Need for protection

Painting the ends of the log house should be carried out almost immediately after the construction of the log house. The wood dries for several years, but the ends of the logs will not be additionally protected, the process will be uneven: first the moisture evaporates at the ends, and cracks appear on them. The log will warp much more as it loses moisture unevenly over several years.

This is easy to verify if you look at any log that has lain in the open air for a year. An untreated end will quickly lose its natural wood color, turning black, and mold spots may additionally appear on it. The material is quickly attacked by fungus; it is at the ends that black spots and other traces of pest activity can be seen first.

How to treat the ends of the log house? It is important to choose a product that will not interfere with natural air exchange and uniform drying of the wood.

Classic technology involves treating with lime - this method has been used in Russian villages for hundreds of years. However, today several new means have appeared that make it possible to provide the end part of the logs with no less reliable protection:

- “Senezh Tor” is a Russian product that can penetrate several centimeters deep into wood, providing a reliable coating that allows air to pass through, but does not allow the wood to lose moisture. This prevents rotting and cracking, and the wood will be protected for a long time.

The product is environmentally friendly. It does not contain any prohibited components. It changes the color of the end part of the logs slightly.

- Neomid Thor Plus is an effective product that forms a thin water-repellent coating on the surface of wood. It allows you to protect the material from putrefactive processes and cracking, and prevents the appearance of mold and mildew. Externally, the product allows you to preserve the natural texture of the wood, so it does not reduce the decorative qualities of the log house.

- “Biotor” is another answer to the question of how to treat the ends of logs. The composition does not allow the appearance of shrinkage cracks, the penetration of moisture, the coating will provide good protection against rotting and exposure to any damaging factors. The treated material will have much less curvature during drying.

Thus, timely processing of the ends of the log house allows you to reliably protect them from cracking and other negative consequences of uneven drying. Russian products are not inferior to imported analogues, so there is no need to spend extra money on processing.

Technology for protecting the ends of a log frame using special means

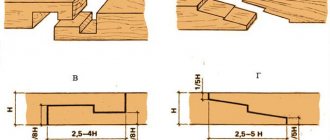

Trimming the frame is the first part of the work, which is carried out immediately after its assembly. It involves leveling the logs using a chainsaw or other tool, after which the log house will take on a neat appearance. The logs should not be too long; the ends should have a flat and smooth surface.

It is quite difficult to carry out trimming on your own; this work requires precision and accuracy. Further processing of the ends is carried out in several stages:

- Sanding the ends of the frame is a cleaning that allows you to remove all existing irregularities, mold stains, if they have appeared, and other defects. Cleaning the ends should be carried out until an even layer of clean wood is obtained; the easiest way to process this is to use a belt sander; sometimes a grinder with a flap attachment is used.

The initial processing is carried out with a machine with coarse grain P40-60, then you can move on to finer work. A completely cleaned surface will be ready for application of protective compounds.

It is important that sanding is carried out only in dry weather, when the log is dry. If you work with damp wood, lint will appear on it, and the work will simply be useless. In good weather, paint for the ends of a log house will also adhere much better and will require significantly less consumption.

- Impregnation is the application of a special composition designed to protect wood from drying out, rotting and other destructive processes. For work, you can use a wide brush, the composition is applied generously.

It needs to be given time to absorb into the wood, after which a second layer is applied. It is important to process the entire surface of the end, paying special attention to the edges.

- Application of special sealants. This is an additional treatment that allows you to create a moisture-resistant coating. How to paint the ends of the frame?

- It is necessary to purchase a special acrylic sealant designed specifically for this type of work. Examples include Kordin WV456, Zobel and others.

When choosing what to cover the ends of a log house with, it is important to pay attention to the environmental friendliness of the products and their composition. When processing, you will need significantly more protective composition than for a section of wall of the same area. The end of the log absorbs the protective substance like a sponge, and it is necessary to carry out treatment in several layers.

Thus, how to protect the ends of a log house, and is it necessary to do it at all? Without additional processing, the end of the log will lose a lot of moisture in the first month after the frame is assembled, after which cracks and other damage will appear on it. Today, a wide variety of products are offered to protect wood, so it will not be difficult to choose the appropriate composition.

To start work, you will need a grinder and a sanding disc with P60-80 grain. Carefully sand the ends of the frame using a grinder, since the quality of these actions will determine how deep the protective composition gets into the structure of the log.

Impegnerants and septics

As a primary protection, you can use impregnating solutions, which contain various biocides that protect the tree from harmful bacteria, fungi and insects (the most dangerous of which, for example, the bark beetle). Such solutions are produced by both domestic and foreign manufacturers, for example, Tikkurilla offers seven positions of protective compounds.

Impregnating solutions are applied using a wide brush in several layers. Each subsequent layer is applied only after the previous one has dried. It is recommended to apply two or three layers of this solution with a time interval of no more than 12 hours.

The disadvantages of impregnating solutions are that they evaporate over time, so to reliably protect the wood after treatment, it is advisable to cover it with an additional layer of sealant.

Please note that the log house purchased from the manufacturer must already be treated with an antiseptic. Moreover, the processing should be deep - with logs immersed in baths with a solution, i.e. one that cannot be performed.

Oils and paints

But there is a more budget-friendly option to protect the log house - treating its ends with used machine oil, which you will find at any car service center or garage cooperative. For reliable protection, applying oil twice at intervals of 8-12 hours is sufficient.

Once a year it is necessary to carry out preventive greasing of the ends. Drying oil can also be used to protect a log house, since it has a reasonable price and is similar in effect to sealants, although over time it will evaporate and the treatment will need to be repeated. You can also paint the ends of the frame with paint that has been thinly diluted with a solvent. This method of applying acrylates or oil compounds will allow them to penetrate the wood fibers and seal them, keeping them from moisture and fungus.

One of the important points when building a wooden house is the process of processing the end part of the log/timber. Trimming/trimming of a log frame is carried out immediately after assembling a wooden house using a chainsaw; the corners are sawed off vertically at the same level. Then grinding is carried out - coarse fibers and obvious roughness are removed. A prepared and smooth end surface is the key to a uniform and beautiful finish, as well as less material consumption.

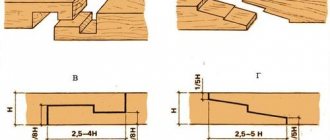

Moisture-proofing treatment of the ends of timber (logs) is not a whim of paint and varnish manufacturers, but has a technological justification. During growth, wood is nourished through fibers located in the direction of tree growth. Along these fibers, tree sap moves to the top, nourishing it. After the tree has been cut down, the movement of sap stops, but the channels remain unchanged, which is why liquid is absorbed along the end about 60 times faster than through layers of wood. Rapid moisture exchange at the sawn end leads to sudden changes in humidity and provokes internal stresses in the wood, which lead to cracking and bending of the timber (log).

The end of the log (timber) has a porous structure. And it is from the end part that the moisture exchange of the array occurs especially intensively. Therefore, it is necessary to stabilize the moisture balance of the wood, preventing the rapid escape of moisture through the end, to create a kind of protective and, at the same time, hermetic barrier. This will make the moisture exchange in the timber (log) more uniform, and the drying of the wood will be more gentle; accordingly, internal stresses and cracking of the wood will be minimized.

Wood cracking is perceived as a negative factor, which is mainly considered from the point of view of the decorative aspect, but we should not forget about a more significant aspect, such as energy efficiency. Indeed, in places of deep cracks, the thickness of the timber (log) is halved. More serious consequences are also possible: a quick-drying timber (log) can “lead”, bend, etc., which is fraught with loose connections in the cuts and drafts during the operation of the house.

That is why moisture insulation of the ends of timber (logs) is an inexpensive, but extremely effective means of keeping the house beautiful and comfortable.

On the Internet you can find many recommendations for performing moisture-proof treatment of the ends. But how effective are they? — Our detailed technological analysis of the main methods will allow us to debunk the myths and focus on the “pseudo” advice from dacha and construction forums.

The most popular methods for processing the ends of a wooden house:

1. Machine oil in two layers.

2. Drying oil (treatment is carried out every year due to the evaporation of drying oil).

3. Oil paint.

4. Lime.

5. PVA glue + acrylic varnish.

6. Professional end protection material.

1. Treatment with machine oil in 2 layers.

Oil repels water, thereby protecting the wood from moisture. In addition, the method is budgetary, machine oil is inexpensive, and on the Internet it is often recommended to use “working off”

Disadvantages of the method:

Although machine oil repels water, it does not leave a film or dry residue, so it is “washed out” quite quickly.

Oil makes the wood “greasy”, so treating it with something on top will be very problematic

Any manufacturer of paints and varnishes in the description of the material recommends preparing the surface before painting: “the surface of the wood must be cleaned of dust and oil and grease contaminants”

2.

Preventive annual treatment with drying oil.

Drying oil, when cured, “binds” wood fibers and blocks pores.

Disadvantages of the method:

Drying oil is a dehydrated, semi-drying oil that hardens due to the oxidation of atmospheric oxygen. The fact is that drying oil hardens throughout its entire service life and its hardness increases over time. At some point, the hardness and fragility of drying oil becomes such that any movements of the wood (and the wood continues to “breathe”) lead to cracking of the drying oil and its effectiveness drops by an order of magnitude

Drying oil was invented several centuries ago, and technology has changed significantly since then. Today it is almost impossible to buy Oxol drying oil made in accordance with GOST. As a rule, modern drying oil is produced from the fatty acids of tall oil, which is subsequently associated with the same problems that arise when using machine oil.

3.

Oil paint

. Oil paint, when cured, “binds” the wood fibers and blocks the pores.

Disadvantages of the method:

Oil paint is the next stage in the development of drying oil. The difference from drying oil is that instead of oils, a synthetic varnish is used, the curing mechanism of which is absolutely identical to drying oil. Accordingly, the disadvantages are the same as those of drying oil

Oil paint becomes brittle over time and can only be covered (painted over) with oil-based compositions.

4. Lime

.

Disadvantages of the method:

This method is the most difficult to comment on, since lime absorbs moisture and how this can positively affect the moisture protection of the massif is not clear. Initially, lime will “pull” moisture from the timber, the so-called “lime slaking” process, but the binding capacity of lime is limited. Once moisture is bound, there will be no moisture-protective effect.

Lime will be problematic to paint with paintwork

5. PVA glue + acrylic varnish

.

Disadvantages of the method:

This method is not effective, since PVA is not moisture resistant and the PVA layer easily allows moisture to pass through. The only positive aspect can be gluing the end and thereby preventing the opening of cracks, but this argument becomes untenable with sudden moisture exchange.

6. Use of specialized material for Teknos end protection

.

Specialized materials for end protection have the following main characteristics that make them indispensable:

They form a dense, but at the same time elastic film, which reduces moisture exchange tens of times

Dries quickly

Easy to apply

Compatible with most finishing paints

The materials are designed exclusively to protect the ends, so they have unprecedented moisture-proof properties, which are proven not by rumors “from the Internet”, but by official research reports, and at the same time have no disadvantages.

The Finnish concern Teknos has developed a unique end-face compound formulation, which today has no analogues on the wood coatings market. The manufacturer specifically draws attention to the advisability of using this material, since experience shows that the problem of cracking is the main “headache” along with the problem of the appearance of blue stains and mold on wood. The film-forming composition is particularly weather-resistant and elastic, as well as excellent adhesive properties. The use of this paint is also possible at the construction stage, protecting the end of a raw log (timber), the likelihood of cracking during shrinkage and shrinkage of the log house is reduced tenfold. It should be noted the special properties of the forming film of this sealant; it is vapor permeable, i.e. When applied to the ends, edges and cuts of wood, moisture is released evenly over the entire surface of the log. The paint does not block wood pores, but prevents the rapid flow of moisture in particularly vulnerable areas, such as the ends. The work of the Teknol JRM end compound and the dynamics of moisture absorption change in inverse proportion. The untreated end absorbs 44% of moisture on day 7, but when treated in one layer, this figure is reduced to 31%, and with a two-layer application, the positive result is especially obvious - 4%. Therefore, the paint should be applied in 2-3 layers. The film should be clearly perceptible, reminiscent of a “rubberized coating”, only in this case the material will work and fully perform the functionality assigned to it. Paint consumption is economical - 1 liter per 2 - 3 sq.m of end. The operating temperature, as for aqueous material, is optimally comfortable, above + 5ºС. When choosing a color scheme when painting a house, this material can also be tinted in either a glaze or a covering color. Another advantage of edge paint is its good compatibility with all acrylic paints and water-based varnishes. Despite the optimally adapted properties of this material for painting not only in factory conditions, the manufacturer recommends consulting with technical specialists. Detailed information about the use of Teknol JRM end compound, preliminary surface preparation and further selection of a suitable scheme for painting a wooden house with Teknos materials can be obtained from the managers of our company.

When constructing wooden houses and assembling log houses for shrinkage, the most unprotected area of the wood, even after applying moisture-repellent impregnation, remains the end sections of logs, beams and finishing boards. This is explained by the high hygroscopicity of wood.

When wood dries naturally, it is susceptible to cracking. As air humidity rises, the untreated ends of timber and logs will absorb moisture from the atmosphere like a sponge. It remains to resolve the question of how to process the ends of the logs.

How to paint a log house inside a bathhouse

Competently performing such an important job as painting the inside of a log bathhouse requires taking into account some technological features. They are related to the operating conditions of the resulting decorative coating. First of all, this is constant exposure to moisture and heat, which is especially important for rooms such as steam rooms and shower rooms.

Therefore, a number of requirements apply to the paints used. Firstly, they must maintain performance characteristics at temperatures from minus 20 to plus 120 degrees. An equally important parameter of paint is elasticity, which will avoid the appearance of cracks and damage to the integrity of the coating. Most often, water-based protective and decorative varnishes are used for interior decoration. They not only give the wooden surface a pleasant appearance, but also reliably protect it from rotting, mold, microorganisms, and other negative effects of high humidity.

As a conclusion, the following should be noted. The current Russian market for construction materials provides many different options for paints, varnishes and impregnations that can be used to decorate a log bathhouse both inside and outside. They differ significantly from each other in price and operational parameters, which allows anyone to find an option that suits them.

12/08/2017

Specialized materials for painting and protecting the ends of timber and logs

- “Protection for ends” of the German brand “Biofa”, filling the pores of end-cut wood, compacting, gluing, reducing the surface area of evaporation and moisture absorption, which prevents cracking and reduces the risk of fungus and mold. The coating creates an even, rough layer, which allows the ends of the frame to be painted without additional primers. Used for external use.

- A log house has open sections of logs inside the house. Door and window openings will look more attractive if you give them some protection. For interior work to protect the ends of wood materials, the German company offers a product that forms a moisture-proof film.

- The elastic means of Italian are used a little more widely. It is a transparent, adhesive primer. “Borma” is a good base for applying water-based or alkyd-based paints. You can simply add color - an aqueous pigment paste - to the transparent protective agent, and no additional painting is required. When using this product, the wood will receive protection from moisture, fungus, and mold. Used for external work to seal ends and fill cracks.

- The range of applications of protective wax from German, in addition to sealing the ends, consists of processing all external cuts to prevent the formation of cracks. This moisture protection product is distinguished by its dirt-repellent surface and environmentally friendly composition.

- Hirnholz-Wachs wax, developed by the German company, will help protect the ends from external factors. Its penetration into the wood is capillary, which makes it possible to deeply seal the channels of the end cuts. Thanks to this, the log, timber, or board will not suffer major damage to the end sections, as happens with untreated wood.

It is easier to avoid damage to the crowns and deformation of the building material if you treat the edges of the crowns immediately, without waiting for the effects of excess moisture, ultraviolet rays, or temperature changes on them.

Damage is caused by both overmoistening and overdrying of wood materials. To reduce the area of evaporation and moisture absorption, special end treatment products are used.

Special protective materials are viscous, because for reliable protection they must fill the pores of the cut. This is possible only on the condition that the product will not be absorbed into the wood, take away moisture from it, or peel off.

Being a novice in using wooden buildings, I did not know what processing is necessary for a log house. Everyone knows that, being natural and environmentally friendly, the material is susceptible to the negative influences of the atmosphere and various beetles. Therefore, I had an understanding that a log house should be processed, however, I did not know at all how and with what to carry out the processes. A huge amount of information and a builder I knew, an expert in caring for log buildings, came to my aid. Let's look at how to treat the ends of the logs after the construction of the house is completed and in what time frame all measures should be carried out.

We process the ends of log logs with our own hands

How to choose a material for painting exterior walls

When choosing what to paint a log house with, you need to select materials that, after drying, will retain the natural ability of wood to regulate the level of humidity in the room.

Also, painting materials are selected in accordance with the design decision. The exterior design of the house should correspond to its style. A house that looks like an old manor can be painted in light colors: white, blue. An old-style log house can be dark in color with white ends. Most often, houses are painted with transparent varnishes or paints to match the wood from which they are built.

Let's look at the advantages and disadvantages of wood paints.

Types of paints for wood

| Type of paint | Advantages | Flaws |

| Oily | They have an affordable price, protect well from moisture, and give the surface a glossy shine. | They form a vapor-proof film on the surface, are toxic, the coating is short-lived |

| Alkyd based paints | protect from moisture | Toxic and short-lived |

| Water-soluble acrylic paints for wood | Allows walls to “breathe”, protects the surface well, is non-toxic, and retains its original color for a long time | Apply 3 layers at long intervals to dry |

| Acrylic resin-based scuba tanks | Non-toxic, creates a colorless coating | Lasts less than paints |

| Glazing impregnations, oil-wax | Protects the texture and color of wood | The protection period is short; permanent stains are left on oak wood. Suitable only for spruce and pine. |

If “breathable” acrylic paint is chosen for processing, then you need to ensure that before applying it, the vapor permeability of the walls is not damaged by antiseptics or an alkyd-based primer with white spirit. All products used to treat the wall after sanding must be vapor-permeable and environmentally friendly. Primers and antiseptics without organic solvents based on:

- acrylic and acrylate;

- wax;

- natural oils.

They should not form an airtight film on the wall being painted.

What tree care should be carried out

Processing the end logs of a log house yourself

There are very divergent opinions among users of many forums. Some people think that the processing of a log structure should be carried out in the shortest possible time. And someone proves that the house does not need immediate treatment. For an answer, I turned to Valera, who had been building wooden houses for several years. And as it turned out, when building houses from solid logs, complete processing for the first couple of years is not required at all. Due to the fact that the log house is not sawn, it has natural protection against fungus and rot. In this case, you just need to properly process the ends of the frame.

Important! If negative manifestations appear in a new house, this means that the log house was not completely dried before installation work.

Protection of the ends from the outside should be carried out upon completion of the construction of the house, since they are the most vulnerable. Since the tree completely dries out over several years, the ends tend to dry out much faster. If the surface is not treated, the ends will begin to darken, losing the natural color of the log house, and fungus will soon appear on them.

How and with what to paint a wall after treatment with Belinka?

Belinka paint and varnish products are produced in Slovenia and are of high quality. Compositions of this brand are often used for painting furniture and facades, and for other interior and exterior work. The coatings are durable and retain excellent decorative properties for a long time, but periodically require updating. What to consider when choosing paint to apply over Belinka?

How to paint a wall over Belinka paint? This can be done with a composition on the same basis. It is important to pay attention to preliminary preparation:

- wash the wall with water or brush,

- peel off the peeling coating to a solid base,

- eliminate unevenness and wait for the plaster to dry,

- treat with a primer.

How to repaint Belinka coatings? To apply paint of the selected shade, use a synthetic brush, roller or spray gun. When painting, it is important to follow the manufacturer's recommendations. It is not recommended to paint walls in high humidity or under direct sunlight. Be sure to maintain the drying time between layers, as the quality and strength of the coating depends on this.

Materials for processing

We process the ends of log logs ourselves

Before purchasing the material with which the log house will be protected, you should know that it should not be an obstacle to air exchange and uniform drying of the wood.

When doing the processing yourself, you can use the classic method, which involves the use of lime. It is still used today in many villages. However, the modern construction market is overflowing with possible mixtures that, thanks to their components, provide good protection for a log house.

Let's look at the most common means for processing ends using a small table as an example:

| Name | Manufacturer | Properties |

| Senezh Tor | Russia | Good protection due to the penetration of the material several cm deep into the log house. It has the ability to allow air to pass through, but does not release moisture from the material. This means that the log house will dry as naturally as possible. Environmentally friendly product |

| Neomid Thor Plus | Russia | Forms a thin film on the surface of the log, which is water-repellent. Protects wood from cracks and putrefactive processes |

| Biotor | Russia | Thanks to the solution, the log will deform significantly less, since the product protects against dried cracks |

Important! When choosing a material, you should pay attention to Russian manufacturers, since their products are in no way inferior in quality to modern imported brands. A huge advantage is the good price, which is significantly lower than the cost of foreign mixtures.

Popular means

When choosing how to treat the ends of logs, you should pay attention to special products with antiseptic properties. If you want to save money, you can resort to folk remedies. Traditionally, lime was used to treat the ends of logs immediately after the installation of a log house, which:

- disinfects wood and prevents rotting;

- provides protection from ultraviolet radiation;

- affordable.

After shrinking the log frame, the end sections should be coated with a compound that forms a film on the surface. This can be drying oil, paint containing wax or oil.

Today, many foreign and domestic manufacturers offer special tools for processing ends. Popular options on the Russian market include:

- "Senezh Tor". Penetrates wood to a depth of several centimeters, creating a gas-permeable coating that does not allow moisture to pass through. This prevents cracking and rot, and damage from insect pests. The composition is environmentally friendly and does not contain components harmful to health. The treatment product practically does not change the natural color of the wood and provides reliable protection for several years.

- "Biotor." As a result of staining, a moisture-proof film is formed on the surface of the wood. This protects the logs from deformation and cracks during drying, and prevents the development of fungus.

- "Neomid Thor Plus". Allows you to create a water-repellent coating, so that fungus does not grow in logs, the wood does not rot and is not damaged by pests. The treatment also prevents the appearance of cracks and distortions during drying. The product does not affect the natural color and structure of the wood.

Do-it-yourself processing process

How to treat the ends of logs

Trimming a log frame is the very first process that is performed after the construction of a building. Thanks to this, all logs become smooth and neat. Trimming is done using a chainsaw. If you carry out trimming yourself, then be extremely focused on the important process and be careful in your work. All processes must be performed in a specific order:

- Sanding a log house with your own hands involves cleaning, which is necessary to remove all irregularities. During this process, possible manifestations of mold and mildew on the material are also removed. A belt sander will help with this process.

- Surface sanding should be carried out correctly and only under warm and dry weather conditions. At the same time, the log house itself must be dried - if it remains wet, the hairiness of the material will not allow you to carry out the planned process

- Impregnation is the term used to protect the logs outside the house from premature drying, fungal growth and cracks. You can use a wide brush as a tool, and apply the solution itself quite generously. The protection is applied in two layers, the second is applied after the first has dried.

- Next, sealants are applied to create a durable, moisture-resistant coating. If painting is necessary, a special acrylic sealant is purchased.

When choosing a mixture with which to protect the ends of logs, preference should be given to environmentally friendly compounds. Do not forget that wood tends to absorb water well, so the solution will be applied in several layers. As you can see, processing the ends of the logs is a mandatory activity that should take place as soon as possible after assembling the structure.

Processing technology

To ensure good protection of a log house made of rounded or chopped logs, solid timber of natural moisture, it is necessary to follow a certain procedure.

At the first stage, the frame is trimmed immediately upon completion of the assembly. Trimming is the alignment of the protruding parts of the crowns (releases). Typically a chainsaw or electric saw is used. Traditionally, outlets are cut so that the end surfaces form a vertical plane.

To perform quality trimming, you need a good tool and experience working with wood, since the process requires accuracy and precision. Trimming allows you to give the log house an aesthetic appearance.

At the second stage, the end cuts are polished. Grinding is necessary to prepare the surface for impregnation with a protective composition. During the grinding process, irregularities are removed; if the log house was assembled some time ago, then various contaminants and mold stains are also removed. It is important to strip down to a layer of clean, undamaged wood.

Rough grinding is performed with a belt-type grinder; the grain of the abrasive surface should be coarse (P40-60). Then grinding is performed with a finer abrasive. Instead of a grinder, you can use a grinder equipped with a sanding flap attachment.

Grinding is carried out only in dry weather, and only dried logs can be treated with abrasive. When a sander acts on a wet surface, small scuffs (lint) are formed on it, that is, it is impossible to do the job efficiently and achieve a smooth surface.

The third stage is impregnation. This term refers to the application of a wood preservative to the prepared ends of the frame. Regardless of the choice of product designed to protect the tree from rotting, damage by pests and uneven drying, the composition is applied using a wide paint brush.

You should act according to the instructions of the manufacturer of the special equipment. General recommendations are as follows: the composition is applied generously, in two or three layers, with intermediate drying for several hours. You should work carefully, completely covering each end with the product and paying special attention to the edges.

It is recommended to carry out work in dry weather. Before processing the ends of the frame, make sure that the wood is not raw. In this case, the protective composition will adhere better and be absorbed better (if it has impregnating properties), while the consumption of the product will be less.