Standard sizes

Doors for baths in a store

The main inconvenience associated with non-standard dimensions is the price of the product . In addition, it must first be made to order. It’s much easier to come to the store and buy something ready-made.

Door installation: inexpensive and professional - https://sevendoors.ru/zamer_i_ustanovka_dverej.html

In principle, there is no significant difference between the doors in a bathhouse, residential or public place . The standards for them are the same, and all the nuances relate only to high humidity and temperature changes, which are characteristic of baths, but this is a separate topic.

Previously, it was necessary to focus only on GOST , but now, if it is possible to order products from abroad, you need to take into account the dimensions of bath doors according to Western standards .

According to GOST

Let's start with the fact that inside the bathhouse you can install doors made of wood, glass and plastic . However, wood turns out to be decisive in this regard , because companies that work with plastic are ready to make any size of bathhouse door, and glass models do not differ in size from standard wooden ones.

Wooden

The regulatory document according to which doors for residential and public buildings are manufactured is GOST 6629-88 .

Below are two plates that give the width and height of the door leaf without the frame in millimeters, and at the intersections of the rows and columns - the designation of the dimensions of the doorways in decimeters.

ATTENTION! The opening is quite significantly larger than the size of the canvas - 10 cm.

Table 1. Wooden doors for a bathhouse: dimensions of glazed panels

| height | width | |||

| 700 | 800 | 900 | 1100 | |

| 2000 | 21-8 | 21-9 | 21-10 | |

| 2300 | 24-10 | 24-12 | ||

Table 2. Dimensions of blind panels

| height | width | ||||

| 600 | 700 | 800 | 900 | 1100 | |

| 2000 | 21-7 | 21-8 | 21-9 | 21-10 | 21-12 |

| 2300 | 24-10 | 24-12 | |||

In practice, no one will make such high heights in a bathhouse, but more on that below.

According to European standards

In general, the standard dimensions of a bathhouse door can be specified in three ways: the door leaf itself without a frame, with a frame, and the size of the light opening . However, there is nothing difficult in independently calculating the entire trinity, knowing one of the values and how much less or more the other values are, because the opening and the box are larger than the canvas by constant amounts.

Table 3. Interdependence of the opening, frame and leaf

| Dimensions | Width of single door doors (mm) | |||

| Nominal opening in masonry | 625 | 750 | 875 | 1000 |

| Box in quarters | 595 | 720 | 845 | 970 |

| Fused fabric | 610 | 735 | 860 | 985 |

| Canvas without overlap | 590 | 715 | 840 | 965 |

Self-production

If you have already had successful experience in manufacturing wooden structures or have lined a bathhouse with wood panels yourself, you are quite capable of making the canvas yourself. This decision is also supported by the cost of the doors to the bathhouse, which are offered by src=”https://rubanya.com/wp-content/uploads/2017/07/Zaklyuchitelnaya-dver.jpg” class=”aligncenter” width=”400″ height=”552″[/img]

For the glass door, special heat-resistant glass is used.

In addition, the installation of such a canvas requires special fittings.

In this regard, prices for even the simplest glass doors can be unpleasantly surprising.

And if you want to add a sandblasted design to the canvas or choose colored glass, the price can be comparable to the cost of finishing the entire bathhouse.

Wooden or combined doors are cheaper, but the price range is discouraging for many. The cost of a door depends on the wood from which it is made.

Pine is one of the most inexpensive materials, but a door made from it has many disadvantages. Larch is a more suitable material for a bathhouse, but its cost is quite high.

However, we should not forget that a significant part of the price of a bathhouse door is the direct work involved in its production. By making it yourself, you can save a lot.

And if you already have all the necessary tools and experience in creating wooden structures, a home-made door will become a real source of pride.

Information. Many bath attendants note that doors made by themselves last much longer and are of higher quality than those assembled in production. This is explained by the use of good material and the efforts of the master himself, who literally puts his soul into his work. When manufactured individually, any miscalculations are immediately eliminated, so such a door has the best quality and durability.

To a Russian and a Finnish bathhouse - is there a difference?

There is a difference, but whether to take it into account or not depends on whether the person is a strict adherent of traditions or not.

It is easy to guess that only one room is of key importance. Therefore, the whole difference comes down to the size of the door to the steam room in the bathhouse . Apart from her, everyone else will be subject to interior or entrance standards.

To the steam room

Not every steam room is designed to conserve heat. But first things first. Let's consider the size of the door to the steam room.

Russian

This is where it is important that during the soaring period there are no drafts at all . We can say that this is the most important condition - a small door with a high threshold, which does not allow air to move across the floor, and a low lintel, which does not allow steam to escape. The modest dimensions of the door itself retain more heat, and most importantly, steam inside the room.

Ceiling and threshold in a Russian steam room

The minimum size of the door will be 160 cm in height and 60 in width , and the height of the threshold will be 15-20 cm. Based on these figures, lovers of Russian baths can choose a door with dimensions that are more acceptable to them, for example, a glass one.

There are three options for purchasing a non-standard door for a Russian steam room: buy a ready-made one (they are available specifically for baths), order it, or make it yourself. See the article about choosing or making.

Finnish

The sauna is different in that in this type of bath the most important condition is vigorous air exchange . This means that it is necessary to ensure a sufficient flow of air, whose temperature will quickly rise to the standard temperature due to high convection coming from the stove. For this purpose, a gap must be made at the bottom , the width of which is about five centimeters. In this case, there is no threshold. If desired, the gap can be equipped with blinds.

Door in the sauna - no threshold

CONCLUSION: The size of a door to a sauna made of any material: wood, glass or plastic will be standard for interior doors.

For other premises

Plastic and double-glazed windows in this bathhouse perfectly separate the wash room from the rest room

The remaining rooms in the bathhouse are a washing room, a rest room (there is rarely a separate door leading into it), and a bathroom. There are nuances in what material and what design the doors leading to these rooms should be made of, but this does not affect their dimensions in any way.

In other words, you are free to install any door you like that will withstand high humidity , which is generally characteristic of bath rooms.

Entrance

Separately, it is worth mentioning the front door, because its dimensions differ from the interior ones. It should be thicker and more thorough. Must patiently endure temperature changes and, if unlucky, survive a break-in attempt.

It is customary to distinguish between single-field and double-field , as well as options with a transom - this is a window located directly above the opening.

We believe that the majority will choose a single door entrance door to the bathhouse , the dimensions of which vary within the following limits:

- the height of its opening can vary between 2070 and 2370 mm;

- width – between 910 and 1010 mm.

The thickness is regulated solely by the material used. As the latter, they most often choose either wood, metal, or plastic.

Selection of material and accessories

The best material for making a bath door, despite the variety of its glass counterparts, is still wood. There are very reasonable reasons for this. When the steam room heats up, it releases healing essential oils into the air, which are extremely beneficial for the body. Another factor is the availability of wood and the ease of its processing, which allows you to make and install a bath door with your own hands.

The material for it can be oak, linden, cedar, aspen or larch. All these types of wood have a healing effect during bath procedures, and not only that. The cost of the chosen door design will depend on the use and value of a particular wood. To optimize costs, the steam room door leaf, made of cheap material, can be sheathed with valuable species.

The main thing in choosing door hardware for a bathhouse is its anti-corrosion resistance in a humid environment and low thermal conductivity. Touching a metal door handle in a hot steam room can cause a burn. Therefore, it is much safer to use wooden handles and latches on the bath door.

Door hinges must be made of non-ferrous metals, for example brass. They do not rust and have an attractive appearance. When using hinges made of ferrous metal, they must first be painted with a heat-resistant anti-corrosion compound - enamel or paint. When opening the steam room doors outward, getting burned from the heated hinges is extremely problematic.

Construction of doors, frames, openings

It was already mentioned above that three types of dimensions - canvas, box and opening. The latter is finishing and wall, the first is the amount of free space between the jambs, and the second is the space between bare walls without a frame.

The door leaf is attached to the frame using hinges; the frame is secured in the opening in various ways (see our article about the simple and straightforward installation of doors in a bathhouse). The gaps between the canvas and the box do not exceed 2-3 mm , and between the box and the opening the gap unfilled with foam can be several centimeters (but no more than the width of the casing that covers it).

Reference. An important aspect is the insulation of doors to the bathhouse.

When laying an opening in the wall, you can be guided by either standard or non-standard dimensions of future doors. Usually it is 10 centimeters larger than the size of a bath door with a frame, which gives 5 cm on the sides and 10 on top (if without a threshold).

In the photo: uncut and not covered with casing foam holding the door

IMPORTANT! The gap between the box and the wall may be smaller, but it is required, and the minimum may be one centimeter.

Dimensions with box

Very often, the main dimension that is taken into account when choosing a door is the external size of its frame. Below we provide a table showing new options for the interdependence of the dimensions of the module, box and opening:

Table 4. Door to the bathhouse: dimensions with frame

| Modular size (decimeters) | Outer box size(mm) | Doorway size (mm) |

| 10 x 20 | 990 x 1990 | 1000 x 1990 |

| 9 x 20 | 890 x 1990 | 900 x 1990 |

| 9 x 19 | 890 x 1890 | 800 x 1980 |

| 8 x 20 | 790 x 1990 | 800 x 1990 |

| 8 x 19 | 790 x 1890 | 800 x 1890 |

| 7 x 19 | 690 x 1890 | 700 x 1890 |

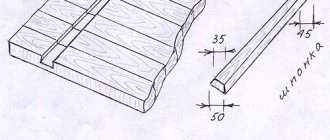

Assembling the door leaf with trim

There is a more complex option for making a door. It will be used both as an entrance and in the steam room.

- The material for the door leaf in this case will be a 36 mm thick linden floor strip. The tongue-and-groove assembly is carried out in the same way as described above, with one exception. The length of the board is reduced to 1670 mm from the standard 1800 mm. This is done in order to leave room for door trim. The width of the canvas assembled from the slats will also be 130 mm smaller, that is, 570 mm.

- The door leaf, assembled with glue using the tongue-and-groove method, is sheathed on both sides with linden clapboard. In this case, the thickness of the canvas is 60 mm.

- The door frame is made from a 65×80 linden block. A double cut is made along the inner part of the frame with a side of 80 mm, with the expectation that in the center there will be a groove 36 mm wide and 15 mm deep, into which a door leaf consisting of a 36 mm thick slats could fit.

- The grooves of the trim are coated with glue and it is put on the prepared door leaf. After this, the frame is pressed on all sides with wedges to the main structure and the door is left in this form for two or three days.