Related Articles

Which sauna stove is better?

04.05.2020

A bathhouse and a gazebo under one roof - an elegant solution for a summer cottage

12.04.2020

Criteria for choosing a stove and stones for a bath

31.07.2019

Air containing oxygen is a vital necessity for all people. This is especially true when you are indoors. Therefore, the correct arrangement of ventilation in the sauna, bath, bathhouse and other rooms where high temperatures and high humidity are maintained is important.

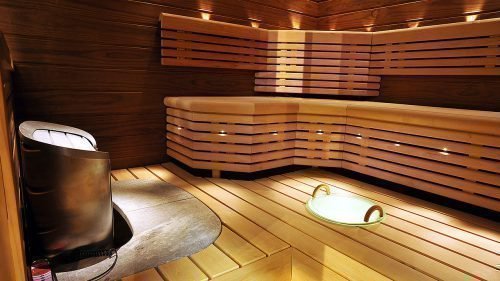

Steam room ventilation

At first glance, it may seem that installing ventilation in a steam room is impractical, because much-needed heat is removed along with the exhaust air. In fact, the opposite is true: ventilation in a sauna steam room is even more necessary than in a regular living room.

In addition to the fact that oxygen is consumed in the process of people breathing, there is another factor at work here. If in a Russian bath sweat flows down the skin due to high humidity, in a dry sauna it evaporates, poisoning the air. So, in the absence of ventilation, staying in the sauna will seem painful instead of pleasant.

Ventilation in steam room and shower

It is obvious that the purpose of the steam room and its characteristic conditions determine special requirements for ventilation:

- the incoming air warms up. Therefore, the inlet openings should be located near the stove;

- The hood is not located at the top, as usual, but at the bottom. The hot air located under the ceiling is the most valuable, and it is also rich in oxygen: a fresh stream heated by the stove rises here. But what has cooled down and sank downwards, having absorbed evaporation and carbon dioxide, must be removed;

- flexible regulation. The temperature regime depends on the operation of the ventilation, but it does not remain constant: some people prefer a hot sauna, others prefer a cooler one. The ventilation system itself depends on constantly changing weather conditions, and preliminary calculations do not allow us to predict with absolute accuracy the effect of ventilation.

The listed points encourage the user to accurately regulate and customize the ventilation operation in accordance with his preferences and the prevailing weather.

They do the following:

- control dampers are installed in the supply and exhaust openings;

- fans with adjustable rotation speed are used;

- make several exhaust holes at different heights in order to select the most suitable one during the setup process.

Along with traditional steam room ventilation schemes, new ones are increasingly being used. For example, they practice supplying fresh air directly to the canopy. A bowl made of soft material is installed there, into which the user, lying on the canopy, lowers his face.

For convenience, place a pillow stuffed with herbs nearby. Since the described method has not yet become widespread, classical ventilation schemes will be considered next.

In addition to the steam room, there are other rooms in the sauna, and they all also need ventilation.

Ventilation device in the sauna

The question about the correct arrangement of effective ventilation in a bathhouse interests many owners of country houses.

The features of the electric heater determine the requirements for the design of bath ventilation. The manufacturer's recommendations are indicated in the operating instructions for this equipment along with the most appropriate air exchange preparation scheme.

Supply and exhaust ventilation

In the shower room and the adjacent room with characteristic high humidity, without ventilation, mustiness reigns, and colonies of mold and other fungi actively develop. Therefore, it is obvious that rooms for other purposes require ventilation at different rates.

The latter is characterized by a special parameter - the air exchange rate (K), which indicates how many times within an hour the air in the room should be completely renewed.

For sauna rooms, the standards establish the following air exchange rates:

- steam room: K = 5;

- shower: K = 50;

- dressing room (rest room): K = 3;

- massage: K = 5.

Example: for a steam room with an area of 2x4 m with a ceiling height of 2 m, that is, a volume of V = 2*4*2 = 16 m3, it is necessary to organize ventilation with a capacity of Q = V * K = 16*5 = 80 m3/h. The cross-section of air ducts, fans, etc. are selected based on the calculated performance. The following types of ventilation systems are distinguished: natural and forced.

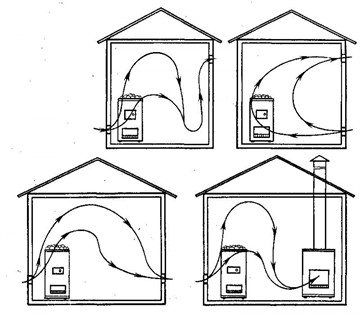

Natural

Air circulation is caused by convection - the tendency of heated air to rise upward due to a decrease in density. In the relaxation room it “flows out” through the exhaust hole near the ceiling, in the steam room it squeezes out the low-lying cooled air near the floor.

Natural ventilation

Advantages of natural ventilation:

- simplicity and low cost: nothing is required except dampers and air ducts;

- energy independence.

But its capabilities are limited.

Forced

Air circulation is provided by a fan, depending on the location of its installation, they are distinguished:

- supply ventilation : the blower is placed in the supply duct;

- exhaust : respectively, in the exhaust;

- supply and exhaust: a fan is installed in each part.

Forced ventilation is more complex, more expensive than natural ventilation and requires electricity, but it is more functional:

- does not depend on the outside temperature;

- not blocked by strong winds.

In addition, it allows the use of filters, recuperators, air heaters or coolers: natural draft would not be enough to overcome their aerodynamic resistance, while a properly selected fan will push air masses in the required volume even through several such devices.

Requirements for developing a ventilation circuit

In order to successfully complete the entire planned list of work, you need, at a minimum, to take a meaningful approach to the implementation of technological operations, study practical recommendations and photos of various options for exhaust systems.

Mechanical diagram

At the same time it is the most expensive, but also the most effective. The kit will require ventilation valves for the sauna, filters, diffusers, a device for neutralizing noise and other components.

This type of sauna and steam room ventilation is considered the easiest to organize with your own hands. But this can only be said about the process of its installation, because sufficient air exchange can be organized only after accurate calculations. In addition, such a system also has a number of negative aspects. For example, it depends on the wind speed and its direction.

Such a hood in a sauna can rightfully be considered the best engineering solution. It combines efficiency, low cost and is easy to do yourself.

We turn on the fan, fully open all the valves and doors - within 5-10 minutes the air is completely replaced with fresh air.

Warm-up process

A sauna always needs a system with ventilation ducts. With such a device, there will always be a good microclimate in the bathhouse. Whether it is in a cottage, an ordinary house or a basement, sauna ventilation is an integral part of it.

Only complete distribution of air flows can create the most favorable indoor climate. There are several types of sauna ventilation, but they all must meet certain requirements. As a rule, a combined or fully mechanical hood is installed in such a room.

The second option is more expensive, so many people prefer to equip the room with a forced type of air exhaust. A natural type of hood can also be used. When air masses are removed naturally, due to the difference in temperature between the street and the sauna.

The difference between the types of hoods is as follows:

- combined - provides for the provision of the required pressure due to the operation of the fan;

- mechanical - the air flow is supplied and taken away by the installed device;

- natural - the necessary flow of air masses is carried out naturally through the temperature difference between the street and the steam room.

The combined type is advantageous in that it is possible to avoid the placement of vents along cross lines, as required by the natural exhaust pattern. They can be installed only based on the characteristics of the building. Similar options for hoods can be installed when the sauna is located in the basement.

Scheme of operation of forced and natural ventilation

The basic requirements of a sauna ventilation system include:

- the exhaust pipe must match the supply pipe or be slightly larger;

- The cross-sectional area of the hood openings in the system is proportional to the area of the room, taking into account the following indicator: 1 cubic meter. m is equal to 24 cm;

- pipes extracting and supplying air cannot be mounted opposite;

- To ensure the ability to control the air flow and its intensity, it is necessary to install a valve.

Subject to these rules, ventilation for the sauna will be as effective as possible. If you do not comply with at least one of the points, it will be impossible to provide a full microclimate in a Finnish sauna or any other. Also, the ventilation hole must have valves, then temperature indicators can be controlled. The ventilation device in the sauna must correspond to the layout of the room.

The bathhouse must have a good ventilation system. Intense air flow is simply necessary in a steam bath or sauna. In one hour, several full volumes of air can change there. It is better to have a detailed technical design before making ventilation in the bathhouse. Now there are many standard bathhouse designs with working drawings. There you can find an option for any area.

Many baths, especially medium and large ones, are equipped not only with the main stove, but also with additional heaters. They can also be added to general ventilation if their design provides for heating the air in the flow.

The overall system design must take this into account. Another new solution in this area is convection ovens. They are very effective. Bath options have a pipe for external air supply.

Most often, this is placing the supply valve at the bottom next to the stove. In a convection oven it is only required as a backup and is closed at normal times.

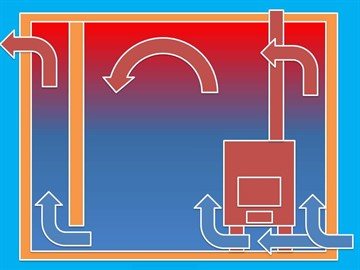

The term is translated from Finnish as “bad” - a bathhouse, and “stuga” - an insulated wooden structure. A common name is “Finnish sauna”. Ventilation in the Bastu bathhouse is a closed air space in the upper part of the sauna room, and below is a supply and exhaust system. This configuration ensures that warm air accumulates at the top of the sauna.

The system resembles an inverted dome with a closed upper volume. The room must have sufficient thermal insulation and tightness so that air does not leak through all the cracks. Heating is economical. The scheme has been tested in Finnish saunas and is very popular there.

Ventilation in the Russian bathhouse “Basta” is rarely done. There is a slightly different type of steam room. With large amounts of steam on the heater, this type of ventilation is inconvenient. It leads to stagnation of air in the room. At the same time, nothing prevents you from providing this ventilation option for variety.

The absence of an exhaust hood at the top of the steam room is the main condition under which the “Basta” ventilation works in the bath; the circuit must necessarily switch to the normal ventilation mode. To ensure this, it is built according to the usual standard rules, which are described in this article.

To the standard set of upper and lower dampers, you need to add one more lower hood. As is the case with standard steam ventilation, the inlet and outlet should be as far apart from each other as possible. The optimal location is access to the opposite walls of the bathhouse, but this is not always possible.

READ MORE: How to properly connect a digital set-top box to your TV

In order for the “Bastu” ventilation to work in a Russian bath, the upper hood is closed and the lower one must be opened. In this case, the natural draft in the upper hood is greater than in the lower one. This must be taken into account when choosing the cross-section of ventilation ducts.

Very often, a sauna stove is installed in the middle of the sauna (so it simultaneously heats all three rooms). In this case, air must be supplied through a metal duct. You can’t just make a hole in the steam room to the street and cover it with a grate! This will certainly lead to drafts, which are completely unacceptable in the steam room. The air must be warmed up near the stove.

Of all the rooms in the bathhouse, good ventilation is necessary, first of all, in the steam room. The air temperature and humidity are high there, so intensive air exchange is necessary. Ventilation in the steam room is created with your own hands based on standard schemes and proven solutions.

This allows you to avoid mistakes, such as drafts. This problem is solved by placing a supply valve with a valve near the stove at a small height from the floor.

The answer to this question is always unequivocal - yes, it is necessary. During operation, ventilation operates continuously and is often manually adjusted to a comfortable temperature. The steam room usually has a small volume of air and intense steam formation occurs there.

All this requires increased air exchange. At the same time, it is important not to overdo it. If ventilation is too intense, no stove, even the most powerful one, will ever heat the steam room to the required temperature.

In the bathhouse, under no circumstances should odors from washing waste accumulate.

There are two main rules here.

This is a good drainage system and good supply and exhaust ventilation of sufficient capacity.

If the quality of the waste system needs to be taken care of in the washing department, then in the steam room ventilation comes first. It is described in detail in any manual. On our website we provide the most detailed description.

Ventilation in the steam room is always supply and exhaust in various designs. All other schemes, for example, recirculation, as in a split-system air conditioner, are completely unsuitable here. There are two main elements in the supply and exhaust system.

This is a supply valve (air intake, inlet, inlet deflector) and an exhaust hood.

It is not necessary to have only one hood and only one supply valve.

Proper ventilation in the steam room has air flow adjustment.

The same amount of firewood is not always used for the same amount of steam.

Climatic conditions also vary throughout the year.

The comfort temperature for visitors is also different.

You can't do without adjusting the ventilation. Ventilation adjustment is carried out using manual valves.

This old simple option remains the most convenient to this day. In the steam room, two valves are simply installed.

Arrangement scheme

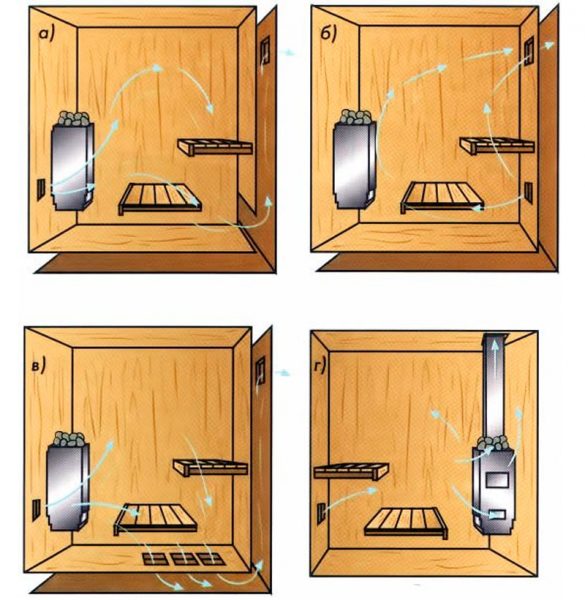

There are several options for ventilation in the sauna steam room:

- the inlet opening is located at the bottom of the wall (20 cm from the floor) behind the firebox. The exhaust is on the opposite side, at the same level. The air coming from the street is immediately heated by the stove and, due to convection, “floats” to the ceiling. As it cools down, it falls back to the floor and is removed through the exhaust hole. This scheme provides a high temperature in the sauna;

- if you need softer heating, the supply hole is made a little higher - 50 cm from the floor, also behind the stove. The exhaust hole is made as in the previous version. The air moves along a similar trajectory, but not as actively, which ensures uniform heating;

- if there is a base, vents are made in it, protected from insects by a mesh. The air entering them enters the steam room through cracks in the floor around the stove. The hood is also located on the side opposite to the stove.

In addition to ventilation, the scheme ensures ventilation of the floor, and this has a positive effect on its service life.

Advantages and disadvantages of natural cellar ventilation

Natural ventilation of the cellar is very popular among owners of private estates. And there are the following good reasons for this:

- small financial investments when arranging the system, which go only to pipes, insulation, deflector and fastenings;

- the system does not require power supply;

- ease of installation and operation;

- there is no need for constant control over ventilation, with the exception of one-time visits during severe frosts.

But situations still arise when natural ventilation in the cellar is not effective. The reason for this is due to its dependence on temperature differences. Where the outside air temperature is most often high, it is not possible to ventilate the storage room. Here it is necessary to use combined air exchange.

Combined system

Often they resort to a mixed or combined method of ventilation: part of the premises is ventilated naturally, and the other is forcibly ventilated. For example, in summer, natural ventilation works effectively only in a steam room, where the air is much hotter than the outside air; in other rooms, its performance drops sharply, since the air temperature in them and outside is approximately the same.

In the rest room the situation is saved by open windows, but in the shower a catastrophe cannot be avoided. If you install an exhaust fan here, it will provide the required performance at any time of the year.

The combined option is appropriate when the sauna is located in a cottage and the steam room has only one outer wall.

Natural ventilation is installed in the relaxation room, and forced exhaust ventilation in the steam room: both openings, the supply and exhaust, are located in the outer wall; the first is 20 cm from the floor, the second is 20 cm from the ceiling. Thus, they find themselves opposite the stove, which is usually installed in such saunas near the inner wall. A fan is installed in the exhaust hole.

Forced draft provides a powerful incoming flow of fresh air. He crosses the entire steam room, encounters the stove, rises up and, thus going around the room in a circle, leaves through the hood.

Regulations for the low-rise sector SP 55.13330.2016

This is one of the main sets of rules applied to the design of residential buildings with one apartment. The standards for ventilation of a private house collected in it relate to the design of autonomous residential buildings, the height of which is limited to three floors.

A comfortable microclimate is created in the interior of the building using ventilation equipment. Its characteristics are specified by GOST 30494-2011.

In most cases, an individual house is heated by an autonomous heating boiler. It is installed in rooms with good ventilation on the first or basement floors. Possibility of accommodation in the basement of the cottage. With a heat generator power of up to 35 kW, it can be installed in the kitchen.

The design of any building, regardless of its area, number of storeys, purpose, necessarily includes the “Ventilation” section with the development of a diagram, calculations and recommendations for construction

If the heating unit operates on gas or liquid fuel in the boiler room, measures are taken to thermally insulate equipment and pipelines in accordance with the conditions of SP 61.13330.2012.

The collection offers three principles for ventilation design:

- Exhaust air is removed from the premises by natural draft through ventilation ducts. The influx of fresh air occurs due to ventilation of the rooms.

- Mechanical air supply and removal.

- Air intake naturally and the same removal through ventilation ducts and incomplete use of mechanical force.

In individual houses, air outflow is most often arranged from the kitchen and bathrooms. In other rooms it is organized as required and necessary.

The air flow from kitchens, bathrooms, restrooms with strong and not always pleasant odors is removed immediately outside. It must not enter other premises.

For natural ventilation, windows are equipped with vents, valves, and transoms.

An important advantage of the supply and exhaust system is stability of operation, independent of the temperature and air density inside the room and outside the window.

The efficiency of ventilation equipment is calculated taking into account a single change of air within one hour in rooms with the constant presence of people.

Minimum volume of air removal in operating mode:

- from the kitchen – 60 m3/hour;

- from the bathroom - 25 m3/hour.

The air exchange rate for other rooms, as well as for all ventilated rooms with ventilation, but when it is turned off, is taken to be 0.2 of the total cubic capacity of the space.

Air ducts laid in an open way are fixed to building structures using brackets. To reduce sound vibrations, the holders are equipped with noise-absorbing elastomer pads

Cylindrical or rectangular air ducts are attached to building structures using various devices: hangers, brackets, lugs, brackets. All fastening methods must ensure the stability of ventilation lines and prevent deflection of ventilation pipes or ducts.

The surface temperature of the air ducts is limited to 40°C.

Outdoor appliances are protected from low negative temperatures. All structural parts of the ventilation system are provided with free access for routine inspection or repair.

In addition, there are also collections of standards such as NP ABOK 5.2-2012. These are instructions for regulating air circulation in residential buildings. They were developed by specialists of the non-profit partnership ABOK in development of the regulations discussed above.

Work order

The method of installing ventilation ducts depends on the material of the building structures:

- concrete base . To make vents in the basement, large-diameter plastic pipes filled with wet sand are installed in the formwork before pouring concrete, which will not allow the solution to seep into the pipe. Next, concrete is poured into the formwork and after it hardens and the formwork is dismantled, sand is selected from the air. Finally, a protective mesh is installed;

- frame walls . The air duct is laid after installation of the power elements. Next, it is covered with insulation and sewn up;

- brick walls . Air channels are laid at the design stage. During the construction process, they are formed, leaving half-brick or brick-sized gaps in the wall.

In general, the order of work looks like this:

- technical requirements design. First of all, this is the calculation of ventilation performance for different sauna rooms;

- selection of ventilation type (natural, forced or combined), based on the required performance. Calculation of the cross-section of air ducts, selection of fans by power;

- development of design documentation - drawings and specifications (list of parts and assemblies);

- division of work into those suitable for independent implementation and those requiring the involvement of professionals;

- system installation;

- commissioning works.

In places protected from high temperatures, plastic air ducts are used; in other cases, galvanized ones are used. Plastic gases at temperatures above +880C - it emits gaseous substances harmful to health.

In addition to ventilation, the scheme ensures ventilation of the floor, and this has a positive effect on its service life.

Basic mistakes

Most often, ventilation rules are violated as follows:

- The supply and exhaust openings are located on opposite sides exactly opposite each other. In this case, a draft is formed, which significantly disrupts the temperature and humidity conditions;

- choose the wrong cross-sectional ratio of the supply and exhaust air ducts. According to the rules, the former should have the same cross-section as the latter, or slightly smaller.

Sometimes fans and other electrical equipment with a low class of dust and moisture protection are mistakenly used. And it cannot be less than IP44.

The need for constant ventilation of the cellar

Since the task of an underground pantry is high-quality and long-term storage of agricultural products, creating a microclimate is the most important task here. For root vegetables and home canning products, the following conditions are required:

- supply of fresh air flows;

- appropriate storage temperature;

- standard humidity not exceeding 90%.

Good ventilation of the cellar is carried out in such a way that there is no stagnant musty smell in the room and, at the same time, there is no draft, which contributes to food spoilage and drying out of root crops.

Creating optimal temperature and humidity conditions ensures proper air exchange.