The main areas in the bathhouse and the features of using the floors in them

The bathhouse is divided into several thematic areas:

- Steam room.

- Washing room.

- Waiting room.

- Rest room.

There can be even more zones, for example, sometimes a shower and sauna are added. Conversely, some sectors can be combined and reduced to two - an area for direct procedures and a locker room/rest room. Therefore, the whole question of how to cover the floor in a steam room of a bathhouse comes down, first of all, to the degree of exposure to harmful factors in a particular place.

The most extreme conditions for the floor are created in areas of high humidity and temperature, as well as from exposure to detergents. At the same time, in the waiting room these destructive factors are practically excluded. However, the proximity to the bathhouse and the street always carries excess moisture. Therefore, even here it is necessary to use special processing tools.

The main factors of material destruction are:

- Heat.

- High humidity.

- Water.

- Formation of mold and mildew.

- Detergents.

- Temperature changes during the cold season.

Destruction of a wooden floor in a bathhouse by rot Source ytimg.com

Important! When choosing a treatment product, it is first necessary to take into account the likely harm to human health, and only then the degree of protection of the materials.

Bathhouse, steam room, washing room

Premises in direct contact with water and heat are exposed to the most destructive factors. Therefore, first of all, you need to know how to cover the floor in the bathhouse and steam room. As a rule, there is a special antiseptic for this. However, the effectiveness of the products used depends not only on the composition, but also on the structure and material of the floor surface.

In the steam room and washing area, the floor is made of wood or concrete. The first option has two varieties:

- Torrential . It is lined with boards located at a short distance from each other. Water naturally drains down into the gaps that form during bathing procedures.

- Solid . It also has a wood base, but unlike the version described above, water does not pass through the surface, but goes into the sewer system through specially equipped drains.

The concrete floor in the bathhouse is continuous and sloped to facilitate water removal. A wooden sheathing is usually placed on top of the screed. A metal flat bowl for catchment can be additionally installed at the bottom of it. In addition, tiles made from natural or artificial materials are often laid at the final stage of finishing.

Important! The use of a wooden or concrete floor in a bathhouse in winter requires insulation. This is only possible with proper hydro- and vapor barrier. At the same time, all structural elements must be treated with an antiseptic to eliminate the processes of rotting, mold and mildew.

Dressing room, rest room

The steam room and washing room are only half of the bathhouse, because in many ways the effect of the procedures depends on the correct subsequent rest. Therefore, it is also important to know what the floor in the dressing room should be like - what is best to make it from in order to provide all the necessary conditions for the relaxation room and locker room.

Insulation of the floor in the dressing room with expanded clay Source banyabest.ru

See also: Catalog of companies that specialize in the construction and repair of baths and houses

The floor in the dressing room is made based on how the bathhouse itself is used. If it is fully used all year round, then the floor surface must be insulated. The peculiarities of the operation of this room are that steam, splashes, dampness, and temperature contrast will also be constantly present in it. They are protected by a properly selected coating and a well-assembled structure - double flooring, insulation, hydro- and vapor barrier.

Advice! For comfortable use of a bathhouse at any time of the year, it is important to know not so much how to make a floor in a dressing room, but how to properly insulate it. When leaving the steam room to relax, a person can easily become hypothermic from contact with a cold floor covering. The optimal modern solution is the installation of heated floors. As a technical solution, heating can occur through pipes with water heated from a sauna stove.

Modern heated floors in the bathhouse Source pikabu.ru

Do-it-yourself warm floor in the dressing room: tips and tricks

The construction of a dressing room is a responsible task: the warmth in the bathhouse, and therefore the health of loved ones, depends on it. Correctly carried out work with finishing and insulation, as well as ventilation, significantly affects the temperature in it. In this article we will find out how to build and insulate a dressing room with your own hands and how to insulate the floor reliably and for years.

Preparation for construction

Before you make a dressing room with your own hands, you count the materials that will be needed for the work. Traditional Russian baths are built from wood, and the same material is taken before adding a dressing room. It is treated with an antiseptic in 2-3 layers. If this is not done, the dressing room will become covered with fungi and mold in a short time. It is recommended to treat the wood with fire-fighting mixtures, since fires in the bathhouse are not uncommon.

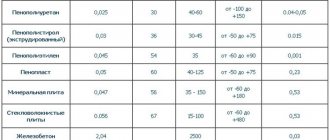

Moisture-resistant materials of inorganic origin are used as insulation for the dressing room. Inorganic materials are very resistant to water, unlike organic ones. It is better to insulate with stone wool, polyurethane foam, polystyrene foam, glass wool, polystyrene foam, etc. Polyurethane foam is the best material for insulation, as it is durable, has high moisture resistance, fire-resistant, noticeably insulates and evens out sudden temperature changes.

When deciding how to make a dressing room, you cannot do without a drawing. A well-thought-out project will not only help in the work, but will also prevent possible errors when measuring area and counting materials. To calculate the area of the dressing room from the inside, use the principle of 1.3 m^2 per person. The standard room area is 1.4x2.3 m^2.

How to install a foundation

Installation of the foundation begins with the removal of the top layer of soil.

At this stage we highlight the following actions:

- digging a trench 0.5 m deep and 0.3 m wide;

- filling the trench with compacted sand;

- installation of formwork;

- placement in the resulting structure of reinforcement 0.8-1 cm, along the edges of which galvanized steel pins are fixed;

- concreting.

After the concrete has completely dried, we cover it with roofing felt. Now you can add the dressing room itself.

Installation of the dressing room frame

To install a wooden frame, we perform the following algorithm:

- install a lower frame made of beams with a cross-section of 10 cm2;

- fix the corner posts, checking them for accuracy with a building level;

- install intermediate racks;

- install the top frame from beams (section 10 cm);

- fix the corner braces for rigidity of the building;

- fix the logs from unedged boards;

- secure boards for the frame of door and window openings;

- fill the frame with a wind and waterproof membrane;

- make external cladding.

Providing ventilation in the room

In the room, air circulates through openings - windows and doors. There are different opinions on how to properly install windows and doors in the dressing room. One number of experts believe that large windows are needed in the waiting room for additional ventilation.

Others recommend not installing windows at all or making them very small so that heat does not escape. When planning a dressing room, you can include windows in your project, or you can do without them.

But, one way or another, to maintain the microclimate in the steam room, you need to make vents. Ventilation plugs must fit snugly to the vent, and in the closed position absolutely do not allow air to pass through.

Flooring: how to insulate a dressing room

The bathhouse will become much more comfortable if the floors are insulated. Installation of a heated dressing room floor is usually made of wood using heat-insulating materials.

There are now several options for insulating the floor in the dressing room. There are several options:

- electric;

- water;

- infrared.

Electric heated floor

This type of flooring is a certain tape, cable or special heating film, which, by converting the current flowing through them, produces heat.

Installation of such floors occurs in several stages:

- gravel or crushed stone is poured onto the prepared soil to a thickness of 15 cm, then compacted thoroughly.

- form the basis

- then a concrete solution is poured there to a thickness of 5-7 cm

- Next comes reinforcement and filling with mortar,

- when the solution dries, the warm floor of the dressing room is installed directly.

- at the end the work is done once again by pouring and facing.

The preparation process itself is not complicated, but it is still better to entrust the actual installation of the system to professionals. This will allow you to avoid mistakes that are unacceptable in this matter: if even a local breakdown of the system occurs, it will no longer be possible to get to it.

Ceramic tiles are considered an excellent lining for electric heated floors. Firstly, it is practical and beautiful, and the heating of the system prevents it from being cold.

Water floor

This type of heated floor comes in two types according to the type of installation: flooring and concrete. In both cases, the heating element is a pipe filled with hot water. Now plastic or, alternatively, metal-plastic pipes are successfully used for these systems.

The peculiarity of their installation is the ability to create a completely sealed system, virtually eliminating breakdowns. This system works ideally in wooden houses and bathhouses. These materials are non-toxic, very hygienic and inert to water. Moreover, their warranty period is over 50 years.

For heating, you can also use not only water; the following coolants are suitable for this:

- antifreeze;

- ethylene glycol;

- specialized solutions.

To reduce heat losses, pipes should be laid on a layer of heat-insulating material. To increase heat transfer, place it on foil. They are mounted in two ways - “snail” or “snake.” The “snail” distributes heat more evenly. The “snake” is easier to install.

Further arrangement usually takes place in 2 options:

- use polystyrene plates equipped with grooves and lay pipes on top of them;

- lay the floor on a wooden base;

- They install the pipes and cover them with concrete screed.

Infrared heated floors

This heating system works thanks to the properties of natural heat, which is the infrared spectrum of radiation. Such a floor in the dressing room is usually made using a film into which heating elements are soldered.

The system operates from the network, so you need to be prepared for additional expenses on energy consumption. The good news is that they are easy to turn on and off as needed.

It is easiest to install such floors: the film is placed on the ground over the entire surface of the dressing room. A wooden flooring is made on top.

Interior decoration

Upon completion of insulation, work begins on finishing the dressing room. Usually it is covered with wooden clapboard, taking into account the unique design and style of the bathhouse. When covering the floor, the first step is to lay the beams on the waterproofing layer. And again, the entire tree needs to be treated with a water-repellent solution.

You need to fix the floorboard to the beams using self-tapping screws using the tongue-and-groove system. It would be a good idea to install a rubber coating on top of the boards. After the floor is covered, we proceed to finishing the ceiling and then the walls. You can sheathe walls in different ways. So, you can make clapboard cladding horizontally, vertically or diagonally. This is where your imagination comes into play.

External dressing room finishing

The exterior cladding of the bathhouse must match the style of the entire finishing of the bathhouse. Frame buildings made of wood look beautiful and aesthetically pleasing without additional finishing. Therefore, the bathhouse frame can be left in this form. Varnishing is an important final stage in working with the outer surface.

The completed dressing room in the bathhouse needs to be caulked and all beams thoroughly polished. After sanding, it is recommended to coat the wood with varnish for wood coatings or with a special paint.

When choosing a paint, we settle on the one that is intended for exterior work on a wooden surface. Insulation of the dressing room and proper ventilation maintain a favorable microclimate in the steam room. Due to the high humidity in the bathhouse, do not forget that organic materials need to be treated with moisture-resistant compounds.

Follow our advice - and a warm bath room will delight you for many years.

teplota.guru

What, when and with what to start processing

Before you start looking for a solution to the question of how to cover the floor in the bathhouse vestibule, you need to find out which places to treat first and which ones secondarily. You need to start with the structural elements located at the very bottom - the floor beams. This is done at the stage of construction of the log house. It is advisable to pre-process and dry them - even before placing them in the lower crowns.

You need to use special antiseptics for baths for this purpose. The number of layers depends on the instructions, manufacturer and component composition. However, in most cases it is recommended to impregnate the beams at least 2-3 times, after each complete drying of the previous layer.

Here it should be taken into account that this structural element will not be accessible during operation and will be subject to maximum exposure to destructive factors. In addition, the durability of the flooring will depend on its preservation.

Creating a double sex in a bathhouse Source blog-potolok.ru

Choice of impregnation

In order to reliably protect the floor structure from rot, fungus and other destructive factors, you need to know exactly how to cover a wooden floor in a bathhouse - namely, what types of impregnation exist for this. Today on the market you can buy compositions of the following 4 modifications:

- Water soluble . Suitable for rooms where direct exposure to water is excluded - dressing room, rest room, locker room.

- Organic solvent based . Ideal for use in steam rooms, washing rooms, showers - where there is maximum surface contact with water.

- Oil solution . Limited in use - suitable for areas with slight differences in humidity and heat.

- Combined . It has a universal set of properties - water resistance, antiseptic, fire protection.

Recommendation! Before applying impregnation, a long-painted, whitewashed or varnished surface should be cleaned down to the wood layer, carefully sweep away the shavings and sawdust and dry.

Colored impregnations for wood Source instrumentgid.ru

Selecting a Finish

Knowing how to cover the floor in the dressing room or the bathhouse itself will not only give the finish a modern, stylish look, but also preserve the surface from premature destruction. Varnishes and paints are used for finishing.

Varnish coating

The floors in the bathhouse are varnished at the final stage - after the previously applied impregnation has dried. In this case, you need to select either a composition specially designed for bath rooms, or one that does not include toxic substances and does not release their dangerous derivatives when heated.

Positive effects of varnishing the floor in a bathhouse:

- Protection of the flooring from mechanical damage (abrasion, drying out, cracking).

- Increasing the resistance of wood to physical and chemical factors - temperature changes, moisture, detergents.

- Giving the material antiseptic properties - which will provide it with protection from insects, microorganisms and fungi.

Apply varnish to the surface only after it has been thoroughly cleaned and dried. For even distribution it is better to use a roller or brush.

Painting

It is permissible to paint bath floors only using special paint. It should not contain harmful substances, including their release under the influence of hot water, air and radiation from heating devices.

When choosing paint, you need to take into account both the operating conditions of the room and the type of wood. For example, for coniferous species it is extremely undesirable to use compounds that form a dense, hard surface layer after drying. This can only worsen the situation with the formation of rot.

Advice! Oil paints are well suited for painting wooden bath floors. Among other advantages, they are distinguished by a wide range of colors, form a durable surface layer after drying and keep the natural texture of the boards visible.

Choosing flooring material

The main thing when creating flooring in a dressing room in a bathhouse is the correct choice of material, since moisture will always be present in this room. Water will constantly fall on the floor, then it will penetrate into the cracks and holes in the floor.

When choosing a material, you should rely on the following criteria:

- When you come to the store to choose material for the floor in the waiting room, its cost should be the last thing you pay attention to. The most important thing is to create a warm floor in the dressing room with your own hands. After all, no one likes stepping out of their steam room with their bare feet on the cold floor. You can also make a heated floor in the bathhouse under the tiles, this is quite effective and practical.

- For the floor, you should choose materials that will warm up quickly and remain warm for a long time.

The best option for making a warm floor in the dressing room is to use wood as a covering. It is recommended to additionally treat it with special protective agents.

Conclusion

Arranging the floors in the dressing room is not a very difficult task, so even a non-professional builder can solve it, the main thing is that everything is done according to the instructions. During the construction of a bathhouse, the correct construction of the flooring in the dressing room is very important. Depending on how the floor in the dressing room is insulated, good or bad, the air temperature in the room will depend, and how long this indicator will remain.