When building a house or adding an extension to it, many are faced with the problem of choosing high-quality insulation. There are many materials available on the construction market, so to determine which one is more suitable, it is worth learning about some of them in more detail. Many people cannot decide what to choose - stone, basalt or mineral wool. But when choosing, it is worth considering the features of using insulation, since the named types belong to the same class. To understand whether mineral or basalt wool is suitable, it is worth considering in detail all the features of both types of materials.

What is a roofing cake for an attic roof?

Structurally, all roofs are divided into two main types:

- “cold” - do not involve installation in the attic of residential premises, the roofing cake does not include thermal insulation;

- “warm” - immediately or subsequently focused on exploiting the space under the attic as residential or utility.

Regardless of the design and architecture, for every house the roof is one of the most important functional protective and decorative elements. It protects the building from external atmospheric factors and various mechanical influences, and also prevents the outflow of heat from the building during the cold season. Heat always tends upward, and if it is not contained, heat loss through the roof alone can reach 35%, and this is a significant overexpenditure of energy resources and operating funds. To minimize heat loss, and, consequently, costs, specialized thermal insulation materials must be used during construction or reconstruction. The difference is that in the case of a cold attic, the floor is insulated, and when arranging a residential attic, both the floor and the roof slopes are insulated. When insulating the floor of a cold attic, the maximum possible layer is laid in it to prevent heat loss. In the ceiling of a warm attic, a smaller layer of thermal insulation is laid, mainly to increase acoustic comfort, while the main “line of defense” is precisely in the slopes. The attic roofing pie consists of several functional layers.

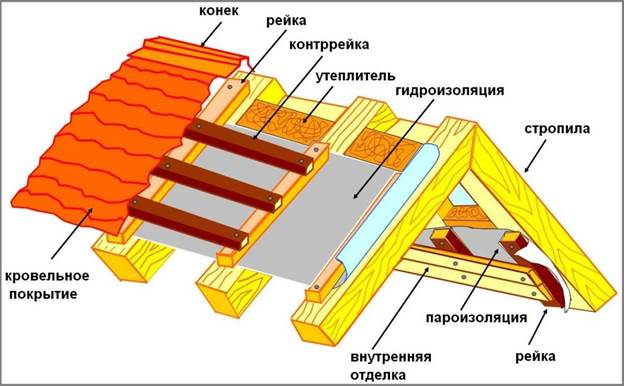

- Vapor barrier - prevents steam released as a result of vital activity from entering subsequent layers of the roof. Even impermeable films with taped joints do not guarantee absolute tightness and retain the bulk of fumes, but some amount still gets inside.

- Thermal insulation is the main functional layer formed from a specialized thermal insulation material. It prevents the outflow of warm air in cold times, overheating of the under-roof space in the hot season, and also provides acoustic comfort, which is no less important for residential premises. The thickness of the insulation is selected based on the standards for thermal resistance of enclosing structures for a specific region of residence and type of thermal insulation. For the bulk of the regions and most materials, a layer of 200 mm is considered the minimum, for the southern regions - from 150 mm.

- Waterproofing – protective membranes laid on top of insulation under the final roofing covering are also called windproof membranes. Vapor-permeable membranes prevent moisture from entering from outside, prevent convective heat transfer (weathering) and release steam from the insulation. It is removed by ventilation of the under-roof space. The use of impermeable films as waterproofing and wind protection is gradually disappearing, since their use requires the construction of two ventilation gaps: between the insulation and the film, and between the film and the roofing. Whereas the membranes are laid directly on the insulation without a gap, which simplifies installation.

The key to the energy efficiency of the design and long years of operation is dry insulation, since when moistened it does not lose its thermal insulation properties. The insulation is maintained in its original condition thanks to a vapor barrier that traps the bulk of vapors from the inside and waterproofing that prevents it from getting wet from the outside.

Preparatory stage

Insulating the attic from the inside with thermal insulation material - mineral wool - begins with preparatory measures.

Preparing for insulation

- Inspection of surfaces for fixing mineral wool.

- Coating wooden surfaces with an antiseptic, and metal with anti-corrosion compounds.

- Replacing damaged areas, drying damp areas.

- Inspection of the rafter system and repair.

- Removing the packaging film from the cotton wool so that the material takes on the desired shape.

- Preparation of protective clothing for safe installation: suit, gloves, respirator, goggles.

Stone wool for attic insulation

One of the most common insulation materials in pitched roofs is stone wool, as the optimal material in terms of performance and cost. It has such properties as:

- low thermal conductivity;

- biostability;

- fire resistance;

- non-flammability;

- sound absorption;

- minimal hygroscopicity;

- durability;

- practicality (and ease of installation, and preservation of the original parameters for the entire service life).

When vapor passes through the fibers, the stone wool is not moistened, its thermal conductivity and volume remain unchanged, that is, during operation the insulation remains dry and effective and does not lose its properties.

ra093FORUMHOUSE Member

Please give advice on how best to insulate the attic of a 10x10 m timber house, Middle Urals. The pie is now standard: flexible tiles, ventilation gap 50 mm, membrane, rafters 200x50 mm. The attic is quite low, I don’t want to lower the ceiling too much.

I see options:

- 200 mm stone wool. Then straight finishing. The rafters look like cold bridges. But how much heat do they take away, considering that 200 mm, and my house itself is made of 190 mm timber, essentially like a cold bridge.

- 50 mm gap between the wool and the membrane, 150 mm of wool, there is already a 30 mm pier plate on the rafters. It turns out more expensive, but it seems to me it should be warmer than 200 mm of wool. The downside is that the ceiling will be lowered a little more.

What other options are there that are not too expensive? Of course, I would like to blow out everything with 150-200 polyurethane foam or lay it all out with slabs, but the price turns out to be very high. Can he handle the entire feast with 100 mm slabs? Judging by the advertised thermal conductivity, it will be like 200 mm of wool.

Anatoly Zemlyanko Technical specialist of ROCKWOOL company

Definitely the first option. 200 mm stone wool, which is the most effective vapor-permeable and breathable material. All other materials will act as a vapor barrier, so it is not advisable to mix these insulation materials. Logs are not cold bridges, since the thermal conductivity coefficient of wood is quite low, which indicates its effectiveness.

Which mineral wool is best for the attic

According to experts in the field of private housing construction, mineral wool is considered the best thermal insulation material.

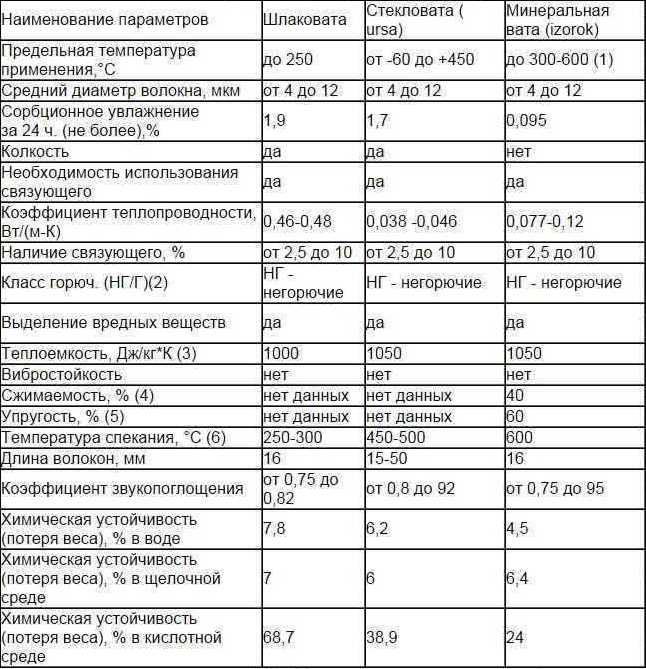

In order to verify this, we will perform a comparative analysis of cotton insulation on different bases.

Slag wool was popular in the former USSR more than 30 years ago. Its disadvantage is its high hygroscopicity. This quality is unacceptable in insulation for rooms with high humidity. Modern builders prefer modern glass and basalt products.

Comparison of mineral wool on different basis

On the Russian market we can distinguish the TOP of 7 manufacturers whose high quality products best correspond to the price:

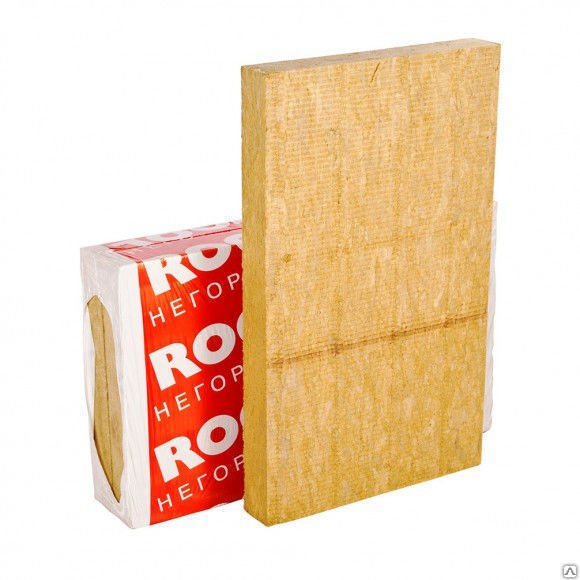

Rockwool basalt wool

The leader is the Danish company Rockwool, which produces basalt-based thermal insulation. According to reviews from builders, it maintains a high standard of 10 points out of 10 possible, and ensures maximum quality without unnecessary unjustified overpayments.

Insulation technology for pitched roofs

For the most part, when the attic floor is initially planned as a residential floor, insulation is carried out as follows.

Anatoly Zemyanko Technical Specialist

When the insulation is installed before installing the waterproofing layer and roofing - the most risky, but also the most popular installation procedure in Russia.

Risky, because it is not always possible to install insulation and cover it with waterproofing in one day, and if the weather turns bad and it rains, both the rafters and the thermal insulation will get wet, which is unacceptable when insulating the roof; the thermal insulation must be dry. But even when insulating an already closed circuit, mistakes are often made. On the forum there is approximately an equal number of “What should I do?” questions asked after installing the roofing.

AGontarForumHouse Member

Help is needed. We have a country house with a 2-pitched roof (attic). On the roof (from outside to inside): corrugated metal sheet, roofing felt, sheathing, rafters. The fact that it is necessary to disassemble and make a counter-lattice is understandable, but the house is not for permanent residence, but rather a weekend cottage (spring, summer, autumn) and a couple of times in the winter, so I want to minimize costs. I need advice on what can be done to prevent the roof from rotting.

Today I see 2 options:

- fill the corners of the rafters with sheathing with 50 mm slats and stretch the membrane, then insulation;

- stretch the membrane from the inside along the rafters (leaving the thickness of the rafters as a ventilation gap), and somehow attach the insulation on top.

Anatoly Zemyanko Technical Specialist

Mount bars between the rafters to create a ventilated gap, then install a windproof membrane with a snake, and lay insulation in the free space. On top of the entire structure, make a lathing with a vapor barrier and a final coating.

kolkapFORUMHOUSE Member

Colleagues have a question, I want to make an attic, the ceiling and rafters are 50x200 mm timber, sheathing and temporary roofing material have been made, I want to cover it with metal tiles and insulate it. How to properly insulate and do it wisely?

Anatoly Zemyanko Technical Specialist

Standard roof:

- – metal tiles;

- – sheathing;

- – counter-lattice;

- – sealing tape;

- – hydro-windproof membrane;

- – self-adhesive tape;

- – logs;

- – stone wool insulation;

- – vapor barrier;

- – self-adhesive tape;

- – sheathing;

- – finishing coating.

“Classical” technology for insulating a pitched roof - in a training video.

Properties and features of mineral wool cladding

Mandatory requirement: when insulating, the insulating material should be laid in two layers. This design most closely matches the thickness of the rafter system and provides better thermal insulation for the attic. It will be warm here in winter and cool in summer.

Roofing pie

Insulation of the attic from the roof side is carried out according to the following scheme:

- slate or metal tiles;

- sheathing;

- roofing felt as a waterproofing material;

- mineral wool insulation;

- vapor barrier film.

Efficiency of single-layer insulation

As for the method of laying insulation, for a long time there was an opinion that cross-insulation is more effective.

id1932564FORUMHOUSE Member

Tell me what to do: the roof is attic, the insulation is 200 mm in size for the rafters, I bought rolled mineral wool insulation for the roof. There is an idea to add 50 mm cross-insulation from the inside. The builders did not approve. Does this make sense? Tatarstan region.

Anatoly Zemyanko Technical Specialist

It is better to insulate in one layer than in several. Increasing the speed of work by reducing the number of technological operations, reducing waste due to cutting layers when performing run-ups.

Six fragments of walls with stone wool slabs were tested in the climatic chamber of NIIMosstroy:

- In three layers and in one layer - the plates are joined without a gap (good installation).

- Three layers and one layer - slabs with a gap of 2 mm (normal installation).

- In three layers and in one layer - a gap of 5 m (everything is bad - it needs to be redone).

A seam width of up to 2 mm is acceptable in most building structures and appears in the standards. This is due to the fact that under climatic conditions, convection at a seam of such width is not intense. Therefore, it is not detected by a thermal imager as a cold bridge. Previously, there were studies on the uniformity of two-layer and single-layer insulation while maintaining the width of the seam.

The research revealed the following:

- Single-layer and multi-layer insulation used in external enclosing structures are equivalent in their effectiveness.

- A gap of 2 mm between adjacent insulation boards has virtually no effect on heat transfer resistance.

Anatoly Zemyanko Technical Specialist

Advantages of minimizing thermal insulation layers (2x100 mm and 1x150 mm are better than 4x50 mm and 3x50 mm):

- reduction of labor costs during the preparation and installation of insulation;

- reduction of material scraps during work;

- insulation with a thickness of 100 mm or more is less prone to deflection than a thickness of 50 mm, due to which it is more securely held in the frame, which is important when installing on vertical and inclined surfaces;

- A single-layer solution is ultimately cheaper than insulation with two or more layers.

Insulating the ceiling of a cold attic of a house with rolled mineral wool

Insulating the attic floor with mineral wool is done in the same way as wall cladding. It happens in two layers, but the algorithm for performing the work is different.

Stages of insulating the attic floor with mineral wool:

- Attaching the vapor barrier membrane.

- Insulation of the attic floor on wooden beams with rolled mineral wool.

- The final stage of insulating the attic floor is attaching the water barrier. You can use roofing felt, plastic film or a vapor barrier membrane.

The above recommendations will help even a novice builder to insulate an attic with mineral wool. As a result, the usable area of the house will almost double.

Signs of a “correct” pitched roof

High-quality materials, coupled with compliance with insulation technology, guarantee a long service life of the roof without “crying” walls in the attic, mold and mildew. A properly insulated pitched roof provides a comfortable microclimate in the attic without the need to increase the power of the boiler in winter or the air conditioner in summer. You can technically verify the effectiveness of roof insulation by examining it with a thermal imager. The device will show the absence or presence of zones through which owners “drown” the street. But even without equipment in winter, the main sign of mistakes made can be seen with the naked eye - “garlands” of icicles. On a roof where the insulation is done correctly, the snow lies in a uniform mass, without melting, and there is nowhere for icicles to come from.

Materials and tools necessary for insulating the attic

If mineral wool is chosen as the thermal insulation material, and you plan to do the insulation process yourself, then you cannot do without special tools and materials:

- glass or basalt wool;

- waterproofing film;

- vapor barrier fabric;

- wooden planks;

- timber 50×50, maybe less, but not less than 25×25;

- plane;

- axe;

- chisel;

- hammer;

- stationery knife;

- stapler;

- marker;

- measuring instrument;

- fastener

Conclusion

In order for a pitched roof to fulfill its purpose and reliably protect the house not only from external influences, but also from increased operating costs due to heat loss, it must be well insulated. In this case, living in the attic will be as comfortable as possible without overpayments, and the need for major repairs will not arise soon.

About single-layer insulation - in the previous material. Owners of wooden houses will find the article about insulating a timber house with stone wool useful. The video shows how to choose and lay stone wool correctly.

Subscribe to our Telegram channelExclusive posts every week

Manual calculation

The next step in insulating a cold attic of a house with mineral wool is calculating the thickness of the layer.

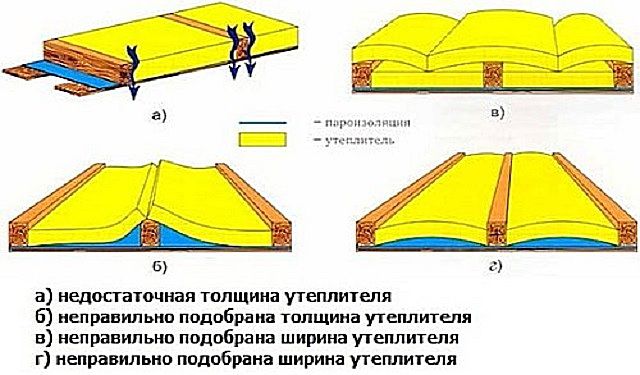

Errors when choosing the thickness of the mineral wool layer

Manual calculations are carried out in accordance with the set of rules “Thermal protection of buildings”. The given formulas and calculations will require special training from a non-specialist.

It is impractical to understand the nuances of manual technology for calculating one individual attic. It is recommended to use free calculator programs from the Internet.

Dew point problem

Ideally, the roof in the attic should be insulated from the outside at the stage of forming the roofing pie. However, often this is done the other way around from the inside, when the house is already covered with a roof. And here certain problems arise.

The correct and ideal roofing pie is several layers of different materials laid on top of the rafters tightly on top of each other without gaps. Such a sandwich ensures that the dew point will be located on its outer side. As a result, all condensate formed outside will quickly evaporate into the atmosphere.

By doing insulation from the inside, after installing the roof, it is impossible to form the exemplary roofing pie described above. It will not be possible to press the insulation onto the roof so that there are no voids left between them.

But steam always moves towards cold air. And then, each of the formed cavities will begin to accumulate condensation and moisture. And this is a direct path to damage to the thermal insulation material and wooden elements of the rafter system.

When insulating an attic internally, the dew point has to be shifted into the space between the laid roof and the insulation, leaving an additional 5–10 cm gap there for ventilation. Only such a technology and such a cake will avoid moisture in the insulating material.

To reduce the amount of water vapor in the insulation, its installation should be done using a vapor barrier film. A vapor barrier is installed from the inside of the attic on top of the thermal insulation material.

The steam must first encounter this film and mostly remain in the room. The less of it gets into the insulation layer, the better.