Thermal insulation requirements

The bathhouse has a different mode of operation than a residential building. This means that the requirements for thermal insulation of this building are significantly different. For a bathhouse, it is important not only to retain heat, but also to provide good hydro- and vapor barrier.

You should think about insulating a bathhouse already at the construction stage. Click on photo to enlarge.

Insulation of a brick bathhouse begins at the stage of laying the foundation. A layer of insulation is laid inside the foundation screed. As a rule, mineral mats are used for this.

Bathhouse layout

The layout and dimensions of the bathhouse are important for maintaining heat.

A standard building usually has an area of 6-9 square meters. It is necessary to provide a vestibule to protect against cold air from the street.

After the vestibule there is a dressing room with an area of 4 sq.m. It is not recommended to enter the steam room directly from the dressing room.

This will result in too much steam entering the dressing room. It is better to arrange the passage in the form of a small corridor.

Materials and tools

Now there is a large selection of insulation materials on the market and we must remember that bath procedures will bring a healing effect only if natural products are used inside the bath. In this case, the following requirements are put forward for thermal insulation products:

- Environmental friendliness of insulation. At elevated temperatures and high humidity, insulation materials can release toxic substances. Therefore, before insulating the bathhouse, this indicator must be taken very carefully;

- Hydroscopicity. The insulation should not get wet during operation;

- Thermal conductivity. The lower the coefficient of this material, the less heat this product transmits through itself over a certain period of time;

- Biological inertia. There should be no impact of harmful impurities on the human body;

- Fire safety;

- Ability to maintain its shape;

- Budget cost and easy installation.

Comparison of insulation according to different parameters

To understand which insulation is best suited for a bathhouse, you need to know their parameters. Let's take a closer look.

For a long time, this material has been used to preserve heat in Russian baths. The indisputable advantage of this insulation is its naturalness and accessibility. But there are also many disadvantages:

- Fire hazard;

- High hygroscopicity;

- Difficult to use;

- Susceptibility to rodents.

In this regard, the use of organic insulation fades into oblivion and is used very rarely.

In these natural products, synthetic or adhesive compounds are used during manufacturing.

These include:

- Reed slabs;

- chipboard;

- Peat slabs.

Such insulating materials can be used to insulate the outside of a bathhouse with additional protection from precipitation, but they cannot be used from the inside on the walls of steam rooms.

These products are manufactured under industrial conditions and are divided into two types:

- Polymers. Among them, polystyrene foam and polystyrene foam stand out.

- Polyurethane foam.

It is impossible to insulate a bathhouse inside, especially in a steam room, with such material, since polystyrene foam emits a harmful substance at high temperatures - styrene. However, this is an ideal option for thermal insulation of a building on the outside.

Penoizol. This is a foil insulating material used in the steam compartment. It is an exception from a number of polymer materials due to its reflective properties.

Foil insulation

Mineral wool. Basalt wool and glass wool belong to this group. Their advantage is fire safety and resistance to thermal insulation. The disadvantages include high hygroscopicity, which determines the use of films.

Basalt wool is an environmentally friendly material that is recommended for use in steam rooms and saunas. Having chosen the appropriate insulation, you need to purchase related materials, as well as prepare the tools.

| Material | Application | Characteristics |

| Basalt wool | Thermal insulation inside the bath | 100 mm (hard) |

| Vapor barrier film (penotherm) | Protecting insulating material from dampness | Heat resistant |

| timber | For frame | 50×50 mm |

| Planed board | Wall cladding | 100×20 mm |

| Reiki | For frame | 30×25 mm |

We suggest you familiarize yourself with: What kind of insulation to put on the ceiling in a bathhouse

If you plan to make a concrete screed for the floor, the list of materials will increase, including the following products:

- Mesh for reinforcement;

- Composition for pouring screed (sand, water, cement);

- Damper tape;

- Lighthouses.

For the external filling of the ceiling you will need expanded clay and powder polyurethane.

Tool

From the tool you need to prepare:

- A circular saw;

- Hammer;

- Level;

- Hacksaw;

- Fasteners (nails, screws).

When installing facing material, the heads of nails and screws must be deepened inside the boards to avoid burns from accidental contact during bath procedures.

Floor insulation

Insulation of a brick bath includes mandatory insulation of the floor. The soil under the floor must be covered with expanded clay or slag. The layer of this insulation should be one and a half to two times thicker than the walls of the bathhouse.

Various materials are used for bathhouse flooring, but the most common flooring is still wood. For a wooden floor, the layer-by-layer insulation design looks like this:

- Expanded clay (slag) pillow.

- Beam floors.

- Vapor barrier layer.

- Rough floor.

- A layer of insulation (most often polystyrene foam).

- Waterproofing.

- Finishing floor boards.

Other recommendations for insulating a bathhouse

If the insulation of a brick bathhouse inside, tested over the years and recommended by experts, is carried out mainly with materials such as mineral wool, expanded clay, vermiculite, penoplex, polyurethane foam, basalt insulation, fiberglass and so on, then do not forget that there are other bottlenecks , in which small but heat losses also occur.

Of course, these places are mainly either door or window openings, usually external. In this regard, when building baths, it is not advisable to install large windows looking onto the street or courtyard, as well as very high doors. At the same time, it is recommended to place window openings as low as possible, and the front door should be equipped with a threshold.

In order for the insulation of a brick bathhouse inside to be more reliable, it is preferable to install triple-glazed windows on the windows, and choose doors made of wood with insulation inside, or from heat-resistant, shockproof, durable glass.

Another small nuance that should not be neglected when building a brick bathhouse is the implementation of local protective impregnation of the brick from the effects of harmful bacteria. It is recommended to perform this procedure mainly in rooms such as steam rooms and showers.

It is equally useful to know several reasons why it is not recommended to carry out external insulation of a brick bathhouse. One of them is an undesirable and very expensive pie of insulation on both sides of the brick. By insulating the walls of a bathhouse from the outside, the consumption not only of building materials increases, but also of fuel. The other is significant losses in heating cold bricks in winter.

A simple calculation based on the laws of physics will help you avoid the formation of condensation on the ceiling in the steam room: thermal insulation for the ceiling should always be proportionally thicker than for the walls.

Thermal insulation of walls

Often people at the construction stage do not think about how to insulate a brick bathhouse, believing that brick itself is a warm material, and the interior decoration will be enough to retain heat.

In fact, the thickness of the brick is not always enough for the economical consumption of thermal energy in the room. Therefore, the walls of the bathhouse must be additionally insulated.

The main task when building a bathhouse is to ensure rapid heating of the room and long-term heat retention.

There is no easier way to insulate a brick bathhouse than external insulation with foam plastic. The technology of work here is quite simple and even novice craftsmen can do it. Here's what you need to do:

- Clean the walls from dirt and mortar residues.

- Prime the walls.

- Set the lower starting profile.

- Secure a layer of foam plastic to the walls using mounting foam or dowel nails.

- Strengthen the second layer of polystyrene foam on top of the first, bandaging the seams.

- Secure a layer of waterproofing material.

- Finish the façade of the bathhouse.

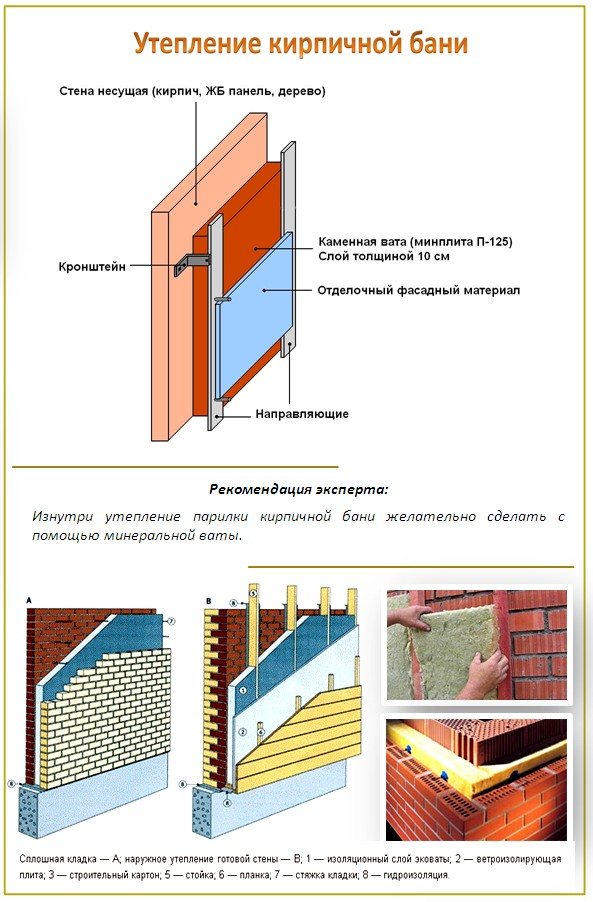

The walls of the bathhouse are insulated from the inside with mineral wool. The walls are covered with waterproofing, on top of which a wooden sheathing is placed. A layer of mineral wool is attached to the sheathing, and a layer of vapor barrier material, most often aluminum foil, is attached to it. The finishing of the room is carried out on top of the insulation.

Material selection

Brick, as is known from practice, cools quickly and warms up slowly. Moreover, it holds heat like a sieve. Therefore, it is imperative to insulate the bathhouse. Otherwise, instead of pleasure and health, the lover of a steam bath will face complete inconvenience against the backdrop of an eternal cold.

To insulate a bathhouse from the inside, you can use the following materials:

- tree;

- glass wool;

- mineral wool;

- polyurethane boards;

- polystyrene;

- porous cellulose boards;

- pressed reed mats;

- expanded clay

Each of them has its own disadvantages and advantages, but the main role when choosing a material is played by price. If you have enough money, you can even use special insulation with foil. It's expensive, but really worth it. A layer of insulation (mineral wool or polymer) keeps the cold out, and the foil reflects heat from the source back into the room. According to some data, the return is up to 97% of the generated thermal energy. The goal of maintaining a constant high temperature is achieved, but at a certain cost.

Experts advise using a differentiated approach to insulating a bathhouse from the inside. Simply put, use different insulation in different rooms. For example, in the relaxation room and locker room you can get by with simple mineral wool, but for the steam room it’s worth forking out for foil.

Return to contents

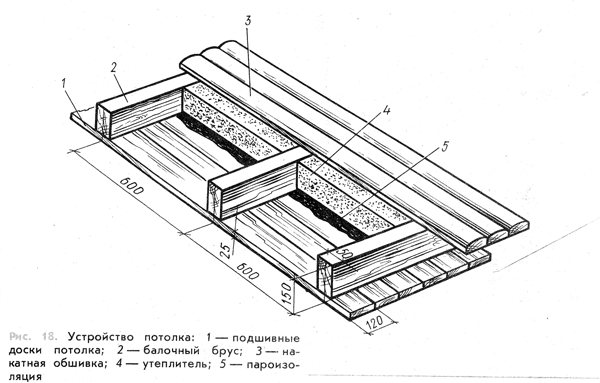

We insulate the ceiling

The ceiling of a bathhouse, like any other room, must be insulated. Click on photo to enlarge.

When deciding how to insulate a brick bathhouse, you should not concentrate only on insulating the walls. Insulating the ceiling is an equally important task. Up to 20% of heat loss occurs through the ceiling. It is possible to minimize them by carrying out proper insulation.

Insulation of the ceiling from the attic side occurs as follows:

- A layer of fiberglass is laid on top of the ceiling.

- The ceiling is covered with a mixture of clay, sand and sawdust in a 1:1 ratio. The optimal layer would be 20-30 centimeters thick.

- The next layer, after the first has dried, will be a solution of clay and sand with vermiculite, about 5 cm thick.

- When the solution has dried, foam plastic is laid on top of it, 10-15 cm thick.

- Fill the floor with cement screed.

From the inside, the ceiling of a brick bathhouse is insulated according to the same principle as the walls. A layer of waterproofing, a layer of insulation, a vapor barrier and interior finishing. As a decoration in a bathhouse, lining is usually used to cover the walls.

External and internal thermal insulation

Before you start insulating the inside of a brick bathhouse with your own hands, you need to prepare the surfaces: seal the cracks, coat the wooden products with an antiseptic.

Then follow the steps step by step:

- Step No. 1. Cut the beams and make a sheathing with a pitch slightly smaller than the width of the insulation, and then attach it to the brick wall, after drilling holes with a hammer drill (the cross-section of the beam must correspond to the thickness of the insulation).

- Step No. 2. Place the slabs in the prepared cells.

- Step No. 3. Apply a vapor barrier film on top. It needs to be laid starting 5 cm on each side. As a rule, a foil covering is used in the steam room. The waterproofing sheet at the joints must be sealed with aluminum tape for better tightness. And also seal the joints between the timber and the insulation, while covering at least 5 cm from the insulation side.

- Step No. 4. To better preserve the vapor barrier and create a ventilation gap, a frame of 20 mm thick slats under the lining is mounted on top of it. It is recommended to do it with a vertical arrangement of the slats, so that in the future condensate can flow freely between the facing and vapor barrier material.

- Step No. 5. Cover with clapboard or simple planed boards (they are attached to the sheathing in a horizontal position). The sheathing material must be attached in such a way as not to damage the vapor barrier layer.

We invite you to familiarize yourself with: Ventilation in a frame bath: the principle of organization

Insulation of a brick bath

The steam room at the dacha is not used very often, so during downtime, especially in the winter season, the brick walls freeze over. When insulating the walls externally, you will have to warm up the entire layer of cold bricks. This will take much more time, heating resources and will negatively affect the retention of warm air in the room.

How to improve insulation

No matter how you insulate a brick bathhouse, if the windows in it are not airtight, the insulation will be of little use. Most of the heat will escape through the window frames.

If the glass is not inserted tightly, you cannot avoid drafts. Unsealed windows will fog up, and moisture from them will contribute to the appearance of fungus on the walls.

Windows in the bathhouse should not be abandoned altogether. But you shouldn't make them too big, and it's best to make them so that they can't open. The frames need to be fitted as tightly as possible to the window sashes, cracks and holes should be carefully insulated.

The ideal option for a bathhouse would be double-glazed windows. If it is not possible to install these, in any case, make a window with double, or better yet, triple glazing.

Insulation of a brick bath

Despite the fact that brick is not very popular in the construction of bathhouses, nevertheless, such a building can be an excellent alternative to a traditional log house. You can properly insulate a brick bathhouse with your own hands, and the result of the work will meet all expectations.

In this case, special attention should be paid to the steam room, because this particular room is the “holy of holies” of the traditional Russian bathhouse.

The main stages of thermal insulation of a brick bath

Here the following structural elements are subject to insulation:

- Floor.

- Ceiling.

- Walls.

- Roof.

- Waterproofing.

As you can see, there is a lot of work planned, so let’s get straight to the point.

Floor

The procedure for insulating the floor in a brick steam room is similar to the complex of works carried out for wooden buildings.

Walls

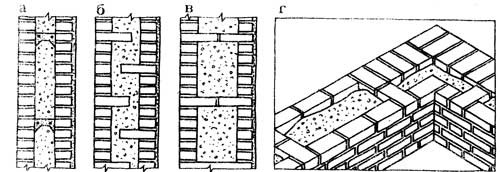

Well masonry.

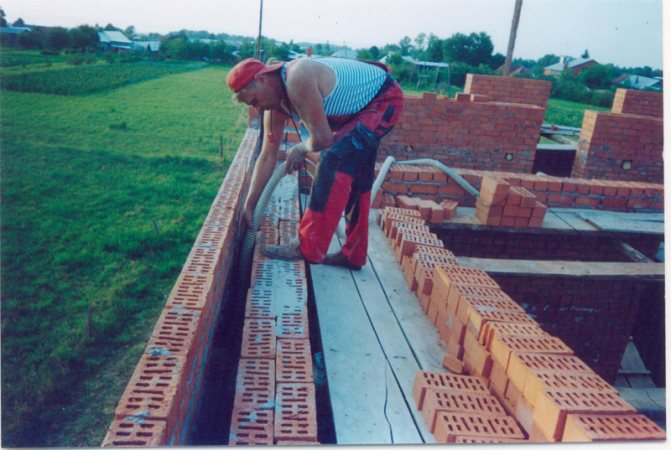

Insulation of walls in a brick steam room is carried out already at the stage of their installation.

Advice! Since brick tends to absorb water well, walls made of this material should not touch the ground. To do this, the base is covered with roofing felt, or coated with mastic, which consists of talc, bitumen, asbestos and lime.

- The walls should be laid with well masonry . It is made in half a brick in two rows. The thickness of such a wall should be no more than 40 cm.

- The gap between the rows should be about 15 cm , it is thanks to this that thermal insulation will be ensured.

- In between should be placed a layer of light insulation . Expanded clay, slag, wood sawdust, etc. would be an excellent option.

Nowadays, insulation of steam room walls using this method is increasingly done using modern materials, which include mineral wool and polystyrene foam. They can be glued or installed by surprise, precisely adjusted to the size of the cavity to be filled.

The photo shows insulation of well masonry with ecowool.

Walls insulated with this method are not completely protected from heat loss. To do this, it is necessary to cover the walls from the inside.

We cover the walls from the inside

If you are interested in how to properly insulate a steam room, then you should know that without internal wall cladding it is impossible to achieve truly high-quality insulation of a bathhouse.

Internal thermal insulation of walls in the bathhouse

- Using self-tapping screws, wooden slats should be secured to the brick wall in increments of 50 cm. It is on them that the lining will be attached.

- We fill the gaps between the slats with a thin layer of sheet or roll insulation. It is best to use mineral wool for these purposes.

- The insulation should be covered with foil, the main purpose of which is to ensure the proper level of waterproofing.

- After this, the walls are covered with clapboard.

Ceiling

Ceiling insulation with foam plastic.

The insulation of the ceiling in the steam room should be more dense than in the case of the walls. The fact is that warm air tends to constantly strive upward, which means that heat loss through the ceiling can be very large. Therefore, there is no need to spare the insulation here.

Scheme: thermal insulation of the bathhouse ceiling

Advice! In order to insulate the ceiling of a bathhouse from the roof side, the easiest way is to use a 15-centimeter layer of mineral wool covering the entire ceiling surface.

Let's look at how to properly insulate the ceiling in a steam room from the inside:

- We lay vapor barrier foil on the floorboards. We carefully glue it with aluminum tape. Ideally, there should not be even the smallest gap between the ceiling surface and the foil.

- Foam boards should be laid on the foil, the gaps between which should be sealed using polyurethane foam.

- We install sheets of facing material.

Wall insulation with Rockwool slabs

One of the easiest ways to reliably insulate the walls of a bathhouse is to use special Rockwool “Sauna Butts” slabs, produced specifically for insulating saunas and baths.

Rockwool slabs are made from natural stone, which is melted at a temperature of 1500°C in special furnaces to produce stone fiber, from which thermal insulation slabs are formed.

The insulation material is not afraid of moisture, as it is pre-treated with a special solution that repels water, and is also absolutely fireproof.

Mineral wool slabs made from natural stone Rockwool are covered on one side with aluminum foil, which prevents moisture from penetrating into the slabs from the steam room.

Before laying the insulation, waterproofing should be laid on the inside of the brick wall.

Rockwool boards are mounted on the inside of the walls, laying the foil side inside the steam room between bars nailed onto the wall at regular intervals corresponding to the width of the insulation boards.

For this purpose, 50x50 mm bars, fixed to the wall every 50 cm, are quite suitable.

The insulation is placed between them by surprise, after which the seams between the plates are taped with special metallized tape, which prevents moisture from entering the insulation layer.

When using metallized mats, it is not necessary to lay a layer of vapor barrier, since a layer of foil perfectly performs this function.

After laying the slabs, a sheathing of bars 50 mm wide and 20 mm thick is installed on top to provide an air gap between the insulation layer and the finishing clapboard cladding.

The sheathing is attached to the bars with self-tapping screws, between which the insulation is laid. A clapboard is hammered on top of the sheathing.

Please note that if you plan to use non-foil mineral wool insulation, then the inside should be carefully covered with a vapor barrier film to prevent condensation from falling into the insulation layer.

Insulation of walls with ecowool

Another type of modern material that is increasingly used as insulation for brick walls is ecowool.

Ecowool is crushed cellulose fibers impregnated with special compounds for hydrophobization and fire retardants that prevent the spread of fire.

If ecowool is produced in accordance with the technology, then it is a highly environmentally friendly insulation material that is not afraid of fire or water, does not support the spread of mold and mildew and can serve for many years.

We invite you to watch a short video about this amazing modern material.

https://www.youtube.com/watch?v=wm1q_X5klK0

The only thing you should remember when purchasing is that you should not save money and purchase insulation from unknown dealers, since under the guise of ecowool you can simply buy ground waste paper that does not at all correspond to even a small part of the declared characteristics.

Tags: bathhouse, brick, steam room, insulate

« Previous entry

Insulating a bathhouse from the inside with your own hands: log house

Insulating a chopped and well-caulked bathhouse from the inside would be a tragic mistake. This is not only pointless and destructive for the walls, it contradicts the very idea of a chopped bathhouse.

Log houses for baths are made for two reasons:

- To get a classic Russian steam bath, which takes a long time to heat and maintains the required level of heat and humidity for a long time. It is the tree that accumulates heat and moisture and gradually “gives it away”. In this case, the inside of the bathhouse cannot be lined; You will also have to come to terms with the high consumption of firewood.

- For the image. No bathhouse looks as cool in appearance as a chopped one. But I often don’t want to waste time and firewood; I want the bathhouse to be heated in an hour, so insulation, vapor barrier and clapboard cladding are done. The log house works only as an external frame; the meaning of the material is lost. In this case, it is cheaper and more correct to build a frame bathhouse.

Plaster? Why not…

Another way to insulate the walls of a brick bath is plastering. And although this method is not very popular these days, let us recall the main points of its implementation.

So, a metal or fabric mesh is stretched over the brick walls of the bathhouse, and the solution is applied in three layers: initial (5-10 mm thick), primer (50-60 mm) and “covering” (3-5 mm, finishing layer)).

Adviсe:

- the locker room and rest room can be lined with wooden lining or slabs made of pressed shavings;

- in the steam room it is advisable to add a layer of mineral wool (between the layers that protect against steam and moisture);

- in the washing room, the walls are protected and at the same time decorated with tiles (heating occurs due to the heated floor).

Insulation of a frame bath from the inside

To insulate a frame bath, rolled mineral insulation is most often used.

To insulate the walls of a frame bath from the inside:

- Insulation is placed in the interbeam space of the structure;

- The next layer is vapor barrier (foil);

- Ventilation gap;

- Sheathing.

The photographs below show how KochevniK insulated his frame bathhouse. Insulation – basalt wool.

Insulating a bathhouse from the inside with your own hands: step-by-step instructions.

Foil acts as a vapor barrier, so it is important that there are no even the slightest holes or damage in it, and that all joints are well taped with high-quality tape. The tape is always sold together with foil, and its quality must be checked in the store (glue the tape to the foil and try to tear it off).