With the development of progress, the market for building materials has increased and the range has become so rich that it can be difficult to make a choice on your own. When choosing the type of log house for a bathhouse, many questions always arise: Which log house is better for a bathhouse? What to build a bathhouse from? How to save on this or that type of material? Which is more environmentally friendly and better suited for the construction of a log house. Users of numerous forums argue about which log house is better for a bathhouse. We tried to analyze this information and combine it in one article.

Log house made from chamber-dried rounded logs according to an individual project

Types of log houses for a bathhouse

A log house for a Russian bathhouse is usually made from chopped timber, laminated veneer lumber or profiled rounded logs. There are options to install a bathhouse made of bricks or blocks, but this one needs to be additionally insulated. The log house of the bathhouse is placed on a ready-made foundation. It is better if the foundation was allowed to settle for up to 1 year.

You need to choose what to build a log bathhouse from based on quality characteristics, the pros and cons of the material and your own wallet. More details about the disadvantages and advantages of various baths can be seen in the table:

| Qualitative characteristics | Type of material for a log bathhouse | |||

| Beam (profiled, edged, glued) | Chopped log | Brick | Blocks | |

| Environmental friendliness | Eco-friendly material, except glued | Eco-friendly | Eco-friendly, except decorative with various additives | Eco-friendly |

| Speed of installation | Quick assembly | Heavy logs cannot be installed alone; additional equipment is required. Labor-intensive cutting of corner joints and selection of logs by size, which complicates assembly | Quick assembly | Quick assembly |

| Additional insulation | Profiled and glued beams are not necessary; edged beams need to be additionally insulated and caulked | Caulking and insulation. | Complete wall insulation. | Additional insulation is required |

| Finishing | Glued and planed profiled ones are not needed, edged and unplaned ones are needed inside and out. | .To give an aesthetic appearance, finishing is needed, but you can do without it. | There is no need to finish the façade, but you will have to do it inside | Interior and exterior finishing required |

| Type of foundation | Lightweight | Lightweight foundation (column, strip) | A strip foundation requires a lot of time and money. | Same as brick |

If we compare all the pros and cons, then a bathhouse made of rounded or profiled timber is the most profitable. They do not need additional finishing and insulation is easy to perform. Glued laminated timber is not entirely environmentally friendly and can crack from high temperatures. Bricks and blocks are easy to install, but they need to be additionally insulated and finished.

When choosing a log house for a bathhouse, you should pay attention to the degree of drying of the material. Log houses made of laminated veneer lumber and chamber-dried timber will shrink less, and the structure can be used immediately after its assembly. In any case, it is better to give preference to natural wood of larch, linden or aspen. Having chosen round timber or timber, there will be problems with joining the material in the corners and T-shaped ones.

What is the best material to build a wooden bathhouse from?

(22.08.14) Stanislav

Hello. I just can’t choose the best log house for a bathhouse. Please advise me where to stop?

Steam room made of logs

Since ancient times, bathhouses have been made from tree trunks. When choosing the material, we paid attention, first of all, to the ease of wood processing and its durability. There are still ongoing debates about what kind of wood is best to use to build a bathhouse. There are different breeds that can be used with varying degrees of success, let’s try to look at their characteristics.

Pine log houses are quite popular due to their remarkable properties. Pine is a fairly soft and light material, easy to process. Building a bathhouse from it is a pleasure that does not require serious skills. Pine wood is little susceptible to deformation; logs in a log house are not “built” and practically do not crack. In addition, this material is one of the cheapest.

Spruce is also easy to process. Unlike pine, which darkens over time, it retains an eye-pleasing white-golden color for a long period. Spruce logs are quite cheap, but, similar to pine, spruce has an unpleasant feature - resin in the wood structure. In addition, the resin from a spruce log is released more intensely, which requires mandatory internal lining.

Coniferous wood

Larch is another conifer that has strong and durable wood. When dry, its logs harden, approaching the strength of oak wood. A bathhouse made of larch can last much longer than structures made of spruce and pine, since it is less susceptible to fungus and moisture. This is due to the presence of a natural antiseptic in the resin of this wood. This bath has a general strengthening and healing effect, and also helps in preventing diseases of the cardiovascular system.

A cedar steam room is a luxury that not everyone can afford. Today, the harvesting of Siberian pine is seriously limited; this wood is mainly exported. Cedar has unique properties: thanks to its fibrous structure, logs do not shrink, practically do not bend or crack. In addition, cedar is a source of essential oils, the evaporations of which make the cedar bathhouse a real healing place.

Hardwood

Oak log houses for baths are practically not used today due to their high cost. Oak wood is the hardest and most durable of all types of trees growing in our country.

Linden is a material for true connoisseurs and connoisseurs of a real Russian bath. It creates a unique microclimate in the bathhouse. Its light aromatic wood can give the steam room an excellent healing effect. Thanks to the linden bath, immunity is increased, colds and liver diseases are treated.

Advice from the master!

According to its characteristics, aspen can be compared to linden. It is light in weight and easily processed, and grows in large quantities throughout the country, which makes it low in cost. Dried aspen logs do not warp, warp or crack. In addition, an aspen log house can withstand moisture better than linden, requiring much less repair.

poparimsya.com>

Cutting joints

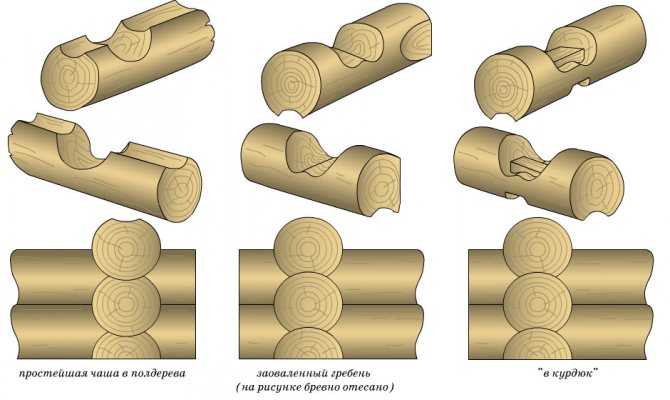

You can lay logs in corner joints in a bowl or in a paw. The bowl can be connected with or without a cut.

Connecting logs into a bowl

The connection into a bowl can be seen in the construction of old baths. A semicircle is cut out of the log and placed on the bottom one. The joints are insulated with jute or moss. The connection into the bowl is also called “in the oblo”. The design withstands low temperatures and strong winds well. But such cutting reduces the area, so ¼ is subtracted from a log 2 m long. Excessive consumption of material when connecting into a bowl 0.5 m from each link. This is one of the most common methods of joining sauna logs. The structure assembled in this way is durable.

Connection into a bowl with a socket

This is also a connection into a bowl, but complicated by cutting out the locking connection. A thorn is cut out in the upper part of the oblo, and a groove in the lower part. The bowl fits even tighter. The only negative is that it is difficult to make such a bowl with your own hands. The work progress is as follows: a straight line is drawn to the depth of the bowl in the middle of the end, the width is measured from it and a semi-oval is cut out. You can simplify the work by making a stencil and working on it. Professionals perform this work with a special device - a cup cutter.

In any of the methods, it can be placed in the bowl from above or below. The bowl downwards is less susceptible to moisture ingress and cracking.

An example of cutting into a bowl with your own hands can be seen in the video:

Chopping in the paw

This is the most complex method of connecting a log. In this case, part of the end is cut down, so the corners become less resistant to freezing. But they can be additionally insulated, but the working length of the logs is not lost. The cutting into the paw is divided into a simple connection into a tenon and a complex connection into a root tenon.

Such a connection is cut out according to a pre-prepared template, since any defects will lead to a loose connection and the corners will be strongly blown out. It will be difficult to install insulation in these places, and sealed ecowool and urethane foam are not cheap. You can see the connection in more detail in the photo.

The prepared stencil is applied to the end of the beam or log and future cutting is marked with notches.

It’s easier to order cutting of bowls from specialists, the price for work starts from 350 rubles. for the connection.

Choosing a foundation for a log bath

You can build bathhouses in dacha and suburban areas from any materials, but traditionally preference is given to wood: rounded logs, timber, etc. Saunas made from logs are most common due to, first of all, their environmental friendliness, excellent thermal conductivity qualities, and the unique aroma coming from the heated walls, which not only allow you to relax, but also improve your health.

Alternatively, if the plot is small, the log house can be attached to the house, but most often a separate building is erected. Before starting construction, it is necessary to make a project and decide how the bathhouse frame will be installed on the foundation, decide on the location for construction, examine the soil, etc.

Log bathhouse.

How to properly build a foundation for a log bathhouse

Photo of a bathhouse on a slope by the river.

There are no special requirements or restrictions for placing a bathhouse on the site, but a natural slope to the south, or, in extreme cases, to the west or east, would be preferable. A site near a river would be ideal: in this case, there is a slope, a natural reservoir is within easy reach, and there is no need to build a swimming pool.

But if there is no natural reservoir, the question of building a pool may arise - in this case, a study of the level of groundwater will definitely be required, since if they turn out to be surface water, this idea will have to be abandoned.

What factors does the choice of foundation depend on?

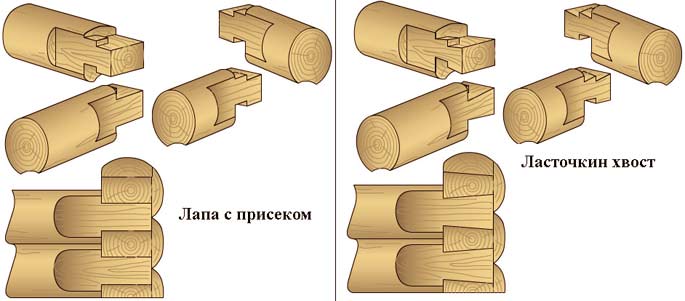

Map of average soil freezing depths.

How to build a foundation for a log bathhouse depends on many reasons.

In addition to the economic component, you should pay attention to the following points:

- type of soil and degree of its homogeneity;

- freezing depth;

- groundwater level;

- the nature of soil swelling and its strength.

All this research can be done independently or you can turn to professionals. It is especially important to contact specialists to determine the level of groundwater, since this indicator can subsequently have a significant impact on the strength and reliability of not only the foundation, especially the strip type, but also the entire structure as a whole.

The freezing index is also related to the level of groundwater and the type of soil; data on this is contained in special reference books, but the following factors must be taken into account:

- denser soil freezes deeper;

- soil moisture also affects the speed and depth of freezing;

- average depth of snow cover - the higher it is, the less soil freezing.

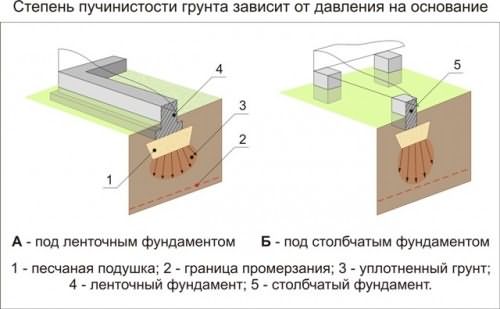

Although there is a rule according to which a strip-type foundation is installed on average 10-20 cm below the freezing level, in some cases, especially when the groundwater level is high, it is possible to make a shallow foundation that will fully withstand the log house of a bathhouse.

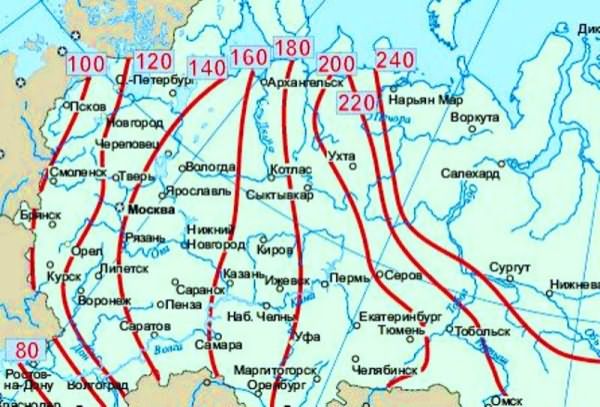

This will avoid the negative impact of the natural process of soil swelling, the strength of which is also directly related to its type, humidity and groundwater level.

How to choose the right type of foundation

Heaving soil.

Once the site for construction has been determined, you can start making a design for a bathhouse from rounded logs and choose the most optimal and correct method for constructing its foundation.

As a rule, the frame of a bathhouse on the foundation of a bathhouse should be placed, first of all, taking into account the type of soil - for any of them there is the most optimal option, which allows you to achieve the strength of the base itself and the reliability of the entire structure as a whole, which, naturally, affects the service life of the structure .

So:

- strip foundation, prefabricated or monolithic, suitable for marshy, clay and loamy soils;

- for construction on heaving soils and in cases where the structure is located on a steep slope, on rocks, the best option is a pile-screw structure. It should also be given preference when building on sand or peat bogs;

- columnar foundation methods should be used on soils consisting of fine gravel, sand, and clay;

- A slab foundation, which is of the floating type, can be installed on sandy soils, peat bogs, or used for wetlands; it can provide reliability to a structure that is being built on so-called soft soils.

Comparative characteristics of foundations of different types

Heaving of soil under different foundations.

Despite the fact that the most common method of constructing a foundation is the strip method, in the construction of wooden structures (baths) it most often gives way to the columnar method.

Recently, builders have turned their attention to the pile-screw option, which allows construction to be carried out year-round; it is also indispensable on very difficult and problematic soils.

The popularity of a columnar base is often determined by the fact that its price is one of the lowest and allows significant savings on construction costs. It should be noted that both the columnar and pile-screw methods are less labor-intensive, for example, in comparison with the strip method, and also benefit from the time criterion.

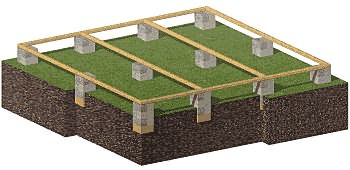

Features of a columnar foundation

Columnar foundation.

A columnar foundation consists of pillars slightly buried in the soil below the fertile layer, which are located:

- at the corners of the building;

- at the intersection of internal walls and partitions;

- on long straight sections, a spacing between posts of 1 to 2.5 meters is used.

To construct this type of bathhouse base, the following types of materials can be used:

- concrete;

- stone or brick;

- wooden poles treated with antiseptics against rotting;

- asbestos pipes that are filled with concrete, etc.

Not applicable when constructing buildings:

- on the slopes;

- on soils with low bearing capacity and “floating”, or with a high probability of possible movement..

Advice. Columnar foundations are justified on heaving soils or in regions with a large depth of soil freezing; they are used mainly for light buildings, including those made of logs or timber.

Features of the strip foundation device

Strip foundation.

The strip base is arranged:

- for buildings with a large total mass for uniform distribution of pressure on the ground;

- its installation is also possible for wooden houses.

Despite the fact that this type is one of the most expensive, you cannot do without it in the following cases:

- on unstable soils;

- if there is a need for a basement.

If you use a strip foundation for a log bathhouse, then its construction is possible in several ways:

- monolithic;

- prefabricated;

- shallow;

- buried slightly below the soil freezing level, although this method for a bath is used most rarely due to the very large, but not always justified, financial costs.

Features of the slab foundation

Slab foundation.

This type of foundation is a monolithic slab under the entire structure, characterized by high load-bearing capacity and versatility for use on most types of soil, including problematic ones.

The slab plays the role of a kind of stabilizer of the building, providing it with the necessary rigidity and protection from subsidence. It is indispensable at high groundwater levels.

Slab foundations are mainly used in cases where other types of construction are not acceptable in a particular situation, mainly due to the fact that:

- large material costs are required for its construction;

- the complexity of the process itself;

- large amount of work;

- time factor - instructions for the construction of monolithic structures require compliance with deadlines in the technology for performing all stages.

Methods for assembling logs into a log house

You need to connect the logs using one method, either in a paw or in a lock. You should not take logs that are shorter than the wall of the bathhouse. Each joint is an additional loss of heat, and this is unacceptable in a bathhouse.

The logs are assembled using metal brackets, wooden dowels or using rectangular wedges. Rectangular wedges are the most labor-intensive method, but one of the best in terms of strength. To do this, wooden blocks measuring 10–15 cm in length, 5–7 cm in width, and 3–5 cm in thickness are made. Grooves are cut into the log on both sides to suit the size. The block is driven into the lower log with a hammer, and the upper one is put on it.

We have already talked about how to connect logs using dowels (). Iron elements for joining wooden parts are not recommended. When drying, the logs may crack and the glands will be visible, and this is unsightly.

When assembling a log house, window and door openings are cut out in half. It is worth leaving a couple of connecting links; they will hold the geometry of the log house for the bathhouse during shrinkage.

Chamber drying

Chamber-dried profiled timber is one of the options for building a log bathhouse. It is impossible to dry a chopped log for the construction of a log house for a bathhouse or a house, since the solid wood cracks severely, but timber and rounded logs can be dried to the following indicators:

- 12% outer layers

- 16-18% - internal part

But all kiln-dried lumber is expensive. Thus, the price for 1 m3 of rounded pine log of natural humidity with a diameter of 240 mm is 9,500 rubles, and a cube of rounded chamber-dried pine log of the same diameter costs 22,500 rubles. At the same time, to implement the project of a one-story 6x6 bathhouse, 30-50 m3 of logs will be required.

Advantages of chamber drying

- Dimensional stabilization

- Minimizes torsion and buckling

- Reduced cracking

Disadvantages of chamber drying

Research has shown that drying wood at high temperatures changes the physical and mechanical properties of wood. And before you build a log bathhouse in Moscow or another region, study the negative aspects. The exact figure depends on the drying technology and the type of wood. On average, this is:

- Compression along the fibers is reduced by 1-10%

- Radical chipping is reduced by 1-12%

- Impact strength – reduced by 5-11%

What kind of lumber can be dried in a kiln?

When thinking about which log house to choose for a bathhouse or home, keep in mind that it is unrealistic to dry a timber with a cross-section larger than 150x200, because wet wood will remain inside.

This is due to the fact that wood has low thermal conductivity, so in the chamber the internal layers are heated only to 50 °C, while the temperature sufficient to evaporate moisture is 100 °C or more. Such indicators are observed on external surfaces.

If we talk about rounded logs, then only pine with a diameter of 240 to 400 mm is subjected to forced drying.

Humidity of kiln-dried logs

Humidity 8-12% is found only in advertising; in practice it is higher. When installing a house and a bathhouse, the dry timber begins to absorb water until the outer layers reach equilibrium moisture. In different climates this figure ranges from 11 to 19%. The hygroscopicity limit is about 30% of the initial moisture content of the log from which the frame was built.

How to insulate a log house?

The log house of the bathhouse was traditionally insulated with moss. This method is still used today. But there are materials that hold back heat better: jute, tow. They are not deformed and are sold in a convenient form - in the form of a tape. It is easier to lay them down during assembly. Tape insulation is laid between timber or logs and secured with a stapler.

If you do this at the stage of assembling the bathhouse, then you don’t have to caulk it in the future. When shrinking, tow and moss may not fill all the cracks and additional caulking work is required. Caulking is carried out along the entire perimeter of the log house, both outside and inside. For this they use a hammer and a special tool - caulk, jute or tow, pre-twisted into a rope or ready-made. It is unacceptable to caulk the walls one at a time, as this could warp the bathhouse.

Choosing the right log house is only half of the solution; it is important to assemble and install the bathhouse in accordance with all standards and recommendations. It’s not difficult to build a wooden frame with your own hands, the main thing is to do it correctly and with love. If you don’t have enough patience, and you don’t have the experience and ability to use the tool, then it’s better to save your nerves and entrust the work to professionals.

Nuances of log processing

Initially, the log bathhouse must be kept under the roof so that the material used in construction (logs or timber) is dried as much as possible in at least 8 months. It is important to note that these months should be as dry as possible. Usually, bathhouses are installed from a log house in December, so that they have time to dry out before August. If it is possible to wait a longer period, then drying can last 1.5-2 years.

We invite you to familiarize yourself with the DIY bathhouse from scrap materials

While the log house is drying, it is necessary to carry out a number of other works. Having installed the logs, it is necessary to treat them using special antiseptics, which are based on solvents. They are necessary to prevent fungi or mold from forming on the surface of the logs. To prevent the wood from tearing when drying, it must be treated with a different composition, for example, “Teknol JRM” is suitable.

Glued laminated timber

It is believed that laminated timber does not shrink, but in practice the shrinkage rate is 1-2%. Cracks in such houses and bathhouses also occur. In addition, there is laminated veneer lumber, made using glue of different qualities, which affects the environmental friendliness of the product.

The different quality of wood used to make lamellas and the degree of toxicity of the glue do not affect the humidity of wooden houses and bathhouses. All other things being equal, the quality of a bathhouse or a house made of laminated veneer lumber is influenced by the price of the wall kit and the cost of assembly work.