Home / Baths

Back

Published: 08/03/2020

0

0

- 1 Bathhouse lining without outside help is easy 1.1 Internal lining

- 4.1 Frame installation

How to cover a bathhouse with siding

Content:

- Siding features

- Types of material

- Preparation

- Finishing order

- Frame

- Insulation

- Sheathing

Finishing a bathhouse with siding is a fairly current way of cladding a building. This is due to the financial availability of the material and its ease of installation. In addition, siding perfectly protects the surface from the destructive influence of atmospheric phenomena and can skillfully imitate any material (brick, beams, stone, etc.). In this article we will look at how to cover a bathhouse with siding with your own hands.

Features of siding for finishing a bath

Before proceeding with the installation steps, it is recommended that you familiarize yourself with the technical characteristics of the siding:

- High wear resistance

. Siding is a strong and durable material that does not require frequent maintenance. But when washing it, it is recommended to avoid using strong detergents and rough brushes. Thus, you can significantly increase the service life of the material.

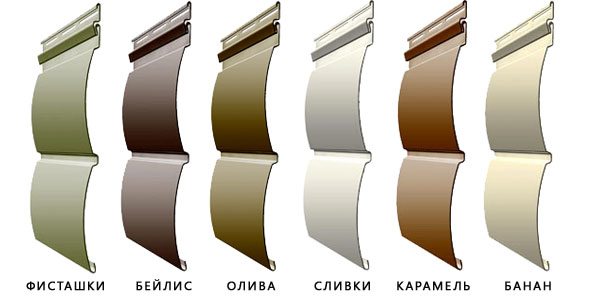

Large selection of colors and textures

. Siding can copy natural materials 100%, which is why many people choose it.

Easy to install

. Siding panels are installed on any material in a similar manner. All steps are repeated for concrete, wood, brick, foam blocks. It is worth noting that installation operations are described in detail in the manufacturers' instructions.

Environmental friendliness

. For the production of siding, raw materials are used that are not afraid of mold, fungi and parasitic insects. Siding does not cause allergies, so many people use it for cladding walls inside.

Availability

. Siding is one of the most affordable products among facing materials in Russia.

- Additional properties

. Siding panels perfectly insulate a building from sound and retain heat inside when using thermal insulation materials. The siding also has protection from ultraviolet rays, so it does not fade or crack in the sun.

Features of the structure of a log bathhouse

A traditional Russian bath is characterized by a combination of high humidity and relatively low temperature, compared to a dry sauna, for example. Wood, preferably a log, as a building material is best suited to support such a regime.

Types of siding for cladding a bathhouse

To decorate a bathhouse with siding, wooden, vinyl and basement types are used:

- Wooden material

. Contains various resins and additives that increase resistance to moisture and temperature changes. When choosing wooden material, remember that it needs to be treated with special substances that repel pests.

Vinyl material

. This type of siding is made from polyvinyl chloride. It consists of two layers: the first protects the building from atmospheric influences, and the second is a durable substrate.

. It is used specifically for covering the base and has high strength characteristics. Basement siding is made from polypropylene resins and special components are added to improve durability.

Bathhouse cladding with imitation timber

Imitation timber is a type of lining that is used for cladding facades. Board dimensions: thickness – 1 cm, width – from 10 to 16 cm.

A distinctive characteristic of the material is the presence of a central groove to relieve stress in the wood, which helps extend the service life of the finish.

Imitation wood is made from various species, but coniferous wood is considered the best.

The main advantages of the finishing material include:

- environmental safety;

- affordable and quick installation;

- resistance to aggressive substances and damage;

- aesthetics;

- variety of standard sizes - width, length and thickness;

- high thermal insulation characteristics;

- long service life.

But even such a practical material is not without significant drawbacks:

- the need for periodic treatment with antiseptics and fire retardants;

- susceptibility to fire and rot;

- the possibility of deformation due to insufficient drying or the use of low-quality raw materials for manufacturing.

The log house of the bathhouse is sheathed horizontally with the tenon facing outwards. This type of fastening is resistant to deformation and moisture penetration. The material is mounted on a flat surface using wooden or metal sheathing. Before painting, the imitation wood is carefully sanded with fine-grain sandpaper.

Preparing to cover the bathhouse with siding

Before starting work on installing siding for a bathhouse, you need to be well prepared:

Remember that the finishing of the external walls of a wooden bathhouse begins only after it has completely settled.

Make sure that there are no cracks in the walls of the bathhouse and that the surface is completely flat. Otherwise, the finish will look crooked and adhere unsteadily to the sheathing.

For the sheathing you will need a punch, hammer, tape measure, fasteners, spring punch, tin snips, staple gun, punch and level.

Preparing the structure

Before this work, you will need to thoroughly prepare the bathhouse. Despite the fact that siding is used quite often for bathhouse cladding, in some cases it is better to prefer other options.

So what's important to know?

Stages of work

| The walls should be as smooth as possible | Only then can high-quality fastening of the sheets be achieved. If you plan to finish a wooden structure, it is better to wait for it to completely shrink. Otherwise the structure will look bad. |

| Between the caps and panels of the parts you need to leave a small space (about 1 cm) | Temperature changes can cause siding to warp. |

Having familiarized yourself with these requirements, you can proceed to preparing the bath.

Here are the important points to remember:

- There should be no cracks or holes in the walls, otherwise the panels will be attached unstable.

- It is better to choose self-tapping screws or nails made of stainless steel. They must be at least 30 mm in length and at least 8 mm in diameter.

Tools required for installation:

- Hammer.

- Spring center punch.

- Scissors for cutting metal.

- Roulette and hammer.

- Parts for fastening.

- Punch punch for perforation.

- Stapler for construction work.

How to determine the amount of siding for a bathhouse

These panels are of high quality and have an attractive appearance.

First, measurements are taken:

- It is necessary to measure the walls.

- Window.

- Broken and triangular pediments.

- Soffits are also calculated.

Here are instructions that will help you correctly calculate the required amount:

- Having received the overall dimensions of the walls (this includes width and height), it is necessary to calculate the working area. To do this, use the formula S= wall length * wall height.

- Using the same principle, the size of the remaining walls is calculated, then the indicators are added up and the main footage is obtained.

- Then you need to calculate the area of doors and windows. The resulting number is subtracted from the area of the walls of the building.

- The same formula is used to calculate the area of one siding panel.

- The area of the house is divided by the area of the panel, the number that is needed is obtained.

The table shows an approximate calculation of the amount of material for buildings of different sizes.

| Bath length | Bath width | Height | total area | Area of doors and windows | Quantity of material required |

| 8 | 5 | 3 | 24 | 7 | 17 |

| 9 | 8 | 3 | 27 | 9 | 18 |

| 15 | 12 | 3.5 | 52.5 | 15 | 37.5 |

The procedure for finishing a bathhouse with siding

Covering the outside of the bathhouse with siding is carried out in several stages. Let's get to know them better.

Creating a frame for attaching siding to a bathhouse

Install vertical supports made of wood or metal profiles. If you prefer wood, prepare bars 30x40 or 50x50 mm; if a metal profile, use a ceiling profile 60x27 or 50x50 mm. Remember that the distance between wooden or metal posts should be 40-60 cm.

The creation of the frame begins with the installation of corner supports. To form the corners, connect the supports together so that they are at an angle of 90 degrees to each other. Then attach the remaining studs to the walls using straight or short hangers. The choice of hangers depends on the distance that needs to be left for the insulation or ventilation gap. The hangers are screwed using self-tapping screws (used for wooden walls) or dowels. To make work easier, stretch a cord between them - it will serve as a guide for installing the next racks.

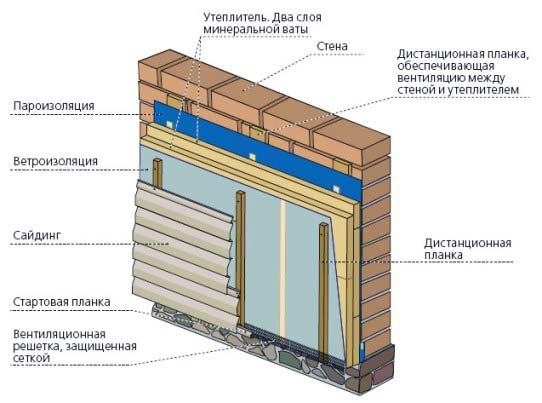

Laying insulation when covering a bathhouse with siding

For insulation, glass wool and its variations are used mainly, as well as polystyrene foam and polystyrene foam of different densities. Insulation is sold in the form of rolls, mats or thermal insulation boards. When choosing the shape of the insulation, be guided by the size of the gaps between the frame supports, since it will need to be laid exactly there. For example, if the gap size is about 50 cm, it is convenient to lay 50x100 cm mineral wool mats.

The thickness of the insulation depends on the climate of the region in which the bathhouse is located. In the south of Russia, the thickness varies between 5-10 cm, in the north - 20-25 cm. After installing the insulation, cover it on top with a waterproofing film - attach it to the sheathing with a stapler. Start with the bottom row and stretch the film horizontally. Install the next rows with an overlap of 100 mm on the previous ones. After this, make a counter-lattice under the siding.

The procedure for covering a bathhouse with siding

Using a level, measure the line of the end of the base ebb, on top of which you need to attach the starting strip. Install an H-profile where the panels join. This element is optional, but over time dust will accumulate at the joints, which can ruin the appearance of the bathhouse.

Installation of siding begins from the middle of the wall to the edges. First, set the starting bar. Attach it using self-tapping screws to the lower points of the frame supports in a horizontal direction.

Facing with siding panels is carried out from the bottom up. Each panel is equipped with special grooves in the lower and upper parts. Take the next panel and slide the bottom of it onto the starting strip. Place and snap the top row panel onto the top groove of the installed panel. There is a cutout on the side of the siding panels designed to allow each panel to overlap the other. Thus, there will be no voids between the panels.

Warm plaster

In brick saunas with a solid foundation, a mortar based on cement and sand is used for cladding. It is used less frequently in wooden structures. In this case, you need to caulk all the cracks so that there are no holes or gaps left.

Before cladding, the building is insulated. You should prepare a beam 3–5 cm in size, which will be used to create the sheathing. In addition, you will need dowels shaped like “umbrellas,” glue for polystyrene foam, polystyrene foam, a reinforcing mesh made of plastic, and a frame for creating “warm plaster.”

Installation must be carried out in strict sequence:

- Make a sheathing.

- Attach the insulation panel with dowels (strictly horizontally). When fastening, it is necessary to monitor the position of the seams. They should not be along the same line.

- Lay the second heat-insulating layer vertically. Secure it with glue capable of securing foamed polystyrene.

- Cover the structure with reinforcing mesh.

- Apply “warm plaster”.

The service life of “warm” cladding is several times longer than other cladding methods.

Finishing a bathhouse with siding: useful properties

Most often, the outside of a bathhouse is decorated with wood, but this method is gradually becoming outdated. New cladding options make the building more interesting and modern.

Note. Quite often, many people are concerned about this question: is it possible to cover a bathhouse with siding? This method is affordable, and all the work can be done independently.

Before choosing a material and starting sheathing, you should carefully read the positive characteristics:

- Ease of installation . The panels can be easily installed on a wide variety of materials, be it wood or concrete.

- Attractive price.

- Large assortment of different colors . Siding can serve as an imitation of wood or other material. This partly explains its popularity.

- Strength and durability. The panels do not require careful maintenance. It is only important when cleaning not to use too hard brushes or intense chemicals. They can cause harm.

- Immunity to sudden changes in temperature and aggressive environmental influences.

- Does not cause an allergic reaction.

- Not subject to rotting processes.

Safety and environmental friendliness. Special materials are used to create them that prevent the appearance of mold, harmful insects and fungus.

Covering a log bathhouse: options

The log house itself is an aesthetically attractive sight. And no matter how much you want to protect it, you no less want to preserve its appearance. Siding for a log house, or block house, can easily cope with this task.

The finishing consists of thin cladding boards made from various materials, imitating the shape of a rounded log, the structure and color of wood.

- Its main function is to protect the base walls of the building from the effects of sun, rain, snow and wind. Therefore, its defining qualities are moisture resistance, resistance to fungi and mold, resistance to fading and severe frosts, and, of course, the ability to withstand high wind loads. The ideal option is easy to clean and lightweight, in order to simplify the installation and dismantling process as much as possible. And, of course, affordable cost is an important factor, since it is the finishing that will be damaged first and require replacement. But the bathhouse covered with a block house will not suffer at all.

Thermal and sound insulation properties are not mandatory qualities.

Is it possible to cover a bathhouse with siding: types for exterior decoration

The following types are used for the exterior decoration of bath buildings:

Vinyl

Made from polyvinyl chloride.

- The first provides reliable protection against aggressive influences.

- And the second acts as a reliable substrate.

Wood

Advice. However, such species require additional treatment with antiseptic compounds that prevent the appearance of harmful insects.

Tsokolny

This type is made from polypropylene raw materials. To make it more durable, special components are added.

Finishing a bathhouse with siding: instructions for covering

Why do you need to decorate a bathhouse with siding? The question is ambiguous. If the bathhouse is built from rounded logs or peeled timber, then no cladding is inappropriate. The tree already has an attractive appearance. People consider the opportunity to somehow decorate a building when its appearance does not fit into the overall design of the site.

Another reason for external cladding is the material used in construction. For example, adding originality to a brick bathhouse by covering it with decorative stone will be expensive, but why not use siding in this case?

Siding is a simple and inexpensive option for finishing an old bathhouse when other options for adding attractiveness are unacceptable or expensive.

Paneled bathhouses in suburban areas are not that uncommon today, despite the large number of opponents of this material. Siding is inexpensive, and you don’t need to invite specialists to install it; you can do everything yourself, armed with the necessary tools.

Lining

The facade of the bathhouse sheathed with natural materials looks aesthetically pleasing and gives the building individuality.

A bathhouse made of rounded logs or laminated veneer lumber looks attractive and does not require additional finishing of the facade. But what if the construction was framed or made of cinder blocks? It is necessary to finish the bath and give it an aesthetic appearance. There are a lot of finishing materials on the market, but making a choice on your own can be difficult. How to cover the outside of a bathhouse, what materials are suitable, their features, pros and cons, we will consider together with our readers.

To preserve the appearance of a traditional Russian bathhouse, when decorating the external walls, a common cladding material is used - clapboard. Eurolining is especially in demand. This is a wooden board of small thickness. Lining has all the advantages and disadvantages characteristic of wood. To extend the service life of eurolining, it is treated with antiseptics and coated with varnish or paint.

In order for the cladding of the bath to be done correctly, it is necessary to strictly adhere to the installation technology. Step-by-step execution of all operations will allow you to carry out the cladding yourself:

- Install brackets on the wall. In this case, it is necessary to observe a step that should not exceed 50 cm. The brackets must be positioned horizontally.

- Cover the outer surface of the wall with mineral mats. For fastening, use the prepared adhesive composition. The use of dowels is acceptable.

- Attach a guide to each bracket. To check the correct location of these finishing parts, use a building level or plumb line.

- Cover the insulation with waterproofing material.

- Attach the lining to the fixed guides.

Bathhouses can be lined with clapboards with a humidity level of no more than 15%. Otherwise, after drying, unwanted gaps may appear in it.

Types of siding for finishing

It is impossible to separate the panels used for covering the bathhouse separately. We can only say that siding is used for exterior work. The interior decoration of the bathhouse is made with wooden lining; the plastic from which the panels are made is completely inappropriate here.

A variety of siding models, varying in size, color and material used in production, allow you to create a rather unique design. The most common option is vinyl siding. He was the first to come to the Russian market, and it is from him that panels today are commonly called vinyl. Although this is a general expression. Siding is made from various materials, and there are even wood panels. The variety of colors and structures also allows you not to focus on one thing. Panels with a smooth surface, embossed, plain and colored - the choice is simply huge.

Vinyl panels are made from PVC. When molding, the siding is pressed into two layers: the bottom one is responsible for mechanical stability, the top one, treated with protective compounds, is resistant to climatic factors. These two qualities allow vinyl panels to “work” more efficiently on any walls, be it a brick or frame bath.

Decorative siding is also attractive for finishing baths. These are panels that imitate various materials: wood, brick or natural stone. With proper stitching, the external finishing with such siding will exactly repeat the structure of these materials. If you are finishing a log bathhouse made from untreated logs, then it is better not to use plastic panels. It is more appropriate to purchase siding made from pressed shavings. Plastic does not interact very well with wood. That is, there are no prohibitions on installing PVC panels, but you will additionally have to install waterproofing to prevent condensation from accumulating on the wood. When using wood panels, this is not necessary.

Front area finishing

The cladding of the front part of the steam room is made from the material used for finishing the facade. The material used in the construction of this segment of the bathhouse is also important:

- The wooden pediment can be covered with any material. First you need to install waterproofing, for which a membrane material is used.

- The concrete gable parts are pre-leveled, the sheathing is attached to them, and the sheathing is mounted. The use of molded relief elements is permitted.

Attaching the sheathing material to the pediment is done in several ways:

- Using aluminum stands. They are attached directly to the gable surface of the bathhouse building.

- If the upper front part of the facade is made of wood, the siding is attached directly to the surface.

- Using slats made from wooden materials. The elements are pre-installed on the gable part of the building.

After covering the gable and roof, drains must be installed and a sewerage system for wastewater must be installed. These measures will provide additional protection to the building.

Installation instructions

Installing siding panels is easy. To work, you need to prepare a minimum set of tools that any home craftsman has:

- hammer drill or impact drill;

- metal scissors and stapler;

- level, tape measure and plumb line;

- hammer and pliers.

The sheathing for siding can be made from both ordinary bars and metal profiles.

There is nothing supernatural about installing siding. And given that the bathhouse, as a rule, is not large in size, you do not need to build scaffolding to install the slats under the roof; you can get by with a good stepladder. The material is prepared in advance, and before installation it must be allowed to rest outside the packaging for several days. It is better to choose vinyl panels for a bathhouse; they are less susceptible to moisture.

If enough time has passed since the construction of the bathhouse, that is, the shrinkage process is over, and the log house has already found its permanent place, you can begin work. And first you need to prepare the surface. Recommendations for cladding will be given regarding a log bath, and for each material the preparatory process is carried out in its own way.

Decorative design of the pediment

What is the best way to cover the gable of a bathhouse? The answer to this question depends on what material was used to manufacture it and decorate the facade of the building.

- The wooden pediment is sheathed with any material with preliminary waterproofing of the surface.

- Concrete and brick pediments have no restrictions; the only requirement is leveling the surface and installing sheathing under the cladding.

The pediment cladding is made with the following materials:

- professional sheet;

- siding;

- bitumen shingles;

- block house;

- stucco.

The finishing material is attached to the pediment on a prepared surface, on a wooden sheathing or aluminum posts.

To decide what material to cover the facade of a bathhouse with, it is important to take into account not only your financial and technical capabilities, but also the design features of the structure. At the same time, all the work on installing the cladding can be done independently, the main thing is to follow the basic rules and recommendations.

Installation of panels

The photo shows the installation of the starting strip before siding.

The base strip is attached first. This will be the starting point on which the evenness of the entire installation will depend, so you need to check it 5 times before installing it. To mark the installation line for the plinth strip, you need to be 20 cm above the level of the ventilation ducts in the bathhouse foundation. Having secured the base strip, the horizontality is checked again, and if there are no deviations, you can proceed to further actions.

All subsequent panels are installed until the lock clicks, if panels with such fastening are selected. The planks, installed in a tongue-and-groove or overlapping manner, are fixed with staplers or small nails in special places, which are then covered with the next panel. In this way, the entire wall rises. At the level of installation of windows or doorways, the panels are cut to the required size, and the corner joints are closed with additional strips.

The entire installation process is carried out under constant control of the level of horizontal laying of the panels. Even a slight misalignment can affect the evenness, ruining the entire appearance. The panels are fastened with self-tapping screws; there is no need to screw them in all the way, leaving 2 mm for the deformation gap. Then neither heat nor frost in winter will affect the integrity of the finish and the appearance of the bathhouse finished with siding will cast a yoke of envy on the neighbors for a long time.

Work order

Finishing bathhouse siding requires care and precision.

All work is carried out in several stages:

| Vertical supports are installed. | You can use wood or metal profiles. The gaps between the posts are about 40-60 cm. |

| A frame is created. | Corner supports are being installed. To form the corners, you need to connect the supports at right angles. Then the other posts are attached to the walls. For this purpose, direct hangers are used. They are screwed using self-tapping screws or dowels. |

| Insulation is being installed. | Glass wool is usually used; polystyrene foam is also popular (see Insulation for facades under siding: how to choose). When choosing a shape, you need to take into account the size of the distance between the supports of the frame itself, since the insulation is placed there. It is advisable to cover it with a special waterproofing film after laying layers of insulation. |

| The line of the end of the base ebb is measured. | The starting bar is fixed on top. The panels themselves are installed from the middle to the edge of the wall. First, the starting bar is set. It is attached with self-tapping screws to the lower support points in a horizontal position. Paneling is done from bottom to top. Each panel has special grooves at the top and bottom. There is a hole on the side of the panels designed to allow the new panel to fit behind the previous one. |

Is it possible to cover a bathhouse with siding?

The bathhouse, 6x3, made of 100x150 timber, has been standing and pleasing for more than 10 years. There have already been renovations, some of the crowns have been replaced, the floors have been re-laid, etc. One thing is bad: the birds stole all the tow, I have no desire to caulk, I just want to cover the outside of the bathhouse with siding, with roll insulation, so that the temperature does not drop so rapidly. I want to do everything as it should be, with vapor barrier, wind protection, etc. It was only when I shared my plans with my neighbors and work colleagues that I heard: a bathhouse? siding? Nobody does that. Why? But the devil knows him, it’s not accepted. Indeed, I walked through the gardens and looked. I didn’t see a lined bathhouse anywhere. Maybe there is a secret meaning to this?

White Cat wrote: Maybe there is a secret meaning in this?

There is no secret meaning, sew whatever you want for your health. Moreover, it has been worth insulating for a long time, only for the good. As for what no one does for you, let you be the first.

White Cat wrote: Why? But the devil knows him, it’s not accepted. Indeed, I walked through the gardens and looked. I didn’t see a lined bathhouse anywhere. Maybe there is a secret meaning to this?

Everything is simpler. Bathhouse - impulse use. 3-4 hours per week. How much will you save on insulation? One extra log? Is it worth it? Another thing is that there shouldn’t be drafts. There is caulking for this. Cover it from birds with a strip or sealant special for log houses. If you add siding, the log house will dry out more slowly and you will end up with dampness and all that it entails. There is no point in insulating a bathhouse with siding.

Vladimir_Vas wrote: get dampness with all that it implies.

In fact, it is always possible to open a door, a ventilation window, or a pipe in the stove.

Vladimir_Vas wrote: the log house will dry out more slowly

Don't you think that wood absorbs like a sponge and gets wet through and through, but dries outside?

Vladimir_Vas wrote: If you pile up the siding, the log house will dry out more slowly and you will get dampness with all that it entails. There is no point in insulating a bathhouse with siding.

So for this purpose ventilation must be provided. For drying, I mean. And good, because the room is damp.

Vladimir_Vas wrote: Everything is simpler. Bathhouse - impulse use. 3-4 hours per week. How much will you save on insulation? One extra log? Is it worth it? Another thing is that there shouldn’t be drafts. There is caulking for this. Cover it from birds with a strip or sealant special for log houses. If you add siding, the log house will dry out more slowly and you will end up with dampness and all that it entails. There is no point in insulating a bathhouse with siding.

It's not about logs. When I come in winter, I get the impression that the heat goes away very quickly. If in the steam room it is even more or less, then in the washing room it is quite cool, and in the locker room it is quite cold. The heat just flies away through the cracks and doesn’t stick around. There are no problems with firewood, the sawmill is nearby, they generally give away the trimmings for free, as much as you take away, it’s all yours.

Covering a bathhouse with siding with your own hands: Step-by-step instructions + Photos and Videos

Covering a bathhouse with siding with your own hands - video + Photo.

Why is it necessary to cover a bathhouse with siding? This question is ambiguous. If the bathhouse was built from peeled timber or rounded logs, then in this case no type of cladding would be appropriate, since natural wood is attractive in itself. People consider finishing a building if its appearance does not fit into the design of the site as a whole. Another reason to carry out external cladding is the material used in construction. For example, to make a brick bathhouse original, it can be lined with decorative stones, which will be quite expensive.

In this case, the possibility of covering with siding seems appropriate. This material is a simple and, most importantly, inexpensive option for finishing a bathhouse of an old building, since other options for creating an attractive appearance will be too expensive or simply unacceptable.

Finishing the gable of the bathhouse

The cladding of the pediment is carried out depending on its design and the material used to decorate the facade. It is also important what the pediment itself is made of:

- A wooden pediment can be sheathed with any material, but it must first be waterproofed using a membrane material.

- For concrete gables, the surface is first leveled and the sheathing is installed. The sheathing is attached to the sheathing.

Finishing the gable of the bathhouse will give the facade a finished look and additionally protect the structure from moisture.

In order not to disturb the unity of the ensemble, the gables of the bathhouse with finished imitation or siding are sheathed with the same material. For brick and concrete structures, stucco can be used in the form of various relief elements. Iron sheets are well suited for finishing the gables of a bathhouse, but due to the high cost, this option is rarely found. The easiest and most inexpensive way to cover a gable is with siding panels.

In the photo on the right you can see the pediment of the roof of the bathhouse with an attic, trimmed with plastic lining. It goes well with the siding that was used to cover the facade. If you take lining in a contrasting color, you can give the structure a unique design.

There are several ways to attach the material to the pediment:

- Using aluminum posts that are mounted on the gable.

- On a wooden gable, siding or imitation timber can be sewn directly onto the surface.

- Using wooden slats, which are pre-attached to the pediment.

We invite you to familiarize yourself with Tiles in a washing room in a wooden bath

After covering the outside of the bathhouse, it is necessary to take care of additional protection. A drainage system is installed on the roof, and wastewater is drained. This is all easy to do with your own hands.

When choosing a material for cladding the outside of a bathhouse, you must take into account your financial capabilities, the material with which neighboring buildings are sheathed, and design features. It is necessary to purchase from well-known retail chains, so there is less chance of encountering counterfeits. And you can do the finishing yourself, the main thing is a little diligence and desire so that the bathhouse will last for many years.

Covering a log house with siding - your home is not only beautiful, but also reliably protected from the aggressive influences of nature

Today, finishing of this kind is very popular and relevant, it will not require any special financial expenses from you, installation operations are not labor-intensive and are easy to perform.

Siding is made from both natural and artificial materials. Both types have excellent quality indicators and consumer characteristics.

When thinking about how to cover a log house with siding, you must remember that the panels:

- excellent resistance to ultraviolet rays;

- absolutely not afraid of strong temperature changes;

- resistant to moisture;

- do not rot;

- are not afraid of insects and mold;

- are resistant to dirt, artificial dyes, and mechanical stress;

- the material is resilient and elastic.

During the production of siding, the following materials are used:

- absolutely harmless to humans;

- do not contain toxic substances;

- fireproof.

Therefore, covering a bathhouse with siding often occurs not only from the outside, but also when performing interior work.

Is it possible to line a bathhouse with siding from the inside? Answer to photo

In addition, the material has the following additional qualities:

- decorative properties;

- There is a wide range of colors to choose from;

- many different textures (log siding, brick or stone);

All this makes it possible to give buildings and bathhouses an aesthetically perfect appearance.

Sauna siding panels can be either vinyl or wood

Before asking the question: is it possible to cover a bathhouse with siding, let's look at its types.

Siding can be:

- wooden;

- vinyl.

Wooden siding, in turn, can be:

- smooth;

- embossed;

- different colors;

- different types of wood.

During production, these panels are treated with special compounds and resins, which gives them strength, wear resistance and moisture resistance.

The products are environmentally friendly, dense, but lightweight - they can be used in various climatic zones.

Color options for “log” siding – the choice is large, the price is reasonable

Vinyl siding is made from several varieties of PVC.

Two-layer product:

- the top layer is resistant to moisture;

- bottom layer - provides decent mechanical protection.

If the bathhouse has wooden walls, the log house is covered with siding using cladding panels made of wood shavings. The finishing of buildings made of stone and brick is also relevant.

When wondering: how to cover a log house with siding, you should take into account certain features and conditions:

- the surface of the walls must be perfectly flat - only then can high-quality installation be achieved and the panels will be securely attached to the sheathing;

- If the bathhouse is built of wood, it can be lined only after shrinkage.

Finishing should be done using simple tools:

- spring punch for perforation;

- level;

- roulette;

- metal scissors;

- hammer.

For any finishing option, siding fasteners must be only aluminum or stainless steel, and their caps must have a diameter of at least 8 mm.

For proper installation there are simple instructions and certain rules

Due to temperature changes, vinyl siding is subject to slight deformation, so a small gap (about 1 cm) should be left between the fastener head and the panel. The fasteners are located in the center of the holes, which are made using a hammer drill - the fasteners must be inserted strictly perpendicular to the panels.

The panels are directly attached so that they can move within certain limits of the holes. Installation of siding begins from the center of the wall, gradually moving towards its edges.

Finishing a bathhouse with wood siding looks very attractive

The choice of finishing method for the pediment depends on the material of its construction. The tree is lined with different materials. Waterproofing is pre-installed. For this, membrane material is used. Concrete gables require preliminary leveling of the surface and installation of sheathing.

To ensure an attractive appearance of the bathhouse, it is recommended to cover the gables with the same material as the walls of the bathhouse. If the structure is made of brick and concrete, then stucco is made. The pediment is finished with iron sheets. This material is expensive. An alternative is siding panels.

To give a unique design, lining is used, the color of which differs from the color of the walls. To fasten the material, aluminum racks are used, which are mounted to the pediment. If the pediment is made of wood, then siding or imitation timber is attached to it with screws with wide heads.

The planks are fastened to wooden slats, which are pre-treated with an antiseptic and attached to the pediment with self-tapping screws or dowels. Sheathing a bathhouse from timber is a good option for improving its appearance and insulating the building. On the modern construction market there is a large number of finishing materials, which are selected according to the intended design and financial capabilities of the owner.

General information

Finishing bathhouse panels in a suburban area today is not uncommon, despite the fact that there are many opponents of this type of finishing material. Siding is relatively inexpensive, and its installation does not require the invitation of specialists, since everything can be done with your own hands; you only need to equip yourself with the tools necessary for installation.

Types of siding for finishing

It is impossible to somehow separate the panels that are used for lining the bathhouse.

We can only note that siding is used for external work. But the internal lining of the bathhouse with siding is carried out with your own hands using wooden lining, but the plastic from which the panels are made will be completely inappropriate. A variety of types, which differ in color, size and material used in production, make it possible to create quite interesting designs. The most common option is vinyl siding. He became the first-born on the Russian construction market, and it was thanks to him that the panels began to be called vinyl, although the expression itself is generalized.

In fact, siding is made from many different materials, there are even wood panels. The variety of structures, colors and types of imitations also make it possible not to focus on one thing. There are embossed, smooth surface, colored and plain panels - the choice is incredible.

Vinyl panels are made from PVC. In this case, during molding, the siding begins to be pressed into two layers - the lower one will be responsible for resistance to mechanical damage, and the upper one, which is treated with protective compounds, will be resistant to climatic factors. These two qualities make it possible to “work” with vinyl panels more efficiently on any surface, be it brick walls or a red bathhouse.

Decor

The decorative type of material is also attractive when covering the bathhouse with siding on the outside. These are special panels that imitate materials such as brick, wood or natural stone. If the material is stitched correctly, the outer finish will perfectly match the structure of the selected imitation material. If you are planning to finish a log bathhouse that is made from untreated logs, then it is better not to use plastic panels.

In this case, it would be more appropriate to buy siding made from pressed shavings, since wood and plastic do not interact well. As you can see, there are no restrictions on installing PVC panels, but you will have to lay additional waterproofing so that condensation does not begin to accumulate on the wood. When using wood panels, this is not required.

How to cover the outside of a bathhouse: lining, imitation timber, siding, block house

The facade of the bathhouse sheathed with natural materials looks aesthetically pleasing and gives the building individuality.

A bathhouse made of rounded logs or laminated veneer lumber looks attractive and does not require additional finishing of the facade. But what if the construction was framed or made of cinder blocks? It is necessary to finish the bath and give it an aesthetic appearance. There are a lot of finishing materials on the market, but making a choice on your own can be difficult. How to cover the outside of a bathhouse, what materials are suitable, their features, pros and cons, we will consider together with our readers.

What material is best to use for exterior finishing?

External finishing of a bathhouse is usually done with facade insulation. Since the bathhouse is small in size, it is more profitable to save internal space and install insulation on the outside. The simplest and most correct option is a ventilated facade. This way, moisture will not accumulate on the walls and the bathhouse will last longer.

For the ventilated facade of the bathhouse, the following materials are used:

- Siding (vinyl, metal).

- Fitting (plastic, wooden).

- Imitation of timber.

- Block house.

Each has its pros and cons. Let's take a closer look at them.

Siding for finishing the facade of a bathhouse

Metal siding does not burn and is considered one of the best materials for finishing a small bathhouse.

Siding is panels with a width of 20 cm and a length of 120 cm. Based on the material from which they are made, it is divided into: vinyl, iron.

The panels come in more than 15 colors, the most popular of which are: pistachio, sedge, cream, and chocolate. Manufactured by foreign and domestic companies. Imported ones are considered more durable, but their prices are higher. The price for material from a domestic manufacturer is from 120 rubles. Before finishing the bath, you need to calculate the required number of panels. The material is attached horizontally from bottom to top, moving 10-20 cm away from the base of the bathhouse onto a lathing made of wood or metal profiles. Self-tapping screws are used as fasteners, which are screwed into a special fastening part.

The main advantages of siding:

- Protects the facade of the bathhouse from snow, rain and wind.

- Tolerates temperature changes well.

- Does not fade over time.

- Resistance to mechanical and chemical influences.

- Made from non-toxic material.

- Permeates oxygen.

- Does not rot and is not afraid of rodents.

- Not hygroscopic.

- High fire resistance.

- Easy to install.

But the material has disadvantages that provoke negative reviews on numerous forums:

- The price of the panels is low, but the connecting panels: external and internal corners, joining are expensive.

- When finishing, the surface of the walls must be perfectly flat or the sheathing must be leveled. If there are slight distortions, the panels will lie unevenly and the facade will look untidy.

- If improperly fastened, the panels may become deformed.

- Although the panels are non-toxic, there is no point in talking about environmental friendliness.

- Dark-colored metal siding gets very hot in the sun.

By choosing this material for finishing the facade of a bathhouse, it is easy to do the work yourself. No special experience or skills are required when attaching panels. The only thing you need to do is start the installation from the bottom and fix the first panel as evenly as possible; the further type of cladding will depend on this.

Imitation of timber for finishing the facade of a bathhouse

You can finish a bathhouse using imitation timber with your own hands, without any experience.

Imitation timber completely copies the appearance of timber masonry. The material costs from 210 rubles, but is considered one of the best for lining a bathhouse outside and inside. If it is not possible to build an expensive all-wooden bathhouse, you can cheat and sheathe a structure, for example a frame one, with imitation. Only specialists can distinguish the bathhouse from the outside.

Imitation timber is a more modern wooden lining, with a width of 10 cm. For external decoration, it is better to take a width of more than 15 cm and a thickness of at least 1 cm. A smaller one will visually reduce the height of the wall and will look like ordinary lining. On the technical side, the imitation of propylene timber has a special groove that relieves tension in the wood and the material will last a long time.

They produce imitation timber from various types of wood. For exterior finishing it is better to use coniferous species, so the material will rot less.

The main advantages of imitation timber include:

- Environmentally friendly, as it is made of wood.

- Easy to install.

- High resistance to mechanical and chemical influences.

- Beautiful appearance.

- Large variety of sizes, both in length and width, thickness.

- Additional thermal insulation.

- With proper care it will last more than 20 years.

But even such modern material has disadvantages, which are discussed on numerous forums:

- It is necessary to constantly treat with water-repellent and antiseptic compounds.

- Wooden material burns well.

- Afraid of mold and insects.

- If you purchase a low-quality one with poor drying, the material will become deformed.

Before purchasing, you need to calculate the amount of material, this way you can avoid unnecessary costs. The outside of the bathhouse must be sheathed horizontally, with the tenon facing upwards. This way the fastener will be less susceptible to moisture penetrating into the lock. The finishing is done on a leveled wall using wood or metal lathing. Wooden sheathing must be coated with antiseptics before installation. The material is processed before installation; this can be done at the end of the work, but then the lock and the inside will not be processed. Before the finishing coating, the imitation is sanded with the finest nozzle. You can take a simpler route and purchase ready-made painted material. The price for this one is from 270 rubles.

Block house for finishing the facade of a bathhouse

Bathhouses lined with a block house look no worse than those made entirely from processed logs, and their price is 3-4 times lower.

The block house came to us from Finland and Canada. This is another type of imitation timber, but with a rounded outer side. a bathhouse sheathed with material is similar to a building made of rounded logs.

Since it is difficult to dry a rounded log, cracks appear on the walls over time. They have to be additionally caulked, which means costs and loss of appearance. The problem can be solved using a block house. The panels are processed and dried in chambers at the enterprise. The standard humidity of a block house is not higher than 12%.

Pros of a block house:

- Environmentally friendly, as it is made of wood.

- Beautiful appearance of the facade.

- It is economically profitable, since a bathhouse made of rounded logs is expensive.

- Easy to install.

- Convenient size.

There are few reviews about the disadvantages of a block house. The most popular ones are related to improper installation. If you create a non-ventilated façade and do not leave a gap under the material, condensation may accumulate.

Attach to the sheathing in increments of 70 cm from bottom to top. Additionally, it is sanded and coated with protective paints and varnishes. It is easier to fasten with self-tapping screws. To do this, drill a small hole with a diameter wider than the screw head. A self-tapping screw is screwed in there and the top is closed with plugs or covered with varnish and sawdust and sanded.

Lining for the facade of a bathhouse

Plastic lining is used for finishing the outside of the bathhouse. This is the most economical finishing option, and that’s probably where its advantages end. The lining costs from 37 rubles, but its width is 50-60 mm. There are more than 20 color solutions, but not everyone can be used to create an aesthetically attractive facade.

The disadvantages of the material include:

- Not breathing.

- Not environmentally friendly.

- Easily breaks and bends.

- Fade over time.

- Burns with toxic fumes.

Choosing this material for lining the outside of a bathhouse should be done as a last resort. You can see in detail what a bathhouse lined with imitation timber looks like in the video:

Any of the listed materials can be attached using components. Corner joints of imitation timber and block houses are decorated with special overhead corners. They will give complete realism to the masonry with the remainder.

When decorating the outside of a bathhouse, do not forget about the gables. If you leave them unsheathed, the appearance will be unfinished.

Finishing the gable of the bathhouse

The cladding of the pediment is carried out depending on its design and the material used to decorate the facade. It is also important what the pediment itself is made of:

- A wooden pediment can be sheathed with any material, but it must first be waterproofed using a membrane material.

- For concrete gables, the surface is first leveled and the sheathing is installed. The sheathing is attached to the sheathing.

Finishing the gable of the bathhouse will give the facade a finished look and additionally protect the structure from moisture.

In order not to disturb the unity of the ensemble, the gables of the bathhouse with finished imitation or siding are sheathed with the same material. For brick and concrete structures, stucco can be used in the form of various relief elements. Iron sheets are well suited for finishing the gables of a bathhouse, but due to the high cost, this option is rarely found. The easiest and most inexpensive way to cover a gable is with siding panels.

In the photo on the right you can see the pediment of the roof of the bathhouse with an attic, trimmed with plastic lining. It goes well with the siding that was used to cover the facade. If you take lining in a contrasting color, you can give the structure a unique design.

There are several ways to attach the material to the pediment:

- Using aluminum posts that are mounted on the gable.

- On a wooden gable, siding or imitation timber can be sewn directly onto the surface.

- Using wooden slats, which are pre-attached to the pediment.

When covering the gables of the bathhouse, it is necessary to use a level and fasten the planks on the same plane. If this is not observed, the integrity of the structure will be compromised.

After covering the outside of the bathhouse, it is necessary to take care of additional protection. A drainage system is installed on the roof, and wastewater is drained. This is all easy to do with your own hands.

When choosing a material for cladding the outside of a bathhouse, you must take into account your financial capabilities, the material with which neighboring buildings are sheathed, and design features. It is necessary to purchase from well-known retail chains, so there is less chance of encountering counterfeits. And you can do the finishing yourself, the main thing is a little diligence and desire so that the bathhouse will last for many years.

banyabest.ru>

Installation - step by step instructions

Installing siding panels is actually not difficult.

For work, you should prepare a minimum set of tools, and everyone will have these in their home:

- Metal scissors, stapler.

- Impact drill or hammer drill.

- Pliers and hammer.

- Tape measure, level, plumb line.

You can make lathing for siding from metal profiles or from ordinary bars. There is nothing super complicated about installation. Taking into account that the bathhouse is usually not too large in size, installing the slats under the roof does not require the manufacture of scaffolding; a good stepladder is quite suitable. The material should be prepared in advance and before installation if you need to let it rest without packaging for a couple of days. For a bathhouse, vinyl siding would be the ideal choice, since it is less susceptible to moisture than other types.

Enough time will pass from the moment the construction of the bathhouse begins, and if the shrinkage process ends and the log house finds its permanent place, you can begin covering the bathhouse with siding with your own hands. First you should prepare the surface. Recommendations for cladding will be based on a log bathhouse, and for each material the preparatory process is slightly different.

First, the surface of the wood should be completely cleaned of any types of deposits, and then the wood should be treated with fire retardants and antiseptics to protect against fungus. After this, you should fill the sheathing of bars in increments of 0.5-0.6 meters. Here you must definitely maintain the level.

On the walls of a brick bathhouse, this will be much easier to do, since the stone has a uniform surface, but the logs are different in size and diameter, and with any difference, the level should be replenished with the help of small inserts, and each plank should be adjusted to the level. Sheathing made of wooden beams is not the most technologically advanced option, since for vertical alignment you will have to place inserts of various sizes under the racks.

If you plan to carry out work on insulating a bathhouse, then this should be done at the stage of laying the material when you can insert insulation between the bars. It will be better if you buy insulation in advance and install a vertical type of sheathing with a pitch that is equal to the width of the material. It should be laid without cutting, in one piece.

After this, cover the insulation with a waterproofing film, which is laid in a horizontal plane, while also covering the bars. The material should be attached using staples from a construction stapler. Secure the joints with reinforced tape.

Siding installation procedure

To cover a bathhouse with siding, you need to prepare the following tools and materials:

Siding fastening diagram.

perforator;

- punch for perforation;

- construction stapler;

- metal scissors;

- roulette;

- building level;

- planks;

- docking elements;

- brackets;

- corners;

- wooden bars for sheathing;

- insulation;

- waterproofing material;

- fasteners.

If you plan to sheath a wooden bathhouse made of rounded logs, then it is important that the building is not new, and the wood is not damp, since otherwise it will shrink, which will lead to deformation of the sheathing. The finishing material itself must be stored indoors at a temperature of no more than 55 ° C, and also placed on a hard and flat surface to prevent its deformation. For a bathhouse, it is better to buy vinyl panels, which always look attractive and are of high quality. It is very important that the selected type of material for the sauna is resistant to high humidity.

Do-it-yourself sheathing installation

Siding panel installation technology.

Before carrying out facing work, it is necessary to prepare the surface that will be covered, that is, make it as smooth as possible. This will allow you to avoid additional financial costs for repairs and reconstruction of the facade in the future. To do this, you can use lathing, which makes it quite easy to give the walls the required evenness. If the bathhouse is finished with vertical siding, then the lathing is laid horizontally, but if you plan to lay the siding horizontally, then the lathing should be vertical .

Wooden blocks of 2.5x8-5x5 cm are perfect for creating sheathing. The main thing is that they are even, as this will prevent the wall from becoming wavy after covering it.

The distance between adjacent bars should be about 30-40 cm.

If you plan to lay a layer of insulation under the siding, then first a wooden sheathing is constructed with a step equal to the width of the mat or roll insulation. This lathing is performed perpendicular to the subsequent counter-lattice from the siding profile.

After installing the insulation, it is covered on top with a waterproofing film, which is attached to the sheathing using a construction stapler. The film is stretched horizontally, starting from the bottom row. In this case, each subsequent row is mounted with an overlap of 100 mm on the previous one.

After securing the waterproofing, you can move on to the counter-lattice directly under the siding. For this, it is recommended to use a metal profile, since the wood must be additionally treated with an antiseptic, and during operation it can become deformed.

Installation of siding panels

First, using a level, you need to mark the fastening line of the base ebb, on top of which the starting strip will be attached. Then the H-profile is attached at the junction of the panels. You can do without this structural element and mount the panels overlapping, but over time the joints will become clogged with dust and become visible.

After this, you can proceed to the installation of siding, starting with the bottom panel, which is fixed to the starting strip. The panels of the upper row are snapped onto the panels of the lower row and attached to the counter-lattice (Fig. 4). In this way, the entire wall is sheathed up to the top, where the finishing strip is fixed.

There is nothing complicated about covering a bathhouse with siding. The main thing is to strictly adhere to all instructions and recommendations of specialists. In this case, you will get high-quality cladding that will serve you for many years.

Everyone knows the expression that claims that a real Russian bathhouse cures all diseases and ailments, restores youth and beauty, and prolongs life to two hundred years. It is also known that only a steam room built from logs, and not just any wood, has such amazing properties.

Covering a bathhouse with siding