Log frame from carriage: advantages and disadvantages, main characteristics

In the photo below is a log carriage from Norway. The main feature of such a log house is the fixation of parts together, which has a name - a Norwegian castle. From the outside, the building looks like a traditional frame. But inside there is a strong and original cut. This type of fastening serves many purposes. Many specially fixed corners increase the strength of the building. A significant area of contact between two parts increases the friction force in the pair. This technique promotes proper load distribution within the ligament. This way, there are no areas of excess stress.

Let's note the advantages of this material:

There are also certain disadvantages to the material:

- complex, expensive and labor-intensive construction process;

- construction must be planned several years in advance in order to prepare the material for it;

- every 2-3 years it needs to be treated with antiseptics, and after 3-6 years it needs to be caulked.

In the table below you can see how much a carriage costs. The price per cube depends on the manufacturer and the characteristics of the material.

| Photo | Type and characteristics | price, rub. per cubic meter |

| Carriage diameter 200 mm, groove width – 140. | 15000 | |

| From northern pine. Wall thickness – 190, beam height – 240. | 13000 | |

| Carriage of natural humidity. Wall thickness – 140, log height – 140 | 10500 |

For your information!

Even a carriage structure is susceptible to many problems of any wood. For example, the processes of decay, moisture and insect invasion.

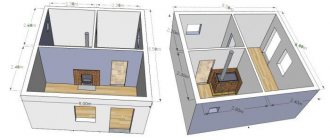

Choosing a construction project from a gun carriage

There is a wide variety of gun carriage projects. One-story buildings are relevant. They are used for permanent residence and as buildings for. They are performed in different styles. The area can vary from 75 to 80 sq.m.

There are classic options with square structures, as well as projects with hipped roofs. Durable buildings are made of cedar. Projects can be made in country, country, modern or chalet.

Exist . Such designs make the building more expensive.

Reliable designs of two-story projects. Moreover, buildings can be made in Russian style, and not just in Norwegian or country style. An excellent option is. Such a building will not require a complex foundation.

For your information!

Such buildings do not need insulation, since the thickness of the walls is 20-25 cm and retains heat remarkably well.

Houses made from gun carriages: original designs and features of buildings

Projects of houses made from gun carriages are distinguished by a thoughtful and laconic design. At the same time, the facade part remains in its natural form and does not require additional cladding. You can add an unusual color to wood material using impregnations. This solution is a mixture of color and antiseptic. Oval-hewn logs represent a unique decorative element. Hand-made patterns look great on the gun carriage.

You can do it yourself. At the same time, it is worth thinking through everything to the smallest detail. Perfectly suited for such an environment. It will perfectly complement wood walls. The internal surfaces of the walls also need not be finished.

The table below shows some projects of houses made from gun carriages and prices:

| Image | Home and company | Description | price, rub. |

| House 99 sq m (Northern house) | Pine carriage. The project includes a living room, two bedrooms, a terrace, a boiler room, a hall and a bathroom. | 1180000 | |

| Pine bathhouse 100 sq.m. m. (Northern House) | The project consists of a living room, shower room, steam room, hallway and terrace. | 1150000 | |

| Building 280 sq.m. (Northern house) | There are several bedrooms, a living room, a wardrobe, a kitchen, a terrace, a bathroom and a hall. | 3900000 | |

| Log house 8*8 (log house) | Has a six-wall configuration | 1454000 | |

| House Adonia (Iva) 368 sq. m. | The building has two floors. | 5420000 |

Let's also look at reviews from owners of houses made from gun carriages.

Elena, 36 years old.

Penza: “We have a house made of gun carriages, so far we’ve been using it for a year. After the heating began, small cracks appeared, but this happens in any wooden structure. But since our family only likes wooden buildings, this drawback does not bother us. But the climate: aroma, humidity and air cannot be compared with anything else.”

Evgeniya, 43 years old, Yaroslavl:

“We are very pleased with the carriage structure. There are cracks, but this creates a special charm, since the building is alive and breathing. We have long dreamed of a log house and now we are enjoying it. There is an opinion that such a house does not breathe, but gradually collapses, but this process drags on for many years.”

Maria, 30 years old, Tambov:

“A house made of gun carriages is very practical. My parents’ kitchen at the dacha was made of timber, so it’s already 40 years old and holds up well. So in those years there weren’t even the impregnations that we have now. About three years ago, an outbuilding was built from a gun carriage. For now we are just happy.”

For your information!

If you treat the carriage correctly, small cracks will complement the decorative look and will not cause any harm.

How to make a bathhouse from a gun carriage

It is popular from a carriage with an attic. A structure made using this technology not only has a unique appearance, but can also be stored for decades. Projects of such buildings are developed taking into account the characteristics of this material. The carriage will provide an ideal indoor microclimate and natural humidity.

In addition, such buildings are durable and have heat-saving properties.

Examples of construction from gun carriages: our work

A tenon and an opening for the tenon are cut out in the bowl to prevent direct air access. Over time, due to the shrinkage of the house, the system of wedges and internal tenons jams, so the lock received another name - self-jamming. It is also very important that logs of natural moisture connected using this technology, from which the carriage is most often made, do not twist due to internal stress when the house shrinks.

Speaking about fire monitor technology, it is necessary to note the particularly strong and reliable rafter system, which allows the use of any roofing material. The Norwegian rafter system traditionally consists of completely chopped gables - both external and all internal rooms of the second floor.

Any house built from material with natural moisture shrinks, so before starting full heating, it must stand for six months to a year so that the moisture gradually evaporates. If you start heating the house too much immediately after construction, cracks will appear. The technology is becoming increasingly popular in our country.

Builders call the carriage a gable beam; it is made mostly using a semi-mechanized method, which increases the cost and reduces the quality of the materials. Step 1.

At the sawmill, saw off two side parts of the round logs so that the width of the remaining part is 24 cm. Use an electric plane to remove the bark and level the surfaces. This is quite difficult work; the master must constantly hold a heavy tool in his hands. The quality of surfaces directly depends on the professionalism of the performer, but even the most experienced carpenter will not be able to make the surfaces absolutely identical. A plane is used to remove all the bark and sapwood from the log.

Step 2. Soak the carriages with combined solutions. They must protect lumber from rot and fire at the same time. This is a very important operation, dry houses quickly ignite.

Using a sprayer, apply a protective composition to the wood. Step 3. Under the first crown, cut down one semicircular side of the carriage, this row will be the base, it should lie stably on the foundation. The carriage for the lower crown should be flat at the bottom.

Step 4. Start chopping the remaining crowns. We will describe in detail how locks are made in this article a little lower. Please note that all joints are wedge-shaped; as the house shrinks, the tightness of the fit increases, the crowns go deeper into the locks.

Due to this, heat losses at the joints are reduced and the stability of the structure is increased. Step 5.

What is a carriage

To reduce the likelihood of cracks, treat the ends of the frame with acrylic sealant. The fact is that it is through the ends that moisture quickly escapes, and this process causes the appearance of a large number of deep cracks.

This is a violation of the wood drying process.

If you are building a house from dry lumber, then there is no point in sealing the ends. Dowels are installed only when the house has two or more floors. Single-story ones are firmly held by original locks; they resist wind and snow loads without any problems, and are not afraid of static and dynamic multidirectional forces.

Practical advice. From small sections you can build various small architectural forms: tables and benches, swings, benches, etc. Do not throw them away, do not use them for firewood. Leftover wood can be used for decoration and creating furniture.

If you order a house from a construction organization, they do not immediately erect the building on site.

Home carriage. We are constructing a log frame from a carriage for a spacious residential building.

All work is done in the industrial zone of the enterprise, this is how the quality of the assembly is checked. Everything is normal - every detail is numbered and the house is disassembled. Ready-made parts are assembled for the customer at the site. The carriage is a log that is half hewn.

In addition, the lower part of the log is adjusted closely to the dimensions of the adjacent carriage. In ancient times in Scandinavian countries, this technology was used in the construction of fortresses, which indicates its reliability. The photo shows the construction of a bathhouse from a gun carriage.

In addition, such baths have all the advantages of wooden houses, among which are: Of course, there are no advantages without disadvantages; therefore, fire monitors also have some flaws: In general, the construction of a bathhouse from this material is not much different from the construction of log houses from timber or round timber. The same foundation is used, the roof is also installed, etc. Basically, the differences lie only in the construction of the walls.

When constructing standard log cabins, the connection is made into a cup. Its obvious disadvantage is the need to wait for the building to shrink, which may take a year or even more.

At the same time, the more dried the logs are, the better, since they will shrink faster and smaller. Cedar wood is strong, but malleable enough to process. Cedar resin contains natural antiseptics that protect wood from biological pests. House made of larch carriage. Durable wood, maximally protected from moisture thanks to the resin that impregnates it. The advantages of larch wood include its hardness, resistance to temperature changes, high thermal insulation qualities and excellent antiseptic properties that suppress the proliferation of pests and putrefactive mold.

Any wood must meet quality requirements. For construction, logs are selected that are free from cracks at the ends, traces of blue stains, bark beetles, mold and mechanical damage. Houses built from natural moisture carriages undergo a long process of drying and shrinking. Dry carriage is the optimal material and has important advantages:. The process of natural shrinkage in a building made from a dry carriage is 3 times faster than that of a material with natural moisture.

Wood protection. The optimal temperature regime in the drying chamber destroys mold and pests. Wood quality.

Surface cracking is not as severe as with green logs. When choosing house designs from gun carriages for construction, construction prices will vary over a fairly wide range. In fact, there are many ways to connect logs, from which the most suitable one is selected.

If you want to create, for example, a Scandinavian-style house, you should opt for cutting into a Norwegian bowl, which has its own advantages: The structure is durable and warm. The connection is sealed during operation, the joints are sealed, and heat loss is minimized.

Construction is becoming cheaper. The Norwegian lock reliably fixes the monitor logs from displacement and deformation, which makes it possible to use cheaper material with natural moisture. The construction of a country house from a gun carriage has its own specific features: Making a log house. At the first stage, all structural elements are prepared. The dimensions are checked and each log is marked.

Sometimes a trial assembly is carried out: the logs are placed in a log house, then dismantled and transported to the site. Production time. The cutting time is affected by the size of the project.

It will take approximately 1.5 months to cut a house with an area of 1 m2; fewer crowns are designed per floor than for construction from timber or rounded logs.

The foundation for a fire monitor house is selected and prepared as for any wooden building. The final assembly of the log house on the prepared foundation takes approximately 2 weeks. The combination of modern construction techniques, the imagination of the architect and the financial capabilities of the customer makes it possible to realize a country house from a gun carriage of any complexity.

By ordering a house from a gun carriage, the price of which depends on the choice of project and wall materials, the future owner can maintain the Scandinavian style, taking care not only of the traditional Norwegian layout, but also of the interior elements. A stove or fireplace, simple wooden furniture, fluffy carpets and textiles with a checkered pattern will look good in the house.

The construction of projects from a turnkey carriage allows you to get a house completely ready for living, with utilities installed and excellent heat saving indicators. The construction company will undertake the entire range of finishing works, including installation of stairs, installation of window and door casings, sandblasting and painting of walls.

The cost of a country cottage built using the carriage technology is unique, just like the house itself. Average prices in the Moscow region can serve as guidelines:.

Pine carriage thickness mm.

Features of Norwegian technology

Now let's look at the technology of Norwegian carriage cutting. Its peculiarity is the creation of a Norwegian bowl, that is, a special connection method in which water does not penetrate into the structure. In this case, the gables are chopped, and the roof has a slab structure. All parts are adjusted with great precision. It is worth considering that log structures also require caulking of gaps and cracks.

The Norwegian cedar carriage has a special locking joint, which becomes more dense over time and does not cause twisting of the logs. Cracks that appear are not a problem, since they do not become through. This connection is one of the most durable, reliable and warm. During the shrinkage process, such a locking device self-jams. In addition, a special hidden tenon can be used, which guarantees the rigidity of the log house and also increases the thermal insulation qualities of the structure.

Construction of a log house using the “paw” method

Cuttings “into the paw”.

The use of this method is one of the oldest methods of building log houses from real wood, in which the trunks at the corners of the building are cut into a “paw”. A tenon is made at the bottom inside the corner, then a groove is made on the next crown, also in the form of a tenon. The weight of the block presses the “Paw”, and over time, during the shrinkage of the log structure of the building, the structure does not dry out and becomes compacted. The process of mounting the walls of a house made of wood using the “paw” method has the following feature: the log trunks do not stand out from the corners of the building.

This cutting method is also called “no residue”. At the beginning of the cutting process, the ends of the trunks to a length of one and a half meters from their diameter are cut into four edges, thus making them look like square bars. Then the ends and sides of the logs are carefully marked. Using a special diagram, all edges of the “paw” are drawn.

After this, the excess wood is carefully and carefully cut off, resulting in a “paw”. If the “paw” is made correctly, the corners of the log house become self-clamping. To create an additional margin of safety, the connection of the beams of the building can be made with the addition of a root tenon - a protrusion on the inside of the beam, which is located close to the corner. The best solution would be to make the tenon oblique. In this case, it will not allow the beams to gradually move to the outside of the log structure.

Return to contents

How to make a carriage with your own hands

The construction of houses from gun carriages is often made from northern pine. Moreover, its diameter can be 29-37 cm, and after processing - 22-23 cm. The carriage is made using special equipment. The supporting part of the carriage is made after applying the markings.

Here are the main stages of work:

- The markings should only be done by a specialist. Then the lock is cut out;

- The longitudinal groove is marked. In this case, a line is drawn with an adze;

- The edges are polished, which helps create smooth surfaces;

- they also cut corners from a gun carriage;

- All parts are treated with an antiseptic to prevent rotting and mold formation.

After preparing the material, the building is erected. In this case, a foundation is made, under which a layer of waterproofing must be laid. When assembling a structure, the parts are precisely adjusted to each other. For window and door openings, a groove 50 mm wide is selected. Large beams are selected for ceiling installation.

Before finishing, you need to choose a style. You can treat surfaces with translucent protective compounds. Special tinting is often used.

With the right approach, the carriage will turn out to be one of the most reliable building structures. This option is recommended for areas with cold climates. The unique technology makes it possible to create durable buildings that will last for tens and even hundreds of years.

Article

For the construction of residential buildings, various attention is used. It is especially popular because it has unique performance characteristics. The shape of the trunk of trees used in construction can be different. Recently, a large number of houses built from gun carriages have appeared. At the same time, not everyone understands exactly what a gun carriage is. Knowing what advantages this type of material has and how individual elements are laid, you can build a reliable house that can last for many years.

To begin with, it’s worth deciding what a carriage is in construction. From this point of view, a carriage is understood as logs hewn on both sides. The shaping of a special interlocking connection allows the construction of a structure with high thermal insulation and strength characteristics. These were actively used in the construction of various objects, but special locking fasteners were proposed relatively recently by Norwegian builders.

The use of this material in construction with a relatively small wall thickness (only 20-24 cm) allows you to avoid using. It is mounted in a horizontal plane and is often used as floor joists.

Attention!

In Russia, the carriage sometimes has a second name: double-edged or gable beam.

For woodworking, what a carriage is has a different meaning. For its production, logs with a diameter exceeding 40 cm are used. They should be in the range of 12-15%.

Features of the construction of houses and baths from gun carriages

Northern pine is used for gun carriage construction. The choice is due to its low cost and acceptable construction properties. Pre-processing consists of the following steps:

- manufacturing a carriage using equipment;

- sharpening logs with an electric planer;

- markings, which directly affect the quality of construction; therefore, markings are the prerogative of experienced carpenters;

- lock cutout (Norwegian bowl). This is careful and hard work that requires certain experience and skills. Using a line, a longitudinal groove is made, which is selected using a chainsaw and an ax;

- grinding the edges for a tighter and smoother connection;

- antiseptic treatment of the entire surface of the log with specialized compounds in order to prevent rotting and mold.

A hut from a gun carriage... in your own apartment!

After the preparatory work and delivery of the material to the construction site, installation of the carriage begins, which includes the following work:

- pouring the foundation, which is covered with waterproofing to prevent damage to the lower logs;

- assembly of the carriage into a log house. This stage is the most labor-intensive and time-consuming, since it is very important to ensure that the connection of the elements is accurate and durable; – to install doors and windows, cut a 50 mm groove in the openings and insert a guide beam into it. This mechanism for fastening windows and doors ensures their safety when the carriage shrinks. During the final shrinkage of the log house, the window frames will be pressed as tightly as possible against the logs;

- the ceiling is often left open to create an original and interesting interior;

- The finishing of a log house built using Norwegian technology can be absolutely any at the discretion of future residents, but often the walls are covered with a protective compound to preserve the natural beauty.

If desired, the wood can be painted or varnished.

Choosing a log house from a gun carriage

For those who decide to use a carriage for construction, photos of log houses will help them choose the appropriate option. Most often we are talking about.

For a large family this area will not be enough. In this case, either build or give preference.

The carriage has a number of advantages, thanks to which the choice is made in favor of this material. The main advantages include:

- Safety. Natural raw materials are used to produce the material;

- Ease of processing, allowing you to give the required shape;

- Attractive formed surface. The internal wall is externally indistinguishable from the surface formed from calibrated. If desired, you can refuse subsequent cladding;

- Possibility of assembling any structure without the use of metal fasteners. To increase the operational load, the ligament is strengthened during settlement using special fasteners;

- Low thermal conductivity. Wood with a thickness of 240 mm is comparable in thermal conductivity to a wall with a thickness of 380 mm;

- Uniform wall thickness;

- Saving internal space due to the hewn part of the logs;

- High quality of the material used due to increased requirements for raw materials and subsequent multi-stage processing;

- No deformation during subsequent operation of the erected buildings. A special manufacturing technology, which involves the use of a special “Norwegian lock,” allows for reliable fixation of each log in the nest;

- Long service life of the erected structure, ensured by its design features.

The disadvantages of this building material include:

- Complexity, labor intensity and cost of construction work;

- A long preparatory stage that can last for several years;

- The need for periodic treatment of walls with antiseptics, which experts recommend every 2 to 3 years. Also after 3-6 years caulking should be done.

For most, during the construction process, costs become the main criterion for choosing the appropriate option. For those who decide to choose a carriage, the price per cube will allow you to approximately estimate the cost of the material for the construction of the structure. The price depends on the transverse dimensions and configuration of the carriage:

The cost of the material also depends on the type of wood that was used to make the carriage. With the same log sizes, you will have to pay the most for larch, and less for pine. Cedar occupies an intermediate position.

Choosing a project for your site

Another advantage of choosing a standard design is the fact that a similar structure already exists somewhere. Having learned in advance the reviews of the owners of the house from the gun carriage, we can conclude that it is advisable to erect a similar object on their own.

Attention!

One of the varieties is half-laft houses, in which only one side is hewn, intended to form an internal wall. Such houses are similar in appearance to ordinary log houses.

Options for a bathhouse from a gun carriage

The carriage is used in the construction of buildings for various purposes. From this material you can build not only a residential building, but also. Taking into account the characteristics of the material used and the special manufacturing technology, it is possible to ensure a long life of the constructed structure.

Bathhouse sizes may vary. It is not necessary to erect a large one-story building. The design of a bathhouse made from a gun carriage with an attic looks beautiful. In this case, the area that the building will occupy remains unchanged, and the usable attic allows you to equip a recreation room of a fairly large area

From the outside, the Bathhouse may look different. Decorative elements can be provided to add attractiveness to the structure.

Construction Features

In general, the construction of a bathhouse from this material is not much different from the construction of log houses from timber or round timber. The same foundation is used, the roof is also installed, etc. Basically, the differences lie only in the construction of the walls.

Walling

When constructing standard log cabins, the connection is made into a cup. Its obvious disadvantage is the need to wait for the building to shrink, which may take a year or even more. At the same time, the more dried the logs are, the better, since they will shrink faster and smaller.

Drawing of a “Norwegian castle”

When building a bathhouse or other structure using a carriage, logs of natural moisture are used. Since the corner fastening method (“Norwegian castle”) is used when constructing walls, when drying the logs begin to fit even more tightly to each other, we can say that the logs “cling to each other” even more strongly. In this case, the shrinkage is not so significant.

Advice! It is best to use cedar to build a bathhouse, since this wood is not afraid of temperature changes and exposure to chemicals. In addition, cedar has healing properties.

Ventilation

As a rule, in wooden walls, ventilation is carried out due to cracks in the joints of the walls, however, in the structure under consideration, these cracks are absent. Therefore, small openings are made under the roof for air exchange, which are called vents. These openings must be made around the perimeter of the entire building so that they are present in every room.

Note! In the steam room it is necessary to make not only one hole at the top, but also two at the bottom.

Internal corner

Bath heating

There is no fundamental difference in the heating of such a bath. An ordinary wood-burning sauna stove copes with this task perfectly.

When installing it, you must follow two basic rules:

- The stove should be located at a distance of at least 30 cm from the walls;

- The stove must be mounted on a pedestal to prevent the wooden floor from catching fire.

Ready-made baths made from gun carriages

Building a steam room from a carriage with your own hands is much more difficult than a timber frame, since the main difficulty lies in making the locking connection. However, many companies offer ready-made designs.

In this case, the buyer can only assemble the bathhouse, which is accompanied by instructions, like a construction set. All logs are already adjusted at the factory and have locks. In this case, the construction of a bathhouse resembles construction from profiled timber.

As a rule, when purchasing ready-made structures, companies offer a choice of various designs for bathhouses made from gun carriages. Thanks to this, you can choose a building of a suitable size, with the optimal number of rooms.

Note! When installing doors and windows, it is necessary to take into account that the log house in any case goes through the shrinkage stage. Therefore, doors and windows are installed on a special structure. Over time, the structure falls into place and the pressure on the frames decreases.

Features of Norwegian technology for cutting logs and building houses

In order for the erected structure to last long enough, the logs should be properly prepared and laid. The basis of any log house is a log house, consisting of logs stacked horizontally on top of each other, forming a crown. Tree trunks longer than 6 m are used.

Attention!

If the equipment allows, it is possible to process logs 11 m long. This material is suitable for the construction of large buildings.

The Norwegian carriage cutting technology involves the formation of a groove that ensures good joining of the elements used to form the walls. An inter-crown is inserted into the formed groove. Special notches with a wedge-shaped profile at the corners of the logs are used as locks.

Norwegian technology appeared relatively recently. Just about 15 years ago. It assumes that the wood dries out in the log house. The formation of the carriage occurs in several stages:

- The sides of the logs are cut off;

- The bark is removed from the remaining part;

- The elements are given a semi-oval shape.

If the technological requirements are met, the logs are smooth to the touch. This avoids additional processing, and also ensures a tight fit of the elements during the assembly of the structure.

Attention!

To form a log house, wood with natural moisture is used.

The use of Norwegian locks with a special design leads to the fact that as the fire monitor shrinks, the joints self-jam under the influence of gravity. This eliminates any possibility of the carriage turning. How strong the formed connection will be depends on the degree of shrinkage of the structure.

For the construction of houses, high quality timber is used that meets certain regulatory requirements. The logs must have a uniform structure along their entire length. There should be no damage or bark on their surface. In the future, it is almost impossible to get rid of existing damage: traces will remain.

An environmentally friendly antiseptic based on resins and turpentine is applied to all trunks.

Particular attention is paid to the ends and areas where, as a result of processing, the fibrous structure of the wood was damaged: grooves, places of cutting. The logs are sorted by shape and length.

Logs are cut to the required size, followed by marking in accordance with the assembly drawing. When installing a log house, the logs are gelled. Dowels are used as additional fasteners that prevent movement of elements during wood drying and increase the rigidity of the structure being built. As a result, the verticality of the walls of the constructed structure remains unchanged.

Any type of wood can be used to construct buildings. Most often, preference is given to coniferous species: pine or larch. However, the Norwegian cedar carriage demonstrates high operational loads.

Cutting a log house using the “bowl” method

Cutting logs into a bowl.

In total, there are three different methods of cutting “into the bowl”: Canadian, Russian and Norwegian. The essence of the Russian bowl method is that the groove in the higher crown of the log frame exactly repeats the contour of the previous crown. In Canadian and Norwegian bowls, the lower crown is cut into a cone and, accordingly, the bowl that goes higher in the crown also has a cone shape. The Russian bowl is the most aesthetically pleasing because the bars look even. If we take the technological side of the issue, then the Norwegian and Canadian bowls have a more dense connection of logs (especially if the work is carried out entirely manually); in principle, these methods are closer to the “paw-to-foot” log house.

The Russian bowl is the best method during the manufacture of wall sets using rounded beams, where the grooves are selected using a cutter, and the diameter of the log is known in advance and practically does not change. In such conditions, there is no need for additional clamping of the corner by cones and gravity. At the same time, if cutting is carried out manually, then it is better to carry out such work using the Norwegian or Canadian bowl methods. Although with manual work and using these methods, financial costs become higher, and the aesthetics are not so attractive, for the sake of practicality and reliability. The cost of construction made using the “bowl” method is slightly higher than when using the “paw” method. This is because for a log building of the same size, a different number of logs will be required, since the remains that stick out have at least 200-250 mm, adding both corners of the building 400-500 mm.

To be honest, we thought for a very long time whether it was worth posting information about this economy class bathhouse on our website. On the one hand, at first glance it looks somehow sad compared to our other beautiful and stylish houses and baths. But, on the other hand, we receive many letters asking for help in building a high-quality warm bath, but at the same time very economical in cost.

Hand on heart, we have long been practicing the construction of such log houses (lovingly called by our cutters a fence), but they, as a rule, are built by our carpenters for themselves or their friends. These, at first glance, unsightly walls can be covered with clapboard or blockhouse outside and inside (you can, of course, also use siding, but we do not recommend this for wooden walls). It will turn out very well, and, most importantly, you will know that there is real wood inside these walls - all the advantages of log walls will remain with you.

An example of a bathhouse made from scraps of a gun carriage - a warm and high-quality economy version of a bathhouse

So, let’s take a closer look at the approaches to building a log house for such an inexpensive bathhouse:

- the walls are made of a 20 cm thick carriage, all the necessary horizontal webbing between the crowns is preserved, only the overcuts are missing;

- the width of the carriage crowns (i.e. height) is 26-45 cm. By reducing the number of vertical log connections, we get very warm walls; this cannot be compared with timber, especially non-profiled timber;

- the crowns are connected to vertical pillars made of timber (section 20*20 cm) using grooves and tenons, insulation must be laid everywhere;

- to assemble such a bath, you do not need to call a crane - this significantly saves installation costs;

- and now the best part is that the price of such a log house is half that of a log house made from a solid carriage (approximately 5 thousand rubles per square meter of floor area, instead of 10 thousand rubles) - for many this is an important factor.

If this information interests you, let's follow the entire process of assembling such a bathhouse.

The bathhouse was built under the roof and the walls were not finished yet, so the horizontal connection of the crowns through the vertical beam is clearly visible. Please note that along the lower part (lower crown) and along the upper part there is a harness made of solid timber - this ensures the rigidity of the structure.

View of the log house from the other side, you can see the window opening, veranda and space for the front door. Pay attention to the width of the crowns - sometimes they are twice the width of the beam and amount to 45 cm.

Well, now let’s take a closer look at the entire process of installing a log house on the site.

The lower frame is made of timber with a cross-section of 20*20 cm. Grooves are cut into place in the timber for installing vertical beams.

In the photo on the left we see ready-made holes (grooves) into which the tenons of the vertical beam will be installed, and in the photo on the right such a beam is visible. Pay attention to the spikes at its ends and the longitudinal groove into which the spikes of the carriage crowns will be installed.

The photo on the left shows the installed vertical beam, and the photo on the right shows the installation of the crowns. At first, the crowns are held in place with supports. Pay attention to the tenons at the ends of the crowns; they will connect to the longitudinal grooves of the vertical beams. In general, due to the lower and upper trims, the structure will be very strong.

The walls are gradually growing. The photo on the right shows a vertical beam, which in the future will form a window opening; note that the longitudinal groove in it has a gap into the window block. Also pay attention to the insulation stapled to the ends of the wall from the carriage.

For the construction of residential buildings, various attention is used. It is especially popular because it has unique performance characteristics. The shape of the trunk of trees used in construction can be different. Recently, a large number of houses built from gun carriages have appeared. At the same time, not everyone understands exactly what a gun carriage is. Knowing what advantages this type of material has and how individual elements are laid, you can build a reliable house that can last for many years.

To begin with, it’s worth deciding what a carriage is in construction. From this point of view, a carriage is understood as logs hewn on both sides. The shaping of a special interlocking connection allows the construction of a structure with high thermal insulation and strength characteristics. These were actively used in the construction of various objects, but special locking fasteners were proposed relatively recently by Norwegian builders.

The use of this material in construction with a relatively small wall thickness (only 20-24 cm) allows you to avoid using. It is mounted in a horizontal plane and is often used as floor joists.

Attention!

In Russia, the carriage sometimes has a second name: double-edged or gable beam.

For woodworking, what a carriage is has a different meaning. For its production, logs with a diameter exceeding 40 cm are used. They should be in the range of 12-15%.

We make a carriage with our own hands

Ready-made material is expensive. This is why some homeowners decide to make a gun carriage with their own hands. In this case, the work should be performed in the following sequence:

- Log debarking. Bark from tree trunks should be removed in advance. To do this, you can use a homemade scraper or an ordinary ax. Actions must be careful to avoid damage to the surface;

- , during which the slabs should be removed. You can use a regular chainsaw equipped with a 75 cm bar. The latter should be sharpened for a longitudinal cut;

- Work at the sawmill. The equipment model is not of fundamental importance. The main thing is that its characteristics allow it to process logs of a certain size. The sawmill settings should be adapted to the required geometric parameters of the lumber. At this stage, the supporting part of the carriage is formed;

MAYBE

Promising building material

A carriage is a log hewn on both sides, resembling a tetrahedron in shape.

What is a carriage used in the construction of wooden structures can be seen in the photograph. In fact, the material is a cross between a tetrahedral beam and a log. The two opposite sides of the carriage have a flat surface, and a recess is carved into its lower side. For the manufacture of half beams, 6-meter logs with a cross-section of up to 350 mm are used. After turning the side edges, the standard distance between them should be from 200 to 260 mm. The height of the half-beam is 240-300 mm. Carriages of such dimensions are used in the construction of external walls, and half-beams 150 mm thick can be used for the construction of internal partitions.

The most common types of wood used for the construction of fire monitors are pine or larch, but some construction companies offer to build log houses from cedar, citing the fact that cedar pine has better resistance to aggressive environments and temperature changes, and also better insulates noise.

Carriage houses have a number of advantages over brick houses, which have long become the most common type of buildings in the country.

In terms of heat conservation, they are several times superior to stone buildings due to the fact that air accumulates over time between the fibers in the half-beams, which serves as an excellent heat insulator.

In addition, a house made of this material provides natural ventilation, and the owner of a wooden mansion will simply not be aware of such phenomena as wall freezing or moisture condensation.

Return to contents

Inexpensive chopped sauna from a carriage: a selection - from the series cheap and cheerful

As a result, the entire massif was put to work, and no other materials were required for construction, since the internal partitions and rafter structure were also made from gun carriages. Norwegian houses were reliable and warm due to the thickness of the logs and the special design of the corner joints. There were no attics; the roof was flat and covered with turf and grass. This created effective thermal protection, and they also say that goats often grazed on the flat grass roofs.

A traditional Norwegian house today is built only from gun carriages. Large-diameter logs are still used to make gun carriages - from 28 to 50 cm, which is why the houses look solid.

When making a Carriage, the side surfaces of the log are first removed, then the bark is removed from the semicircular surfaces, then all surfaces are carefully planed by hand. The next steps are very important: this is the selection of a groove on one of the semicircular surfaces of the carriage to ensure a tight fit of the logs to each other, as well as the manufacture of a corner bowl.

A house made from a carriage has the appearance of a timber frame with a wall thickness of cm, but it looks more stylish and impressive due to the high height of the crown - the size of the original log. Due to the fact that the carriage is made from large-diameter logs, the wall requires much fewer crowns than when building from timber or logs with a diameter of cm.

This is a very serious advantage: after all, the fewer crowns, the fewer joints of logs, the so-called cold bridges, therefore, the house’s heat saving and durability indicators increase. When building a house from a carriage, special attention is paid to connecting the logs at the corners - these are the weakest points, they are most exposed to air and freeze.

There are various ways to cut corner joints, but in a house made of gun carriages, the so-called Norwegian lock is used, which has its own characteristics.