The bathhouse has its own microclimate, which creates steam, which contributes to better comfort for hygiene procedures. The properties of steam differ from simple room temperature air, including density and pressure. The durability of the building depends on a well-equipped vapor barrier, no matter what materials are used for construction. Experts recommend following 6 tips for arranging a vapor barrier in a bathhouse.

>

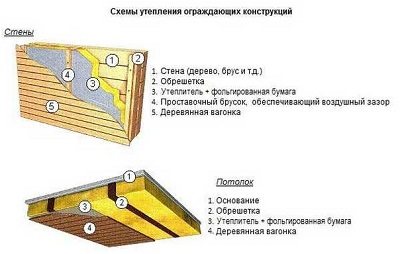

Walls

It is worth noting that the vapor barrier of a bathhouse made of timber and its walls is not much different from the technology of ceiling insulation.

The only difference is that the insulating layer of the ceiling must be several times thicker than the vapor barrier of the walls.

Foil or membrane film is usually used as an insulator for walls.

The places where the vapor barrier material meets the openings for windows or doors must be carefully coated with glue.

The sequence of laying insulating materials is described in the picture.

Attention! It is necessary to avoid the appearance of holes or gaps in the insulating pie, and seal all seams with metallized tape.

Introduction

Do you need a vapor barrier for the ceiling in a bathhouse and why do it, because previously there were no hydro-vapor barrier materials and bathhouses were built of wood and were used for a long time. In fact, of course, it is necessary and people have always thought about how to increase the service life of buildings and how to better conserve heat. Hence, as a consequence, modern solutions to these problems have emerged and new methods and materials for vapor barriers continue to be developed.

Is it necessary to protect the bathhouse from exposure to steam?

The service life of structures and buildings made from any modern construction material depends on a number of factors, many of which have an extremely negative impact on the elements of the structure. It is very important to neutralize them already at the stage of creating a construction project. Everyone knows that high temperature and humidity are mandatory attributes of a bath.

Humidity in the bath

When a person takes water procedures, they have a beneficial effect. But for the construction itself, it’s the other way around. Over time, moisture destroys the ceiling and walls of the bathhouse. These phenomena should be combated with the help of measures that provide high-quality protection from steam. It is worth considering that the baths consist of several compartments, characterized by their own level of humidity. The most moisture is always found in the steam room, where, in addition, very hot air circulates.

Slightly less water vapor in the shower room. And the “dryest” room in the bathhouse is the room for relaxation and rest, but even there the moisture level is always quite high. Materials for vapor barrier measures are selected so that the most reliable of them are installed in the steam room. But less effective means of steam protection can be used in the rest room and shower. This will save you money, and at the same time you will be able to make a high-quality vapor barrier with your own hands.

Materials for vapor barrier measures

As a rule, bathhouses these days are lined with wood materials on the inside. Through the cracks in such finishing, hot steam will penetrate to the insulation with each wash, destroying both it and the structure itself.

To avoid this, they perform a vapor barrier, installing it between the heat-insulating layer and the wooden sheathing. The walls and ceiling of the building need protection from steam. They are the ones who are susceptible to the negative effects of high humidity. Floors also require protection from condensation and water. But here we are no longer talking about vapor barrier, but about other operations - about waterproofing and drainage for a bathhouse.

Features of waterproofing a wooden floor

Wood is an ideal material for creating a bathhouse, but at the same time it is also the most short-lived. Because under constant exposure to water, such a floor will quickly deteriorate. In addition, it can become a source of mold growth. And while waterproofing bath floors under tiles is not difficult, protecting a wooden structure requires a special approach.

It is carried out in the following sequence:

- installation of floor logs (wrapped with film) at a level and arrangement of drainage to drain water from the bathhouse;

- laying a layer of thermal insulation (mineral wool, expanded polystyrene);

- waterproofing with rolled material, for example, roofing felt, additionally treated with liquid bitumen;

- wooden floors treated with an antibacterial compound.

It is very important to leave a gap of 3 centimeters between the finished floor and the waterproofing for ventilation.

All these actions will protect the floor in the room, including where the humidity is highest - in the washing room and provide a comfortable atmosphere inside.

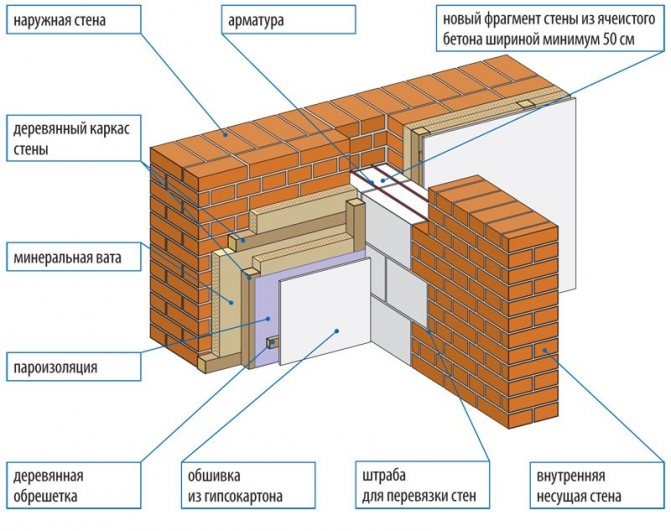

Vapor barrier for brick walls

Such baths are very rare and belong to elite and expensive buildings. Their vapor barrier is quite complex, in most cases two-layer. Brick baths must have insulation on the walls, and it is highly desirable on the interior. We have already explained why this is so.

Brick wall insulation scheme

Step 1. Selection and calculation of the quantity of materials. The quantity is easy to calculate: measure the quadrature of all surfaces and increase the resulting number by ten percent. It is more difficult with the selection of materials. As we have already noted, only materials that are safe for health can be used for thermal insulation of indoor baths. Not “environmentally friendly”, as it is now fashionable to say, but safe.

Penofol foiled with Aluf Reflective insulation from Penotherm

Step 2 . Surface preparation. Mineral wool must be protected on two sides: on the wall side from condensation moisture and on the bath side from steam. Carefully inspect the wall surface, remove all sharp protrusions. The fact is that most vapor barrier materials are not very durable; sharp protrusions can damage them, and this will significantly reduce their effectiveness.

Step 3 . Attach a layer of waterproofing to the wall, which will prevent the mineral wool from absorbing water from the relatively cold brickwork. You can use any cheap materials, the best option is liquid rubber. When attaching insulation, try to make do with a minimum number of holes in the material. If you use roll coverings, they are fixed with wooden slats, between which mineral wool will be laid. The width of the slats should correspond to the thickness of the mineral wool, the distance between them is approximately 40÷50 centimeters.

Waterproofing with liquid rubber

Waterproofing of brickwork by injection of microcements and methacrylate gels

Penetrating waterproofing

Step 4 . Place mineral wool in the free space between the slats and the wall, making sure there are no gaps. To ensure natural ventilation, a gap must be made between the insulation and the sheathing.

Insulation of walls with mineral wool

Step 5. For vapor barrier, we recommend using a composite material: aluminum film coated with polyurethane foam. It is stronger than ordinary aluminum film and has, albeit small, insulation. This material can be bent at different angles and can withstand fairly high tensile forces. In addition, a thin insulating layer seals the holes from the fastening hardware.

Vapor barrier with foil

Step 6. Carefully unwind the vapor barrier roll and nail it to the slats with thin strips. In this case, the planks need to be drowned a little in mineral wool - there will be a gap between your “pie” and the upholstery paneling.

Step 7 . Seal the joints of the vapor barrier material. To do this, you can take tape, metallic tape, or use silicone glue.

Vapor barrier for brick walls

Now you can start covering the walls with natural clapboard.

Prices for liquid rubber

liquid rubber

Video - What will happen when installing vapor barriers?

Features of the technology

To perform vapor barrier, simple technology is used. To make a ceiling vapor-tight, you must adhere to a certain scheme. On the rough boards you need to attach a roll of waterproofing (polyethylene film) or a special water barrier, which can be fastened with an ordinary stapler. The insulation is laid as a second layer. Its tasks are as follows:

- minimize steam leakage through ceiling cracks;

- cause heat to move from cool objects to warm ones gradually;

- minimize the impact of outside air on indoor temperature.

It is difficult for one insulation to cope with the functions assigned to it. Absolutely all brands of material are negatively resistant to moisture. This also applies to the most used option - mineral wool.

No material can compare with the latter in terms of thermal conductivity. But if water constantly gets on it, over time it becomes lumpy and stops performing its intended functions.

An important point is to protect the insulation from getting wet from the outside and inside. This task will be performed by a vapor barrier, which does not allow hot steam rising to the ceiling to moisten the insulation. To do this, for example, the same foil is attached to the top of the material.

Vapor barrier materials – which ones to choose?

The walls of the bathhouse can be protected with any traditional and more modern materials. The main thing is that they perform their task effectively. The easiest way to do a vapor barrier on walls with your own hands is to use an inexpensive polyethylene film. Firstly, it is completely waterproof, and secondly, it reduces the time required to heat the steam room.

Unfortunately, polyethylene deteriorates very quickly due to high temperatures in the bathhouse. Therefore, it makes sense to install films made from it as a vapor barrier only in a relaxation room after taking bath procedures. Moreover, it is allowed to use only polyethylene material that does not have seams formed when folding it. It is along these seams that the film literally begins to creep apart during operation. This problem can be solved (for a while) by gluing the folds of polyethylene with heat-resistant tape. But even in this case, the polyethylene vapor barrier will not last long.

Polyethylene vapor barrier for baths

The rest room in the bathhouse can be protected from steam with special construction cardboard - the so-called kraft paper. It has a high density, which makes it possible to slow down the process of moisture penetration into the walls. But, having been saturated with steam, it will also spread out and will have to be changed again. Some craftsmen perform vapor barrier with roofing felt, pieces of glassine and roofing felt. Theoretically, such materials are suitable for protecting bath elements from high humidity, but when the temperature rises, they release substances harmful to our body. And the “aroma” emanating from such vapor barriers leaves much to be desired.

Professionals advise using modern materials when carrying out protective measures in all bath rooms. These include:

- Aluminum foil. It does not emit unpleasant odors or harmful compounds when heated, and easily perceives elevated temperatures without changing its shape. It is placed overlapping on the walls of the bathhouse, connecting the joints between individual strips of material with heat-resistant tape.

- Vapor barrier films of different brands. They are truly innovative materials for protecting baths from moisture. Below we will take a closer look at films under the Izospan brand, which have recently become increasingly in demand both among construction professionals and among those who like to do housework with their own hands.

- Foamed foil polymers. They are also very popular, being an innovative combination of two materials at once - aluminum-coated foil and a foamed polymer compound. This vapor barrier is ideal for wall insulation. But it is not recommended to mount it on the ceiling - it may well melt under the influence of high temperatures.

We will consider materials for ceiling vapor barrier below.

Bathroom floor waterproofing technology

Waterproofing a concrete floor in a bathhouse begins with preparing the base. It must be cleaned of dirt and dust, all sagging must be removed, unevenness must be eliminated, and cracks and other defects must be filled with cement mortar.

If you plan to lay roll insulation, then the floor is treated with a bitumen primer and only then roofing felt or polymer film is laid.

Almost all types of mastic can also be used to insulate a concrete floor, as well as penetrating compounds that fill the pores of the building material. All of them fit perfectly onto the surface of the base and, after drying, form a waterproof continuous coating.

If the concrete floor and the bathhouse itself are insulated with mineral wool or expanded polystyrene, then the thermal insulation must be protected on both sides with a water vapor barrier membrane.

Izospan - excellent protection for walls

Products under the Izospan brand began to be produced in the early 2000s. This brand belongs to the Russian company Hexa. At the moment, Izospan films for protecting rooms with high humidity are sold in all CIS countries, receiving extremely positive reviews from consumers. The line of vapor barrier films under this brand includes different materials.

Izospan film for protecting rooms with high humidity

The leader of consumer liking is considered to be Izospan FB - a foil vapor barrier based on durable kraft paper, to which metallized lavsan is additionally added. This unique material can be used at temperatures above +100 °C. It has special characteristics due to which it can reflect thermal energy and at the same time serve as an excellent vapor barrier.

Izospan FB guarantees: a significant reduction in heat loss in the steam room through the roof and walls; protecting the ceilings and walls of the bathhouse from moisture. Vapor barrier Izospan FB is completely safe from an environmental point of view. The material has all the certificates indicating its high efficiency and absolute harmlessness to human health. Other combined materials of the Izospan brand are also worthy of attention. They can be used to protect against steam in saunas and baths, as well as other rooms with high humidity.

"Izospan FB" for vapor barrier

Pay attention to the following brands of films:

- FX is a complex vapor, hydro and thermal insulation made of metallized film and 2-5 mm polyethylene foam filled with gas bubbles.

- FS is a material made from non-woven polypropylene raw materials, which is covered with a metallized layer. It perfectly protects the structural elements of the bathhouse from steam penetration into them, and also protects them from moisture and reflects thermal energy.

- FD is a high-strength material made of woven fabric on a polypropylene base.

How to choose insulation and vapor barrier for a bathhouse ceiling (video)

Before moving on to insulating the ceiling from steam, you should talk about the basics of arranging a bath ceiling, namely insulation from the cold outside the room. The bathhouse should be designed so that the same temperature can be maintained in both winter and summer without loss.

How thermal insulation is produced in a bathhouse:

- Mineral wool. This is a very durable material, resistant to various types of influences. Moisture and high temperature are not harmful to mineral wool.

- Ecowool. Environmentally friendly and fairly cheap material.

- Expanded clay. It has exceptional thermal insulation properties, but it is a rather heavy material that requires good vapor barrier.

- Foam plastic and penoizol. A cheap, lightweight and convenient material that scares some people with its ability to release toxic substances when heated.

The best steam and waterproofing for a bathhouse is a foil-based material. It perfectly retains steam and, at the same time, reduces losses by reflecting heat waves into the room. There are people who are sure that foil for a bath does not affect anything, and this is a waste of money, however, as practice shows, almost everyone uses foil-coated materials when building baths.

Naturally, no one will use simple thin foil, since it is very easily damaged. Construction foil with a paper base is preferable.

There are several types of such material available on the market:

- RufIzol S. Has a moisture-repellent base made of kraft paper. Can be used at temperatures from -60 to 120 °C.

- Alucraft. This type of material has an additional intermediate layer between foil and kraft paper in the form of polyethylene film.

- Izospan FB. It is craft paper with a layer of metallized lavsan. It is not considered a metal, which raises questions about its suitability for use in a steam room. However, according to the manufacturer, the material can withstand temperatures up to 140 °C.

- Megaflex KF. Similar to the previous option.

- Yutafol H170 AL. It has a membrane consisting of 4 layers, and this vapor barrier is suitable for saunas and baths.

Naturally, the cost of such material will be significantly higher. It has enhanced thermal insulation properties, so it will be possible to save on additional thermal insulation (reduce the layer).

According to the manufacturers, fiberglass insulation is environmentally friendly, making it ideal for finishing baths. Although you will have to pay three times more for it than for kraft paper-based material.

Almost all the material on the market is unbranded.

Among the famous brands are:

- Thermofol ALST – up to 400 oC;

- Folgoizol;

- Armofol - up to 150 oC, there are variations on a self-adhesive base.

The following brands of foil material are available:

- Isover Sauna;

- Ursa (Ursa);

- Sauna Butts.

Bathhouse construction belongs to the category of structures with special operating conditions. The formation of a microclimate acceptable for the adoption of beneficial procedures, fuel consumption, and the time for warming up the premises depend on its proper design. The concept of “proper design” refers to a number of technological processes, one of which is the insulation of the bathhouse ceiling. After all, it is the insufficiently thermally insulated upper floor that contributes to the leakage of almost a third of the thermal energy.

The heated air, obeying the strict laws of physics, rushes upward. If there is no impassable barrier in its path, its further work will be aimed at heating the atmosphere. To stop such unreasonable spending, you need to erect a reliable barrier. Moreover, it must be done in such a way that it does not contribute to the formation of condensation on the wooden elements of the ceiling, so that this moisture does not favor the settlement of colonies of microorganisms that destroy building materials.

Based on the design features of the roof, bathhouses made of logs or timber can be divided into two types: buildings with and without attic space. In the path of warm air flowing out of bathhouses with attics, there will be a much more powerful ceiling, into the layer cake of which thermal insulation material is usually laid during the construction process.

The under-roof space itself, filled with an air mass, also inhibits the leakage of thermal energy, and the insulation of the roof structure also slightly moderates the agility of the “escaping” heat.

However, this does not mean that insulation of the ceiling in a bathhouse with an attic or attic is not necessary. Increasing the thermal insulation characteristics in it is no less necessary than in a building without an attic, where the heat leaking out encounters few and too weak barriers in its path.

The durability of buildings and structures made of any building material is always influenced by many factors, which must be neutralized at the design stage. This includes both the aggressive external environment and the climate in a particular area. No less harmful can be internal factors - exposure to moisture and steam indoors.

Insulation

Since ancient times, various natural materials that are still available today have been widely used to insulate wooden log houses: felt, moss, flax tow and hemp. These materials provide good air exchange in the room, are well sealed and, most importantly, they are absolutely safe from an environmental point of view.

To insulate baths, red moss is used, which is not subject to rotting and is popularly called building moss. The length of its fibers reaches 30 cm, which is convenient for caulking and interventional insulation. Cuckoo flax moss, which has bactericidal properties, is also used as inter-crown insulation. Moss is often added to flax fiber and tow to protect them from rotting.

Materials of natural origin are not without drawbacks; they can be damaged by insects and birds, are extremely inconvenient to use and are inferior to industrial materials in many respects. At the same time, in order to fully protect them from rotting, fire and insects, they often have to be impregnated with chemicals harmful to the human body.

Modern industry offers people more advanced insulation materials based on the same natural components - flax and jute fibers.

Jute insulation is rot-resistant, dense, environmentally friendly, and is cut into strips of different sizes, which ensures ease of use and an aesthetic appearance. It is produced in several types, such as: jute felt, flax wool and flax jute felt. Flax fibers are added to compensate for the stiffness and brittleness of the material.

When insulating walls, floors and ceilings, slab thermal insulation materials are widely used: mineral wool, polystyrene foam and foam glass. All three types are non-flammable, have high sound and heat insulation properties and are easy to install. Mineral wool insulation is produced in the form of rigid, semi-rigid and soft mats, slabs and rolls.

Advice from the master!

Everyone knows about the properties of foam plastic, but foam glass is a new concept for many. The whole essence of this insulation is contained in its name - it is a glass mass with many air pores inside. This insulation costs slightly more than those listed above, does not bend, can break during transportation and work with it, but does not contain any harmful chemicals.

Standing apart from other insulation materials is the so-called ecowool - insulation made from recycled cellulose (paper waste) with the addition of borax and boric acid, previously used in medicine. The last two components make it non-flammable and unattractive to rodents and insects. Once ingested, they are freely excreted from the body. The greatest harm that these chemicals can cause is boron poisoning (in case of kidney disease and direct entry into the body).

Loading …

Loading …

In order to protect the thermal insulation layer from steam, use:

- Membranes

- Various films

- Glassine

- Metal foil

- Tol

- Ruberoid

Roofing felt, roofing felt and glassine release substances harmful to health when exposed to heat. Therefore, although these materials have long been widely used for finishing steam rooms, their use should be abandoned.

Polyethylene protects the thermal insulation layer well from condensation. This method of vapor barrier is the most affordable and simplest. But the disadvantage of this method is the unpleasant smell.

Which insulation is better depending on the type of building?

When insulating the walls of a bathhouse from the inside, especially when working with a steam room and shower, it is worth taking into account the design features and materials of the building, as well as selecting a material that has a number of properties useful for this case.

The heat insulator for a bath should:

- be as low-hygroscopic as possible or non-hygroscopic at all;

- be environmentally efficient - non-toxic and environmentally friendly, chemically passive;

- have the ability to withstand high temperatures and be non-flammable;

- differ in steam and moisture resistance;

- have a high ability to maintain its original shape over time.

Taking into account all these characteristics, the most relevant choice for thermal insulation of a bathhouse is mineral basalt wool in combination with foil for the steam room.

The approach to the placement of insulation in a bathhouse depends on what material the bathhouse is made of and with what design features .

You may be interested in an article about insulating a wooden house from the outside.

From timber

A bathhouse made of timber or a log house requires comprehensive insulation of all rooms only if the size of the timber is small or the initial selection of not very high-quality materials for construction.

In other cases, it is enough to caulk all the rooms except the steam room in a wooden bathhouse along the cracks and carry out special treatment with solutions against the influence of mold, fungi, humidity and temperatures.

The steam room in a timber bathhouse is insulated with a single layer of basalt wool cake using a foil covering as a vapor barrier.

Made of brick

When insulating a brick bathhouse, it is necessary to ensure that the brick, which freezes very quickly in winter, cannot in any way influence the heat exchange processes in the bathhouse.

Warming up a brick bathhouse in winter without thermal insulation is a task beyond reason.

There are two ways to insulate a bathhouse (steam room only) made of brick:

- the second wall is made of timber;

- two layers of thermal insulation.

It is best to use wooden sheathing and walls in combination with thermal insulation, avoiding the use of metal, since it has a high thermal conductivity. Combustible insulation materials should be treated with fire-resistant compounds and anti-rotting agents.

Made from expanded clay concrete blocks

Insulating a bathhouse made of expanded clay concrete blocks requires the participation of a moisture-resistant heat insulator , since the porous structure of the walls of such a bathhouse retains heat well, but is extremely vulnerable to conditions of high humidity.

This structure is insulated with basalt wool in combination with waterproofing and vapor barrier layers, and additional ventilation can also be provided . When adding foil insulation to the structure, the insulation layer itself can be quite small, but waterproofing is required.

Sources used:

- https://remoskop.ru/folgirovannaja-paroizoljacija-potolok-bani-svoimi-rukami.html

- https://rubanya.com/utepleniy/kak-vybrat-i-smontirovat-paroizolyatsiyu-v-bane-svoimi-rukami.html

- https://banya-expert.com/uteplenie/paroizolyaciya-dlya-bani.html

- https://banya-expert.com/uteplenie/teploizolyaciya-dlya-bani-i-sauny.html

- https://moistenki.ru/izolyatsiya/uteplitel-dlya-bani-iznutri-na-steny.html