Not everyone can afford an oak bath due to the very high cost of the building material.

Oak wood is special, its main feature is its density of structure and strength, these properties allow the wood not to warp or crack under the same conditions in which other wood does. You can rarely find a bathhouse made of oak, not only because of the high cost of the material, there is another reason, this is the thermal conductivity of the material. Oak gets very hot and is uncomfortable to sit on or touch in a heated steam room. So, those who want to build a bathhouse from oak can be recommended to additionally cover the steam room with a more comfortable material.

Material selection

When choosing timber, you should pay attention to its quality. The manufactured spruce beam must be even and smooth . You need to choose the material very carefully, because... there should be no knots on it. You also need to pay attention to the color of the log.

Spots of characteristic shades are a sign of rotting wood. The timber should be light and monochromatic without various pigmentations. It is necessary to carefully examine the timber for cracks. The fewer cracks in the wood, the longer it will last.

Our advantages

- Professionals

- Special equipment

- Delivery within the Moscow Ring Road

- Environmental friendliness

- Profitable price

- Guarantee

has a full staff of highly qualified specialists and a fleet of all necessary equipment from tractors to mobile power plants and high-performance logging complexes. We do not have to hire outside workers or rent equipment, which allows us to significantly reduce costs, and therefore the cost of a finished hand-cut bathhouse. The price includes delivery to the Moscow Ring Road and the northern part of the Moscow region. Before shipping, quality control of wood and cutting is always carried out.

We build baths and houses from environmentally friendly materials. Logs are harvested in the forests of the Kostroma region, far from large cities and factories. When relaxing in a bathhouse built by our company, you will be sure that you are breathing clean and healthy air.

comments powered by HyperComments

The main steps when creating a bathhouse from spruce

As with any construction, the first stage is the foundation . It is this that is the key to the stability of the future structure. In addition to stability, the foundation protects the structure from groundwater.

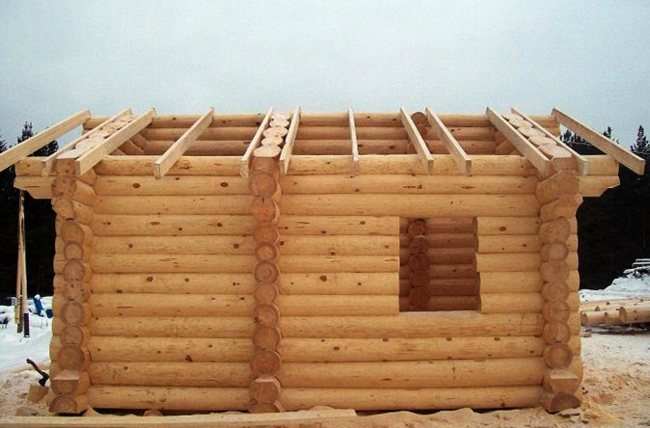

Then the laying of the timber begins. Each subsequent link is superimposed on the previous one. At the same time, at the junction points, the logs should fit perfectly on top of each other. To lay logs in the areas of window and door openings, the material must be adjusted in advance in size, based on the design of the bathhouse.

Fastenings and additional elements when building a spruce bathhouse must be purchased in advance, depending on the main material used.

In order to understand why many people choose this tree species, it is necessary to understand its positive and negative qualities.

Construction of a building

The process of building a bathhouse can be divided into several separate stages. Each of them has certain characteristics.

Foundation and floor

Under a wooden bathhouse you need to make a strip foundation. It is suitable for different types of soil and can withstand the weight of a two-story building. Construction of the foundation:

- Mark the boundaries of future construction and trenches.

- Remove all trash from the designated area, cut down trees, and uproot stumps. If possible, remove the fertile layer.

- Dig trenches. Their depth depends on the freezing point of the soil. The suitable range is from 50 to 80 cm.

- Place a 20 cm layer of sand at the bottom of the dug trenches, pour water over it, and tamp it down.

- Assemble wooden panels from boards and bars. Cover the inner sides of the boards with thick polyethylene film. It is needed to prevent the cement from leaking out.

- Put together the panels into a single formwork and install them along the boundaries of the trenches. Spread with bars.

- Tie a reinforcing frame from reinforcement and install it inside the trenches.

- Pour cement mortar. Stretch it evenly over the entire base. Tamp the solution so that air bubbles come out.

The foundation will take about 30 days to dry. After this, you can dismantle the formwork, level out the unevenness, and begin further work.

Construction of a strip foundation (Photo: Instagram / artem_pososhkov)

Walls

Construction of walls:

- Before laying the crowns, you need to cover the concrete base with liquid mastic and lay out 2 layers of roofing material.

- It is recommended to cover the beams for the first crown with used motor oil to protect them from rotting, the spread of fungus, and mold.

- The assembly of the crowns occurs through choppers, which are driven into the drilled holes. It is necessary to lay out jute or flax between the crowns.

- The rounded timber is placed in special grooves, which are located in the corner joints.

A frame house is assembled differently. A strapping crown is fixed on top of the foundation. Vertical racks with braces are installed on top of it. The entire structure is connected by an upper strapping crown.

Windows and doors

The arrangement of window and door openings can be done in two ways:

- Cut openings in the finished log house using a chainsaw.

- Designate the location of doors and windows in advance. Lay out the timber in a certain sequence.

The ends of window and door openings need to be reinforced with metal corners.

Windows for a bathhouse (Photo: Instagram / tovary_dlya_bani_)

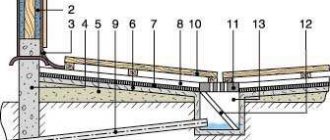

Ceilings and roof

Arrangement of the roof, ceilings:

- Ceiling beams are fixed on top of the last crown at intervals of 60 cm from each other.

- Identical pieces of boards are placed on top of the ceiling beams, which will be the rough ceiling.

- Separate sections of the rafter system are assembled on the ground, installed on top of the ceiling beams, and assembled into a single system using lathing.

- A vapor barrier wire is secured to the sheathing with a construction stapler.

- A counter lath is placed on top.

The last stage is the installation of roofing material.

Communications

Communications are an important stage in the construction of any private house or bathhouse. If you do not lay a water supply pipeline or install a sewer system before starting interior finishing, problems with dismantling may arise.

Electricity

Wires can be laid over the finishing material, closing them in special protective boxes. You can also hide them inside the walls if you pass them through corrugations made of non-combustible material.

Sewerage

Sewage drains in summer cottages are carried out to drainage wells or septic tanks. They are assembled from large-diameter plastic pipes, since this material is cheap and more resistant to chemicals and liquids.

Septic tank (Photo: Instagram / aqua_search.ru)

Water supply

To assemble a pipeline for supplying technical and drinking water, it is better to use plastic pipes. A drain point must be installed in the system so that liquid can be removed before the onset of winter. When laying a pipeline along the street, it is important to protect it from the effects of cold with a special protective casing.

Wall treatment

When treating wooden surfaces in the steam room, you cannot use chemical antiseptics or fire retardants. Surfaces can be impregnated with special oils or wax for saunas and baths.

Thermal and waterproofing

Thermal and waterproofing consists of several layers - a vapor barrier film, a wooden frame made of bars, insulation, foil film, slats, and finishing material.

When purchasing insulation, you need to consider what zone it will be used for. For the dressing room, you can use mineral wool. For a washing room or steam room, it is better to choose foam glass.

Positive aspects of using spruce in the construction of a bathhouse

- Spruce belongs to the category of coniferous trees. One of the main advantages of this material is its availability in the markets . Prices for this material leave much to be desired, so when building a bathhouse, you can choose the most optimal size of the structure based on your own budget.

- Because This breed is easy to process; the material can be easily manipulated and modified at will.

- Spruce is a fairly durable material, so when the wood dries, the deformation of the elements is insignificant, which helps to avoid cracks in the wooden elements.

- It is worth noting that wood has the property of natural filtration. This allows you to minimize dampness in the bathhouse.

- The use of coniferous wood is determined by the lightness of the material. Thanks to this property, there is a small load on the foundation. Therefore, when creating a foundation for a bathhouse, you can significantly save on the amount of necessary materials.

- The quality of this material is reflected not only by its technical properties, but also visually. Spruce retains its shade of whiteness relatively longer than other tree species. Therefore, the process of treating the bathhouse with pesticides from the inside can be eliminated.

Calculation of building dimensions

When calculating the dimensions of a building, several parameters need to be taken into account:

- Constant number of bathhouse visitors.

- Number of rooms. There must be at least 3 functional rooms - a dressing room, a washing room, a steam room. The remaining rooms will be used as a recreation area.

- The amount of free space for visitors. Builders recommend taking 2 m2 per person for each room.

- Availability of free space on the site.

You can save space by adding a terrace, a full second floor or an attic.

Bathhouse with attic (Photo: Instagram / domikbani)

Disadvantages of using this type when building a bathhouse

- The use of spruce in the construction of a bathhouse, along with its positive qualities, also has some disadvantages:

- One of the negative qualities of using not only spruce, but also other types of wood is the release of resin . This property is especially active at high temperatures. And because The bathhouse requires exactly this temperature, which makes it inconvenient to use. Moreover, in some cases, this can negatively affect human health. Resin is released in smaller quantities only after a couple of years of operation of the bath. After about three years of using the sauna, the resin will no longer seep through the log. Because The release of resin is comparatively greater than that of other species; the tree is finished with material from deciduous plants.

- Along with the cessation of resin secretion, the dried spruce will begin to accumulate moisture, and this is fraught with the appearance of fungus. To avoid exposure to fungus and mold, the log will have to be treated with special chemicals.

- Over time, the log settles up to 14%. Because of this, you will have to make some efforts to preserve the positive properties and visual qualities of the bathhouse.

- The outer walls of the bathhouse are exposed to natural phenomena: rain, sun, etc. This has a negative impact on conifers. In order to extend the life of the log, it is necessary to treat its outside with protective agents.

Requirements for structures

Requirements for the location and construction of wooden baths were invented to make the building safe for visitors. They are spelled out in several government documents:

- SNiP II-25-80.

- SNiP 2.01.07-85*.

- SNiP 2.02.01-83*.

- SNiP II-L.13-62.

Requirements for distance to other objects and buildings:

- residential building - 8 m;

- trees - 3 meters, bushes - 1 m;

- natural, artificial reservoirs - 25 m;

- neighbor's plot - from 1 m;

- wells, wells - from 12 m;

- forests - 10–15 m;

- roads - 6–10 m.

These are average standards, errors are possible.

Fire safety requirements:

- Electrical appliances inside the bathhouse must be grounded.

- There must be a working fire extinguisher in the rest area room.

- The walls around the stove should be covered with reflective screens.

- A metal sheet must be fixed to the floor in front of the combustion chamber.

- The stove should be located above the floor level at a height of 12 cm.

- Do not use flammable mixtures or chemicals to light stove equipment.

The bathhouse should be located on a hill and not create smoke in residential buildings when the stove is fired. You can install an electric oven.

Forest (Photo: Instagram / makc_krupskiy)