In wooden log houses, it is unacceptable to use concrete blocks as floors: load-bearing walls will not withstand such a load. Therefore, all structures are also made of wood: a special installation technology is used for this. The lifespan of the house largely depends on the chosen installation method and quality-made floors.

Wood floors - general provisions

It is also very convenient to make the floor in a wooden frame from wood, so as not to disturb the natural harmony. A floor covering made of material identical to the entire building will only increase the warmth, comfort and softness of shades provided by the log house.

And although humanity has used wood as indoor flooring throughout its history, new, constantly improving installation technologies can sometimes surprise even experienced craftsmen.

In order to be less surprised and be able to carry out the installation yourself, let’s look at all the nuances of this important matter.

Single layer coating

The peculiarity of this coating is that it can be laid either with or without joists. This is affected only by the thickness of the boards being laid. In this case, the distance between products should be no more than sixty centimeters.

Double layer coating

The peculiarity of this floor is that it also has a rough layer on which the insulation material is laid. Both sheet versions and a mound of expanded clay can be used as an insulating material.

Advice: between the finishing and insulating layers you should leave a void of about two centimeters to ensure ventilation. This will prevent the boards from breaking.

When you make a subfloor in a log house with your own hands, you need to consider the following points:

- The rough layer should act as a rigidity frame for the entire structure and be the most durable.

- mineral wool;

- polyurethane;

- expanded polystyrene;

- glass wool;

- mineral mats;

- polystyrene foam, etc.

Also very important is the creation of ventilation. Regular ventilation flows dry the base and prevent the appearance and spread of rot and mold.

For this:

- We drill holes in the corners of the room or under the walls in a convenient place with a diameter of about half a centimeter.

- We close the cluster of holes with decorative special grilles.

- Alternatively, ventilation can also be done in the floor fillet.

Insulated floor in a log house

To live in a house permanently, the floors must be insulated. To fix the thermal insulation material, a subfloor is laid. To do this, bars are placed on the lower part of the logs, on which the boards of this floor will rest. The rough flooring may not be continuous, if polystyrene foam or polystyrene foam is used as insulation - the sheathing will also withstand it perfectly. If mineral wool acts as thermal insulation, then it is better to make a continuous subfloor.

Solid subfloor

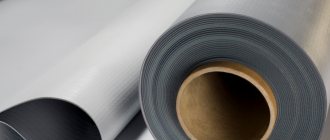

- waterproofing is installed;

- the floor is insulated;

- vapor barrier is laid;

- counter lathing is mounted on the joists;

- the floor is laid.

Waterproofing is necessary to protect the thermal insulation material from possible moisture ingress from the subfloor. With proper backfilling, this option is practically excluded, so this is largely a precautionary measure.

Insulation is carried out in two layers. The second layer is laid out so that it covers all the joints of the first layer - this will help avoid cold bridges. If the insulation is made with materials based on polystyrene foam, then the joints can be filled with polyurethane foam.

The vapor barrier is designed to protect the insulation from moisture from entering the house. During human life, the air is constantly saturated with water vapor - with quiet breathing, about 1 liter of moisture is released per day. It is not recommended to tighten the vapor barrier too much during installation - it is better to let it sag slightly.

Wooden blocks are used as counter lathing. It is designed to form an air gap between the insulation and the floor itself. This will keep all the materials dry, which will extend their service life.

The flooring technology is similar to a cold floor. The material used is not necessarily a tongue-and-groove board. These can also be sheets of plywood, on which laminate and other floor coverings can subsequently be laid.

Installation of wooden floors

We have become familiar with the general provisions of this type of coating. Now we will consider in detail the construction of the floor in a log house, made in different ways.

On support pillars

- We remove soil from the underground to a depth of half a meter.

- Pour gravel or river sand into the freed space. We wet each layer of the embankment and thoroughly compact it with a vibrating plate.

- At the end of the process, the level of the pillow should be twenty centimeters higher than the chernozem.

- We install support pillars around the perimeter of the building, and then on the inside. We use red bricks or ready-made concrete products as pillars. The installation step is 70-90 cm. We maintain a distance of about a meter between the rows.

You should know: in buildings with a small area you can do without internal supports. Since they can be completely replaced by floor beams.

- We lay waterproofing in the form of plastic film or roofing felt on top of the supporting products.

- We install timber logs on the water-repellent material.

- Using a spirit level, we level the level of the joists by placing wood wedges.

- We place them at a distance of about seventy centimeters from each other, securing them with nails.

- We lay the boards on top along the light falling from the window.

- We install the first one, retreating 10-15 mm from the wall. This will ensure air movement under the decking. When finishing the interior, we will cover it with a baguette.

- For better fixation, hammer the nails at an angle. We choose their length so that they are at least twice the thickness of the wood product.

- We putty the joints and nail heads and paint. After drying, the coating is ready for further work.

This method of implementing flooring is convenient in buildings that are heated during the cold season. Because frost causes the gravel or sand cushion to expand and can damage or displace the support pillars.

Single from boards

In this case, two execution paths are possible.

- If the distance between supports does not exceed one meter:

- We lay beams on the ends of the supporting columns.

- We fix the boards on them with nails.

- If the distance between supports is more than one meter:

- On top of the beams we install logs in the form of beams with a cross-section of 5 cm and a pitch of 50-60 cm.

- We check the evenness of the surface with a spirit level. If necessary, level it using pads.

- After leveling the sheathing, we fix it with steel nails.

- Only after the work has been done can the rough or finishing coating be applied.

In both cases, when installing the rough layer, an unedged board is used, and when installing the finishing layer, an unedged board is used.

Double plank

Subsequently, linoleum or laminate can be laid on the rough surface. The finishing one is covered with several layers of varnish.

The price of such work is relatively low, which makes this method the most accessible. A significant disadvantage is poor thermal insulation.

Double plank

Double coating, as we noted earlier, means the presence of both rough and finishing layers.

The following instructions will help with its installation:

- We install cranial bars on the surface of the beams.

- We tightly install unedged boards about thirty millimeters thick across the bars. Even the use of low-grade lumber treated with anesthetics is allowed.

- We create a thermal insulation layer on top. Suitable materials for this are listed above. It is also worth mentioning the possibility of implementation. What will be the most effective, but also expensive solution.

tongue and groove floorboard.

Subsequently, linoleum or laminate can be laid on the rough surface. The finishing one is covered with several layers of varnish.

The price of such work is relatively low, which makes this method the most accessible. A significant disadvantage is poor thermal insulation.

Double plank

Double coating, as we noted earlier, means the presence of both rough and finishing layers.

The following instructions will help with its installation:

- We install cranial bars on the surface of the beams.

- We tightly install unedged boards about thirty millimeters thick across the bars. Even the use of low-grade lumber treated with anesthetics is allowed.

- We create a thermal insulation layer on top. Suitable materials for this are listed above. It is also worth mentioning the possibility of implementation. What will be the most effective, but also expensive solution.

A tongue-and-groove floor board is a lightweight solution to the problem.” href=”https://shkolapola.ru/derevyannie/394-shpuntovannaya-doska-dlya-pola”>tongue-and-groove floor board.

Subsequently, linoleum or laminate can be laid on the rough surface. The finishing one is covered with several layers of varnish.

The price of such work is relatively low, which makes this method the most accessible. A significant disadvantage is poor thermal insulation.

Double plank

Double coating, as we noted earlier, means the presence of both rough and finishing layers.

The following instructions will help with its installation:

- We install cranial bars on the surface of the beams.

- We tightly install unedged boards about thirty millimeters thick across the bars. Even the use of low-grade lumber treated with anesthetics is allowed.

- We create a thermal insulation layer on top. Suitable materials for this are listed above. It is also worth mentioning the possibility of implementation. What will be the most effective, but also expensive solution.

I-11=»»>Concrete flooring

It is necessary to pay attention to this method of resolving the issue.

Although this is not the most harmonious solution to the issue, it can also be used.

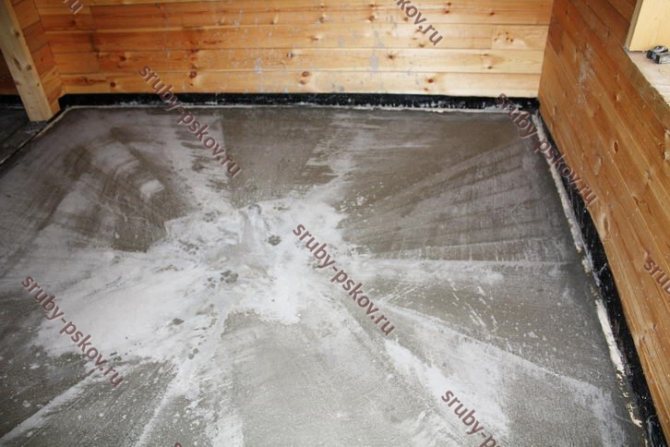

- We determine the level of the screed by marking it along the perimeter of the walls.

- Cover the base with plastic film for waterproofing.

- Pour in the cement mortar and also cover the top with film to speed up hardening.

- We moisten the surface for a month to prevent it from cracking.

- Next, for convenience, you can use a self-leveling mixture and pour it onto the concrete screed surface.

.

Linoleum tiles: selection and technology for installing vinyl covering” href=”https://shkolapola.ru/elast/linoleym/raznovidnosti/288-linoleumnaya-plitka”>tiles, laminate, linoleum

.

I-12=»»>Conclusion

The wooden house is cozy, warm, bright and lively. Floors in such a structure should be made of a similar material to enhance the positive effects.

A cement base is also suitable, but it will always give off an alien feel in the abode of nature. In addition, an appropriate foundation should be laid under it.

Wood flooring has several ways of implementation. Choose the one that best suits your preferences, needs and budget. And be sure to take care of high-quality insulation.

The video in this article will provide more material on this topic. In general, installing floors in a log house is not very difficult. Good luck with your construction work!

» width=”640″ height=”360″ frameborder=”0″ allowfullscreen=”allowfullscreen”>

A strong construction of crowns in a wooden frame alone will not be enough without strengthening them with logs. In addition, without them it will be impossible to lay either the floor or the ceiling. What they are, how they are installed, and construction features will be described below.

Preparatory work and installation of logs

Before starting work, black soil is removed from the underground, and the space is filled with fine gravel or river sand. The bedding level should be higher than the ground level around the house. This will eliminate the possibility of water getting into the underground space.

Wooden floors are laid on logs - beams that are laid on the foundation and fasteners, such as metal corners, are pulled together with the lower crown, or cut into the second crown.

Laying joists without support posts

Usually, preference is given to the first method, since the insertion violates the integrity of the log structure. If the logs are more than 3 m long, then it is necessary to provide concrete or brick pillars on which they will rest. For their construction:

- After filling the subfloor, it is necessary to make markings. The distance between the lags can be up to 100 cm, between the posts there is about 80 cm;

- According to the markings, columns of the same height are constructed from brick or concrete. This must be carefully monitored, since different heights can lead to distortions and deformation of the floor over time;

- After the solution hardens, waterproofing is laid on the columns, which will protect the logs from exposure to water. With the help of additional layers of waterproofing, minor deviations in column height can be leveled out.

After this, logs are pinned onto the posts and fastened to the lower crown of the log house. It should be remembered that logs are most susceptible to moisture and possible microorganisms, so it is recommended to use cedar or larch as a material.

What are ceilings and floors?

The fact that the house is made of wood implies that all parts of the construction are made of this material. Thus, logs are wooden floors that serve to enhance the stability of the log structure and as a base for the floor and ceiling. Logs in a log house are important elements in the construction of a residential building.

They come in several types: Let's take a closer look at the advantages and disadvantages of all. What do you need to know about each of them before starting construction? Pros:

Now about the cons:

- Weight. This is due to the fact that shrinkage of the house can deform the entire structure. And then the weight of the log will be a threatening factor for the ceilings. This is especially true for multi-storey construction.

- Price. If, when buying a turnkey house, the cost of lumber is not specified separately in the contract, then you need to ask a company representative about this. It may turn out that they will charge for them separately, but a solid log, whether it be the floor joists of a log house or the ceiling ones, is not cheap.

- It will not be easy to install such structures. After all, you will need more than one thing.

Classification of floors

Based on the installation location, the design divides:

- Residential floors are interconnected (including the attic).

- Non-residential attic space from a heated space.

- Basement or basement space from living quarters.

Therefore, floors are classified into:

- interfloor;

- attics;

- basement

Features of types of floors

Each partition in a residential building performs its assigned functions, therefore, when constructing a structure, the emphasis is on the required properties:

- For basement structures, the main function is thermal insulation, especially if there is no basement or the house is placed on a high base. The solution to the problem is the use of effective modern insulation materials.

- Interfloor ceilings carry a significant load, so the emphasis is on strengthening the structure, as well as on reliable sound insulation.

- A large amount of heat escapes through attic structures, so when constructing such floors, insulation is used, as well as a vapor barrier that prevents the formation of condensation.

Timber logs

Unfortunately, this option has more disadvantages:

- High cracking potential. It is best to use timber for the floor. Or take a section for the ceiling no smaller than the one from which the crowns were erected.

- The beam is springy. Having danced on housewarming day, the owner risks first jumping on the trampoline and then falling into the basement due to a broken ceiling. It’s scary to think what awaits such lags on the ceiling.

- When the house shrinks, there is a possibility that they may be pulled out of the grooves. And even inserting a log into a frame and then securing it is little hope for stability. Of course, nothing bad will happen before the construction of the rafter system.

But shrinkage is a phenomenon that happens all the time. Therefore, when the lags “play” is an open question.

How to make floors in a log house

The future peace and comfort of the whole family depends on how well the floors in the log house are made. This stage of work should be taken extremely seriously, so that later there will be no various overlaps in the work. Let's look at how to make a floor in a log house. There are several options for floor designs. You can make floors in a log house using either wood or other materials.

High-quality floor finishing makes it possible to live comfortably in the house.

Depending on the option chosen, you may need:

Self-installation

Next, it’s worth describing the process in detail - how to install logs in a log house. This is important information for beginners. So, let's start with the floors; the actual installation of the ceilings is no different from this:

- Having chosen the option, you need to start inserting from the second crown of the log house, already laid and secured with dowels.

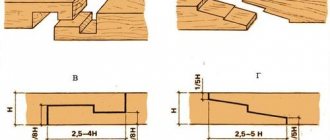

- The insertion of lags is carried out using the dovetail method. That is, the gash represents a carved void in the crown, and the log is a figure. By inserting one into the other, fastening is performed. The crown should not be cut down before it comes out. It is enough if the “tail” is equal to half of the log or timber.

- The elements need to be secured using reliable material - one notch will not be enough. The longitudinal logs are always placed first, then the transverse ones. The pitch of one from the other is calculated from the material - the log can be laid at a distance of 1300 mm, and the boards will require no more than 700 mm.

- After installation, the question of how to embed logs into a log house is no longer of interest; you need to give the house time to shrink and look at the behavior of the newborn elements. It is quite possible that after some time there will be a need to correct them.

Causes and possible solutions to lag-related problems:

- Falling out of cutting or cutting areas due to inappropriate size. This may indicate a low qualification of the hewer.

- Deflection indicates poor drying of the material. This is especially noticeable when installing log joists. Protruding - the same thing.

- Also, ceilings may generally fall out of the grooves if the deformation of the log house is severe. Therefore, to avoid this, there is no need to mount the ceiling elements immediately and make them exactly to length. It's better to cut it off later.

- When it comes to fasteners, it is important to remember that they must fit snugly into the wood and even be recessed into it.

- If, after a period of time, damage is noticed on the material, then ignoring it risks the whole house. It is better to replace such a lag or try to fix it by chipping. But if there is no effect, you need to buy a new one.

That's all. The process that requires attention is outlined. However, if you still have questions, don’t hesitate to ask them to experienced ones.

Selecting the material for load-bearing structures, which are logs, requires great care. The stability of the structure as a whole depends on this. One should not neglect the method of cutting and chopping - they were not invented in vain, and have been tested for centuries.

Until the house has been shrinked and dried, you should not do any work in the log house, and even more so there can be no talk about the rafter system. It is better to devote this forced downtime to supplying communications and choosing interior decoration. After all, with the finishing touches coming soon, these benefits of civilization will be needed more than ever. Good luck!

Methods and rules for installing floor and ceiling joists in a log house

A strong construction of crowns in a wooden frame alone will not be enough without strengthening them with logs. In addition, without them it will be impossible to lay either the floor or the ceiling. What they are, how they are installed, and construction features will be described below.

Log floors on floor beams

When building a wooden house, the most logical and optimal option for the floor is its construction along the floor beams. This is the most common option and professionals don’t see the point in looking for a replacement. This method will help raise the floor to the desired height and allow you to leave room for a basement, as well as eliminate possible contact between the floor and groundwater.

The construction of the floor along the floor beams raises the flooring to the required height, completely eliminating its contact with groundwater.

Depending on the specifics of the construction of the house, the beams are placed either in the frame of the house behind the ground floor, made of brick (concrete), or at the level of the 3rd or 4th crown, counting from the ground, in the case of using only wooden building materials.

The placement of beams, or rather their end parts, can be in the bulk of the log house or through. The through arrangement is more reliable, since the resulting condensate will be able to escape through the end of the beam. Please note that the ends of the beams must be treated with an antiseptic composition, which will protect them from exposure to moisture and various types of bacterial infections.

If the beams in the structure of your house are more than 3 m long, then they need additional support. These can be beams placed on the end, or brick columns, or wooden ridges. Just like the ends of the beams, all wooden parts in contact with the soil must be treated with an antiseptic composition without fail.

If you choose pillars made of brick as support, then you need to build them on a fairly solid foundation. It would be better if it were concrete slabs. You can fill these with your own hands or purchase ready-made factory-made ones. Under the base of these slabs it is necessary to lay roofing material, which will serve as a waterproofing layer.

Experts recommend using building materials that have flat end sides as floor beams: beams, half-beams, and so on. Its cross-section must fully correspond to the cross-section of the material from which the permanent walls are made.

Return to contents

What are ceilings and floors?

The fact that the house is made of wood implies that all parts of the construction are made of this material. Thus, logs are wooden floors that serve to enhance the stability of the log structure and as a base for the floor and ceiling. Logs in a log house are important elements in the construction of a residential building.

They come in several types:

- Solid log.

- Prefabricated.

- Timber.

Let's take a closer look at the advantages and disadvantages of all. What do you need to know about each of them before starting construction?

Solid log

- If the owner understands the importance of solid logs in house construction, then it is no secret that he will choose just such floors for his own home. They are supplied along with the material according to the contract. What are they good for? Firstly, there is no doubt about their stability - the array has always been famous for this quality. Secondly, when turning a log into ceiling joists in a log house or flooring, material suppliers know exactly how much sapwood needs to be removed without damaging the log.

- Further, it is an important fact that the internal appearance of a wooden house must match the external one. That is, if the log house is a log, the logs should be the same - it’s very beautiful.

- Weight. This is due to the fact that shrinkage of the house can deform the entire structure. And then the weight of the log will be a threatening factor for the ceilings. This is especially true for multi-storey construction.

- Price. If, when buying a turnkey house, the cost of lumber is not specified separately in the contract, then you need to ask a company representative about this. It may turn out that they will charge for them separately, but a solid log, whether it be the floor joists of a log house or the ceiling ones, is not cheap.

- It will not be easy to install such structures. After all, you will need more than one thing.

Now about the cons:

Timber logs

Unfortunately, this option has more disadvantages:

- High cracking potential. It is best to use timber for the floor. Or take a section for the ceiling no smaller than the one from which the crowns were erected.

- The beam is springy. Having danced on housewarming day, the owner risks first jumping on the trampoline and then falling into the basement due to a broken ceiling. It’s scary to think what awaits such lags on the ceiling.

But shrinkage is a phenomenon that happens all the time. Therefore, when the lags “play” is an open question.

Prefabricated structures

They consist of three boards with a cross-section of 50*150 mm, fastened together with pieces of the same lumber and anchor bolts, and laid on edge. Today this design is considered the most reliable.

Well, the disadvantages of such logs are the same as for wood in general. That is, susceptibility to rotting, shrinkage, etc.

Self-installation

- Having chosen the option, you need to start inserting from the second crown of the log house, already laid and secured with dowels.

- The insertion of lags is carried out using the dovetail method. That is, the gash represents a carved void in the crown, and the log is a figure. By inserting one into the other, fastening is performed. The crown should not be cut down before it comes out. It is enough if the “tail” is equal to half of the log or timber.

- The elements need to be secured using reliable material - one notch will not be enough. The longitudinal logs are always placed first, then the transverse ones. The pitch of one from the other is calculated from the material - the log can be laid at a distance of 1300 mm, and the boards will require no more than 700 mm.

- After installation, the question of how to embed logs into a log house is no longer of interest; you need to give the house time to shrink and look at the behavior of the newborn elements. It is quite possible that after some time there will be a need to correct them.

Causes and possible solutions to lag-related problems:

- Falling out of cutting or cutting areas due to inappropriate size. This may indicate a low qualification of the hewer.

- Deflection indicates poor drying of the material. This is especially noticeable when installing log joists. Protruding - the same thing.

- Also, ceilings may generally fall out of the grooves if the deformation of the log house is severe. Therefore, to avoid this, there is no need to mount the ceiling elements immediately and make them exactly to length. It's better to cut it off later.

- When it comes to fasteners, it is important to remember that they must fit snugly into the wood and even be recessed into it.

- If, after a period of time, damage is noticed on the material, then ignoring it risks the whole house. It is better to replace such a lag or try to fix it by chipping. But if there is no effect, you need to buy a new one.

That's all. The process that requires attention is outlined. However, if you still have questions, don’t hesitate to ask them to experienced ones.

Selecting the material for load-bearing structures, which are logs, requires great care. The stability of the structure as a whole depends on this. One should not neglect the method of cutting and chopping - they were not invented in vain, and have been tested for centuries.

Based on materials from the site: https://1drevo.ru

To install the floor of a wooden room, logs are used. They are round logs made of pine or other types of wood. An important condition for their installation is low humidity of the building material. Alignment of log logs is carried out if during assembly the condition of compliance with the level was not met, the lumber has defects, or it is not dried well enough. Therefore, all work related to the installation of the floor is carried out several months after the completion of construction, after the log house has given its final shrinkage.

| Name of works | Unit | Price |

| Floor construction | ||

| Installation of logs | PC. | 1000 |

| Alignment of logs | m2 | 200 |

| Subfloor in a log house | m2 | 220 |

| Vapor and waterproofing | m2 | 70 |

| Insulation of the floor in the log house (50mm) | m2 | 60 |

| Laying plywood | m2 | 220 |

| Finish floors in a log house | m2 | 400 |

| Skirting | m.p. | 100 |

Get an individual price

Interfloor ceiling in a log house

Question:

Semenych, my respect. I have this problem: a log house with 8*9 five-wall walls. The builders laid interfloor beams made of logs for me. What should I do? Do I need to plan logs to form beams?

Alik, Ufa.

Answer:

Hello, Alik from Ufa!

Typically, floor beams are laid on top of logs with different diameters perpendicular to the direction in which the logs are laid. Which, while undoubtedly strengthening the floor structure to vertical loads, further reduces the height of the second floor premises (or attic or attic).

Floor joists-beams can be of different sections (from 50*100 mm to approximately 100*100 mm, or even more). It is preferable to lay the beams so that the width of their section is less than the height of the section, so their rigidity (bending resistance) will be greater.

The optimal laying step for the beams is 0.6 meters, which is dictated by the possibility of then laying between them standard types of insulation-sound insulators with a mat width of 0.6 meters. And the floorboard will sag less than with a step of a meter or more.

/What is done in addition to laying such mats between the logs./

However, insulation is not always installed, but only at the request of the owners.

This “checkered” floor structure is quite resistant to deflections, especially with large log areas. Although all the same, the walls-cuts of the first floor are much more effective as reliable supports for floors.

If the owners do not want to bother with the installation of such additional log beams, set strictly at a horizontal level, which involves undercutting and lining in a number of places between them and the overlap logs of adjusting pads from sections of edged boards or plywood of different thicknesses, then the only way out is planing or chopping with an ax the upper plane of the logs for laying beams or directly the floorboard.

Naturally, with large differences in the diameters of floor logs, planing and cutting of excess wood can significantly reduce their resistance to deflection.

So the choice is yours - either additional logs with a lining under them in a number of places of the adjusting elements. Or planing-cutting the surfaces of floor logs.

Good luck!

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Other questions on the topic of log houses:

Replacing logs in log houses

- Cost of replacing the top rims of a log house

- Rotten crowns in the middle of the wall

- Replacing a log frame with a brick or block

- Replacing the lower crowns of a log house

- Replacing rotten crowns with bricks

- How to strengthen a corner in a log house

- When you need a fifth wall in a log house

- Vibrations in the log house

- Remove the three lower crowns of a log house

- Replacing a wall in a log house

- Replacing the lower crown with brick or foam blocks

- Joining logs of different diameters

- Replace the corner of a log frame with sleepers

- Replacing the lower crowns of a log house with a concrete wall

- Rotten log in a log house

- Restoration and cladding of a timber frame

- Reconstruction of an old log house

- Replacing a rotten corner of a house

- Repair of rotten beams in a log house

- Replacing the lower crowns of a log house with blocks

- Replacing rotten logs of a log house

- Replacement of the lower crown of the house

- Replacement of a main wall made of timber

- Transfer of logs in height in a log house

- Alignment and replacement of the lower crown of the log house

- Replacing rotten logs under the window with blocks

- 2 corners rotted at the level of the log house windows

- Cost of work to replace the top rims of a log house

- The log house is rotting next to the vent

- The wall near the log house in the five-wall building has rotted

- Repair of old logs

- Replacing a log house wall with a foam block

- Replacing the lower crown in a wooden house

- Replacing logs in a log house

- Replacing logs eaten by insects

- Replacing the lower crown of a timber frame

- Replacing the lower crowns in the house

- Replacing the top rotted crown of a log house

- Replacement of the lower crowns of the bath

About caulking log houses

- Caulking log corners

- Cold corners in a log house

- Caulking and insulation of a log house

- Caulking a log bathhouse over old moss

- How to caulk a log house covered with clapboard

- Should tow for a log house smell?

- How to fix a chopped pediment

- Re-caulking of a log house

- Caulking and log processing

- Re-caulking the bathhouse with moss

- Calculation of the amount of jute for caulking a log house

- Caulking of a log house lined with bricks

- Caulking tight logs

- Dismantling inter-crown insulation

- Log caulking

- Log house for three years in the open air without a roof

- Re-caulking of a log house

- The basics of caulking a log house

- Caulking and sanding of a log house

- Caulk of a log house from the inside

- Do-it-yourself log caulk

- Caulking of a log house made of rounded logs

- Sanding timber

All about log houses

- Log house made of logs or timber?

- Estimate for finishing the log house

- The first crown of a log house made of oak

- Insulation of the stone base of a log bathhouse

- Overcut in the house

- Basement and blind area for an old shrunken log house

- Uneven shrinkage of the frame

- Repair of an old 2-story log house

- What kind of foundation for a 6 by 8 log house?

- How long does it take for a log house to shrink on a pile foundation?

- Increase the height of the log house without removing the roof

- Wind protection between the foundation and the log house

- Problems when lifting an old log house

- Insulation of a log house with sawdust and lime

- How to lay a log house from timber of poor geometry

- Pouring a concrete floor in a log house

- Interfloor ceiling in a log house

- Waterproofing the log house from the foundation

- Renovation of an old log house

- Repair of an old brick-lined log house

- How to strengthen a log house

- When to put a roof on a freshly assembled timber frame

- When to cover a log house with natural humidity

- Support under the log and shrinkage of the log house

- Beetles in logs

- Door in the end wall of a log house

- A team for the construction of a log bathhouse

- The cut of the log on the outriggers of the log house darkens

- Rot on the lower crown of a log house

- Vertical log house

- Which finishing plaster for clay to choose

- Mushrooms on a log house

- Log house without frame and floor beams on slab

- Dry rot of the lower crown of a timber house

- The upper corner of the frame has been removed

- Demolition of a log house wall

- Displacement of profiled timber in a log house

- How to build up log extensions of a log house for a veranda

- The log house was mowed down

- Installing a shrinkage compensator in a finished log house

- Twisted the logs of the log house before assembly

- Log house with nails instead of dowels

- How to protect a log house without a roof from rain

- A set of works on the external finishing of a log house made from central fiber boards

- Repair of a log house after a fire

- Is it possible to put a roof on a log house for the next year?

- Warm joint with sealant for log house

- Insulation and cladding of a log house made of corrugated timber

- Insulation of a log house from the inside

- Concrete floors in a log house

- Shrinkage of log walls old and new

- The procedure for finishing a log house

- How to preserve timber from spring to winter

- What comes first: flooring or door casing

- Dismantling half of an old log house

- Types of beam connections

- Sealing the joint between the roof and the frame from OCB

- Cleaning a log house from old paint

- Connection of two log houses

- Support column in a log house on stilts

- The difference in the shrinkage of a log house between winter and summer felling

- Dismantling and moving a house made of profiled timber

- Supporting floor beams in a log house

- Preparing a log house for winter

- Guarantees when cutting a log house on a plot

- Chop into a bowl or warm corner

- How to lower the ceiling in a log house

- The timber turned blue in the rain

- Preservation of the log house in a non-temporary gathering place

- Consultations on a timber house

- Sheathing of a house made of cylinders without insulation

- Scheme of a log house with outlets and a ridge roof

- How to lay a carriage while lying down

- Reinforced concrete slab on a log frame

- How to assemble a log house from twisted timber

- Repair of a cut in a log house

- Installation of a log house on a columnar foundation

- The chopped gables of the log house are shaking

- Fastening beams in a log house

- The top beam in the log house was driven into the screw

- How to cover a timber façade

- Waterproofing the frame of an old house from the foundation

- A log house without nails is being pulled apart

- Sheathing a log house

- Cutting the lower crown in the log house

- Settlement of a log house made of used timber

- The log house rotted in the castles

- The corners of the log house are rotting

- How to strengthen a log house

- Work plan for interior finishing of the log house

- Log processing procedure

- How to lay a log house in the rain

- Cut the lower crowns of the log house

- Sheathing a log house immediately after construction

- Heating and windows in a new log house

- Processing the crown of an already built house

- Painting a timber house

- Blind area and shrinkage of the log house

- How to enlarge a house made of timber

- Connecting a timber house with a brick extension

- Finishing a timber frame with jute rope

- Diameter of a log for a permanent home

- Treating the log house with an antiseptic during assembly

- Reconstruction of a wooden house

- Connecting timber in cuttings

- Protection of the ends of the timber at the corners of the log house

- How to connect two log houses together

- Cutting a balcony doorway in a log house

- When to casing a newly assembled log house

- Insulation of gables made of lining

- Gaps between the logs of the log house pediment

- How to preserve logs before cutting a log house

- Raise the frame to increase the ceiling height

- Methods for joining timber in the walls of a log house

- Raise a log house to increase the underground floor

- Cladding a log house with clapboard before shrinking in winter

- When to remove the compensating jacks of a log house

- Log house for three years in the open air without a roof

- How to make a cut in a log house

- Make a house from an old bathhouse (timber)

- Moving the log house to another location

- Log house hanging on dowels

- The fifth wall in a log house made of smaller timber

- Should I paint the backing board in a log house?

- Remove mats to increase log ceilings

- The log house does not match the foundation

- Ceiling mats in the log house

- Construction from fire monitors

- How to remove bark from an already assembled aspen log house

- Transporting an old log house

- Connecting internal timber walls with external ones

- How to repair cracks in a log

- Gap between log and foundation

- Alignment of the first crown of the log house

- Stages of arrangement of the assembled log house

- Treatment of the log house after installation in the summer

- Processing the ends of the frame from the outside

- The log house floated - the walls moved

- An old wooden house sank

- Leveling the crowns when assembling a log house

- How to close the opening between the log house and the foundation

- How to straighten a log house

- Sheathe a log house with protrusions with corrugated sheets

- How to process the ends of a log house

- Collecting the first crowns of a timber frame

- Riser frame

- Preservation of the log house during assembly in rainy times

- Forgot to waterproof the log house from the foundation

- Installation of log shrinkage compensators

- Interventional gaps in a house made of profiled timber

- Gaps between logs in a house

- Communications and finishing in a timber house

- Precision when cutting log houses

- Which log house will be warmer?

- Log house made of timber 200 by 120

- Old log house - reconstruction or demolition

- Partitions in a log house

- Internal partition in a log house

- Beginning of finishing of shrunken timber frame

- Double timber construction technology

- Processing the log house from the outside

- Log shrinkage process

- The walls of the log house collapse during shrinkage

- Insulation of a log house from the inside

- How to build a house from sleepers

- The logs were kicked out of the log house

- Supports (pillars) instead of crosscuts in a 9x10 house

- Do-it-yourself timber log house without experience

- Preservation of a house made of rounded logs for the winter

- Embed additional beams into the frame

- Backing crown - installation tricks

- Log house on brick walls

- Sequence of work in the log house

- How to make a load-bearing partition in a log house

- The log house got wet during assembly

- How to seal cracks in a log house

- Align the vertical wall of a log house

- Vents in timber on foundation

- Timber 200 by 200 construction nuances

- The log house turned blue, what should I do?

- How to seal cracks in cutouts from the outside

- You can live on the second floor of a log house for shrinkage

- Replace rotten logs with mortar

- A non-load-bearing log has shrunk

- Replacing logs with boards in a house project

- Vertical supports in a log house for shrinkage

- Does a large log house need recutting?

- Metal tiles on a non-shrunken log house

- Permissible gaps between timber crowns

- Gaps in log beams

- Replacing parts of rotten logs in a log house

- The logs of the log house are shaking

- The log house was poorly assembled

- The gap between the log log and the foundation

- Protect an unfinished log house for the winter

- How to save a log house without a roof

- Log finishing service

- Assembling a profiled log house in the rain

- Gaps when fastening profiled timber

- Sealing cracks in a bathhouse

- Processing timber with a blowtorch

- Butt beam - is it reliable?

- The wall of the log house is littered

- How to align protruding ends in a built timber house

- Transferring beams in a log house in height

- The corners of the log house disappear from the timber during assembly

- The log house is wet, what should I do?

- Does a log house need a fifth wall?

- How to assemble a log house 10 by 11

- Restoring a log house after a fire

- Processing of a log house made of rounded logs

- Extension of a log house when replacing the roof

- Sand under the crowns for insulation

- Methods for lifting a bath to replace the crowns

- Impregnation of the log house inside and out

- The façade of the log house leaned

- Log shrinkage - problems

- Treatment of timber against bugs

- The smell in the house is from sleepers

- How to preserve the light color of a fresh log house

- Estimate for a house made of timber 7 to 9

- Treatment of exposed ceiling beams

- Strengthening the corner of a log house

- What is the dowel pitch?

- Protection of the lower crown of the log house

- How to check the diagonals of a log house

- Which timber to choose, square or rectangular?

- Spruce and pine log house

- Sequence of work when finishing a timber house

- Insulate an aspen log house from the outside

- How to install a casing on a log house

- What to put between the crowns

- Should I trim the paws of a log house?

- What is the best way to impregnate a log house?

- Window opening in a log house - how to seal it

- Gaps in the assembled frame

- Support pillars in a timber house

- How to move the 5th wall in a log house

- Ants and the lower crown of the house

- Sanding and processing of the log house after installation

- Barked or planed log for log house

- Repairing the corner of a log house of an old wooden house

- Should window openings in a log house be closed when it is in storage?

- Consultation on the size and shape of the log house

- Questions about construction from profiled timber

- Log house and foam block on a single slab

- Preparing an unfinished log house for winter

- Longitudinal cuts in a log house

- Cracks in the ends of logs

- Should I paint a log house with tikuril?

- Strengthening the corners of the log house

- How to secure a cross beam in a log house

- Ventilation gap between insulation and frame

- Moss or tow for building a log house

- Shrinkage of a timber house

- Fifth wall in the log house

- How to raise a 6 by 6 log house

- Distance from the corner of the frame to the windows or doors

- How to cut off the protrusions of the corners of a log house

- Log house without nails

- How to clean a linden bathhouse from darkening

- Impregnation of a log house with fire-bioprotection

- Velo log house

- Questions about cutting a bathhouse after installation

- Painting a log house

- Blackness between the crowns of the log house

- Types of cutting corners of half beams or carriages

- Attaching beam supports to a log wall

- Strengthening logs in a log house 7 meters long

- How to sort through the log gables of a log house

- The beam was squeezed out of the wall

- Is a matitsa needed in a 3 by 3 m bathhouse?

- Priority work after installing the log house

- Entrance door in a log house

- Maintaining the level when assembling the log house

- The corner of the log house and the lower log have rotted

- The sequence of finishing a timber frame

- Insulation of a settled log house

- Restoring a burnt larch frame

- Quality of a 40-year-old oak log

- Permanent roof on a newly assembled log house

- Cracks in logs

- What time of year is it better to cut a log house for a bathhouse?

- What and how to make partitions inside a log house

- Ceiling beams in a timber frame

- Installation of a metal door in a log house

- The crown molding of a log house

- Questions about assembling a log house at home

- Turnkey log house for a season - is it possible?

- Arrangement of the subfloor in a rounded log house

- Common roof for a new log house and its extension

- Ventilation system in the log house underground

- How much does it cost to change the lower crowns of a house?

- Finishing the log house after shrinkage

- Reinforcement as a dowel for a log house

- What to rest the floor joists on in a log house

- Attaching timber to a log frame

- Cover an old house with a new frame

- Extension made of foam blocks to a house made of timber

- Wet lower rims of a new timber frame

- House made of sleepers

- How to cover a log house on screw piles with bricks

- How to strengthen the motherboard in a log house

- Birch log house

- Sauna log - pine or aspen

- The lower crowns of a larch frame as a plinth

- Adjusting anchors for shrinkage of the log house

- How to properly assemble a log house

- Octagonal timber frame

- Is a fifth wall needed in a log house?

- An alternative to dowels when assembling a log house

- Problems after shrinkage of the log house

- What to make partitions from in a log house

- Tongue-and-groove slabs as walls in a log house

- Insulation of the log house inside

- How to strengthen floor joists in a timber frame

- Log houses in Kolomna

- House made of timber or frame house

- Insulation of a log house from the inside

- Work plan after shrinkage of the log house

- Squeezed logs out of the log house

- Where to start after installing a log bathhouse

- Rounded log with Finnish profile

- The timber frame is spreading

- How to align the geometry of a log house

- Large gaps between logs

- Are dowels needed for profiled timber?

- Is it worth overpaying for profiled timber?

- Repairing the corners of a log house

- How to cover an unfinished log house for the winter

- The beam bends out of the log house

- Construction of a log house in the rain

- Processing and insulation of external walls of a log house made of timber

- How far can the outer ends of the logs be trimmed?

- Ceiling beams 7.5 m in a house made of timber

- How to attach a room attached to a house

- Technology for assembling a log house from timber

- Waterproofing log walls outside

- Replacement of the lower crown of an old house

- Interior finishing of the corners of the log house in the paw

- Dry brown rot in log timber

- Shrinkage of timber frame

- Roof on only installed log house

- How to fill the gaps between the log house and the outbuilding

- When to install a log house for a house

- How far can the ends of logs be trimmed?

- When should a log house be treated with impregnation?

- Cutting the end corners of the log house

- Leveling timber in a log house

- Protection of the log frame from the outside

- Replacing log walls with stone

- How to seal the gaps between the foundation and the log house

- How to cover a timber house

- How and with what to seal the gap between the foundation and the log house

- Bark on logs - to remove or not?

- Sandwich panel or log house?

- Preservation of log wood

- How to change the lower crown

- Settlement of a log house made of laminated veneer lumber

- Log house repair

- What kind of foundation is needed for a log house made of 9 by 12 m timber?

- How much timber is needed for a log house 9 by 12 meters

- Foundation for a log house with chopped gables

- When to put a roof on a log house

- How to seal cracks in a timber frame

- Log house on the spring

- Preparing a log house for winter

- Oak backing for the lower crown of the log house

- Log house repair

- Photo of a chopped log house

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Log houses and their maintenance

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Other questions on the topic of gender:

- Logs thickness - table of sections of wooden logs

- The cost of replacing floors in a bathhouse - Estimate

- The floor beams of a country house sank

- Insulation of interfloor wooden floors

- What kind of film is needed to lay a floor on the ground?

- Increase the ceilings in the extension to the house from sleepers

- Pillar for attic floor beams

- Wooden floors in the garage

- Exposed beam ceiling

- Leveling floors in a log house

- Insulation of the attic floor

- Replacing an old wooden floor in a kitchen

- Interfloor ceiling in a log house

- Extension to a one-story panel house

- How to fill the underground

- Why have apartments always had wooden floors?

- Insulation of wooden interfloor ceilings

- Coating a concrete floor in a bathhouse with bitumen mastic

- Strengthening ceiling joists for the attic floor

- Floor beams for the ceiling in a garage 7 by 7 m

- Workers to replace the floor in the country house

- Harmful substances from furniture

- Sagging of the floor between the first and second floors

- Replacing joists and floors under a partition with a door

- Covering an aerated block house with a channel

- Support under the log and shrinkage of the log house

- Make a hatch in the floor to access the subfloor

- Finishing an old concrete floor on a balcony

- Replacing rotten ceiling beams

- Floor screed device

- Insulation of old floors on the balcony without removal

- Floor pie on the ground

- Replacing support posts for joists

- Overlap between the steam room and the residential floor

- Waterproofing the floor in a wooden house on the ground

- Fighting mice in insulated wooden floors

- Ceiling mats in the garage

- House with a mezzanine for children's rooms

- How to insulate wooden floors in a gas block house

- Replacing a rotten floor in a Finnish house

- Calculation of floor beams

- New floor over old wood

- How to insulate floors in a bathhouse

- Round log beam floors

- Concrete floors in a log house

- Floors without insulation in a black bathhouse

- Cost of replacing a wooden floor in a brick house

- Replacing the ceiling with increasing its height

- Leveling a sagging beam without support

- How to fix sagging wood floors

- Warm water floors in a log house

- Floor pie in the bathroom of a log house

- Replacing wood floors in a 1906 house

- Wooden floors in a house made of SIP panels

- The floor in the frame on stilts sags

- Strengthening a wooden floor

- Leveling the deflection of wooden floors

- Wooden floors are swollen

- How to change beams built into block walls

- Cladding the ceiling of an adobe house with euro clapboard

- Changing the floor in a slag-filled house

- Floor on the ground in an old wooden house

- Tiled floors in a wooden bathhouse

- Insulation of a wooden floor

- Plywood floors with joists

- How to level a subfloor under laminate

- How to strengthen a cut wooden floor beam

- Coating floor joists with bitumen primer

- How to restore old beams

- Porcelain tiles on wooden floors

- Replacing joists and subfloors in a timber house

- Ceiling beam sagged

- Repair of sagging floors in a wooden house

- Lower the floor in an old log house

- Laminate flooring in an old country house

- Compatibility of polystyrene foam and wood in construction

- Rebuilding floors in a brick house due to creaking

- Timber logs 150 x 4 meters span

- How to straighten a sagging ceiling in a house

- Replacing rotten floor joists in a log house

- Replacing floors on the ground in a bathhouse

- Waterproofing the subfloor of a house

- Beam ceiling

- The ceiling in the bathhouse turned black

- Floors made of 12 mm plywood in two layers

- New floors on old ones

- Aligning beams in a timber house

- Strengthening interfloor wooden floors

- Wooden ceiling-floor pie

- How to raise a joist without opening the floor

- Option for arranging the floor in a log house from OCB

- Is it possible to replace beams

- Interfloor wooden floors

- How to cut a block diagonally with a circular saw

- Glassine in the house floor pie

- The floors are dry - what to do?

- Repairing the ceiling of an old wooden house

- How and with what to paint OSB

- Attaching the joists to the foundation

- Waterproofing the floor on the ground

- Floating floor on the ground

- Floor pie on floor beams

- Strengthening the ceiling joist

- New ceiling without touching the old one

- Insulating the floor in a village house

- How to strengthen floor joists 150x50 span 6 meters

- Installation of floors in an extension to the house

- Wooden floors on the ground

- Cement screed on the ground

- Cold floors in the house

- Is it possible to install logs after assembling the log house?

- Section and pitch of beams for a span of 5 meters

- Re-cover the floors in a cinder-cast building

- Fastening floor joists in a log house

- Attic floor in an old cinder block house

- Channel or I-beam for floor beam

- The smell of varnish from the floor - how to get rid of it

- Floor on rotten crowns

- The floors in the country house were torn out

- How to decorate a wooden ceiling above a gas stove

- Replacing a rotten floor - price of work and material

- Floating wooden floor in the country house

- Metal I-beam as a ceiling beam

- FC plywood floors on the open terrace

- What's the best way to install wood floors on a concrete slab?

- Laminated plywood for subfloor

- The floors are rotten, what should I do?

- How to change the subfloor without dismantling the finishing floor

- Floor ventilation in a log house on a slab

- A mushroom is eating our house

- Installation of logs to log walls

- Country house made of blocks and wood

- Beam 8 meters what section

- Replacing the subfloor and flooring in a log house

- Insulation of floors with polyurethane foam in a timber house on stilts

- Ceiling joist thickness

- The floor is rotting and moldy

- DSP subfloor and insulation

- Planks for attic floors 5 m

- Replacing a beam under a brick wall

- Reconstruction of an old floor in an old house

- Exposed beam ceiling

- What to support the floor beams on

- Sandwich panel floors

- Log beams

- How to remove part of a floor beam

- Insulating the floor from the subfloor

- Cold floors in a warm brick house

- Floor installation in an old brick house

- Insulation of the floor of the 1st floor in a log house

- Soundproofing the floor of the 2nd floor in a wooden house

- I-beam wooden floor beam

- Insulating the floor in a house on stilts

- Selection of log section for a span of 5 m

- Repairing the ceiling of an old house

- Laminate flooring on the second floor in a log house

- Floor insulation in an old wooden house

- Wooden floors are worn away by a worm

- Ceiling in a wooden house

- Distance from ground to floor

- Protecting floor joists from moisture

- Wooden floor on laminate

- Strengthening wood floors

- How to lay floors in winter in a cold house

- How to replace a rotten floor

- Floor insulation

- How to strengthen floor joists

- Second floor floor beams

- Floor insulation with foam plastic

- Laying floorboards

- Channels as interfloor slabs

- Interfloor ceiling in a silicate brick house

- Chicken coop floor

- How to strengthen the ceiling of a garage basement

- Load-bearing beam 6 meters

- Moldy subfloor

- Raise floors over old floors

- Mastic for covering subfloors and joists

- How to lay plywood on floor joists

- Creaking floors in the apartment

- Floors and drainage in the bathhouse

- The logs and subfloor of the country house have rotted

- Logs 9 meters

- How to cover the first floor of a log house of 8 meters

- Rotting subfloor

- Which ceiling joists to choose

- How to put ceiling beams in a bathhouse

- Transferring beams in a log house in height

- Strengthening old wooden beams

- Covering the first floor of a house without a basement

- Insulation of wooden floors with moss

- About lumber for floors and roofs

- Strengthening or replacing ceiling joists

- Floors on the ground

- Bathroom floor tiles

- Laminate flooring in the country house

- Subfloor and roofing felt

- Replacing the support beam

- Finishing floor on old floor with insulation

- Tiled floor in a wooden house

- How to insulate the underground

- Laying parquet boards in an apartment

- What to put on the veranda floor boards

- Updating an old subfloor

- Fastening the floor joists

- Subfloor repair

- Waterproofing plank floors

- Floor beams - reinforcement

- Thickness of plywood on joists

- How to remove creaking wooden floors

- Strengthening the interfloor ceiling

- Laminated plywood for wood floor repair

- Leveling floors during house shrinkage

- Insulation of wooden floors

- Installation of floor slabs

- Attaching beams to a vertical concrete wall

- How to join three skirting boards in a corner

- Floor joist supports

- Floor beams for a span of 7 m

- Floor installation in a timber house

- How to make a floor in an extension from foam block

- Which timber to choose for a beam floor

- Repair of bath floors

- Second floor terrace floor

- Round timber floors

- How to strengthen wooden floors

- How to change a rotten beam

- Replacing floor beams in an adobe house

- Support to strengthen the beam

- Ceiling joists

- Concrete floor under laminate

- Maximum distance between floor beams

- The middle of the wooden house sank

- Repairing floors in an adobe house

- Heated floors in a wooden house

- Raise the floor in an old house above ground level

- Replacing floor joists in an old house

- Attic floor repair

- Floors - asbestos-cement pipes for pillars under logs

- Attaching joists to slabs

- Strengthening logs in a log house 7 meters long

- Bathroom floor installation

- Insulation of floors using Izospan B film

- Floor ventilation below ground level

- The floors in the timber house are rotting

- Insulation of floors on a concrete screed under linoleum

- How to make garage floors

- Types of flooring for the home

- What thickness of the floor board should be 28, 36, 40...

- Fastening floor joists in a panel house

- Concrete floor in a wooden house

- Repair of wooden floor on the balcony

- Installation of logs in a timber house

- Concrete floor screed over Sip floor

- Strengthening and insulating the floor from blocks

- How to level floor joists

- Strengthening wooden floor beams

- Should a concrete floor be connected to the house?

- Insulation of regularly flooded floors

- Insulating the floor of a house on sleepers

- How to secure floor joists over a round log

- Replacing rotten floors

- Glassine in the underground of a timber house

- The film is blowing up over the subfloor

- Questions about floors in the garage 2nd floor

- Arrangement of the subfloor in a rounded log house

- Monolithic floors on the ground

- What is the best way to cover the walls and floor of a garden house?

- How to level a concrete floor in a panel house

- How to level the floor in the kitchen

- Floor in bathhouse sink

- What to rest the floor joists on in a log house

- How to strengthen interfloor joists in a brick house

- Economical interfloor ceilings

- Insulation of concrete floors

- What is better to put under linoleum

- Subfloor repair

- Floor installation using gas silicate

- Replacing floors in a country house

- Floors made of moisture-resistant slabs

- How to lay linoleum on an old floor in an apartment

- Leveling floors in an old house

- Treatment of genital lags

- Choosing floorboards for your home

- Thermal vapor barrier in the floor pie

- Raise sagging floors without dismantling

- Thermal and sound insulation of the floor in a panel house

- The floor in the hallway of a private house is rotting

- Rotten floor in a wooden house

- How to change the floor under a fireplace

- Concrete floor in garage

- How to wax a floorboard

- How to make a wood floor in a garage

- Repair of concrete floor on the balcony

- Replacing subfloors

- Moisture-resistant laminate for wooden floors

- How to cheaply re-floor an apartment

- Bathroom sink floors

- Arrangement of rough floors

- Sagging joists and floors

- How to change a rotten floor

- How to lay the floor on a loggia correctly

- Wooden floor construction in more detail

- Subfloors made of larch on the 2nd floor

- Second floor subfloor

- How to hide air conditioner pipes in a tile floor

- Replacing a rotten floor

- Floor repair in a panel house

- Lay floors on the attic loggia

- The new wood floor has started to rot.

- Repairing a wooden floor in a country house

- How to insulate a wooden floor

- Again about floor insulation

- Larch loggia floors

- Foundation and floors of adobe house

- Floor in a finished (transportable) bathhouse

- How to arrange the floor on an open balcony

- Underfloor insulation

- Connecting the ends of the floor boards

- Concrete floor in garage

- How to level a subfloor

- How to lay a new floor on an old one

- How to lay a subfloor

- How to raise floors in your home

- How to lay floors beautifully

- Ventilation in the underground

- How to level log beams for flooring

- The subfloor beams began to rot

- Laying the floor with a board without a tenon

- Floors in a country house

- Floor on the loggia balcony

- Floors - leveling log joists

- Asbestos cement pipes to lighten concrete floors

- Insulation of underground space

- Preparing the base for laminate flooring

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Floors

All questions to Semenych about construction

Semenych (author of materials)

Our site is regularly updated with interesting and unique materials and articles on the topics of lumber, building materials and works, the author's opinion and knowledge of a real coven with more than 15 years of experience are provided. There is a section - funny stories of shabashniks. If you would like to receive information about this, subscribe to our website's newsletter. We guarantee that your address will not be shared with third parties.

Apartment renovation in Moscow and Moscow region

We work with a guarantee! Wide range of repair work.

Professional craftsmen. +7 (905) 797-20-34

luxurycomfort.ru

| Country house | Bath |

| For the dacha | Tool |

| Materials | Tales |

| Foundation | Log houses |

| Roofs | Insulation |

| Walls | Siding |

| Floors | Cellars |

| Attics | Doors windows |

| Stairs | Extensions |

| Wells | Toilets |

| Balconies | Loggias |

| Condensate | Flooding |

| Fences | Kennels |

| Sidewalk | Birdhouse |

| Adobe | Carts |

| Garages | Barn |

| Greenhouses | Bath |

| Swing | Brazier |

| Shower |

| Horizontal bar |

Leveling floor joists in a wooden house: basic methods, advantages, disadvantages

There are 3 main methods of leveling log logs, tested by masters:

- ● Chopping the surface with an axe, plane, saw, chisels. To do this, a rope level is placed along each log, along which further alignment occurs. Next, using an electric saw, chainsaw, or ax, a layer of wood is removed, not reaching the marked line of 5 cm. The remaining layer is removed with chisels (plane). The disadvantage of this method is that it is labor intensive and reduces the strength of the structure, as the thickness of the material becomes smaller.

- ● Fastening of edged boards. The sides of the log are subject to cutting off part of the wood. An edged board with its wide side, set straight, is attached to the resulting planes. Fastening is done with hardware with a maximum length of 150 mm, staples, fastening step - 0.5-1 m. The recommended board size is 40 mm thick, 100/150 mm wide.

- ● Horizontal installation of edged boards. Their leveling occurs by laying wedges between the lag and the board. But the ceiling height decreases.

All methods have been tested by the company’s specialists, they give a good result - a flat floor.

Correct level marking when leveling log logs

Alignment of log logs is carried out according to the level. To do this, a basic “zero” floor level is marked, placed 5 centimeters above the main one. Using a laser device or a long tube filled with water, nails are driven at the same height in each corner. Along the perimeter of the room, twine (construction fishing line) is attached to them. More nails are placed above each lag, on which a thread running along the log is also secured. Then equal distances are measured from the obtained level and corresponding marks are made on the tree. This creates the layer that needs to be removed for leveling.

We trust the leveling of floor joists in a wooden house to professionals

In order not to be disappointed in the results obtained, engage professional craftsmen and carpenters to perform work related to the arrangement of a wooden house. They must know all the features of the work being performed, the material, and the technology. Don't try to save money by doing everything yourself. When arranging floors, your mistakes will become fatal. It is recommended to contact official companies that are ready to enter into a written cooperation agreement. This way you will protect yourself from unscrupulous performers.

4 reasons to contact us for lag leveling

To ensure the floor is perfectly level, contact.

We will provide our clients with:

- ● Drawing up an estimate based on measurements made by our specialists. Their departure is free for you.

- ● Services of all types of log finishing (carried out by craftsmen from Russia and Belarus).

- ● Independent delivery of your own scaffolding (for working with logs on the attic, second floor).

- ● Possibility of payment only for work actually completed.

Call us, we will make the logs smooth, right on time!

Installation of floors in a log house | Srubov

Articles

Our works

Chopped bathhouse 5.2x5.2+2.6, Peniki village, Lomonosovsky district, Leningrad region. Season 2014

Log bathhouse 6x8.5, Gorelovo, St. Petersburg. Season 2013

Log bathhouse 5.0x5.0+2.5, Krasnoe Selo, St. Petersburg. Season 2020

The installation of floors must begin after the frame has been assembled and the roofing work has been completed. Traditionally, in a wooden house, floors are made of the same material. Less common is a concrete base. Depending on the seasonality of the home, a decision is made to insulate the floor. For year-round living it is mandatory; in a country house where you plan to live only in the summer, the floor can be left cold.

Concrete floor

Concrete coating is the best option for a bathhouse, since it is not afraid of high humidity, because water only improves its technical performance. Concrete flooring will not rot, which distinguishes it from wood flooring. Moreover, it is easy to maintain and drains water easily. Concrete flooring can be covered with regular tiles to make the room more comfortable and attractive.

Preparing the base

At this stage you will need crushed stone or gravel, you will also need natural stone or broken brick. The soil must be compacted and leveled in advance, and then a brick block must be laid to a height of 15 cm, covered with crushed stone at a depth of 10 cm and compacted thoroughly again.

After completion of the work, the first layer of concrete begins to be poured to a height of 5 cm. This must be done so that the floor maintains an inclination towards the drainage basin.

When the solution has set, expanded clay is poured on top of it to a height of 8 cm and the concrete solution is poured again, but this time it is reinforced with a metal mesh. Next, the concrete surface is leveled and smoothed with an appropriate tool.

Preparation of a solution with the addition of perlite

Perlite is a component added to concrete mortar to give it thermal insulation properties.

Perlite is light and volatile, which means you can only work with it in a draft-free room.

The concrete solution is prepared in the following sequence:

- 2 buckets of perlite are poured into a concrete mixer.

- Pour in 10 liters of water.

- Stir.

When the perlite is mixed with water, 5 kg of cement is loaded into the mixture. Next, the solution is stirred for at least 10 minutes, after which water (5 liters) is again poured into it and stirred until a homogeneous consistency. At the last stage, 2 liters of water and 1 bucket of perlite are poured in, and the solution is mixed until a loose mixture is obtained.

Each time the solution should settle for about 10 minutes, and only then can you continue stirring. At some point, the solution will begin to exhibit the property of plasticity. Excess water may also be released during the process.

Installation of a log floor on floor beams

This option for installing a floor in a log house is the most logical among all others. The method is considered the most common. Even professionals advise making just such an overlap, as it is quite easy to install. Such a floor in a log house has other advantages. It becomes possible to raise the floor to almost any height. You can also think about arranging a basement.

Another plus is that the ceiling will not come into contact with the ground, and therefore it will last quite a long time.

If we are talking about constructing a floor in a log house made exclusively of wood, then the floor beams need to be installed on the third or fourth row of logs. If bricks were used in construction to organize the foundation, then the beams are placed immediately behind the basement floor.

The end parts of the beams on which the floor will be located can either have a through arrangement or be installed in the frame mass.

The second method is considered less successful. If the beams are arranged according to the end-to-end principle, then they must go outside. Excess condensation will have the opportunity to evaporate. This option allows you to make the floor structure more rigid and reliable. All beams that go outside must be treated with special antiseptic compounds that will protect against rot and mold.