Why choose linden

It’s hard to argue with its environmental friendliness.

Let’s list all the properties for which linden is loved by both masters and beginners who decided to build a bathhouse with their own hands:

- Linden wood has a low density - 490-530 kg/m³ (pine 470 kg/m³), which means that after getting wet it dries quickly;

- Linden has virtually no resinous substances, which cause a lot of trouble when heated. But its essential oils, at high temperatures, create a unique aroma in the steam room, which has an excellent therapeutic effect for healing the body;

- The color of linden wood depends on many factors, but it is always warm and light tones. You can choose almost white wood, pastel yellow or pink. Less common, but found, are light brown shades;

- Linden wood withstands changes in humidity without deformation or cracking.

Check purchased materials for compliance with GOST 8242-88

How wood becomes clapboard

Linden is grown on an industrial scale specifically for the production of building materials. This process is not quick - the tree must be at least 60 years old. Logs, or it is correct to say round timber, are sawn into boards.

Raw materials for the production of lining

- They are dried in special chambers for a certain time;

- During this process, many boards are rejected, and the finished raw material is subjected to further processing on special machines - a groove and ridge are formed that connect the boards to each other;

- Finally, each plank is processed and polished. The cost of the finished product is determined by this lengthy process.

Preliminary natural drying

Classification of lining by grade

Regardless of what type of wood the board is made from, the grade standards are the same for all:

- The highest grade is “Extra”. This type of lining is made from the middle part of the tree, which does not contain knots, cracks or any other defects. Has a uniform shade and smooth texture;

- Grade “A” is also of high quality, but the presence of one knot per 1.5 m is already acceptable;

- Grade “B” is allowed the presence of 4 knots per 1.5 m, small cracks and deformations;

- Grade “C” is the lowest in this category and is not suitable for baths. Such a board will become unusable very quickly due to an environment unfavorable for wood.

There is also a separate class of lining - eurolining. Such panels are manufactured according to European standards (DIN) and have a design difference - deeper grooves and, accordingly, longer scallops, as well as additional channels for ventilation and water drainage. The price of eurolining is significantly higher than the cost of “Extra” class panels.

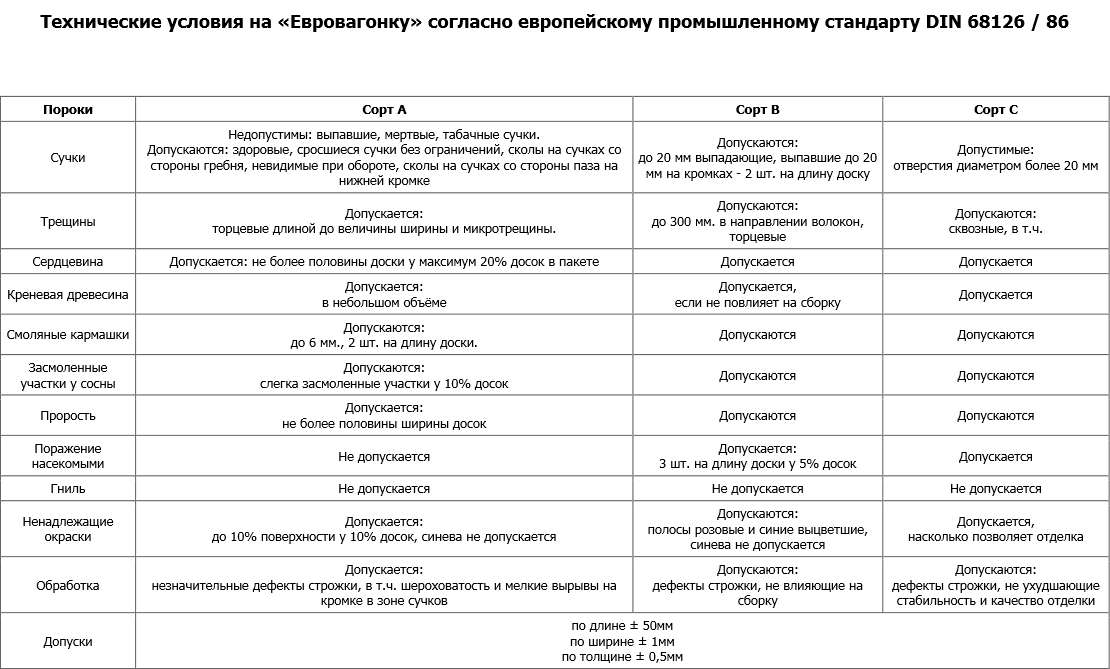

Classification according to DIN 68126/86

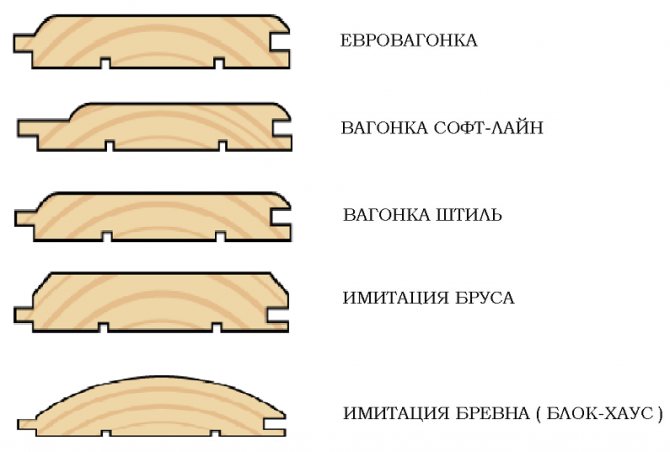

In addition, there are differences in the profile. The photo shows their main types:

Types of imported lining presented on the building materials market

Oak

Oak is a sound wood species. The heartwood of the tree is dark red, tan or light yellow. In addition, oak wood is very hard, strong, it is resistant to rotting, increased strength and beautiful texture.

Oak wood is commonly used in the manufacture of furniture and in cooperage. The resistance of oak to moisture allows the use of oak products in conditions of high humidity. This material is used to produce edged and unedged boards, furniture blanks, parquet, veneer, and doors.

Installation of lining

You can cover the premises of your future bathhouse with linden clapboards yourself. As mentioned above, such wood is easy to work with.

Simple instructions and simple rules will help you avoid mistakes:

- Installation is best done in the warm season or in a well-heated room;

- The lining (any) should lie in a warm place for several days;

- The lathing under the lining is attached horizontally, in increments of 40-50 cm;

We set the sheathing according to the level

- It is advisable to use insulation with an aluminum reflector;

- For baths, according to GOST, a board with a thickness of 12-25 mm is used;

- The lining is placed vertically or diagonally (so that water that gets on the walls does not linger in the grooves, but flows down freely);

The panels should be fixed vertically using clamps

- All surfaces should be treated with an antiseptic. The service life of your coating depends on the quality of processing;

- After the bactericidal solution has dried, cover the wood with protective gels, glaze or special bath varnish (regular wood varnishes cannot be used here!)

Use only special environmentally friendly varnishes

A little advice: for small rooms it is better to use lining 70-90 cm wide. This will create the illusion of a large space. A wider plank size will visually “swallow” both the height and volume of the room.

Perhaps this video will help beginners avoid mistakes when building a bathhouse.

Ash

Ash is a soundwood species. The wood has a light brown core with a brownish tint. This is a durable and strong material with high mechanical and physical properties, which is also easy to process and finish. Products made from ash are also distinguished by high impact strength and flexibility.

Ash is valued in carpentry; it is used for the production of veneer in the furniture industry, for finishing walls and laying floors. Eurolining, formwork, beams, unedged and edged boards, solid parquet boards, and railings are made from ash.

Furniture for a bathhouse made of lining

According to the safety instructions, do not use furniture made of iron or synthetic materials in bath rooms. Wooden sets are both beautiful and convenient. Benches, stools, tables made of linden lining will be appropriate in the interior of the bathhouse. Make sure of this by looking at the photo.

Linden furniture

There is an opinion that finishing with linden wood requires very careful handling. But all wood in the bathhouse requires attention and protection. After 3-4 years, the light colors of any tree can darken significantly, become covered with fungus, or even rot altogether.

Many argue that any coating significantly reduces the beneficial effects of wood on humans. Followers of tradition stubbornly do not want to recognize the latest achievements in the field of protecting wooden coatings in the bathhouse - and in vain.

There are enough products on the market that help preserve wood without compromising its aesthetic and technical characteristics. Thus, the Finnish company Tikkurila offers wonderful products that make the lining more resistant to moisture and dirt.

For the walls in the bathhouse, the oil composition SUPI SAUNASUOJA is recommended, and for the shelves - SUPI LAUDESUOJA on a paraffin-oil basis. There are also domestic products that are no less effective, but cheaper.

Packages start from 2.5 kg

If after treatment you feel that the room smells less of linden, nail a fresh board over the stove. At the same time, the aromas can be changed by hanging any other type of wood over the stove.

Once every 5 years (depending on the intensity of use), it is recommended to clean the shelves, benches and, if necessary, walls, and re-treat them with an antiseptic and protective agents.

Larch

Larch is a woody plant of the pine family; its wood is distinguished by the following properties: good rot resistance, resistance to attack by insects and fungi, high strength and durability, as well as environmental friendliness and hypoallergenicity. In addition, larch wood has a pronounced structure and is available in a wide range of colors and shades; there is also no blue tint on it.

Due to its aesthetic and environmental characteristics, larch wood is used in the finishing of various rooms where it is necessary to create a pleasant microclimate, regulate the humidity of the room, “level” the walls and create acoustics. The most common types are lining, block haz, and larch floorboards. Due to its resistance to rotting, it is also used for the manufacture of planks, terrace and deck boards, imitation timber, which are used for exterior decoration of houses, terraces, verandas, etc.

Review

Aspen baths, advantages and disadvantages

At first it may seem that aspen is no better than cedar or, for example, beautiful alder. You can understand the choice at least by the fact that in ancient times most of the log-type baths were built from special, selected aspen logs. In modern and comfortable steam rooms, aspen is used in those places where it would be better to lay expensive mahogany or plastic. At the same time, as reviews have shown, an aspen log house for a bath without treatment could stand in a damp and swampy area, where only oak and larch would adapt.

Please note that aspen is a very capricious material that requires special attention and approach. Especially when harvesting logs and preparing them for installation in a bathhouse box.

But with the right approach to materials, in the hands of an experienced craftsman, it is quite difficult to find better aspen for building a bathhouse.

Why is aspen better than other species in bath conditions?

The best wood for a bathhouse is aspen. This tree grows on waterlogged soil, and therefore its structure is intertwined thin fibers, very viscous and dense. To build a sauna log house, use tree trunks that are 40 years old, and they must be carefully selected and discarded. After winter drying, the logs need to be sawed and assembled into a log house, and they should be built quickly, joining the crowns at the corners “into a paw.” Very quickly, an aspen log house for a bathhouse shrinks, the wood becomes very compacted and hardens, and cutting it becomes extremely difficult. The advantages of aspen include the following properties:

Properly dried, aged and treated wood is not afraid of rot bacteria, fungal colonies and even certain insects that harm the tree.- Aspen is not afraid of heat, high temperatures, or humidity. Wood will feel better when touched by hand than any other materials, with the exception of African oak or mahogany.

- Dried and fresh wood, due to the high degree of humidity, is quite pliable and soft. In this state, aspen, as well as linden, can be cut with a knife in all directions of the fibers.

Please note that aspen will have a very high degree of strength; joists, door frames, ceilings and window openings are made from bars and boards.

Quite often, an aspen log house is not even lined with additional finishing inside. Moreover, craftsmen say that it is better to leave aspen crowns open. It is believed that aspen heated by steam begins to release special substances that perfectly tone the breath and skin. The popularity of aspen baths is so great that unusual medicinal qualities are attributed to its influence, while aspen wood does not have resins and phytoncides, like conifers.

Why aspen is inconvenient for bathhouse installations

The main disadvantage of aspen wood can be considered the difficulty in choosing a high-quality material. Aspen, like no other material, must be carefully selected and rejected. The better the screening, the longer the bath complex will last. If you come across a log with foulbrood, there is a chance that the entire structure will be infected before the aspen becomes insensitive and susceptible to rot. The second disadvantage is considered to be the darkening of the surface under the influence of sunlight and air. To return the aspen bath building to its original light appearance, it is best to sand the surfaces or process them using a sandblasting machine.

Bathhouse made of linden and aspen

Both of these materials are considered the most affordable and tedious for interior decoration of saunas, steam rooms and dressing rooms. Benches and shelves are usually made from linden, because in a hot steam room, a soft linden bench will always feel even cooler to the touch than aspen, especially after several years of use in a humid environment. How to distinguish aspen from linden? Quite a simple question, but very important when it is necessary not to confuse the materials used for finishing the steam room and the door blocks for the bath. Freshly planed boards and slats made of linden and aspen are almost indistinguishable in texture and color. Aspen has a more pronounced fiber pattern and a slightly lighter, even gray surface tone. Linden can be distinguished by its specific aroma, and sometimes craftsmen check the maturity and dryness of the material with a drop of honey. On aspen it begins to spread and be absorbed; on linden it will remain in the form of a small drop. Naturally, linden is useful only for the cladding and furniture of a steam room, and it is pointless to build a frame or log house of a bathhouse from it.

In some cases, bathhouse customers wonder what is better, linden or aspen in the steam room. Both of these materials are almost equivalent, and they both begin to darken after dirt and water. Only linden will absorb everything that is washed off, but aspen begins to oxidize and become stained. In two cases, texture and colors can be restored. If you need to make a choice between aspen and linden, then it is better to remember the unique qualities of aspen wood to get rid of pathogens. In the old days, it was used to make upholstery and tubs for clean drinking water, which did not bloom or become cloudy.

Alder sauna

If you think about what is better for a bathhouse - aspen or linden, then it is worth considering another option. The texture of alder is unusual and beautiful and can vary from pink-yellow to rich, almost orange shades and colors. Alder, together with aspen and linden, is beginning to be included in the TOP-3 materials that are most often used for finishing the steam room in a bathhouse complex. According to user reviews, alder for a bathhouse is a complex material:

- The strength of wood is low, but with a bath finish there can be no chips or cracks.

- It easily absorbs water, but when stained for a long time in water, it gains strength, like metal or stained oak.

- It is difficult to tolerate overheating, but the aroma of a smoldering splinter or heated wood is considered very pleasant, in some cases even exquisite.

Fresh sawn alder is almost white in color, like aspen or poplar. After drying in air, the surface acquires an orange-red tint, and after treatment with an ammonia solution it obtains a very beautiful color and texture. Alder veneer is used in baths as a method of simulating mahogany. In decorative terms, a well-processed alder surface looks much better than real mahogany, walnut or chestnut. If you need to ensure a pronounced therapeutic effect, then black alder is better suited for a bathhouse. It, like aspen, releases many volatile substances and also has a beneficial effect on the upper respiratory tract.

Bathroom made of larch

All coniferous types of wood are considered to be the most suitable for building walls, ceilings and floors. A larch log house can be easily distinguished from a cedar or pine structure by its darker wood color. The cedar bathhouse looks light, with a yellow tint. The larch tree is popular for its incredible resistance to mold and putrefactive pathogens. Boards and slats perfectly withstand alternating loads at high temperatures and under conditions of high humidity, and therefore a log house made of larch will be the most durable and strong.

The construction of a bathhouse made of larch, without additional processing, has the stability and strength of stained modified aspen. Larch is ideal for insulating sheathing, joists, ceilings, anywhere where structural bath elements come into contact with hot, humid steam.

The only thing in which larch is worse than aspen is its tendency to chips, cracks, splinters, and when heated strongly, it releases resin to which it can stick. For this reason, I do not use it on furniture or the floor of the steam room. Larch cladding has a tart, resinous aroma that never goes away, even after 5 years of use. Many modern projects - banivs in the form of a cedar log house.

Relatively accessible and inexpensive pine wood from Siberia is the optimal material in terms of cost and quality. Unlike larch or aspen, cedar is cheaper, better machine processed, and therefore it has become the most popular building material for bathhouses. A material that has a large amount of resin with a pleasant aroma that is not irritating can cause allergic reactions. For this reason, it is best to use cedar for a steam room that has been bleached using hydrogen peroxide. A cedar steam room is inferior to an aspen room in the richness and durability of the atmosphere.

Exotic woods

Exotic wood species are imported from tropical and equatorial regions of the Earth. Today, the range of such materials is represented by dozens of tree species, which are distinguished by a rich palette of texture patterns and colors: bronze, yellow, green, black, crimson. The undoubted advantage of many exotic tree species is their mechanical and physical properties. In Russia, as well as throughout the world, such tree species as bamboo, zebrawood, kaslin, cypress, ebony and others are used.

If you are original and want to create a unique interior in your home, then you can use exotic wood species to finish the floor, ceiling, and furniture facades. This wood is very practical, which allows it to be used in bathrooms, kitchens, terraces, and winter gardens. These rocks are also used to make lining, parquet, furniture facades and much more.

Russia has many rich forest lands, which are a source of timber. Both coniferous and deciduous trees are used to make various lumber. Thanks to such a wide selection of wooden products, each consumer will be able to choose for construction and finishing those types of wood whose properties will best suit the conditions of its use.

Pine and spruce

Pine wood is characterized by high mechanical strength, ease of processing and low thermal conductivity. The material has a unique textured pattern that does not fade or fade over time, but rather darkens, acquiring a reddish tint. The wood is soft, so it is easy to process and does not crack.

Spruce belongs to a coreless mature wood species. The wood has a uniform white color, sometimes with a pinkish or yellow tint. Over a long period of operation, the material retains its natural color. Spruce bends well, but the difficulty of processing it is that there are many knots on the tree. Spruce wood has less density, strength and moisture resistance than pine and is more susceptible to rotting, but it is not subject to warping.

The chemical compositions of pine and spruce differ little from each other. There is one difference between these species in physical characteristics: spruce is looser, which provides it with better thermal conductivity. Pine, on the other hand, has a very strong aroma due to its higher resin content; this wood retains its bright pine smell even after varnishing.

Wood of these species is usually used for finishing the interior of premises, since in conditions of high humidity the quality of the wood is preserved, but its original aesthetic appearance is lost. Flooring, deck, terrace boards, lining, imitation timber are produced from pine trees.