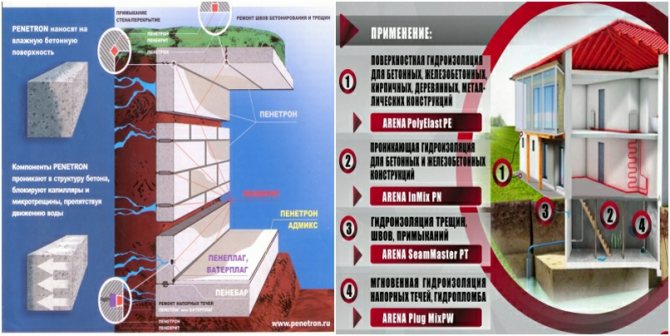

Penetron deep penetration waterproofing for concrete, reinforced concrete and monolithic concrete structures. Helps prevent water from penetrating through concrete in the presence of high humidity and high hydrostatic pressure. Penetron waterproofing increases the strength, water resistance, and frost resistance of concrete. Protects the structure from exposure to aggressive environments: acids, alkalis, sewage and groundwater, sea water. Waterproofing material PENETRON is used for surfaces with pores and cracks with an opening width of 0.4 mm. The higher the humidity of the concrete structure, the more efficient the process of penetration of active chemical components into the depths of concrete occurs; this process occurs under both positive and negative water pressure. The depth of penetration of the active chemical components of the Pinetron material in a continuous front reaches several tens of centimeters. Having penetrated deep into the structure of concrete, the active chemical components of Penitron, dissolving in water, react with ionic complexes of calcium and aluminum, oxides and metal salts contained in concrete. During these reactions, more complex salts are formed that can react with water and create insoluble crystalline hydrates. The network of these crystals fills all pores, capillaries and microcracks. In this case, the crystals become an integral part of the concrete structure.

Waterproofing concrete

In modern construction, waterproofing for concrete surfaces and products is actively used - a mixture necessary to provide additional protection for concrete foundations and other building elements from water and other negative external influences.

Cement waterproofing is used in both industrial/commercial and general residential construction. As a rule, the material contains cement, sand and various chemical compounds. Modern mixtures are able to penetrate more than 10 cm into concrete, thereby providing sufficient protection from water and significantly extending the life of the entire structure.

In this article on our side, we will look in more detail at how penetrating waterproofing for concrete , why it is important to use it, and what its advantages and disadvantages are. We will also consider several different types of waterproofing compounds.

How does penetrating waterproofing work for concrete and brick?

Concrete surfaces and blocks are regularly exposed to moisture. Sometimes very active. Due to precipitation, the foundation and other structural elements may erode over time. This leads to dangerous consequences in the future, including the destruction of the structure.

In addition, there are microcracks in the concrete through which water can enter the basement. In the same way, it penetrates through the seams between structural elements. And if we talk about brickwork, then it has practically no protection from water and high humidity.

To ensure sufficient moisture protection, it is necessary to use penetrating foundation waterproofing. Experts recommend applying it at the stage of building a house. But if this was not done, and the problem of excess moisture arose, then you need to waterproof the basement from the inside.

Features of the effect of basement waterproofing and concrete in general can be described as follows:

- After applying the composition, the concrete begins to absorb chemical additives through the smallest cracks.

- Upon contact with water, the mixture that fills the capillaries of the block crystallizes.

- The crystals fill the microspace, thereby preventing further moisture seepage. These crystals do not dissolve in water, which has a positive effect on the durability of the protective material.

Note! Waterproofing impregnation not only provides protection from water/humidity, but also significantly strengthens the concrete, making it more durable and wear-resistant.

When using such mixtures, the surface where they are applied must be damp. This is its important difference from bitumen mastics and roll-type materials. Therefore, before using the composition, you need to familiarize yourself in detail with the rules for its application.

Where is coating waterproofing used?

Most often, waterproofing work is carried out at the construction stage of a building or during its reconstruction. This is the most effective solution that can be used even in cases where other protection methods cannot be used. Using cement waterproofing, you can protect various objects from moisture:

- basements;

- swimming pools;

- bathrooms and toilets;

- cellars, etc.

Despite all its positive qualities, waterproofing material is still not popular enough. The reason is that many simply do not know about its existence, using old, ineffective methods of moisture protection. Additionally, we will say that penetrating mixtures are not suitable for waterproofing foam blocks.

About the benefits of penetrating waterproofing

The use of waterproofing concrete against water provides good protection against moisture and speeds up the process of building a house. First of all, due to the fact that in this case there is no need to dry the concrete. Less time is required for construction. Moreover, the wetter the concrete surface, the faster the crystallization of chemical elements and clogging of micropores occurs. After applying the composition, concrete does not lose its basic qualities and technical features. He will stay:

- breathable;

- vapor-tight;

- resistant to temperature changes.

After using a waterproofing mixture for concrete, only one indicator of the latter changes - water resistance. And although we said that it is better to use such a composition at the construction stage, sometimes this is not at all necessary.

If necessary, the mixture can also be used in already built structures. To do this, you do not need to dig up the base - the waterproofing is applied to the internal surfaces of the concrete. It does not matter from which side the composition is applied to the foundation, in any case it provides high quality water protection. In addition, the quality of moisture protection is not affected by groundwater pressure.

Note! In addition to protection from ordinary water, high-quality waterproofing also protects from more aggressive compounds. For example, with a high Ph.

What are the disadvantages of penetrating waterproofing?

At the moment, there is no waterproofing that does not have disadvantages as such. The compositions are not ideal, but a number of positive qualities make waterproofing concrete almost irreplaceable.

However, it also has one significant drawback, or, to be more precise, a feature: it is recommended to use such mixtures in combination with other moisture-proofing compounds. For example, in order to properly protect foundation seams from moisture, you need to buy a special substance intended for this purpose.

Of course, the main team can partially cope with this task, but for a better result it is better to overpay.

The second significant drawback of penetrating concrete waterproofing agents is their price. They are quite expensive. You can find budget analogues from little-known manufacturers, but the quality of the composition will raise questions. It is better to choose more expensive mixtures.

Another important point is the rather labor-intensive preparation of the surface before applying the waterproofing compound. It is necessary to thoroughly clean the walls and other surfaces of all contaminants, even minor ones. Otherwise, the material will be poorly saturated, which will greatly affect the quality of the final result.

It would also be a good idea to degrease the surface. Ordinary pressurized water is quite suitable for this task. For example, from a hose. But this option is more suitable for waterproofing concrete outdoors.

Only after preparatory work can you be sure that the composition will penetrate deep enough into the micropores. If there are large gaps and cracks in the concrete, they must first be sealed - the waterproofing composition will not cope with them.

We also note that these waterproofing compounds are not suitable for brickwork. It is better to use more classical methods of moisture protection for it. Or combine means to achieve the desired result.

Despite some disadvantages, a more effective means of protecting against moisture than penetrating concrete waterproofing simply does not exist today. Of course, a lot depends on which manufacturer’s products you choose, how well you prepare the surface and whether you follow all the rules for using the composition. But overall, this is truly a very reliable tool at a very reasonable cost.

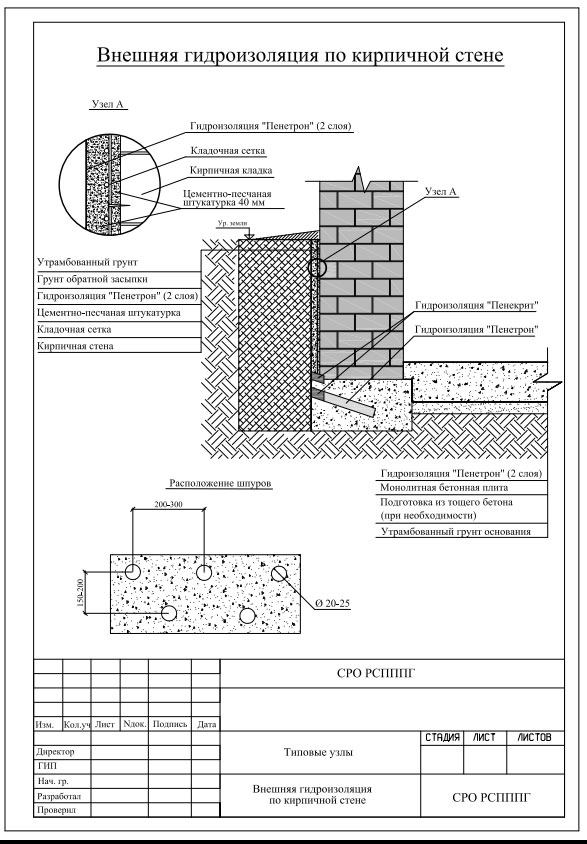

Waterproofing brickwork

When waterproofing a foundation made of brick and stone, the surface must be plastered and treated with a solution of the Penetron . To achieve high-quality waterproofing of the foundation when plastering the surface, it is necessary to comply with the following conditions:

- Plastering should only be done with a cement-sand mortar of a grade not lower than M150. (The use of lime mortars and gypsum plaster is prohibited)

- Plastering is carried out using a masonry mesh (mesh size 50x50mm or 100x100mm), firmly fixed to the surface.

- The gap between the masonry mesh and the brick base must be at least 15mm

- The thickness of the plaster layer must be at least 40mm

- The structure of the plaster layer should be dense, without air gaps

- It is recommended to carry out plastering continuously to avoid the formation of a large number of working seams.

- Before treating with Penetron , it is necessary to soak the plastered surfaces for at least 24 hours (in accordance with the requirements for plastered surfaces). The technology for surface treatment with a solution of the Penetron is standard, the consumption is 0.8 kg/sq.m.

RESTORATION OF HORIZONTAL WATERPROOFING

Restoring horizontal waterproofing is necessary to prevent the process of destruction of load-bearing walls, which begins as a result of capillary suction of ground moisture through the body of the foundation into the brickwork. Due to exposure to dampness and formed salts, the brickwork of a building can be destroyed to a height of up to 2 m. Restoration of horizontal waterproofing is the most important component of moisture protection measures during repair work and restoration of old buildings and structures exposed to capillary moisture. The horizontal waterproofing procedure primarily involves the foundation and walls of a building made of brick, granite blocks, stone in order to avoid the appearance of moisture on the walls, leading to the formation of fungus and mold; to prevent salt efflorescence on brick or stone walls covered with plaster; to enhance the heat-intensive properties of walls and prevent surface condensation. It should be noted that geotechnical drainage work will not be able to guarantee the implementation of restoration work on the interiors of the building. Moreover, in some areas it is simply impossible to isolate brick walls from technogenic water-saturated soils. Only high-quality comprehensive work on restoring the horizontal waterproofing of foundations and walls of buildings, as well as technological operations for anti-salt and antifungal treatment will significantly increase the service life of coatings and wall finishing.

INJECTION METHOD

Of all the existing methods for restoring horizontal waterproofing, the most effective is injecting cement mortar with special additives into the body of the structure, as a result of which a kind of anti-seepage curtain is created that prevents moisture from leaking through the structures and, therefore, the inevitable destruction of the walls. Typically, injection of waterproofing compounds is carried out above the standing water line along the perimeter of the building at the level of the blind area or at the level of the basement floor. As a result of deep penetration of injected materials into load-bearing walls, the interaction of active chemicals of waterproofing compounds with salts and moisture of the building structure, crystal growth occurs, blocking all pores and small cracks. Complex physical and chemical processes occurring in the thickness of the wall ensure the formation of a stable waterproof layer and hydrophobization of the treated surface.

RESTORATION OF HORIZONTAL WATERPROOFING WITH MATERIALS OF THE PENETRON SYSTEM

Among modern materials that have proven themselves worthily on construction sites, the materials of the Penetron , which are successfully used in the restoration of horizontal waterproofing and the elimination of capillary suction, stand out.

The technology of restoration work includes the following stages:

- Holes with a diameter of 20-25 mm are drilled from the inside or outside of the foundation. It is recommended to drill holes in a checkerboard pattern to avoid weakening the wall, at an angle of 30-45 degrees to the horizontal. The drilling depth must be at least 2/3 of the foundation thickness. The distance between holes horizontally is 200-300 mm, vertically - 150-200 mm.

- To saturate the working surface with moisture, the drilled holes must be washed with water.

- Direct injection is carried out using a special funnel: the holes are filled with the prepared solution of Penetron . This solution is carefully and thoroughly compacted, then the remaining space is filled with a solution of the Penecrit . Columns, corners and walls more than 1 m thick are recommended to be treated on both sides.

- If large cracks and voids, or a loose concrete structure are found in the masonry of the foundation or walls, it is necessary to inject a non-shrinking cement mortar into the foundation in advance, before the hole-drilling process.

- Hydrophobic materials "Penetron" , penetrating into capillaries, microcracks and wall voids, forming a crystalline insoluble compound, thus eliminating the capillary rise of ground moisture.

The choice of a specific technology depends on various factors. To find out what is best in your case, call and consult with a specialist +7 (965) 218-50-36

Typical solution:

Main types of concrete waterproofing

We propose to consider in more detail liquid, coating waterproofing and waterproofing paint for concrete. All compositions are actively used at present, but have a number of significant differences.

A few words about liquid waterproofing of concrete

In recent years, so-called liquid waterproofing has been increasingly used. These are special liquid compositions that allow you to quickly and efficiently provide a good level of protection against moisture. There are quite a few protective compounds on the market, but the most popular among them are:

- liquid rubber;

- liquid glass.

The main advantage of such liquid compositions is that they are very convenient to work with. Much more convenient than with bitumen mastics, roll materials and protective films, which are also used very actively. But before purchasing, we recommend that you study in detail all the features of using a particular composition, as they may differ.

Often the cost of such liquid materials is twice as high as dry mixtures. But they can be applied even to rather uneven surfaces, and they provide better protection.

The process of applying liquid waterproofing is very simple - you can use a regular brush or roller. The composition is completely safe for human health, resistant to high temperatures, and serves as a good alternative to roll and other moisture insulators.

The mixture should be applied in a thin layer, and after drying it should be provided with additional protection from mechanical stress. Liquid waterproofing makes concrete virtually invulnerable to water. But in some cases it is difficult to apply it yourself and achieving an even layer is almost impossible. It's better to consult a specialist.

Coating waterproofing for concrete

Buyers often confuse coating waterproofing with impregnation, but these are completely different things. Although their properties are really similar. But if the impregnation penetrates deep into the concrete, then the coating waterproofing covers only the top layer. However, it still provides the necessary level of protection from moisture.

The difficulty of working with the material is that it must be applied very evenly and not skip sections of concrete. Otherwise, the quality of moisture protection will be insufficient. It is also very important to choose the right composition that will have sufficient adhesion, resistance to moisture and elasticity. The latter is especially important, because over time the concrete wears out and small cracks form in it. And only elastic waterproofing will not crack along with the concrete.

Water protection paints for concrete

In a sense, waterproofing paint combines the specifics of the types of waterproofing described above. It is very easy to apply it yourself, without turning to a specialist for help.

This paint comes in one-component and two-component types. At the same time, it is the one-component one that, as a rule, has the proper waterproofing properties. This is an enamel with high technical characteristics, which is often used as suture penetrating waterproofing.

An important advantage of waterproofing paints is their high level of protection against water. This allows them to be used even for insulating the walls of swimming pools and other surfaces that are constantly in contact with water. To apply such paints, special spray guns are used with the ability to precisely adjust the jet coming out of the tool.

Advantages of Penetron waterproofing

Looking at the price tag of this waterproofing, the average buyer will think, weighing the arguments for and against. Indeed, Penetron cannot be called cheap. You can pay 300 rubles for 1 kg of this material only if you are fully confident that it will reliably protect the foundation from water.

In order for your choice to be informed and correct, let’s see what the manufacturers promise us:

- Unlike coating and adhesive waterproofing, Penetron is not afraid of mechanical influences. Its service life is equal to the service life of concrete (up to 100 years).

- The use of this type of waterproofing does not require pre-drying of the concrete.

- The structure can be processed from any side (the foundation does not need to be dug up).

- This composition has the property of self-liquidation of through cracks that appear on a concrete structure during operation (opening no more than 0.5 mm). Water entering these cavities activates the growth of cement stone crystals and they close the crack.

- In 3 months, Penetron increases the water resistance of concrete to the maximum grade W20 (water does not penetrate its structure even under a pressure of 2 MPa).

- Waterproofing does not impair the physical parameters of concrete: mobility, strength and setting time. At the same time, concrete completely retains its vapor permeability.

Why should any building have high-quality waterproofing?

Foundations and other elements of buildings and structures are regularly exposed to water. This includes precipitation, groundwater, and ordinary leaks of engineering systems or sewerage accidents. And water, as you know, has a detrimental effect on concrete - it begins to crack, crumble and collapse. Therefore, you cannot do without high-quality waterproofing. With its help you can achieve impressive results:

- ensure water resistance of concrete and reinforced concrete structures at level W20;

- increase the frost resistance of concrete up to 150 cycles;

- increase resistance to aggressive compounds - acids, sea water, petroleum products, etc.;

- significantly increase the strength of concrete;

- use the compositions for both interior and exterior work.

Remember that it is necessary not only to choose the composition correctly, but also to use it correctly. Otherwise, the level of protection will be insufficient or the protection simply will not cope with the impacts to which it is exposed. We recommend choosing products only from trusted manufacturers that have proven themselves in the market. Yes, their compositions can cost several times more than little-known analogues, but the quality is disproportionately higher.

Instructions for use Penetron

Consultations by phone +7

Penetrating waterproofing Penetron is supplied in the form of a dry mixture. Packaging – 5 or 25 kg buckets. and kraft bags 25 kg.

The purpose of the mixture is to increase the water resistance grade of concrete, increase frost resistance cycles, strength and resistance to the negative influence of an aggressive environment. Concrete treated with Penetron does not lose its ability to conduct water vapor. Cracks with an opening width of up to 0.4 mm, under the influence of the penetrating composition, are filled with the active substance and closed.

Application of penetrating waterproofing Penetron should be carried out at ambient temperatures from +5 to +40 degrees Celsius. During operation, it is desirable that there is no precipitation or strong wind.

Best Penetrating Waterproofing for Concrete

The modern building materials market is replete with a huge number of products of varying quality and in different price ranges. Penetrating waterproofing for concrete is no exception, so we propose to consider several of the most popular brands of this material, which are worth paying attention to when choosing.

Penetrating waterproofing Penetron

This waterproofing for concrete belongs to the middle price segment. It is actively used both in private housing construction and at the commercial/industrial level. The quality is time-tested. The basis of the mixture is sand-quartz and chemical components.

The cost of Penetron waterproofing is higher than many analogues, but this is fully justified by its excellent characteristics. Penetron can be used to protect walls, floors and concrete foundations. And even in more complex situations, this composition can be used to protect swimming pools, wells, structural elements in wet areas, etc. from moisture.

The great popularity of Penetron mixtures has provoked the appearance of a huge number of counterfeits on the market. Therefore, we recommend that you be especially careful if you buy products from an unverified seller.

Penetrating waterproofing Arena

Waterproofing for cement-based concrete Arena and waterproofing additives in concrete that are outstanding in their properties are products that have successfully passed a testing period and are approved by specialists. To ensure that a concrete structure is waterproof, the concrete should be treated with Arena InMix or one of Arena EcoMix or Arena BiMix should be added to the concrete mix.

As a result of the use of these materials, pores, capillaries and microcracks in concrete are filled with insoluble chemical compounds, allowing the water resistance index to be increased by at least 4 levels.

Penetrating waterproofing Lakhta

These are products from a domestic manufacturer, presented in a wide range for different tasks. Including to increase the level of tightness of seams. The composition of the mixture is quite similar to Penetron analogues, but the cost is almost half as much. At the same time, the technical characteristics are almost at the same level.

Lakhta waterproofing is used primarily to protect almost all types of premises from moisture. It is often used to increase the moisture resistance of walls and floors in wet rooms - cellars or garages.

Penetrating waterproofing Kalmatron

A popular mixture that effectively seals even the smallest leaks and enhances the strength of the concrete surface. The composition is very versatile, it can be applied to surfaces made of concrete, reinforced concrete, brick, aerated concrete and foam concrete. In any case, it will be effective. With all this, the cost of Kalmatron mixtures is generally even lower than the analogues mentioned above.

The only important requirement when using Kalmatron penetrating waterproofing is that the Ph level at the site should be in the range of 3-11. Otherwise, using the mixture is not recommended.

Scope of application of Penetron waterproofing

Construction professionals have long appreciated the capabilities and advantages of penetrating waterproofing of the Penetron system. This unique system of materials has been used for 20 years at such critical facilities as nuclear power plants, spent nuclear fuel disposal sites, hydroelectric power stations, water utilities, metallurgical enterprises, housing and communal services and agriculture.

Such a wide scope of application of this system is explained by the high technical characteristics that concrete acquires after treating it with Penetron.

The waterproofing effect is achieved due to the penetrating effect, the depth of which, according to recent research, can reach 90 cm. Chemical components, interacting with ionic complexes of aluminum and calcium, create insoluble crystal hydrates in pores and microcracks. Thus, an openwork mesh of needle-shaped crystals is created, which prevents the penetration of water into the concrete body, but at the same time leaves it vapor-permeable.

Materials of the Penetron system increase the water resistance class of concrete of any brand by more than 4 levels, frost resistance by 100 cycles from the original indicators. The compressive strength of a concrete structure increases by 20%. These characteristics have been confirmed by numerous tests, including the Federal Nuclear Center in Snezhinsk, VNIIZhB RF, independent laboratories in Russia, the USA and European countries. The Penetron material system is certified by the Federal Environmental Protection Agency (USA) and the State Sanitary and Epidemiological Supervision Service of the Russian Federation.

Penetrating waterproofing in new construction.

The scope of application of Penetron waterproofing extends to both existing facilities and those under construction. At the stage of new construction, it is necessary to use the Penetron Admix waterproofing additive. It is easy to use and is used as an additive for concrete when mixing. This additive has no analogues, since it not only increases water resistance and gives high chemical resistance to the solution, but also gives it the ability to self-heal cracks with an opening of up to 0.4 mm.

During shrinkage and subsequent operation, microcracks inevitably appear in the concrete body; thanks to the Penetron Admix waterproofing additive, they are overgrown with crystals, thereby increasing strength and resistance to aggressive environments. It is impossible to break such waterproofing. This is the main advantage of this line of materials. Moreover, surface insulation lasts no more than 4-5 years; its tightness is easy to break even at the construction stage during backfilling of the foundation. Penetrating waterproofing "Penetron" cannot be damaged; it acts inside the concrete for its entire service life. That is why the issue of waterproofing with the help of Penetron can be resolved once and for all. Moreover, the use of this insulation is three times cheaper than traditional materials!

Penetron for restoring damaged waterproofing.

Another area of application is the restoration of damaged insulation in existing facilities. The dry mixture is mixed with water and applied with a brush to the concrete surface. Thus, simplicity is combined with high technology. After 28 days from the moment of application, the concrete acquires all the specified parameters. If the grade of concrete did not exceed the water resistance indicator W0, then after applying Penetron this indicator increases to W8. The waterproofing effect is maintained throughout the service life of the concrete, which does not require repeated work.

This penetrating system is most effective for waterproofing foundations and underground structures when the use of waterproofing outside the facility is impossible. Penetrating into the body of concrete, Penetron protects not only the surface on which it is applied, but preserves the entire thickness of concrete from moisture and aggressive factors. That is why Penetron works where traditional materials fail!

Waterproofing seams.

For waterproofing cracks, seams, joints, interfaces, abutments, and service entries in statically loaded concrete structures, the Penecrit material is used, a dry mixture consisting of special cement, quartz sand of a certain granulometry, and patented active chemical additives. “Penecrete” is characterized by high strength, lack of shrinkage, and has good adhesion to concrete, metal, brick and stone.

“Peneplag” is intended for emergency elimination of pressure leaks in structures made of concrete, stone, brick..

A special feature of this material is its very short setting time (only 40 seconds) and the ability to expand during the setting process. Can be used underwater. To quickly eliminate pressure leaks in structures made of concrete, stone, brick and similar purposes, “Waterplug” is also used. However, the setting time for this material is about 3 minutes. Like Peneplug, it can be used under water, but Waterplug does not contain penetrating additives, so it requires additional treatment with Penetron.

For reliable waterproofing of working seams and junctions, both horizontal and vertical, “Penebar” is used - a composite polymer material, which is a bundle with a cross-section of 19 mm x 25, intended for sealing seams and joints of underground structures, as well as places of passage of utility lines operated at temperatures from minus 60º C to plus 100º C. “Penebar” has the ability to increase in volume under the influence of water. It has low water permeability, as well as high resistance to hydrostatic pressure, the properties of the hydraulic gasket do not change over time, its service life is not limited, “Penebar” is quickly and easily installed, without requiring special devices, work can be carried out all-season.

Bituminous waterproofing of concrete

Bitumen waterproofing of concrete is one of the most common and simplest options for waterproofing concrete surfaces, in particular foundations. Bitumen mastics are easy to apply, do not form seams, and can be used even on elements with a complex configuration.

This concrete waterproofing protects concrete bases from groundwater at the capillary level. But only in situations where these waters are one and a half to two meters below the basement floor line.

An average of 2-2.5 kg of bitumen waterproofing is used per square meter of concrete. Moreover, it must be applied in at least two layers. If the foundation lies at a depth of 3-5 meters, then there should be three or four such layers. The process for applying bitumen waterproofing is as follows:

- Preparing the base. It is important that the base for applying concrete waterproofing mastic is strong, clean and continuous. The edges and corners must either be chamfered or made rounded. If there are a lot of “shells” from air bubbles in the concrete surface, you need to rub the surface with a fine-grained cement mortar. Any dust, dirt and debris should be removed. Also be sure to ensure that the surface to be waterproofed is dry.

- Application of primer. To improve adhesion, you can apply a bitumen primer to the surface. This is a ready-made primer that can be applied without additional preparation. The main thing is to choose a primer that matches the waterproofing used. The primer can be applied with a roller or a wide brush. After applying the primer, you need to wait until it dries, after which you can apply the mastic.

- Applying mastic. The mastic should be applied to the wet side (the one where the water will come from). It is best to use a roller for application. With its help, you can apply the mastic as evenly as possible and without tearing. The direction is bottom-up. Each new layer should be applied only after the previous one has completely dried.

- Waterproofing reinforcement. For reinforcement, you can use fiberglass or rolled materials. For example, you can “drown” fiberglass in the first layer of mastic and roll it with a roller. When the layer dries, cover it with the next one. Reinforcement allows you to evenly distribute the tensile load and prevent the formation of cracks.

Note! We do not recommend using mastics made from pure liquefied bitumen. Such coatings are short-lived and after a few years may lose their original properties.

Waterproofing from the inside

As a rule, foundation waterproofing is done from the outside. It's simpler and often more effective. Internal waterproofing is usually done in cases where external waterproofing was not done at the construction stage. Or in order to improve the quality of waterproofing at particularly high humidity. To insulate concrete from moisture from the inside, you can use different materials:

- roll (bitumen, adhesive) waterproofing;

- membrane waterproofing;

- liquid rubber and glass;

- coating (cement) waterproofing;

- deep penetration waterproofing for concrete;

- injection waterproofing.

The most effective are penetrating, coating, membrane waterproofing, liquid rubber and glass. The choice of the type of waterproofing and the method of its application depend on the amount of precipitation and groundwater level, the characteristics of the room, foundation materials, the presence of a drainage system around the foundation and other factors.

In most situations, you can use universal dry waterproofing for concrete, which is dissolved in water and mixed until creamy. Thanks to the presence of active additives, such a composition penetrates deeply into the structure of concrete, activates a chemical reaction with its components, and forms crystalline complexes that fill all the voids in the concrete.

Thanks to this, the dry mixture for concrete waterproofing effectively prevents the penetration of moisture through the concrete structure, filling pores, microcracks and almost any empty space.

It must be remembered that the use of penetrating waterproofing reduces the thermal insulation properties of concrete. Therefore, in most cases, it is also necessary to provide good thermal insulation to ensure a comfortable temperature in the room. When using penetrating insulation from the inside, remember the most vulnerable areas:

- joints between walls and ceiling or walls and foundation;

- concreting seams;

- places of input-output of various communications;

- any technological holes;

- expansion and expansion joints, etc.

At these points, waterproofing must be carried out especially carefully and precisely so that it completely covers the entire area without gaps. The same applies to thermal insulation. If done poorly, cold bridges will remain. Therefore, if you do not have enough experience for such work, we recommend that you immediately contact specialists.

Waterproofing concrete outdoors

External waterproofing of concrete is usually carried out during the construction of the foundation. It is the foundation walls that act as the protective contour of the basement, the task of which is to prevent moisture from entering the basement. At the same time, it is necessary to qualitatively protect not only the foundation from the outside, but also the floor. Otherwise, moisture may enter from below.

Liquid rubber gives good results. When applied correctly, it creates an absolutely hermetic film on the surface that does not allow moisture to pass through. Moreover, this does not affect the thermal insulation in any way.

As an alternative to liquid rubber, we can recommend polymer-bitumen mastics. They also create a dense and seamless “blanket” over the entire area, preventing moisture penetration. In addition, such a membrane gives very good adhesion to concrete and additionally acts as an anti-corrosion coating.

You can also use coating waterproofing based on synthetic resins and polymers. The principle of their operation is the same as described above - the mixture penetrates deep into the concrete structure, clogs all pores, microcracks and small voids.

Recommendation! Before applying waterproofing, we advise you to first make a sand-cement screed. This way you can easily level the surface and thereby reduce material consumption. For better adhesion, the screed layer should be coated with a primer after drying. And only after that apply a layer of waterproofing.

Application areas of PENETRON

Hydraulic structures: reservoirs (open and bunded), swimming pools (open and closed), wells, docks, berths, structures of treatment facilities (air tanks, settling tanks, collectors, pumping stations), concrete dams, dams. Civil engineering objects: foundations, basements, underground structures (parking lots, garages, passages), balconies, operated and unused roofs, elevator shafts, vegetable pits. Industrial and agro-industrial complex structures: production facilities, cooling tower basins, storage facilities, chimneys, shafts, bunkers, concrete structures exposed to aggressive influences. Civil defense and emergency facilities: shelters, fire tanks. Energy complex facilities: spent fuel pools, pumping stations, spent fuel storage facilities, canals, fuel supply racks, cable tunnels, concrete structures exposed to radiation. Transport infrastructure objects: tunnels (road, railway, pedestrian), subways, elements of bridges and roads.

Mixtures for concrete waterproofing

The modern buyer has access to a very large selection of waterproofing mixtures for concrete. Among them there are products from both domestic and foreign manufacturers. In addition to those listed above (Penetron, Lakhta, Arena, Kalmatron), it is definitely worth mentioning other popular brands:

- Ceresit. These are, as a rule, one-component polymer mixtures, ready for use. They form hard, waterproof coatings, are easy to apply using a roller or brush, and are environmentally friendly and safe. There are mixtures for interior and exterior use, as well as universal ones that are suitable for both tasks.

- Mapei. These are quick-drying compounds based on synthetic resins. The manufacturer also has mixtures for interior, exterior and universal use. The advantage of most of the manufacturer’s mixtures is very fast setting. Among them there are also super fast-setting ones. For example, Mapei Lamposilex, which contains a hydraulic binder, which allows you to literally instantly stop water leaks.

- Quick-Mix. The manufacturer offers both dry cement-based building mixtures and rigid coating waterproofing solutions. Many of them are universal, suitable for interior and exterior work, and can be used to insulate foundations, walls, floors and ceilings from moisture.

- Litokol. One-component and two-component waterproofing compositions with good resistance to temperature changes and even aggressive influences. The manufacturer has mixtures for waterproofing swimming pools that provide water resistance at fairly high pressure - up to 3 bar.

To choose the right concrete waterproofing, follow our tips:

- The mixture must have a declaration of conformity. This requirement is effective from December 27, 2020. If there is no such declaration, we do not recommend using this mixture.

- The packaging must contain information about the mixture’s compliance with the requirements of GOST 56703-2015. This information, as a rule, is not available only on surface waterproofing.

- The packaging or accompanying documentation must also contain instructions for use. Its presence is not only a kind of guarantee of higher quality, but also a mandatory component for proper use.

- The packaging must be sealed and dry. The ingress of water and other compounds can spoil the mixture.

- Pay attention to the expiration date. For dry mixtures it is usually 6 months, and for Penetron mixtures it is up to 18 months. But only on condition that the packaging is intact.

- Buy products from trusted brands. When choosing waterproofing, it is better to overpay a little, but know that you have chosen quality products from a good brand. This guarantees environmental friendliness, long service life and compliance with current standards.