal tiles, etc., the film is mounted with the treated side facing the heat insulator).

Reinforced polyethylene film

If, when insulating rooms in a house, a completely impermeable film is used to create a vapor barrier, it is necessary to provide effective ventilation of the rooms that can remove excess moisture outside.

Vapor barrier films with a porous structure differ in their ability to diffuse. Due to the pores in the barrier, moisture escapes from the insulation to the outside, due to which the heat insulator retains its operational properties, and metal structures in contact with it do not rust, and wooden ones do not rot. Among vapor-permeable membranes there are differences

:

- Pseudo-diffusion. During the day, up to 300 g/m2 of vapor is passed through.

- Diffusion. The amount of evaporation passed per day ranges from 300 to 1000 g/m2.

- Superdiffusive. The evaporation rate exceeds 1000 g/m2.

The first type of vapor barrier film is considered an effective protection against moisture and is used for internal insulation of structures (from the room side). If a pseudo-diffusion membrane is mounted on top of a fiber insulation on an external wall, the vapor barrier will trap moisture in the insulation. Diffusion and superdiffusion membranes, which simultaneously serve as a wind barrier, are suitable for façade insulation.

Superdiffusion membrane

Vapor barrier

Vapor barrier involves various methods of protecting construction objects from steam penetration. It differs from waterproofing in that it is designed to protect the structure not from the penetration of liquid into it, but from steam. Most often it is used in houses built of wood. Indoors, a vapor barrier is installed under a layer of finishing materials. On the outside of the building it is recommended to install it in two layers.

Types of vapor barrier:

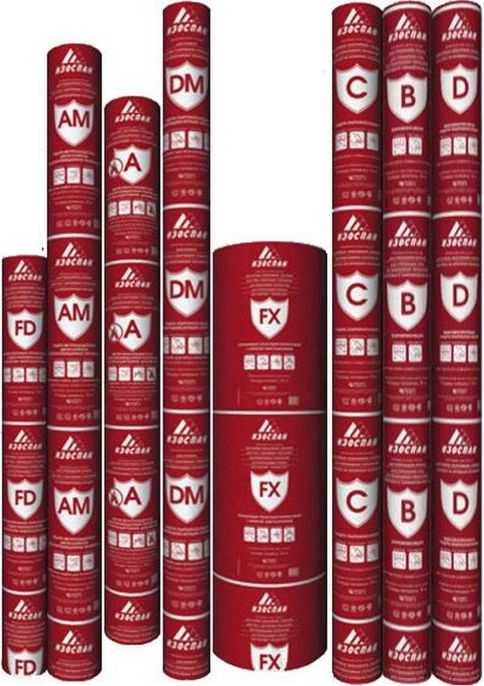

Izospan

Ondutis

trademark Delta company Dorken (Germany)

Yutafol, Yutavek produced by Juta (Czech Republic)

Klober (Germany)

Tyvek films DuPont (USA)

Fakro (Poland)

Our company uses the following types of vapor barrier materials in the construction of timber houses.

Isospan film

Film utafol

Ondutis film

Vapor barrier manufacturers

ISOSPAN trademark for various purposes:

- Izospan A (vapor barrier A). Single-layer membrane, used for vapor barrier of roofs and walls. Its subtype, Izospan AM , is a two-layer membrane that acts as a hydro and vapor barrier (suitable for vapor barrier in a steam room).

- Izospan B (vapor barrier B) is a polyethylene film that is used for vapor barrier of insulation in the house and for external vapor barrier (it is better to use in rooms with gentle temperature conditions).

- Izospan C (vapor barrier C) is a non-woven material with vapor and waterproofing properties. It is used to protect walls and roofs from moisture without insulation.

- Izospan D (vapor barrier D) is a universal material for protection against steam and moisture with windproof characteristics. Can be used for any surfaces.

- Izospan FD and FS – non-woven material with a metalized film. It is used for vapor barrier of walls and roofs with or without insulation, as well as in places where heat sources are installed as a reflector. Suitable for heat and vapor barrier of steam rooms.

- Izospan FX is foamed polyethylene with a metallized film. Acts as heat, moisture and steam protection. Suitable for walls and roofs, including baths and saunas.

- Izospan FL and SL - adhesive tape for gluing canvases.

Places where vapor barrier materials can be used can be walls, ceilings and floors. And the materials you can use are vapor barrier, membrane film, and also covered with foil. Among the domestic products presented on the building materials sales market, the most common types of vapor barriers are “Megaizol” and “Izospan”.

Isospan B is used for vapor barrier of wooden houses walls, floors and ceilings

Over many years of their use, these products have proven themselves as a reliable means of insulating against steam.

Vapor barrier is divided into:

- roll

- sheet

Rolls are mounted by rolling from bottom to top and secured horizontally with wooden slats or galvanized profiles. Between such a layer of protective material and the finishing inside the room, leave a space of four centimeters for ventilation. The strength of the fastening must be checked upon completion of installation.

Under the sheet vapor barrier material, it is necessary to prepare a frame from a profile according to the size of the sheet. Sheets are inserted into the finished structure and secured with self-tapping screws. With their help, the strength of the material is ensured. The insulation must be installed correctly. The vapor barrier layer of the fabric is mounted on the inside to the insulation structure.

Among other things, vapor barrier material can be used to insulate the basement and attic of a house. If surfaces separate warm and cold zones, then the use of a vapor barrier is mandatory. Vapors generated in a warm room have a negative effect on walls, ceilings and floors.

In a house made of timber with an attic (the first floor is timber, the second floor is panel), the vapor barrier is laid in:

1st floor floors

Floors of the 2nd floor (floor and ceiling)

Attic (entire second floor, walls, gables and ceiling)

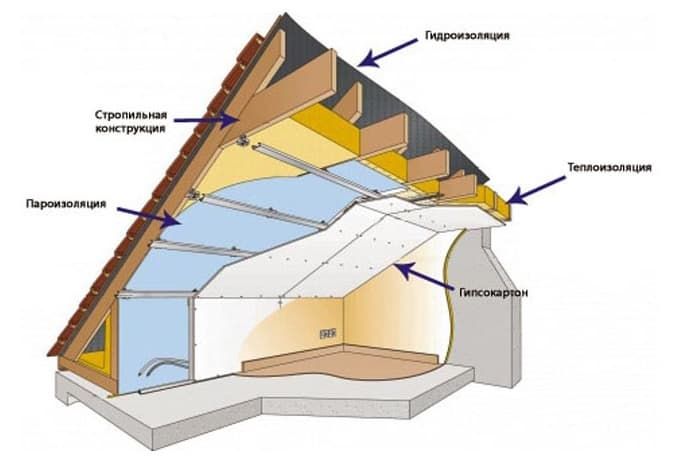

When ordering roof insulation, installation of films is mandatory and a vapor barrier under the roof is required.

To protect your home from gradual destruction under the influence of emitted steam, you will need to install a vapor barrier material, the most common type of which is a vapor barrier membrane film. In rooms with a high level of steam generation, such as baths and saunas, it is recommended to use a film covered with foil as insulation, which will provide protection from steam and will reflect heat into the building.

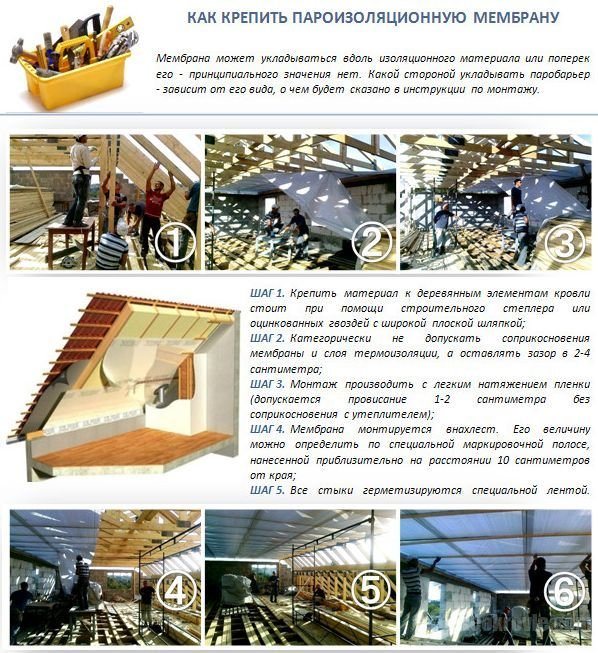

Principles for installing a vapor barrier

Laying a vapor barrier is an important stage in the work of insulating structures with fibrous materials that can accumulate moisture. The work is carried out as part of the repair or reconstruction of a house or at the stage of preparation for finishing a new building. You need to know how to properly fasten membrane sheets together to ensure a continuous layer that protects against moisture penetration, and how to attach the film to structures. Before laying the vapor barrier film, it is also necessary to determine which side it needs to be placed on the insulating material.

.

Preparatory stage

To insulate a block or wooden house or arrange a bathhouse, thermal insulation materials are used, which must be protected from moisture accumulation. For this purpose, a material that does not allow evaporation is installed on the walls inside the house, on the ceiling or floor, on the inside of the roofing pie. Or a diffusion membrane for facade insulation.

At the preparatory stage, you should choose a vapor barrier option, taking into account the installation features and the requirements for the characteristics of the film. Popular options include Izospan (and its analogue Megaizol), a membrane material with high performance parameters. The manufacturer offers a line of membranes with various technical indicators, which allows you to choose a material depending on its purpose - vapor barrier for roofs, ceilings, wall structures made of wood or concrete.

Those who plan to build a bathhouse, not without reason, believe that foil film will reliably protect the mineral wool insulation from getting wet and will help maintain a high temperature in the room by reflecting thermal radiation. Along with the classic “insulation + vapor barrier” scheme, today ready-made non-combustible heat-insulating mats with a foil-coated vapor-proof surface are used.

Correctly attaching reflective vapor barrier

Before laying a vapor barrier, it is necessary to properly prepare the surfaces of the structures. The preparation technology depends on the material from which the walls, floor, ceiling or roof are made. It also takes into account what kind of work is being carried out at the site - construction or repair

:

- When building a wooden house, all wooden structural elements must be treated with compounds against rotting, pest damage and fire.

- During the repair work, the finishing is first dismantled, the surfaces are cleaned, while:

- wooden structures are treated with an antiseptic and fire retardant.

- Concrete and block structures are treated with an antiseptic if they are damp and there is a risk of mold, as well as in wet rooms.

Due to improper preparation of structures, walls, ceilings or rafter systems can become unusable over time or become a source of fungal spores that can provoke allergies, asthma attacks, and exacerbation of respiratory diseases.

How to install a vapor barrier on a ceiling

Installation of a vapor barrier layer on the ceiling is required when insulating a flat or pitched roof in a house without an attic, when insulating a basement, as well as residential premises above which a cold attic is located. The ceiling in the bathhouse is also insulated and vapor-insulated. Before laying a vapor barrier on a roof made of a concrete slab, on a reinforced concrete or wooden floor from the inside, the surface of the structure should be prepared.

The fabric made of film or pseudo-diffusion membrane must be solid so that there are no joints through which moisture can penetrate into the insulation

. If the width of the roll material is not enough, the strips will have to be joined together. The recommended overlap of the canvases is from 10 to 20 cm, while the joints on both sides are carefully taped with reinforced construction tape.

Attaching the vapor barrier membrane

Canvases made of foil film are laid without overlap - end-to-end, and the seam is taped with aluminum tape.

If the base of the roof or ceiling is a wooden structure, you first need to lay a waterproofing membrane (solid sheet) and attach it to the base (a vapor barrier material can be used).

Then, in the spaces between the floor joists or rafters, a heat insulator is placed in the form of mats or rolled material made of mineral (basalt) wool. After this, you can lay a vapor barrier on the ceiling. If the thickness of the heat insulator corresponds to the thickness of the logs, you should nail a counter-lattice made of slats to create a ventilation gap

.

The vapor barrier should be placed on the ceiling in such a way that the fabric extends along the entire perimeter of the walls and that all corners are closed. The joints of the canvases should be on the floor joists - this will allow them to be securely fixed. To properly install a vapor barrier on the ceiling, monitor the tension of the canvas, it should not sag

.

Ceiling installation

We will also consider how to install a vapor barrier on a concrete floor. To insulate a ceiling or flat roof made of a concrete slab from the inside, you need to attach a waterproofing coating (vapor barrier film) to it using self-adhesive tape, and then install a sheathing made of bars or a metal profile.

Vapor barrier of walls

When using residential and utility rooms, moisture inevitably forms. Evaporating, it tends to escape through the walls and penetrates the thermal insulation material used in frame construction. change their structure and geometry when wet .

The filler layer begins to sag, forming voids and cracks. As a result the thermal contour of the building is disrupted , since the main condition for high-quality thermal insulation is a tight fit of the mats to the wall. To reduce the rate of water penetration into the insulation, vapor barrier films are used.

Vapor barriers have a porous multilayer structure.

In the West they are called vapor retarders. The front side of the film has a rough surface, the back side has a smooth surface. The roll is installed with the smooth side facing the insulation. The rough plane faces the inside of the room so that moisture particles settle on it and evaporate .

The walls of bathhouses, saunas, and summer kitchens are lined with vapor barrier materials inside and out. The basic rule here is this: the vapor permeability of the partition should increase from the inside out, so the outer film is placed with the rough side facing the wall, and the smooth side facing the outer insulation . Special vapor barriers should be used:

- Polypropylene films – Yutafol, Yutavek.

- Membrane films - foil Izospan, Izover, Izovek, Tyvek Solid, Tyvek Supra.

Various homemade options, such as polyethylene pierced with nails, are useless and even harmful. It does not retain steam, but only condenses it. The room, meanwhile, turns into a “plastic bag”. The insulation becomes deformed, the walls begin to mold and collapse, not to mention the harm to human health.

- All the nuances of finishing a wooden house with siding are described in detail in this publication.

- Our article will tell you how to properly heat and waterproof roof pipes.

- Read about the types of soft roofing TechnoNIKOL here.

Installation features

It is important not only to install the vapor barrier correctly, but also to ensure a ventilation gap between the vapor-proof layer and the cladding of the structure for finishing, for which purpose counter-battens are placed along the sheathing

. Moisture settling on the rough side of the laid vapor barrier sheets will evaporate naturally without damaging the finish.

Diagram of an insulated roof with a ventilation gap

If the vapor barrier is installed correctly, the insulation is reliably protected from moisture. Almost half of the problems associated with freezing and damage to structures are associated with defects in the installation of the vapor barrier

.

Each of us creates the conditions for our own living with our own hands: the microclimate in the room and a safe environment.

Air humidity has a strong influence on human health. Maintaining its optimal value inside a living space is a complex technical task, which is not always provided not only by home craftsmen, but also by experienced builders.

Correctly installed vapor barrier and waterproofing of all load-bearing structures of the building help to avoid mistakes.

Commercial offers from marketers of individual manufacturers, advertising building films in terms of waterproofing, windproofing and even steam and waterproofing, are used to indicate the normal operating conditions of insulating materials.

But these terms are often intended to increase sales, and they mislead ordinary people, being a prerequisite for creating serious mistakes in construction.

Features of vapor barrier installation

In order not to get confused in the recommendations, you should reduce the rules for attaching a vapor barrier to a wall, ceiling, or roofing to two main positions:

- Which side to attach?

- Is there a need for a gap between the vapor barrier and thermal protection?

A gap for ventilation between the film and the insulation of 2 to 5 cm is left when working with Izospan.

Preparatory work

Preparatory work inside the premises is of a general construction nature. It is necessary to reliably insulate exposed electrical wires, prepare the necessary tools and a workbench. Once again, you should make sure that you know how to properly attach the vapor barrier. Then unwind the roll with the desired side up.

Technology for laying vapor barrier on the ceiling

When installing the vapor barrier on the ceiling, to the inside of the wooden paneling, the vapor barrier is placed with the rough side facing the room. Using a stapler, the strips are secured with an overlap of 10 cm. An overlap of up to 5 cm is left on the walls around the perimeter. The joints are glued with special tape. The film must be stretched, sagging must not be allowed, so it is fixed in the right places with intermediate slats. The rules for laying vapor barrier for the ceiling allow the use of both conventional PVC film and Izospan.

Technology for laying vapor barrier on the floor

Vapor barriers for floors are used to prevent laminate, parquet, and natural boards from absorbing excess moisture.

On the prepared, cleaned and primed base coating (concrete floor), thermal insulation is laid between profile 5-centimeter slats, followed by vapor barrier material (rough side up), the strips are overlapped using tape. It is necessary to release a reserve of up to 5 cm around the entire perimeter of the room, and glue the film with tape with an overlap of 10 cm. Next, heat-insulating foil is laid and secured with tape. Next, the flooring is installed.

Rules for installing a vapor barrier layer on walls

In frame buildings with external insulation, the vapor barrier material Izospan A is used. The material is laid on the outside of the insulation under the outer skin of the building with the smooth side facing out. Laying is done from the bottom up in horizontal stripes, fixed with a stapler, the strips are overlapped by 10–15 cm. Wooden counter-battens are attached on top of the insulation, which are used for installing the sheathing. Be sure to make a ventilation gap equal to the thickness of the slats.

The vapor barrier for the walls of a wooden house is attached directly to the insulation from the inside, with the smooth side facing it. The vapor barrier film should be laid from bottom to top in horizontal stripes overlapping to a width of 10–15 cm.

Principles for creating protection for a building from the formation of dampness

To understand the essence of the issue, let us recall a little the simple natural phenomena that constantly occur in front of us, and pay attention to them.

Physical terms

General provisions

Since school, we know that all bodies come in three states:

This fully applies to water, which in our usual understanding is in the form of a liquid and has fluidity. Its additional names are “moisture” and “hydro” - a word formation from the Greek language. The term steam refers to its gaseous state, and ice refers to its solid state.

What is steam

We assume that you immediately have an image of a kettle with boiling water and clouds of scalding steam coming out of it. Let us try to reassure you that this is far from a complete and partially misleading idea.

The normal gaseous state of water in the air is hidden from our view. We cannot observe vapor dissolved inside the air. But if you feel high or low humidity in it, you can feel worse.

If steam is completely removed from the air, then a person will not be able to live in such an environment. It has been experimentally found that the optimal air humidity for different people ranges from 40 to 60%. Moreover, this indicator is purely individual and depends on many factors.

To maintain optimal humidity in the rooms, natural or forced ventilation is created, which, while ensuring good air exchange, prevents windows from fogging up.

What is waterproofing

A similar phrase is used in construction to designate structures that can resist the penetration of water from the external environment. For example, the roof of a building protects from the action of rain, and the coating created on the foundation protects from the absorption of ground moisture from the soil by the capillaries of concrete structures.

Various materials are used to create waterproofing:

- metals;

- asphalts;

- bitumen mastics;

- plastics;

- mastic sealants and other compounds.

Very good waterproofing works on a submarine, but we are only interested in film materials for buildings now.

What is a vapor barrier and a vapor-permeable membrane?

The term steam refers to the gaseous state of water. It is part of the air around us. Therefore, this is moisture that is dissolved in the airspace.

If we use an analogy with waterproofing, then we must clearly understand that vapor barrier does not allow steam to pass through at all, it isolates it, and even more so water.

Theoretical developments of scientists, which were implemented on an industrial scale by major manufacturers, led to the creation of membrane film materials with unique properties. Without going into their complex structure, let us pay attention to the result: they are absolutely impermeable to water in a liquid state, but they allow steam to pass well in both directions.

And since in our residential buildings moisture evaporation accumulates, created during cleaning, washing, cooking, due to breathing and evaporation through the skin, then their excess must be removed from the premises. Microporous membranes work on this principle.

It should be understood that the term vapor barrier implies insulation of premises from the escape of steam, that is, it creates its accumulation and concentration.

And the function of removing steam through building structures from living rooms while simultaneously protecting against the penetration of wind and raindrops, that is, liquid water, is assigned to vapor-permeable waterproofing.

How is floor vapor barrier carried out?

There are many types of vapor barrier materials. The work can be done with simple or reinforced polyethylene film, polypropylene or penofol. But the most universal and easiest to implement is the vapor barrier of the floor with a breathable membrane. Although this material is expensive, it has serious advantages. Suffice it to name the following:

- Easy installation . Unlike other materials, breathable membranes can be installed without creating an additional ventilation gap.

- One-way steam transmission . A unique feature of such membranes is that they allow steam to pass in only one direction. On the other hand, the material provides not only vapor insulation, but also waterproofing.

- Doesn't take up much space when installed . The vapor barrier is laid on the floor joists. The breathable membrane makes the best use of the space between them.

Now that the material for the vapor barrier has been selected, we should consider the technology of the work itself.

Purpose of films in roofs and walls

Vapor-permeable membranes allow steam to pass in both directions. But, nature so decreed that it always goes along with the flow of air from the warm side to the cold side.

Considering the characteristics of our harsh climate and the length of the heating season in residential premises, we can confidently assume that steam most often leaves the rooms on the street, rather than enters them.

At the same time, the pattern of steam movement through walls, floors, ceilings, doors and other building elements depends on the materials and methods of manufacturing these structures. Let's take a closer look at them.

How vapor diffusion occurs through a single-layer structure

Using the example of a homogeneous wall of a house, it can be argued that the penetration of steam from a warm apartment into the cold outside air of the surrounding atmosphere proceeds equally, evenly. Even in construction descriptions, one can often find an allegory for this phenomenon, when the authors write that the walls of wooden houses “breathe,” using a collective image to describe the processes taking place.

A wall made of any homogeneous building material: wood, brick, concrete, stone, aerated concrete, created in one layer, does not create obstacles to the diffusion of steam. When a structural element has several components, the vapor permeation pattern changes.

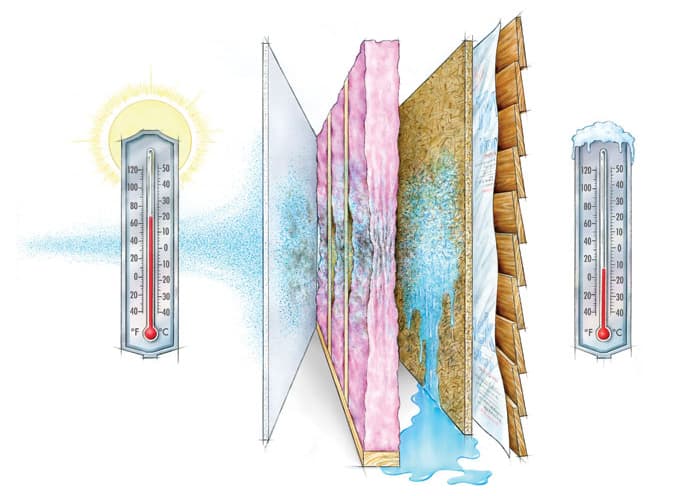

How does vapor diffusion occur through a multilayer structure?

In a wall consisting of several building layers, the vapor permeability increases as it moves towards the cold.

This explains the fact that steam comes out of each successive layer of the wall faster than from the previous one. Therefore, an area of saturated steam does not appear inside a multilayer wall, when it is able to condense and fall out as real moisture - water, forming a dew point.

However, this purely theoretical explanation is very difficult to implement in practice for a number of technical reasons.

Membrane structure and operating principle

The membrane consists of several layers of film with microscopic perforations. The holes are not able to let a drop of water through, but easily allow steam to pass through. Inside the membrane, moisture is distributed over the entire area, evaporates, or flows down through internal channels.

Vapor barrier prevents the penetration of wet vapors into the heat-insulating layer and prevents condensation from falling on wooden and metal structural elements. When wet, thermal insulation ceases to perform its function, accumulates moisture and becomes a source of threat to the wooden and metal structures of the building. Over time, wet insulation develops mold, which spreads to nearby areas and can affect a large area.

A properly installed vapor barrier becomes an impenetrable obstacle to moisture and locks it in. Moisture remains outside the heat-insulating cake, but this leads to the accumulation of vapors inside the room. If some of the moisture nevertheless penetrates into the thermal insulation (through fastening holes, at the junction of the strips, small damage in the film), it is blocked there and begins its negative destructive effect. Ordinary PVC film often provokes such consequences.

A vapor barrier membrane has the property of allowing moisture to pass in one direction, preventing its reverse penetration. Manufacturers even regulate the degree of this penetration, producing vapor barrier materials with different technical characteristics. This allows you to select a membrane with the parameters required in each specific case. Thanks to the correct choice of vapor barrier, optimal ventilation conditions are created in the room while simultaneously conditioning the internal heat-insulating layers. At the same time, the vapor barrier must be attached in strict accordance with the technology, otherwise moisture penetration bridges will arise, which will significantly reduce the overall effectiveness of the protection.

How to install vapor barrier on walls and roof

When installing building structures, for example, composite walls, it is necessary to take into account the actual passage of steam through all elements. Otherwise, a situation may arise when a pair that has passed through several layers does not have time to overcome the next obstacle due to an obstacle that has arisen, and the next batch is already supporting it from behind.

In such a place, steam will begin to accumulate and its saturation will increase. At some point, at a certain temperature, it will reach a critical state and condensation will begin to form at the boundary of the problem layers with the release of water.

In our example, we encountered a “dew point” formed inside a composite wall before the last exit layer, when an obstacle appeared in the steam path, limiting its exit and leading to the formation of condensation.

In practice, a similar situation often occurs when the owner sheaths the walls on the outside of the building with a material with poor vapor conductivity: impregnated plywood, fiberboard, OSB, but on the inside of the wall there is no vapor barrier or it is of very low quality.

As a result, it turns out that moisture accumulates on the inside of the outer skin due to condensation, and the adjacent layer of insulation - mineral wool or polystyrene foam - becomes constantly wet and ceases to fulfill its intended purpose. A dew point formed on their surface.

This technical issue can be resolved in one of two ways:

- based on theoretical knowledge and practical experiments, select building materials for each layer so that in the overall wall structure they eliminate the formation of condensation and do not create obstacles to the passage of steam to the street;

- install a vapor barrier inside the rooms of the building and ensure its maximum tightness.

The first method requires highly qualified workers and high-quality installation work, while the second is much simpler and consists in the fact that steam from residential premises is simply not allowed to enter the walls and roof, but is removed through the ventilation system.

A layer of hermetic vapor barrier installed on the side of the room guarantees the absence of condensation inside the walls and roof.

Construction companies in Western countries follow this path, using one of two materials:

- aluminum foil;

- ordinary polyethylene film 200 microns thick.

Foil has better vapor barrier properties, but is more difficult to install. Therefore, polyethylene is preferred.

The vapor barrier layer must be completely sealed. Since sheets of film need to be joined, builders mainly use two methods:

- installation of overlapping layers with an overlap;

- gluing the joints with special tape.

The first method is widely promoted on the Russian Internet. It's easier to do. But it does not provide complete tightness and steam can pass through small cracks and form condensation right inside the walls, which is very bad.

For this reason, you should use tape, seal all joints, seal openings for electrical wiring, pipelines and all household communications. Only then will the vapor barrier work effectively, blocking steam from entering the wall materials.

Poorly executed vapor barrier causes the formation of a wet wall or roof, creating excessive humidity with all the negative consequences. You can still put up with it if the building is used for living during the summer dacha period, and in the winter it stands idle without heating.

When people live in such a house all year round, the likelihood of condensation forming in the walls and dampness occurring is very high. The volume of accumulated moisture can be measured in liters.

Waterproofing walls before covering with profiled sheets

Cladding facades with cold-formed metal corrugated sheets is an economical and very common solution for low-rise buildings. The cladding technology is simple, but has its own characteristics. A cross-section of an external wall lined with corrugated sheets looks like this:

- Wall.

- Vapor barrier layer.

- Insulation.

- Waterproofing film.

- Profiled sheeting.

The first stage of work will be horizontal waterproofing of the walls. To do this, two layers of roofing material are laid on the horizontal surface of the finished foundation, after which the walls are laid. Ignoring this stage makes vertical waterproofing useless.

Waterproofing walls - causes and consequences

The fact is that a concrete foundation absorbs and retains moisture in its pores . Next, capillary suction (moisture absorption by the wall material) is included in the process. Groundwater freely rises up the load-bearing walls, sometimes to a considerable height (up to the second floor). This causes permanent dampness in the room. It is very difficult to correct the situation: trimming the walls, practiced in these cases, is a very labor-intensive and ineffective solution to the problem.

Vertical waterproofing is a sealed covering of the building's load-bearing frame with rolled material . With today's construction technologies, such an approach is becoming an urgent necessity. Even 30-40 years ago, the thickness of a brick wall reached 75 cm, without requiring additional protection. Today, most walls are two to three times thinner, but have a multi-layer structure.

According to modern regulatory requirements, the strength base of a residential building, consisting of blocks, bricks or timber, has an average thickness of 25 cm. The rest is insulation, waterproofing and cladding. If the frame is even thinner, then insulation boards are laid on the outer and inner sides of the wall. The main attention is paid to the tightness of the layers.

Waterproofing films

For high-quality waterproofing of walls, the following materials are traditionally used:

- Roofing felt is roofing cardboard impregnated with petroleum bitumen and coated on both sides with refractory resin.

- Roofing felt is insulating cardboard treated with coal or tar compounds.

- Glassine is a soft roofing material impregnated with bitumen.

Of the new developments, Gidrostekloizol, Stekloelast, Rubitex, Linokrom, Bicroelast, Bikrost have already stood the test of time.

How is waterproofing created?

After the vapor barrier has blocked the access of moisture from the living space to the wall, it is necessary to prevent it from entering from the street. This function is assigned to a vapor-permeable membrane.

Wind protection and waterproofing of walls

In houses built using frame technology in the West, a vapor-permeable membrane directly protects the outer layer of OSB boards, onto which façade materials, for example, siding blanks, are immediately mounted. They are placed directly on the slabs, without creating air gaps with lathing.

In case of heavy slanting rain due to construction defects in installed windows, leaking roof elements and other reasons, water can get behind the siding and accumulate there. This will lead to rotting of the materials and their destruction.

For this reason, all moisture must be removed. Vapor-permeable membranes with a one-sided operating principle prevent water from getting onto the external material of the OSB wall and at the same time, when it has penetrated there through extraneous means, they facilitate its exit to the outside.

At the same time as water drainage, the membrane provides protection from wind.

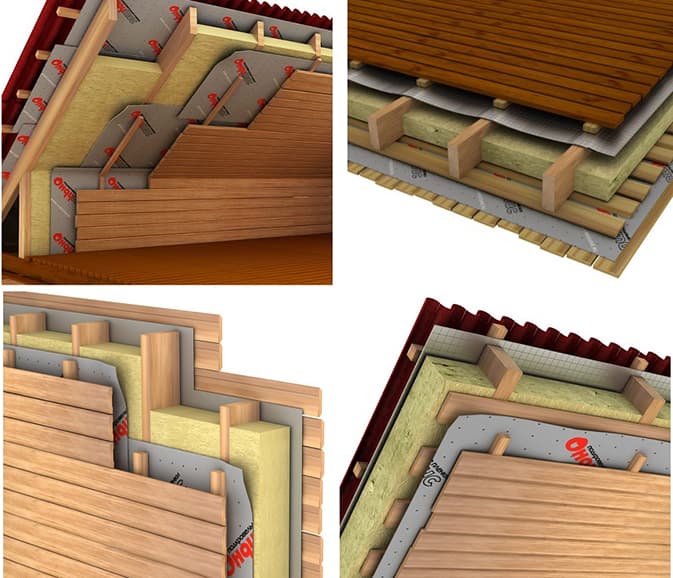

The role of a waterproofing membrane on the roof

On modern roofs using pitched technology, a superdiffusion waterproofing membrane is installed. The prefix “super” denotes increased vapor transmission properties (providing diffusion).

Protective sheathing slabs are usually not placed under a metal tile roof, and the insulation is protected by a vapor-permeable membrane from moisture penetrating into it. It also resists wind well. Therefore, it is additionally called windproof. In the roof, just like on the wall, it is always located outside the insulation.

Structurally, vapor barrier membranes can be manufactured for different methods of placement on insulation and mounted:

- with the creation of a ventilated gap;

- or close.

When installing, you should pay attention to this point.

Where is vapor barrier and waterproofing installed?

Some building owners have a desire to save on materials and install layers of vapor barrier made of cheap polyethylene film on both sides of the wall. This idea can be justified when the entire construction technology is carried out with ideal quality and does not provide a single point of moisture leakage to the building elements.

What do errors in terms lead to?

Manufacturers' marketers are interested in increasing sales of vapor barrier films and waterproof vapor-permeable membranes. They advertise their properties in every possible way, coming up with various names. Thus, the complex word vapor-waterproofing was created, which led to confusion of the characteristics of two completely different materials used to solve opposing problems.

Due to this, building owners can allow the installation of vapor barriers on both sides of the wall structure, when moisture cannot escape from the building elements and will create increased dampness and their destruction.

An even worse situation with moisture occurs when the location of the vapor barrier, which was installed outside the wall, is confused with the vapor-permeable membrane installed inside the room.

Then all the moisture from the room is directed into the wall, and its exit is blocked. As a result, mold, fungi, and dirt form.

Final Recommendations

Let's summarize the use of film materials for the home craftsman:

- In cold climates, the vapor barrier membrane is placed exclusively from the inside of the room, regardless of the type of building structure - wall or roof.

- In order for the vapor barrier to work effectively, it must be made as airtight as possible, using a construction type of tape with a butyl rubber base of glue, which effectively glues the film for the entire period of operation.

- An ordinary polyethylene film 200 microns thick works optimally as a vapor barrier. It is a good alternative to advertised “brand” models.

- The installation location for vapor-permeable superdiffusion membranes is the outside of the building.

- Before installing the membrane, it is necessary to clarify the distance of its location from the surface to be protected: close or at a distance. You can find out this in the instructions that manufacturers put in a roll of film and post on their website, and it is better to double-check the seller’s recommendations.

- The quality of vapor-permeable membranes is higher from well-known manufacturers from Europe and America.

To better understand the topic of vapor barrier and the role of vapor-permeable membranes that create waterproofing, we recommend watching a video by the owner of ASC Group.

Now it’s convenient for you to share the article with your friends on social networks and ask any questions you have in the comments.

The site uses modern web technologies and your browser (web browser) does not support them. To work with the site, update your browser or install any of the recommended ones:

By category

A vapor barrier membrane is a non-woven two-layer material designed to protect insulation from moisture penetrating from premises in the form of steam (which arises from hot water, air exhaled by people, etc.). The membrane prevents the formation of condensation on the insulation and supporting structures, protects the structures from the appearance of fungus and thereby extends the life of the house.

Why do you need a vapor barrier membrane?

Vapor barrier is used to protect hygroscopic (moisture-absorbing) insulation (mineral wool, expanded clay, ecowool, sawdust). Moisture enters the insulation not only from the outside in the form of precipitation, but can also accumulate as a result of normal human activity - cooking, using the shower, and even normal breathing!

The relative humidity in rooms especially increases with the onset of cold weather - the lower the temperature, the more moisture begins to condense on colder surfaces.

Unprotected insulation absorbs moisture from the premises, but cannot quickly evaporate it. This increases thermal conductivity, which negates all the properties of the insulation. If the insulation material remains damp for a long time, the interior decoration of the premises will also become damp. Mold and mildew will begin to develop on it, which can lead to serious illnesses for humans.

How does a vapor barrier membrane work?

The principle of operation of a vapor barrier membrane is to absorb moisture and its further evaporation. The two-layer structure prevents the insulation from getting wet: the fleecy side absorbs and evaporates moisture, and the steam and waterproof layer does not allow it to pass further.

Vapor barrier membranes are much more effective than ordinary single-layer films:

- durable and lightweight material is much easier to install;

- a special absorbent layer prevents condensation from appearing on the film;

- To organize a vapor barrier, laying it in one layer is sufficient.

Where is the vapor barrier membrane used?

The small thickness of the membranes allows them to be used in all types of multilayer structures - frame houses and buildings made of SIP panels, walls and ceilings insulated from the inside. It is used:

- for the attic floor, if the attic is not heated;

- for the roof of the roof, if a warm attic is built;

- for the ceiling - if the upper floor is not constantly heated;

- for interior walls - especially in rooms with high humidity.

For the floor, a vapor barrier can be used on the outside of the insulation if the subfloor is not in contact with the ground, but from the inside it is better to cover the insulation with vapor-permeable waterproofing to ensure ventilation.

Choosing a side for installing a vapor barrier

It remains to understand the principle of which side to attach the vapor barrier.

To do this, you need to imagine where to remove moisture from and where to direct it:

- Floor - expelled under the floor, the rough absorbent side absorbs, the microstructure transports, expels, the smooth prevents return. Rough side up.

- Walls - taken from the room, directed outside, to the street; The rough side inward, into the room.

- Ceiling – removes excess humid air from the room. The vapor barrier is attached with the rough side to the room and the smooth side to the thermal insulation.

- Roof covering - removes moisture from the heat-saving layer to the outside, while simultaneously blocking the penetration of atmospheric moisture under the roof. Install with the rough side facing the thermal insulation and the smooth side under the roof. The inside should be absorbent!

Types of vapor barrier membranes

Vapor barrier membranes are made of non-woven polypropylene and are divided into two types - anti-condensation and foil films (heat-reflecting). The properties and characteristics of membranes determine the scope of its application:

| Anti-condensation films | Foil films | |

| Properties | absorb moisture, preventing condensation | reflect thermal radiation, reducing heating costs, and prevent the formation of condensation |

| Characteristics | — equivalent diffusion thickness from 0.4 to 100 Sd/m; — vapor permeability up to 10 g/m2; — heat resistance from −40 to +80⁰С | — equivalent diffusion thickness from 5 to 150 Sd/m; — vapor permeability up to 10 g/m2; — heat resistance from −40 to +150⁰С |

| Application | all types of walls and ceilings, except for rooms with high temperatures | all types of walls and ceilings, including vapor barrier for steam rooms in baths and saunas |

Vapor barrier membranes Ondutis

Ondutis membranes can be used in frame walls, warm roofs and insulated floors.

The vapor barrier membrane Ondutis B (R70) has a high breaking load (≥110 ≥80 N lengthwise/transversely) with a weight of only 70 g per m2. The equivalent diffusion thickness, indicating resistance to vapor penetration, is 5.4 Sd/m. At the same time, the film is not afraid of temperature changes and is compatible with all types of thermal insulation.

Ondutis R Thermo foil film can withstand temperatures up to 120⁰C, which allows it to be used for vapor barrier in saunas and bathhouses (thanks to 11.54 Sd/m). The film can withstand ≥150 ≥130 N tensile lengthwise/transversely, which makes its installation extremely simple (unlike ordinary foil).

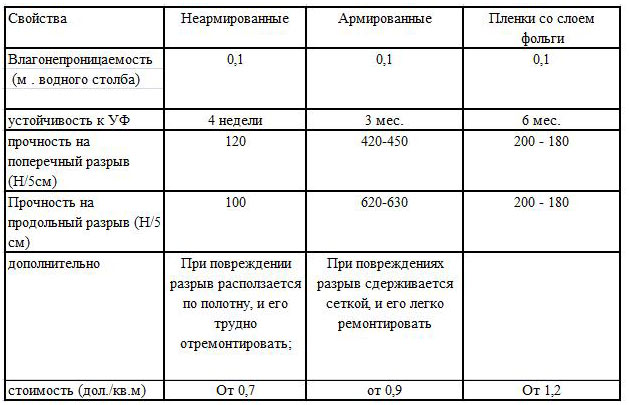

Types of vapor barrier films, properties ↑

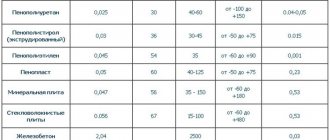

The need for this kind of insulation, like waterproofing, is specified in building codes. According to GOST, the vapor barrier film must have the following indicators:

- Weight. Its value and the value of density, an indicator of insulation strength, are directly proportional. Strong material is not only convenient to work with, but also better resists the effects of gravity.

- Vapor permeability. Its performance properties improve as this indicator decreases. For residential premises in Russian conditions, brands are suitable whose vapor permeability is significantly less than 1 g/sq. m.

The choice of vapor barrier is a crucial moment. We must not forget that technical polymers may contain various additives, for example, plasticizers or ultraviolet radiation stabilizers, which contribute to the accumulation of harmful substances in a confined space. It also cannot be ruled out that the product was made from low-purity base raw materials.

We recommend

Determining the harmfulness of a vapor barrier material is quite simple. If you roll out a roll in a closed, warm room, the low-quality film will begin to emit a specific smell that you cannot help but notice the next time you visit the room.

Varieties for roofing ↑

- Polyethylene vapor barrier film. One of the most popular insulation options. Despite the fact that it is cheaper than others, this option is quite effective. As a rule, the material is reinforced, for which a special reinforcing mesh or fabric is used.

There are:

- perforated, equipped with micro-holes that provide vapor permeability. However, its level does not meet the standard, so the presence of a ventilation gap in the roofing pie is mandatory;

- smooth (non-perforated) - when installing them, use a special tape for vapor barrier film, which is used to connect individual sheets;

- foil vapor barrier films. They have fairly high performance qualities, and also reflect heat back.

Attention!

Laminated insulation is not suitable for vapor barrier in rooms with a normal microclimate. They are widely used when arranging rooms with high humidity, for example, saunas or swimming pools.

Comparison table for vapor barrier films

- Polypropylene. They are distinguished by a very high level of strength and resistance to ultraviolet radiation. Particularly in demand are materials with an anti-condensation layer made of viscose with cellulose, which absorbs and retains moisture. The advantages of such a layer are obvious: it not only completely absorbs moisture, but also dries instantly naturally as soon as the causes of condensation disappear.

- Diffusion membranes. This is a synthetic non-woven material. It is much more effective than polyethylene or polypropylene products. True, their cost is much higher.

- Liquid rubber. This is a cold emulsion of polymers that is sprayed over the surface using special equipment. The undoubted advantage of this option is the ability to use this type of vapor barrier in roofing structures that have even the most intricate shape.

How to choose a membrane

When choosing a vapor barrier membrane, you need to pay attention to:

- Sd index - the higher it is, the lower the vapor permeability;

- temperature range - especially important for buildings that are heated irregularly;

- strength - vapor barrier will be effective only if the integrity and tightness of the film is maintained.

The price of the material also plays an important role in the choice. First of all, you need to focus on the conditions: is the room heated, what temperature conditions are maintained in it, what are the air humidity levels, etc.

You can read more about choosing a vapor barrier in the article “How to choose a vapor barrier film.”

Installation of a vapor barrier membrane

Installation of vapor barrier membranes does not require special qualifications. The main thing is to correctly lay the material with the right side facing the insulation and ensure that the joints are completely sealed.

Important details:

- Before starting work, be sure to read the instructions on the packaging.

- Prepare the necessary tools in advance: scissors, a staple gun, tape measure, insulating tape and a pencil.

- Cut the panels to size and only then proceed with installation.

- Lay the strips with an overlap of 5-15 cm, seal all joints with Ondutis BL or ML tapes.

- When installed indoors, the vapor barrier membrane is laid close to the insulation.

- When carrying out external work, it is necessary to arrange a ventilation gap.

How is a floor vapor barrier carried out?

The procedure does not involve any complex actions. It differs from standard flooring in a house only in the use of a vapor barrier. However, the use of a breathable membrane still requires taking into account some additional aspects.

- Arrangement of a log system . In most cases, logs are placed in increments of 50-100 cm. It is necessary to choose a specific distance taking into account the width of the insulation, which will then be used, as well as the thickness of the boards for laying the subfloor.

- Thermal insulation of the floor . The insulation boards should fit between the joists as tightly as possible. It is best to choose mineral wool.

- Vapor barrier breathable membrane flooring . As previously indicated, the breathable membrane can be laid directly on the insulation, since it does not need additional ventilation. The most important thing is that such material overlaps, which is usually 10-15 cm. To secure the vapor barrier, you can choose staples, small nails or even self-tapping screws. All joints between vapor barrier sheets are taped with mounting tape.

- Formation of the subfloor . After laying the breathable membrane, all that remains is to form the flooring for the finishing cladding. This work is done using ordinary boards. Then the final activities begin.