How to seal cracks in a wooden house

A wooden house is a safe and environmentally friendly home with a special cozy atmosphere. Wood retains heat perfectly, fills the house with a pleasant forest aroma, and is highly durable and durable. This is an aesthetic and attractive material that will harmoniously fit into the landscape and allow you to create any design.

However, wood has a number of disadvantages, including susceptibility to the negative effects of moisture, torsion and drying out, and shrinkage. As a result, cracks appear on the log and timber, as well as between materials.

Cracks and crevices in a wooden house

As the house shrinks and due to strong temperature changes, lack of proper insulation and waterproofing, cracks appear on wooden materials and between them. To avoid this, it is important to treat the wood during construction.

Logs and beams are coated with antiseptics after the manufacture of lumber, during the assembly of the log house and during the final finishing work. In the future, a wooden house also requires maintenance. Protective treatment is carried out every 3-6 years, depending on the type and quality of antiseptics.

In this case, it is very important to carry out competent and reliable insulation of a wooden house, as it protects the timber and logs from severe cracking. In addition, you need to choose products with good drying.

The craftsmen of the construction company “MariSrub” independently produce beams and logs and carefully monitor each stage of production. We use safe and high-quality chamber drying, which prevents wood from cracking. Be sure to treat lumber with protective compounds!

If cracks and cracks appear, the defects must be eliminated. They reduce the thermal insulation properties of the house, as a result the walls or floor will be blown through, and drafts will appear in the room. In addition, cracks greatly spoil the aesthetic appearance of the house. In the future, the cracks grow and aggravate these problems, negatively affecting the condition of the lumber. Therefore, it is important to eliminate defects in a timely and correct manner.

Types of cracks

Longitudinal cracks and cracks form on a beam or log, since the tree has a fibrous structure. But in rare cases, longitudinal defects also form due to overload or wood rotting. With this problem, the affected areas need to be replaced. Longitudinal cracks can be eliminated independently using easy methods.

Longitudinal cracks in structure and direction are of the following types:

- Straight lines coincide with the axis of a log or timber;

- Spiral or uneven are not aligned with the axis;

- Segmental - uneven defects with a fiber transition.

You can seal gaps and cracks using polyurethane foam, tow and moss, putty or sealant, or homemade compounds, regardless of the type of defect. Note that it is better not to use polyurethane foam and silicone for a wooden house, since synthetic products violate the environmental friendliness and safety of wood. After such treatment, the log or timber will not be able to “breathe”. In addition, such compositions often emit a harmful, toxic odor. Let's take a closer look at how and how to seal cracks in a wooden house.

How to seal cracks with caulk

Caulking effectively insulates the house and closes the resulting cracks, reliably blocking the access of cold to the room. Moss and tow are traditional materials for insulating a wooden house and for sealing cracks, which are environmentally friendly and safe. They will not disturb the naturalness of the wood and the aesthetics of the structure.

Before use, take wet moss and dry it completely, and then soak it in water half an hour before starting work. Then the water is drained, the moss is squeezed out and rolled into rolls. The rollers are placed in the crown joints, crevices and cracks, compacted with a hammer or mallet and left to dry for three days. After drying, excess material is trimmed.

Instead of moss, you can use tow or jute fiber, which is placed in joints and cracks. Tow, if desired, is filled with plaster or cement or left in its pure form. The quality of the caulk can be checked with a nail, knife or sharp awl. The product is stuck between logs or beams. It shouldn't go right through! Read more about caulking a wooden house here.

How to seal cracks with sealant

Eliminating cracks and cracks using sealing is the most common method due to its accessibility and ease of installation. Sealants firmly connect the walls of the wood gap. To prevent the product from getting onto the surface of the wood, cover the edges of the crack with masking tape. Then a strand of tow or jute or fabric for compaction is placed in the cracks and inter-crown joints. And the sealant is applied on top using a spatula or a gun.

When applying sealant, seams, joints and cracks are not completely filled to the brim. The composition is applied so that it comes into contact at two points of the tree and connects two opposite edges. The sealant is left for at least six hours, and after hardening, the sealed cracks are painted over to obtain a more aesthetic appearance.

If the product does get on the clean surface of a log or beam during work, remove it with fine sandpaper after drying. The masters of the MariSrub company efficiently and quickly seal a wooden house, which ensures reliable hydro- and thermal insulation, and also prevents the wood from drying out and the appearance of cracks or crevices.

The most optimal solution for a wooden house is acrylic sealant. This is an environmentally friendly and safe product without odor. It is not afraid of temperature changes and dampness, reliably fastens the walls of wood and eliminates cracks or crevices. Silicone sealant cannot be used for a wooden house due to its harmful composition. In addition, such material cannot be painted, and it will ruin the appearance of the wood. The most popular brands are Neomid and Eurotex, made in Russia.

How and with what to effectively solve the problem

But what to do when cracks have already appeared? There are many ways to help quickly and efficiently deal with this problem.

Sealing with putty

Of course, it will not be possible to completely get rid of the cracks that have appeared. But it is possible to completely seal them and prevent the risk of growth.

You can use one of the following sealing options:

Sawdust and PVA mass

This is a homemade sealing impregnation, which is the most affordable. Its components are mixed in the proportions necessary to form a thick base, similar to putty. The mixture is used to completely fill the cracks (if after drying part of the mixture falls off, this place is re-filled with homemade putty). For convenience, use a regular spatula.

wood chips

It is used to seal very deep and large cracks. It is better to select chips of the same length as the logs. The pieces of wood are first sharpened with a wedge and hammered tightly into the splits. The top is additionally reinforced with ready-made putty or homemade PVC putty.

Gypsum with sawdust or crushed bark

This mass is also called “arbogypsum”. This method of sealing provides the log with durability and reliability. To make the mass, dry gypsum powder is mixed with bark or sawdust. The mixture is thoroughly kneaded and diluted with water (the volume of liquid is equal to 1/2 of the gypsum mass). The finished putty is dense and very elastic; it must be mixed to destroy lumps. To enhance penetration, add a little regular shampoo. The crevices are covered immediately after the mass is made (it hardens instantly).

Moss

For larger splits, use moss caulk. Moss is an environmentally friendly and completely safe raw material. It will cover the cracks perfectly. It will also additionally retain heat in cold weather, blocking the access of cold air. Dried moss is used for putty. Before use, it is soaked for 20-30 minutes in clean water, squeezed out and rolled into strong rollers, which are placed in the cracks. Using a mallet, hammer it in more tightly until the layer springs back. After 3-4 days (during this time the moss dries out), the excess material is carefully trimmed off.

All these methods from folk craftsmen will ensure quick and reliable sealing of cracks using readily available means. But don’t forget about ready-made drugs.

Choosing putty

To carry out work on the surface of logs, it is necessary to use products that, in addition to reliable sealing of seams, will protect the surface of the log from frost and rain.

Expert opinion

Levin Dmitry Konstantinovich

Water-based putty, which is thick, will adhere much better and stronger to wood than liquid compounds that contain solvents. Such (liquid) putties are best used for sealing faults that are too large and deep.

There are three types of putties for processing log houses:

. With no odor and good environmental performance. It is easy to apply and dries instantly without allowing moisture to pass through. At the same time, acrylic putties also level the surface and, after drying, do not shrink (dry without cracks). They are best used for sealing small cracks.

Acrylic- Water resistant . It is famous for its high resistance to aggressive manifestations of the external environment (rain, snow, high humidity and temperature changes). Waterproof products are prepared on an adhesive, polymer or oil base, which guarantees good application and quick drying. They are best used when subsequent coating of logs with varnish or paint is planned.

- Plaster . It provides a good microclimate, is environmentally friendly and easy to use, it is better for sealing cracks in logs inside a building. After application and drying, the seam can be further sanded and painted.

- Non-shrinkable . The most durable and high quality of all other types. It is worth working with when sealing serious, deep cracks. By the way, you can choose the color of the non-shrink putty to match the wood being processed - it is available in a variety of colors.

Additionally, it is worth studying the rating of the best manufacturing companies producing putties for sealing cracks in log logs:

| Brand | Advantages | Flaws |

| Tikkurila (Finland) | resistant to temperature changes and humidity, cold-resistant, | high cost, |

| Extra (Russia) | allowed to be used to close faults, both internal and external | Almost all types of putties are acrylic, and they are not suitable for sealing deep cracks |

| Eurotex (Russia) | Nice packaging and packing, it’s easy to work with, the mixture fits perfectly and dries quickly | shrinks after drying, poor color palette |

| Parade (Russia-Sweden joint company) | increased water resistance, easy to apply, after drying can be sanded and sanded | excessively liquid composition, which is inconvenient when sealing cracks, spreads |

| Rainbow (Russia) | dries quickly, is moisture resistant and has low shrinkage | You can work with it only at a temperature of +15⁰С |

Choosing a sealant

Sealants are another common substance that helps to properly seal log cracks. They will additionally insulate the building and are guaranteed to stop the occurrence of new chips in the logs.

When applying sealant, pay special attention to the processing of the ends (they dry out faster than other areas). The ends can also be sealed using drying oil, varnish, oil paint or wax.

The main advantage of this material is the ease of application and the speed of filling cracks. When selecting a suitable sealant, take into account the composition, its technical parameters and color palette.

The following types are used to close splits:

. Resistant to temperature fluctuations and high humidity. This product is environmentally friendly and odorless. It is better to use it for filling internal cracks.

Acrylic- Silicone . A universal substance created for work both inside and outside buildings. Resistant to temperature changes and aggressive external environments. But they are not designed for subsequent painting, although this is not a problem, since manufacturers offer silicone sealants in an expanded range of colors, including transparent ones.

- Bituminous . The most resistant sealant to moisture. It contains rubber and bitumen. Similar products are used to close splits in wood roofing and drains.

- Polyurethane . It has high strength, is resistant to moisture, is a very elastic material, and is easy to work with. But take into account its harmfulness due to the presence of certain additives in the composition. Therefore, it is better to use it for work only on the outside of the building.

When choosing, you need to understand the manufacturers offering popular types of sealant:

| Brand | Description | Add-ons |

| Neomid (Russia) | has high elasticity, resistant to moisture and temperature changes | it is possible to seal fractures with a deformation of 15-30% |

| Eurotex (RF) | a particularly resistant and elastic substance, it can be used with end-side splits | acrylic appearance, additionally provides protection against insects |

| Remmers (Germany) | resistant to aggressive environmental influences, temperature changes, well compatible with paint and varnish coatings | designed for sealing cracks inside and outside buildings, available in transparent and colored versions |

| Ceresit (Poland) | resistant to humidity, temperature changes, gives minimal shrinkage | are produced in the form of silicone/acrylic compounds |

| Check Mate (America) | belongs to elite materials, perfectly protects wood from mold and moisture, gives little shrinkage | acrylic compounds with good elasticity |

When working with sealing compound, do not fill cracks to the brim with it. It is necessary to apply the mass so that it touches only in two places, connecting the opposite parts of the split. When it dries, it will fill the crack on its own.

Cracks in timber - what to do, who is to blame, how to prevent it?

Let's talk about one of the problems when building a wooden or frame house, about cracks in the timber. Let's consider the causes of occurrence, methods of elimination and prevention.

Preventing cracks

There is no 100% recipe for preventing cracks in wood. One of the most suitable methods of protection is drying in natural conditions, in the bark, without exposure to sunlight. Such drying can take years, it all depends on the material and thickness of the trunk.

There is also a method of soaking wood in sea water for 3 years (for oak), but it is used only in the manufacture of joinery and piece products, as it requires significant costs.

Reason #1 - initially raw material

One of the reasons is the use of initially raw material, the use of raw material, profiled timber, logs or timber for the posts of a frame house. As a result, cracks in the timber appear immediately after the timber dries and excess moisture evaporates.

What to do if you bought raw material as racks for a frame house? Without a special drying chamber, you need to properly lay it out on the street. The distance from the ground is at least 30 cm, then we shift each beam or board so that air can pass freely between them. The boards should not sag in the middle or other places.

The most important thing is that the wood should be dried without the sun, i.e. in full shade. The timber should dry to 14% humidity. Only after this can our timber be treated, including with an antiseptic, and used in frame construction.

In a log house, cracks appear no matter how high quality the original material was. This does not mean that you can then take it cheaper and “rawer”, since besides cracks there are other reasons for which you should choose high-quality, dry wood.

Since one half of the beam or log of a wooden house is located outside, and the other part is inside the house, moisture absorption and shrinkage occur unevenly, depending on weather conditions.

As a result, the outer side more often cracks from stress, and these cracks cannot be avoided. And if in a few years you don’t like the appearance of your country house, you can make external cladding through counter. lath As cladding, you can use imitation timber or imitation log - block house.

Sealing cracks in a log house

Owners of log buildings are asking a very natural question about how to eliminate already formed cracks in logs. There are several ways to eliminate them, which are used depending on the size and depth of the resulting defect.

The simplest and most effective method is to purchase a special putty based on acrylic or silicone, which is intended for processing and sealing the inter-crown joints of a log house, cracks in logs (used both on the outside and on the inside). Such mixtures have proven themselves to be reliable and durable materials.

Another, no less effective, but more economical method is caulking with moss or jute. This safe material is suitable for larger crevices. The dried moss is pre-soaked, then twisted into ropes and laid, compacting with a mallet. After five days, the excess material that appears is cut off.

In the case where the cracks are more than 5 mm, it is recommended to take a block of wood similar to the size of the crack, sharpen it and drive it in with a hammer. For the best adhesion to the log house, it can be coated with PVA glue.

It should be remembered that you need to start fighting cracking immediately, because in this case, a minimum of effort will need to be made. Minor defects are easily amenable to ordinary sandpaper, and cobwebs from deeper cracks can be easily rubbed away with a mixture of glue and sawdust.

We invite you to familiarize yourself with the Stove for a closed bath

How to repair cracks in log logs: the best methods from professionals

Sooner or later, cracks appear in the logs (or beams) of a sauna log house. This is a natural process and cannot be completely prevented. And is it necessary? Small tears in wood fabric do not have any effect on the performance properties of the structure. Therefore, some owners of log houses treat the network of cracks on the logs as a decorative element.

But carelessness is not always good. If the width of the defect exceeds 3-5 mm, and the length spreads over the entire surface of the log, you need to expect trouble. Atmospheric moisture will get into the crack, and this is fraught with rotting of the wood.

Also, bark beetles like to settle in secluded tree corners; they feed on wood and are able to “sharpen” the strongest frame with their jaws.

It is necessary, if possible, to prevent the appearance of deep cracks in logs. If they do appear, then learn to close them.

Why do cracks appear on a log?

Most cracks on logs form in the first year of shrinkage. Why? It’s simple: during this period the log house shrinks and the logs dry out. This happens unevenly. The outer layers of wood always dry out faster than the inner layers. The outside of the log is almost dry, but in the center moisture remains. The difference in humidity leads to a difference in the stresses acting on the fibers. Tensile stresses begin to affect the surface layers, and compressive stresses begin to affect the internal layers. Such dissonance causes fiber ruptures in the surface layers, that is, cracks appear.

The faster the surface of the logs dries, the greater the difference in stresses that arise. At the same time, the wood cracks more actively, forming wide and deep cracks.

Method #1. Long natural drying

The best prevention is long-term natural drying of the logs before placing them in the log house. The more uniformly the logs dry across the entire thickness of the fibers, the less likely it is for cracks to appear. The drying rate in the inner and outer layers should be approximately the same. Then moisture from the inner layers will move to the outer ones, and they, in turn, will evaporate it into the environment.

Is it possible to minimize the risk of splits?

Long-term drying of wood:

- Increases the strength of the log.

- Significantly extends its service life.

When drying logs naturally, it is important to ensure their uniform drying, that is, the same drying rate for both the outer and inner layers of the log house.

This can be achieved by creating certain conditions for complete drying. This is a cool and completely dry place in which the logs are allowed to dry out for at least 2 years.

From the appearance of the cracks we can deduce how long the wood has been drying:

- 1.5-2 years: crack size up to 2-2.5 mm.

- 1-1.5 years: the splits are already expanding to a width of 7-12 mm.

- Several months: the cracks become larger and occupy a distance of 12-25 mm.

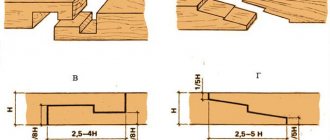

To minimize the risk of faults, a compensation (unloading) cut is sometimes formed on raw logs. This measure relieves the growing stress on the wood fibers and ensures they dry out faster.

The cut is carried out according to special standards:

- it is performed along the log;

- has the appearance of a neat, even groove;

- has a thickness of 7-10 mm;

- it is made with a depth of no more than 1/4 of the diameter of the log itself.

When cutting, to protect the tree from moisture, when collecting, the timber is laid with the cut facing up so that the cut is covered by the log lying on top.