Wooden beams in skillful hands become a material perfect for building the bathhouse of your dreams. Let's talk about whether it has any advantages over other materials and whether construction of a bathhouse from timber

- the best choice.

It must be said right away that the timber “holds” heat perfectly, since it does not have such a vulnerable element as the inter-crown groove, characteristic of the logs from which the walls are made. The primary task of the bath is maximum heat retention. Of course, you can take such logs that the width of the inter-crown grooves is equal to the wall made of timber, and heat retention will be the same, but this will lead to excessive consumption of wood and increased costs for installing a log house. Logs of increased diameter, located in the lower crowns of the structure, take a long time to dry and are susceptible to rotting. So, whatever one may say, a sauna made of timber is the best option.

Walls made of logs or laminated veneer lumber

Since ancient times, bathhouses have been built specifically from wooden materials, since they have all the characteristics necessary for this room. Wooden structures have great heat-saving capacity and are environmentally friendly, which is extremely necessary in the case of a steam room. But not all lumber presented on the construction market is suitable for creating wooden bathhouse structures. Wooden components must have a certain thickness and density to form the basis of the wall.

In order to determine the exact thickness of the timber for the wall, you can use the technical documentation of SNIP, which states that the thickness in this case should be at least 165 mm. It is this minimum indicator that will provide the room with sufficient energy savings and comfort. If the owner has chosen a two-story bathhouse design, then the wall thickness should increase to 200 mm.

It is also worth saying that when building a bathhouse for year-round use, you should definitely use insulation materials, since despite all the positive characteristics, this thickness of the timber will not be enough.

Wooden bath walls

Insulation of wooden bathhouse structures can be carried out both from the outside and from the inside; this issue is decided by the owner himself. Here it is only worth noting the fact that it is best to insulate wooden buildings with basalt slabs, since they are absolutely non-flammable and provide reliable heat conservation. In addition, the calculation of the insulation layer must be made before creating the foundation, since in this case the foundation will be wider.

Number of floors and dimensions of the building

Among the obvious advantages of wood is the strength of the building material. Therefore, when choosing the thickness of the timber, the following recommendations should be taken into account:

- timber up to 100 mm thick is used in the construction of load-bearing structures of one-story buildings. Such parameters guarantee the required level of strength characteristics;

- for the construction of a two-story bathhouse, material is used whose thickness is 150 mm or more. It is used for load-bearing structures - during the construction of walls and floors;

- partitions and other structures that are not classified as load-bearing are usually built from timber with a thickness of 10-15 at the customer’s choice. This leads to savings in material consumption and a reduction in construction costs.

The above parameters clearly demonstrate that the requirements regarding the energy efficiency of the building are of greatest importance when determining the thickness of the beam for a bathhouse. Therefore, the regularity of visits and climate characteristics are considered first when choosing material.

Brick bath walls

Despite the fact that brick does not have high heat-saving characteristics, nevertheless, brick has other equally attractive characteristics. It is a more reliable and durable material than wooden components, which is why it is often used today for the construction of bathhouses. Its main advantage is its low fire hazard, and this is a very important indicator for a bathhouse.

Creating brick bath walls

To calculate the thickness of the brick wall of a bathhouse, the following indicators should be determined:

- Number of floors of the future structure.

- Climatic conditions in which the bathhouse is built.

- What kind of brick will be used for the job.

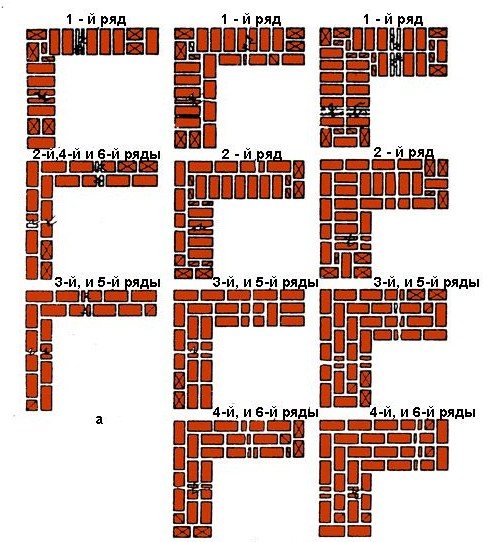

The thickness of the future masonry will depend on all these indicators. There are many options for creating brick walls:

- The bricks are laid in one row, that is, the components are laid horizontally on top of each other in one order or another. This method is called half-brick masonry, the wall thickness is 120 mm.

- Bricks are laid in rows of two components, alternating longitudinal and transverse cladding. This method is called bricklaying, the wall thickness is 250 mm.

- The bricks are laid in rows one and a half pieces wide, alternating the laying of whole and half elements. This method is called one and a half brick masonry, the wall thickness is 370 mm.

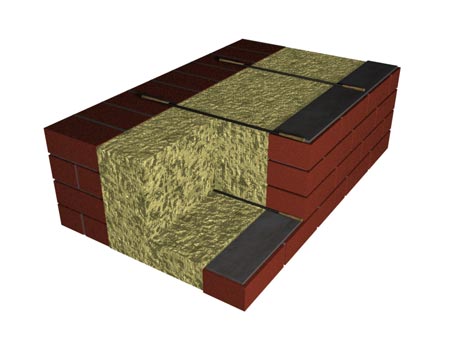

In addition to the above examples, insulation can be used in the masonry of a bathhouse wall, which will be laid between layers of brick, and this will increase the thickness of the wall by another 6-8 cm. Therefore, before deciding on the calculations, you should choose a method of laying the material, and this will add up thickness. Having determined the thickness of the wall, it will be possible to accurately calculate the width of the bathhouse foundation.

Laying bricks with insulation

It is also worth conducting some analysis of the heat conservation of brick structures in order to give future bathhouse builders some guidance. If the temperature outside the bathhouse in winter often reaches -30 degrees, then the thickness of the wall should be 64 cm. That is, masonry is carried out in two layers, double laying of components. At the same time, the same indicators from a wooden wall will require only 17-20 mm of thickness.

Standard timber thickness for bathhouse construction

The standard thickness of timber used in the construction of a bathhouse today is considered to be 150 mm. This is the minimum size that is used for one- and two-story buildings intended for year-round use.

Walls made of 150 mm thick timber do not require mandatory insulation, so material of this size is widely used even in some northern regions of the country. The main reason for its popularity is the optimal combination of the level of construction costs and the comfort of the resulting building.

Calculation of thickness based on CTS

Above was a simple calculation of the thickness of the bathhouse walls depending on the chosen material, but in addition to these methods, there is also a purely technical approach to the issue. To calculate the wall thickness, an indicator such as the thermal resistance coefficient or TRC is used. All coefficients have already been calculated for each Russian region separately and entered into special tables that can be found on the Internet. For example, for Moscow and the Moscow region this figure will be equal to 3.2 m C/W. To make it clear what we are talking about, it is necessary to give an approximate calculation:

- Wall material – gas silicate blocks grade D

- The thermal conductivity coefficient of the material is 0.12 W/m for dry structures.

- The thickness of the block for future walls is 40 cm.

In this case, the calculation of a certain CTS is carried out according to the formula:

V/KTP = KTS.

That is, in this case, it is necessary to divide the wall thickness by the thermal conductivity coefficient and the result is the desired CTC, in this case it is equal to 3.333 m C/W. When taking into account 1% of heat loss, the result is an approximate figure of 3.333, which in turn is greater than the figure in the table, that is, 3.2. This means that the selected thickness is quite acceptable for these latitudes and complies with the standards. If you plan to build walls from different layers of materials, you should simply add up the results obtained and compare them with the requirements of the CTS table. If problems arise with technical calculations, and compliance with all requirements is extremely important for some reason, then you can always contact the architectural department of the settlement administration for help.

Each region of Russia has its own CTS indicators

Determining the thickness of walls depending on the type of their construction

This parameter differs for all materials, which is due to such features as load-bearing capacity, compressive strength, bending, which are calculated at the design stage. The size of the layers of insulation, external and internal finishing, and in certain cases the air gap is added to the main thickness of the wall. The required load-bearing capacity depends on the roof material, the number of storeys of the building, and the type of external and internal finishing. The thickness of the walls is calculated at the initial stage of project development, since it directly affects the size of the foundation.

Chopped structures

For the bathhouse, mainly logs from coniferous wood are used, most often pine, which can be cut down independently, purchased at a logging enterprise or in the form of a finished log house from a construction company. Construction is carried out from rounded logs with a minimum diameter of 200 mm. We use high-quality dried wood, completely sanded and free from insects and rot. Logs must be selected as straight as possible and with the least number of knots.

The process of building a log house from glued or profiled timber is faster and less labor-intensive, since no adjustment of the material is required. According to current standards, the minimum width of walls made of it for a one-story building is 165 mm, for a two-story building - 200 mm. These values are relevant when using a bath only in the warm season.

Important! If you plan to operate a bathhouse made of timber all year round, it is necessary to insulate the walls, the layer thickness of which is calculated depending on the climatic features of the area where the facility is located.

Brickwork

The main advantage of buildings is fire safety and durability. The minimum width of a brick wall is 510 mm, rubble masonry is 750 mm. The high thermal conductivity of the material requires insulation, preferably external, as it is more effective. Otherwise, the bath heats up very slowly and cools down extremely quickly.

Advice! The thermal conductivity of walls can be reduced by using hollow bricks or making well masonry, in which gaps of up to 130 mm are provided, filled with insulation.

Block structures

The construction technology is characterized by reduced time and relative simplicity. Its peculiarity is that the masonry is carried out not with cement mortar, but with a special adhesive composition, which is caused by the high porosity of the material. As a rule, a thickness of 380 mm is sufficient to ensure sufficient load-bearing capacity of a block wall. To obtain the required heat resistance of structures, insulation is required.

To build a bathhouse, cellular blocks from:

- Gas silicate;

- Expanded clay concrete;

- Reinforced concrete;

- Slag concrete;

- Foam concrete.

Types of timber for building a house

How to choose timber for a bathhouse or home? It is not difficult. Compare your desires, capabilities, properties of each type of timber and choose the best option.

⇒ Simple timber with natural humidity

It can be square or rectangular. It requires preliminary sharpening on both or one side; sometimes the sides are also processed.

Between construction and finishing of the house, it is necessary to wait a period of time (about a year), since simple timber shrinks up to 7%.

Unplaned or planed regular timber has the lowest price, but construction costs increase significantly.

⇒ Round beam

Houses and bathhouses made of round (cylindrical) timber of coniferous or deciduous wood look massive and attractive.

The logs undergo mechanical processing and are impregnated with protective compounds. Such timber has natural moisture, so after the construction of the house it must take 9-12 months for shrinkage to occur.

⇒ Glued laminated timber

This is dry solid wood (pine, spruce, cedar, larch) or wooden slats glued together. It has an almost ideal shape, minimal shrinkage up to 2%. A house made of laminated larch or other coniferous timber does not require finishing.

In terms of price, this is the most expensive material, but if the cost of construction does not bother you, then this is an ideal solution for building a house or bathhouse.

⇒ Combined timber

This is a monolithic structure made of pine with layers glued together under pressure along the entire length: the outside is planed wood, the inside is insulated - extruded polystyrene foam.

Houses made from this material are the most economical to maintain, but quite expensive to build.

⇒ Profiled timber

This is a tongue-and-groove double beam of standard shape with strictly maintained dimensions along the entire length. The wood (spruce, pine, larch, cedar) is pre-dried well through chamber drying, so the house does not shrink. Thanks to the tongue-and-groove system, the joint of the timber during construction has no gaps. No additional finishing is required. Vertical laying of timber during construction is also possible.

The price fluctuates in the average range. In addition, this type of timber for building a house is easy to install, and the quality of construction is very high.

Houses made of profiled cedar or other coniferous timber, bathhouses made of calibrated cedar timber are durable, beautiful, environmentally friendly and comfortable, and most importantly economical.

So which is the best timber to use for your home and bathhouse? If you are looking for high quality at minimal cost, then profiled timber is the ideal solution! Our company is engaged in the construction of houses and baths from profiled timber of chamber drying or natural humidity, the dimensions of which are discussed in advance!

Stove selection criteria

When installing a log sauna stove, the question arises of what type of structure to choose. The classic brick version is as reliable as possible and has a long service life. But it also requires a large area, since the stove will be massive. In addition, it takes a long time to heat up, but it will also cool down much more slowly.

The metal structure is more miniature and variable. It is easier to fit into a more sophisticated interior and match different design features. It heats up almost instantly, but also cools down just as quickly. In addition, it is necessary to take into account that a metal stove will require additional maintenance, and its service life is significantly lower than a brick one.

Additional options that will increase the functionality of the oven:

- presence of a steam generator. It will be necessary for large area steam rooms and, if necessary, to create a high level of humidity;

- the presence of an extended firebox. Relevant for a wood-burning stove, as it allows you to add fuel from the adjacent room.

- presence of a heat exchanger. It’s a good option to also provide the steam room with hot water. which does not require additional energy to heat. The water in the tank will be heated due to natural circulation.

The choice of a stove for a sauna made of timber should be made purely for your own needs on an individual basis, guided by generally accepted rules and standards. The main thing is to achieve the optimal combination of temperature and humidity so that the bath has a healing effect.