The source of heat in a house where it is not possible to install gas equipment is a stove. Its action is based on the selection of natural heat that is released when a certain fuel is burned. There are several types of furnaces, which may differ in their external characteristics and internal technical structure. External parameters are formed based on the requirements of the room dimensions. Technical designs are aimed at using the generated heat as efficiently as possible for their own purposes.

It’s no secret that the efficiency of a heating system is influenced by several factors: stove design, efficiency, type of fuel. Theory shows that the heat released during the combustion of a certain mass of different types of fuel is different. Its greatest value falls on the share of firewood. But the choice of fuel depends not only on this; availability or cost makes a significant contribution to the decision on methods of generating heat. In this article we will try to find out what else can be used to heat the stove, besides ordinary firewood.

Anthracite is the highest quality and oldest coal

A couple of phrases about calorific value

In terms of its chemical composition, wood is a rather complex material. It contains the main components - lignin and cellulose. But besides them, the tree contains:

- resins;

- proteins;

- tannins and other ingredients.

When logs burn in a stove (or simply when trees burn in a forest), these components interact with the air at a chemical level. The calorific value of wood (as well as any fuel), or thermal conductivity, is the amount of thermal energy that a unit of weight of the fuel material (in our case, 1 kg of wood) produces during combustion. Kilocalories are used to measure quantities.

The chemical composition among most tree varieties has minimal variations, which causes differences in the number of calories emitted. That is, the heat of combustion of some types of firewood can be as follows:

- for deciduous species the figure is 4460 kcal/kg;

- for coniferous species - 4560 kcal/kg;

- for mixed breeds – 4510 kcal/kg.

As you can see, the differences are minimal. At the same time, it is easy to understand that it is better to use coniferous wood for the stove due to its greater thermal conductivity. Only firewood is supplied to the market depending on volume, not weight. That is, the main criterion for choosing firewood is cubic meters. Density plays an important role here, because the higher it is, the heavier the wood.

For example, let’s take 1 cubic meter of birch logs as a starting point. Then the ratio of the volume of different rocks will look like this:

- oak logs - 0.75 cubic meters. m;

- alder logs - 1.1 cubic meters. m;

- pine logs - 1.2 cubic meters. m;

- spruce logs - 1.3 cubic meters. m;

- aspen logs - 1.5 cubic meters. m.

That is, 1 cubic meter of birch and 0.75 cubic meters. m of oak logs, 1.1 cubic meters. m of alder wood (and so on) will produce the same amount of heat. Knowing this, now, depending on how much firewood costs, you can get profitable savings for yourself.

Criteria for selecting fuel material

To select firewood for the purpose of lighting a stove or making firewood for a barbecue, you need to highlight a number of characteristics. Certain properties depend on the type of wood. Excellent firewood is: well-dried hardwood: which burns for a long time and perfectly, having almost 100% heat transfer from the firewood. Heat transfer, density and humidity are the most important characteristics when choosing wood. These indicators are closely related and the temperature and duration of combustion of the material depend on them. Let's look at each of these indicators.

Density

The quality of the wood species depends on this indicator. This is the first thing you should pay attention to before buying firewood . According to this indicator, wood species are divided into three main categories:

- low-density;

- medium-dense;

- high-density.

High-density wood species are of the highest quality, which means they provide the best specific heat of combustion. They burn longer and hotter, making the best coals for barbecuing and shish kebab.

Rocks with high density present some difficulties when splitting by hand. Because of this, people prefer to purchase softer woods such as ash or birch. Such a tree can be easily split into logs of the required size.

Humidity

This indicator reflects the percentage of moisture contained in the wood. The higher the humidity, the higher the density index. But the specific heat released during the combustion of wet wood does not increase. In addition, damp wood does not burn well. This does not apply to birch, which, due to its low initial humidity, can be placed in the oven immediately after cutting. To reduce the amount of moisture contained in wood and improve its quality, the following methods are used.

- Drying of fresh firewood should take place under a canopy for 80 - 120 days. The exact period depends on the time of year.

- To increase the calorific value, some of the firewood is dried indoors.

- Artificial drying of wood is the best option. The humidity percentage tends to zero, and the calorific value becomes maximum.

Heat dissipation

This indicator is the final result of the two previous characteristics. It shows how much heat wood can provide under certain conditions.

Hardwoods have the greatest heat transfer. Soft wood shows the opposite result. If the necessary conditions are met, the difference between them can be 100%. This explains the cost savings when purchasing more expensive, hardwood.

Also important here is such a characteristic as the combustion temperature of the combustion material. More than 1000oC is produced by such wood species as ash, hornbeam and beech. The heat level reaches 85 – 87%. In this indicator, larch and oak are close to them. Alder and poplar have the lowest combustion temperature of 500°C.

Breed characteristics

The dense structures of deciduous trees are suitable for producing good heat in the firebox. They burn brightly, generating a lot of heat in the process. The trunks of fruiting trees smell pleasant when burned, which makes them indispensable in fireplaces and open hearths.

The smell of smoldering mass depends on the content of esters, resins, and tanning components. Oak releases tart tannins, rosewood scents the space with vanilla, and backout feels about the same.

Coniferous trees have an intense flame, but when burning they emit more smoke than deciduous trees. When using them, the walls and ceiling of the room, as well as the inside of the chimney, become clogged faster. The smell of turpentine, which comes from pine and spruce, spreads into the room.

Oak in the hearth

Initially, oak is considered as a valuable wood for production, so discarded trunks or measured waste are used for fuel. If we talk about full-fledged logs, their cost is high, so such options are rarely used.

It is better to burn with wood cut from middle-aged and not very old trunks. This guarantees long combustion and release of a large amount of energy. Young specimens give off a not too intense heat, and the room in the house has the smell of smoldering wood. Old trunks will leave a lot of ash in the residue, while the energy released is weaker.

Burning quality logs releases a tart aroma with added forest notes. It tones the body, relaxes the nervous system and has a beneficial effect on health. Oak wood is completely suitable for fireplaces and stoves.

Linden for bath

When burned, linden wood produces an even heat throughout the entire process. This is the kind of combustion that is required when heating steam rooms and baths. The raw material is used to maintain uniform temperature in the heating compartment.

Linden firewood emits a sweetish odor that is beneficial for the respiratory organs. It is difficult to ignite raw materials in the firebox, so torches and thin logs are used. Firewood is stored for two years, then its properties begin to decline. The calorific value of linden firewood is 2040 kcal, which is not enough to fully heat a house. Sometimes fuel is used in stoves for cooking.

Birch logs

In terms of density, birch is equal to oak, therefore it is a high-quality fuel for stoves. Its ability to transfer heat is lower than that of valuable wood, but is a quarter higher than that of coniferous trees. When burned, the raw material gives an even flame and does not emit sparks. In terms of calorific value, a cubic meter of birch firewood replaces:

- 1.15 m³ alder, pine;

- 1.3 m³ spruce;

- 0.76 m³ oak logs;

- 1.52 m³ aspen.

The disadvantage is the admixture of resin in the wood, most of which comes from the bark of the trunk.

Logs are placed in the stove, after removing the top layer. The soot released during smoldering clogs the chimney and narrows the working channel of the exhaust gases. When burning birch fuel, a unique smell is felt; volatile substances disinfect the atmosphere and prevent respiratory infections in households. By analogy with linden, birch is stored for only two years.

Characteristics of firewood

Wood of each species has its own individual characteristics, sometimes very different from each other. Therefore, some types of wood are more suitable for construction, while others are more suitable for heating homes. Not all firewood is equally good for heating purposes. In addition, you need to take into account that, by and large, almost all firewood is suitable for the stove (of course, not to the same extent, but still), but for the fireplace you need to choose fuel that will bring into the room, in addition to warmth, also a pleasant aroma will create a favorable, cozy atmosphere. Thus, fuel made from too resinous rocks is not suitable for a fireplace, since such wood creates excessive smoke and soot when burned. Moreover, for example, when pine firewood burns, it very often shoots out embers that can land on flammable surfaces, and then the probability of fire is very high. That is why coniferous species are not recommended for use in open fireplaces. For the stove, it is optimal to choose firewood that burns for a long time, with low intensity and pronounced heat transfer. An important factor for firing a stove is the minimum amount of smoke emitted by burning wood, as well as ash remaining in the firebox. Good firewood, most suitable for heating a stove, should be well prepared for the winter period - dried and folded for storage. All of the above qualities directly depend on the quality of these events. Undried, freshly sawn wood is never used immediately for heating, since it dries out in the firebox, produces a lot of smoke, and then burns very sluggishly due to the large amount of moisture. The combustion of such fuel produces very little heat, and that is why “fresh” wood must be thoroughly dried. You can check how dry the firewood is in the old simple way: if when one log hits another, a ringing sound is heard rather than a dull sound, then the wood is fully ready to go into the stove. High-quality firewood can be obtained from trees that are cut down in winter - during this period there is practically no movement of sap in the tree trunks. But trees cut down in summer or spring require longer drying, since they have a very high percentage of moisture.

Peat

Often you have to decide what to heat the stove with besides wood. We have to abandon this excellent type of fuel for some completely objective reasons. Alternatively, peat and coal briquettes can be considered. Despite the fact that their nature of origin is the same, their properties and calorific value are different.

In order for fuel to be used directly, it often has to be pre-treated, dried, crushed, or chopped. Peat contains a lot of water inside, so it needs to be dried. But when dried, it crumbles and becomes not so much unusable as inconvenient to use. Therefore, it is pressed with the addition of sawdust into special briquettes.

The main parameter for each type of fuel is its specific heat of combustion. It shows how much useful energy can be obtained if a fixed amount of fuel is completely burned.

For peat in various variants, this value does not exceed 17 MJ. However, we cannot evaluate some physical quantities by their absolute value, so for comparison we present a fragment of the table of values.

Ready-to-use peat briquettes

The amount of heat in MJ released by the following types of fuel:

- coal - 27.00;

- brown coal - 12.98;

- anthracite coal - 28.05;

- peat - 12.10;

- peat in briquettes - 17.58;

- peat in the form of crumbs - 10, 84.

Peat in large briquettes

Types of coal. Pros and cons of using

Some solid fuels are transformations of the same organic material. For example, peat first forms in swamps from dead plant matter. It is then carbonized and turns into brown coal. At the next stage - into coal.

The disadvantages of peat and brown coal are a large amount of surface moisture. If you dry them well, they will crumble. This can be eliminated by pressing peat into briquettes. However, when burned, this fuel produces a lot of ash. This makes caring for the stove difficult: you constantly need to clean the grates and ash pan, but even this is made difficult by the fact that the ash is very light and is sprayed around the room.

Peat in briquettes is compressed with sawdust, which makes it of higher quality and convenient for storage and use. Brown coal is not suitable for heating furnaces, so it is practically not used. In addition, it has a low calorific value (3000±500 kcal/kg) and, accordingly, efficiency.

Coal

Coal is of natural, not man-made origin. In some regions of Russia, coal is mined, which is enough not only to supply the domestic market, but also for sale abroad.

Good to know: How to properly heat a stove with coal, basic rules

But coal is divided into several types, which differ in the age of its formation. It is not difficult to guess that higher quality rocks differ in the duration of their occurrence in the layers. There are three types of coal classification, although the same grades are involved in each.

- Classification by formation time. In this division, four types of coal are distinguished: lignite, brown and hard coal, and anthracite coal. These breeds are listed in order of increasing age. They also differ in physical properties. Lignite is presented in the form of crumbs, since it is not able to hold its shape. Brown coal is also not very durable, but it can already be used in home stoves. Although its calorific value is far from its analogues. Hard coal is the most common and accessible type, and anthracite is considered the highest quality rock.

- Classification by humidity and content of volatile compounds. In this gradation, known rocks follow the same sequence. Their humidity decreases from 40% to 5%. A similar picture emerges with volatile substances. In this division, anthracite occupies an advantageous position.

- Classification by calorific value. We had to introduce the calorific value parameters earlier, so it makes no sense to duplicate the indicators. It should only be emphasized that this classification is decisive when choosing fuel for a home stove.

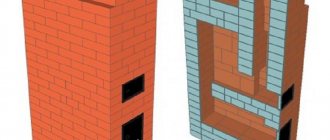

Features of furnaces using coal

The vast majority of real stove models that we remember from our grandparents were adapted to use wood and coal. This averaging of the design was carried out on purpose, because it was difficult to predict what would have to be used to heat the stove in each specific season. However, if you take a detailed approach to the construction of the furnace, then these options should differ.

The temperature inside the firebox when burning coal is much higher than when burning wood. This leads to the fact that the walls of the metal firebox are strengthened using thicker sheets. The volume of the firebox increases due to the lower location of the grate. The ash pit is built to be larger in volume, since the amount of ash when using coal is much greater than that of firewood.

Getting ready to light the oven

Heating with eurowood

I would like to immediately note that ordinary firewood and modern briquettes are a priori different types of fuel, although their operating principle is identical. (Fuel briquettes are closer in nature to coal.) Ordinary firewood has been used for a very long time, but European firewood still has to prove its worth.

By the way, fuel briquettes received the original name “Eurofirewood” due to their similarity with classic firewood both in shape and technical characteristics.

Modern fuel briquettes are produced from food and natural waste. Wood (sawdust, shavings, wood dust, branches and even leaves), straw remaining after processing grain crops (wheat, rye, corn), husks and husks of seeds, nut shells, peat, and in rare cases even manure are actively used. When burning this kind of material, no harmful substances are released for humans and the environment. No other ingredients are added to fuel briquettes.

Fuel briquettes from various materials

Carefully prepared and crushed raw materials are subjected to temperature pressing, during which excess moisture is removed, the material is held together, and becomes dense and strong. Depending on the type of production, all fuel briquettes can be divided into three classes:

- The simplest one is Ruf fuel briquettes.

- More advanced - Nestro fuel briquettes.

- The most modern are Pini-Kay fuel briquettes.

These types of fuel briquettes differ in shape, final processing method (sometimes there is firing to give the final shape and protection from moisture), level of density, which largely depends on the shape of the briquette itself. The composition of Eurowood always remains the same, without adding third-party elements.

Why is Euro firewood so good? Let’s look at its main advantages:

- Created by pressing at high temperatures, Euro firewood has high density and low humidity. That is why the burning time of fuel briquettes is much longer than that of firewood. The level of heat transfer from briquettes is twice as high, which is explained by the same technical characteristics. Ordinary firewood, dried during the year, has a moisture content of about 20%, fresh wood 40-50%, and for fuel briquettes the same figure is 8-9%.

- Made using professional equipment, having the correct shape and good packaging, fuel briquettes are more compact, convenient and easy to store. At the same time, as we have already said, they burn longer and give off more heat than firewood, which means the fuel supply may be smaller. Heating a house with fuel briquettes in Europe is considered a normal practice, moderately economical. In Russia, wood is traditionally used.

Fuel briquettes of the correct shape

- Using fuel briquettes is extremely simple; the technology for burning them is no different from ordinary firewood. You could even say that they are safer to use since the level of fire and its operation can be controlled.

- When storing firewood in the house there is always a lot of garbage, but the briquettes are tightly packed in cellophane and loaded into the oven entirely.

- Eurowood burns with a stable fire, it does not spark or smoke, and the amount of smoke emitted can be called minimal. By loading briquettes into the oven in various ways, you can regulate the intensity of fuel combustion. A small amount of smoke allows you to save on cleaning the chimney from soot, and also allows the use of such fuel in black baths.

- After using fuel briquettes, very little ash remains, approximately 1% of the total volume of fuel. Unlike firewood, briquettes burn almost completely.

- With proper skill and suitable equipment, you can make fuel briquettes with your own hands. At first glance, the task seems impossible, but upon detailed analysis everything turns out to be very simple. In the future, such production will help significantly save the budget on fuel.

tall cellophane packaging for fuel briquettes

Having considered the advantages of fuel briquettes, we move on to the disadvantages that also exist:

- Having a high density, European firewood takes a long time to burn in the firebox. When studying whether it is better to heat a stove, with wood or briquettes, you should definitely pay attention to this. You can't start a fire quickly with alternative fuels; you need the right materials. Even a good, dense, dry briquette takes a few minutes to warm up.

- When burning briquettes of some types, characteristic odors may be present. For example, the aroma of burning seed husks may not be to everyone's taste. The ash from Eurobriquettes smells absolutely disgusting, but despite this it is an excellent fertilizer.

- Fuel briquettes are afraid of dampness, even if they are burned on the outside. A product packed in cellophane is not afraid of moisture, but after being removed from a vacuum package, the briquette becomes vulnerable. Due to humidity, Euro firewood crumbles and becomes unsuitable for use.

- Mechanical impacts for Eurobriquettes are also unacceptable. Even when dry, you can break them, especially if they are of poor quality.

- Fuel briquettes are not capable of creating a unique atmosphere of warmth, comfort and coziness that is inherent in firewood. They do not crackle, the fire from them is too simple, smoldering, and the appearance leaves much to be desired, especially homemade options. From an aesthetic point of view, fuel briquettes are not suitable for use in a fireplace.

Burning briquettes in the furnace firebox

When choosing firewood or briquettes for heating your home, you should also analyze ordinary wood, at least for its merits.

Secrets of lighting a stove

Many people tend to mistakenly evaluate fuel by the ease of its ignition. It will not be possible to light coal without firewood; in addition, the ignition process itself must be carried out correctly. This contributes to a long service life of the stove.

The stove must be inspected externally every time you intend to light it. Substances or objects that are easily flammable and were accidentally placed nearby are first removed to a sufficient distance. Before kindling, the chamber and ash pan must be cleaned, removing unburned food. To prevent small particles of ash from flying around the room, it is recommended to pour a little water into the ash pan.

Household waste containing plastic or bitumen cannot be used for kindling, as they cause the formation of large amounts of soot in the chimney. The firebox door and the ash pan should not be open in pairs. This rule is useful, since when kindling you have to adjust the draft.

Coal is usually stored indoors, but moisture may not be excluded. In this case, it must first be dried. When wet coal is burned, all the water in the form of steam goes up the chimney. A large amount of soot settles on the wet surfaces of the pipe walls.

Crumpled old newspapers are placed on the grate. Small wood chips can be placed on top of them. Wood logs are stacked in a hut or a well, depending on your habits. After this, we light the stove by closing the firebox door and opening the ash pan.

When the firewood begins to burn out and the first hot firebrands form, you can add a portion of small coal, after which larger pieces are gradually added. When burning coal, you should close the chimney damper, this will save heat. But remember that when the damper is closed, there is a high probability of filling the room with carbon monoxide. Watch the flame, a blue tint indicates that it’s time to open the damper.

What kind of firewood is best for heating?

To save on heating, owners of private houses often think about what kind of firewood is best for the stove. Some fuels burn quickly, releasing a lot of heat, but there are also those that produce a lot of soot and tar. Having studied the characteristics of heat transfer and other properties of trees, the owners of country houses choose raw materials for a stove, open fireplace or firebox in a bathhouse. The efficiency of heating a house will depend on correctly selected and stored firewood for the winter . The fuel must burn for a long time, releasing as much heat as possible into the premises. But not every wood has such qualities, so you need to be very clear about what kind of firewood is best to purchase for heating, and how best to organize its storage. There is no breed that would be ideal for use in all cases ; each trunk has disadvantages and positive aspects. Heating with wood is considered a labor-intensive task due to the large number of organizational processes that cannot be resolved with the development of industrial technologies and the release of new units. A large mass of raw materials is processed, harvested, stored, transported, sawn and split. But all the organizational fuss is offset by the economic benefit from the full cost of fuel, and unpleasant moments in the form of smoke and soot fade into the background. The instability of wood pulp leads to cumbersomeness and imperfect calculation of the amount of required raw materials. Its choice is influenced by: heat transfer, ash content, flammability, smoke ability, humidity, density, combustion completeness. Each type of wood has its own characteristic density of structure, and the denser the wood, the longer it will first burn and then smolder in the oven. However, such varieties take a long time to light up, and therefore it is necessary to stock lighter wood with them, which is used for ignition. Equally important for preserving the high quality of fuel is their proper preparation and arrangement of the place for their storage on inclement days of autumn and during the cold and snowy winter period. High-quality and proper firewood can create comfort and special warmth in your home, which cannot be compared with gas or steam heating. When the stove is lit, from which comes the pleasant hum of natural draft and the crackling of logs, a special atmosphere of comfort is created in the room. This is probably why stoves are still installed even in those mansions where there are other types of heating.

Primary requirements

The best firewood for heating stoves is dry. Humidity should be within 20%. This is the main requirement. The calorific value of wood depends very much on its moisture content.

Dry wood flares up and burns well, emits more heat, and smokes less. The logs should not be rotten or saturated with water. Water logs are not suitable for heating stoves.

Good firewood leaves little ash. It is advisable to harvest wood in late autumn or winter, when sap flow stops and the wood is denser.

The size of firewood for the stove depends on the size of the firebox, usually 35-40 centimeters long. The thickness is medium, thick logs split. Small logs are easy to light. They also burn quickly, which must be taken into account when preparing them.

Rare types of firewood

Oak

– the best firewood for the stove. The wood is dense, burns for a long time, gives high heat transfer, and is very economical, because compared to other firewood, much less is consumed to heat the same area. Due to its high cost, it is often used as an additive to other wood. A pair of oak logs will make the burning more intense and longer.

Good oak firewood comes from middle-aged trees; when burned, they release a pleasant tart aroma. Oak firewood is ideal not only for stoves, but also for fireplaces.

Excellent, but also one of the most expensive - alder

firewood. They burn hot, without smoke or soot, spreading a pleasant aroma.

Alder cannot be confused with any other firewood; when cut, it has a color from yellow to deep red. Perhaps this is the best firewood for a fireplace; it burns with a mesmerizing, even flame of a beautiful color. A big plus is that alder firewood lasts a long time and can be stored for future use for 5-6 years.

Rare firewood includes linden

. Although linden is common, linden firewood is rare. The wood is hot, although it takes a long time to burn, but then the stove heats up very quickly. The aroma that comes from linden when burned has healing properties. A bathhouse heated with linden firewood is useful for colds, diseases of the bronchi and lungs, and has a beneficial effect on the condition of the skin.

Regardless of what type of firewood you purchase, make sure that the wood is not rotten. The benefits of rotten mushrooms are zero. In order for the wood to burn, giving off maximum heat, it must be dry. Undried wood burns poorly, produces a lot of smoke and little heat.

For thousands of years, our ancestors used wood (firewood) as fuel. And today, despite the widespread use of natural gas or coal, they remain a popular type of fuel.

Folk tales

Superstitions and beliefs circulate among the people. For example, it is believed that it is better to prepare firewood for a bath during the waning moon. Moreover, the thinner the sickle, the stronger the logs are endowed with healing powers. Once upon a time, the Slavs believed that people who left the world turned into maples in their lives. The appearance of its leaves is akin to open palms, and its branches represent hands raised to the heavens. For this reason, they never fired maple stoves.

In the old days, residents of the Tambov province heated their stoves exclusively with apple trees to keep the house warm throughout the winter, including especially frosty days. Whether to believe all this or not is everyone’s business, but what happened was what happened.

Which ones are best for the oven?

Any wood can be used as fuel. The main thing is that they exist. Each region has its own preferences, depending on what trees grow in the area. Many people believe that birch or alder are the best. The choice is yours.

To the bathhouse

The choice of logs for heating a sauna depends on the design of the stove. Many people prefer:

- Alder. They produce a persistent heat and burn almost smokelessly. There is a popular belief about their healing power;

- Birch. Burns evenly, the heat is strong;

- Willows. The heat transfer is low, you will need a lot of them, but the spirit in the bathhouse will be especially light.

It is not recommended to use oak ones - they take a long time to burn out, the heat is intense, and they emit a large amount of carbon monoxide. Periodically, aspen is used to clean the chimney. If the furnace firebox is remote, the main selection criterion is heat transfer.

For home heating

Hardwood firewood has the best qualities and is used more often. Birch, oak, linden - any, depending on their availability and needs. The main thing is to be dry. In fireplaces it is better to use those types that smoke less and do not “shoot”.

The best of the best: fruity, birch and linden

They emit a pleasant aroma and burn well, but it is difficult to make kindling with any hard logs. Birch and linden are considered the best for heating a stove. Birch has a low amount of moisture even in its raw form. Logs can be placed in the firebox without drying, they will still give off great heat and will smolder for a long time. Linden is valued for its healing properties. If you heat the stove with linden wood, you will have a healing microclimate in your house or bathhouse. Linden burns slowly, with good heat transfer. Thus, the best varieties are hardwoods, and of these, birch and linden.

Softwood

Soft varieties of wood melt quickly, but require drying to a residual moisture of 20% and proper storage. These include coniferous varieties. Disadvantages: large amount of resins, high sparkle (with an open firebox the fire hazard increases). As a rule, common types are used: pine and spruce. They are easy to chop and saw, the cost of purchasing this firewood is quite low.

Special firewood for special occasions

Whatever they say about progress and technology, live fire gives real warmth, a unique feeling of comfort and safety, unity with nature. Throwing logs and seeing how cheerfully the flame flares up, sorrows and hardships are forgotten, the conversation goes faster. But in life, anything can happen: if smoke comes out of the stove, soot appears, it means you put the wrong kindling log.

When choosing firewood, not asking about the type of wood is a crime. Oak, aspen, alder, pine and spruce, linden, fruit, birch - each species is characterized by its own density, heat transfer and degree of combustion.

Some firewood is only suitable for kindling, others burn long and hot, and others fill the room with a pleasant aroma that is good for health and disinfect the room. Without knowing such details, it will not be possible to heat a house, light a stove or a bathhouse.

How to store it correctly?

To maintain the quality of firewood for a long time, you need to ensure proper storage. No special conditions are required for this; a number of points need to be taken into account:

- The woodpile should not be located in a low place where water can accumulate. Otherwise, the wood may rot.

- Logs should be stacked loosely to ensure good ventilation.

- To provide protection from precipitation, a canopy is made.

- There is no need to stack firewood immediately after harvesting. It's better to do this in a few months.

- It is recommended to store it near the house so that there are no difficulties with access to the woodpile.

Basic storage rules

Purchased high-quality wood for heating must be properly stored, since moisture reduces the useful technical characteristics. Arranging a place does not require much effort; owners often use the material to create decorative woodpiles of various shapes. An area for storing firewood is selected taking into account the following characteristics: - a dry and elevated place in the yard is determined in which water flows to lower areas; — stacked firewood is placed loosely so that small spaces between them provide ventilation; - the wood storage area is covered with a canopy or roof (if this place is not in a barn) to protect it from rain and snow; - sawn and chopped logs are not collected in a woodpile for 4-6 months after cutting the trunk from the root; — trees harvested in summer require more time to dry; - for ease of use, the warehouse is located near the entrance to the house - this will allow you to collect fuel in any weather conditions.

The trunks are cut into pieces of equal length, measuring the required distance in the firebox. Short firewood eats up useful space, and long firewood does not allow you to close the stove door or place rings. The thickness of the logs is medium in size. The owners prepare the firewood and store it in full for the winter, so as not to have to deal with cutting in sub-zero temperatures.

How much does firewood cost?

How much firewood for a stove costs is a question that worries those who do not have the opportunity to prepare it themselves. Their price depends on many factors: wood type, region of residence, humidity, packaging (can be bought in nets).

The price range is wide - from 500 rubles per 1 cubic meter to 3,000 rubles. You will also have to take into account the cost of their delivery. The issue of price is also important for those who prepare it themselves. Self-harvesting is often more expensive if you count the costs of material resources, time, and your own labor.