When asked how a metal stove differs from a stone stove, many answer with a smile and without the slightest hesitation - the material of manufacture. For such an answer you can give a three on the five-point knowledge assessment system. To get a higher score, familiarize yourself with the main and fundamental differences; this knowledge will be very useful to you when making a metal sauna stove with your own hands.

Do-it-yourself metal sauna stove

The stone oven is made of heavy bricks and therefore has a large mass. And all bodies with a large mass are characterized by significant inertia - they heat up for a long time and give off heat for a long time. This is not bad for a bathhouse, but only under one condition - the firebox design must ensure the maximum combustion temperature of the wood, otherwise you will have to heat the premises for a long time.

A metal stove, on the contrary, has a low mass, heats up quickly and cools down just as quickly. These features put forward fundamentally new requirements for the firebox; the wood in it must burn for as long as possible. This is the only way to keep the oven hot for a long time.

Sauna stove firebox

Another important requirement for the firebox is related to the characteristics of the steel. When heated to just +150°C, martensite begins to decompose, it recrystallizes and polygonizes, and the physical properties of the metal change.

Dependence of color on metal heating temperature

Look at the table, at this temperature the metal furnace does not change color, it seems to us that everything is normal, but this is no longer the case. Low-temperature tempering occurs at metal temperatures up to +250°, steel loses its resistance to dynamic loads.

Red-hot furnace metal

The dark brown color of the furnace indicates that the metal has heated up to a temperature of +550°C, and at these temperatures medium-temperature tempering of steel begins, martensite turns into ferrite and cementite. Crystalline transformations of a metal change its linear characteristics. Have you noticed that sheet iron does not return to its original size after strong heating and cooling? It may swell, lose linearity, etc. The appearance of the stove becomes “very original” and far from the original.

Not only stoves, but also metal chimneys suffer from high temperatures

But quite often the metal stove heats up even more and turns bright red. This color appears at a heating temperature of +900°C. And this is already a high tempering, the metal becomes very soft and ductile, and the phenomena of residual deformation increase significantly. The stove may warp, and the welds may not withstand the static forces that appear. How to prevent such negative phenomena? It will not be possible to completely get rid of them, but there are ways to minimize them. They will help increase the operating time of a metal stove and improve the comfort of bathing procedures by increasing the time it takes to maintain a favorable temperature in the room.

Effect of tempering on the mechanical properties of steel

Maintenance

Both brick and metal sauna stoves need to be inspected periodically. Routine repair of a brick stove involves a complex of small works, the implementation of which does not take much time. We can say that a brick stove for a bathhouse requires routine repairs if it is necessary to carry out one or more of the following operations:

- replacement of valves, grates, doors;

- filling cracks;

- replacement of individual bricks.

To strengthen and, if necessary, replace the combustion door, it, along with the frame, is pulled out of the stove masonry. Often it becomes necessary to pull out several bricks.

Inspect the frame legs. If they have already become unusable, they must be replaced with new ones. The tabs are also placed on the new door if you are completely replacing it.

The masonry where the door is installed must be cleared and moistened with water. After this, the frame is installed in place, making sure that the legs fit into the masonry seams. It is advisable to leave a 5-10mm gap between the frame and the masonry, which should then be sealed with asbestos cord. If you don’t have a cord, you can lay it close to the frame.

The laying is carried out in the usual way, completely filling the seams with mortar. Individual bricks that have become unusable are replaced with new ones.

When the frame is strengthened, the existing cracks must be covered with clay mortar.

Replacing grates

A brick stove for a bathhouse requires such repairs quite often. Actually, this is not even a repair, but rather a service maintenance of the stove, like treating a bathhouse made of timber with an antiseptic.

The burnt-out grate is removed, the installation site is thoroughly cleaned of ash, and a new grate(s) are installed.

Sealing cracks

Here, too, everything is simple: the cracks in the seams between the bricks must be cleared to a depth of 20-30 mm, the excess mortar must be removed, the cleared area must be moistened with water and filled with clay mortar.

Most often, a brick stove for a bathhouse requires replacement of those bricks that have cracked under the influence of high temperature or its sudden changes.

- The cracked brick is removed by clearing the seams around it.

- In the vacant space, carefully remove the remaining solution.

- The new brick is first tried on for size, then it is well moistened with water, coated with clay mortar and placed in the prepared place.

If the clay has not completely filled the seams, they are additionally coated, carefully pressing the solution.

Typical design of a sauna stove. Finnish and Russian sauna stove

Iron stove in a Russian bath

If we talk about Finnish and Russian baths, they both have similarities and differences.

In a Finnish sauna, the thermal effect is achieved due to higher temperature and dry air.

As a result, fluid is actively removed from the body through sweat.

It is very effective for losing weight.

However, this can be harmful for people with a weak circulatory system or diseases of the internal organs, skin, and endocrine system.

In a Russian bath, a lower temperature is maintained, but a higher thermal effect is achieved by creating increased humidity in the room using steam.

This allows you to add various herbs, infusions and drinks to the water to create steam, transfer steam from the air to the body using a broom, creating a massage effect and creates a healing effect from substances from the leaves of the broom. It is safer for the entire body, but is less effective for weight loss and may be difficult for people with weak hearts.

Traditionally, both baths used a stove, where stones were used to radiate heat from the stove to the steam room. Now stones are used only in Russian sauna stoves, since for a Finnish sauna a regular stove without stones with a good heat convector will be sufficient.

If you want to make a Finnish sauna at your dacha, you can successfully use a ready-made metal stove of the “buleryan” type for it - a Breneran stove with several convection pipes. It will allow you to quickly create the desired air temperature with minimal wood consumption.

In a Russian stove it is necessary to make a stove-heater. This oven uses stones on which steam is splashed. It is necessary to provide access to stones.

It is optimal to place them on top of a metal stove behind a special side so that you can splash water on them and not be afraid that some stone will break and they will fall. Some stoves are made without smoke circulation, passing smoke from the firebox directly through the stones.

In this case, they heat up faster. In this case, the stones should be placed in a lockable cabinet so that the smoke during the fire does not penetrate into the steam room.

They will become covered with soot during operation, which over time can create a faint tar smell from the steam. Some people may not like it, and then the stones should be replaced. In general, such a furnace takes up less space and requires less welding work.

In a Russian bathhouse it is customary not only to take a steam bath, but also to wash. For this, warm water is usually used, which is heated right there in the steam room.

If you do not want to use stones for a Finnish sauna, you should think about a thermal convector. A thermal convector is a device made of many metal plates that have direct contact with the wall of a metal stove, and from which heat is transferred to the bathhouse more efficiently.

You can weld a row of these plates on the side of the stove with your own hands, the main thing is not to burn through the steel of the stove itself during welding. If the stove is cast iron, it is unlikely that it will be possible to weld it; you will just have to make a frame with these plates and fasten it so that it is in contact with the stove.

Let's move on to the design of the furnace itself. Any stove, not just a bath stove, consists of three parts - the combustion part, the smoke circulation system and the chimney.

A do-it-yourself iron sauna stove, the drawings of which are presented below, cannot be compared with any other. Let's start with the combustion part.

The combustion part consists of a firebox and a blower-ash chamber. They are separated by a grate, the ash chamber is located below the firebox.

Electric sauna stove

When wood burns in the firebox, ash is formed.

It is gradually poured into the ash chamber, from where it is raked out as it is filled.

The firebox door must close well to prevent burning logs from falling onto the floor of the bathhouse.

It should have a lock that can be closed by turning the handle.

In addition, it is desirable that the firebox handle be self-cooling - this can be done by attaching a spring to a standard handle, so it can be opened and closed with bare hands.

The ash chamber for a metal furnace is conveniently made in the form of a retractable tray-box. It occupies the entire volume of the ash chamber, and during the fire it is slightly open so that air can flow through it into the firebox for burning wood.

After you have finished steaming, use a poker to push all the remaining ash into the ash pan through the grate, pull out the drawer and take the ash out of the sauna.

The combustion chamber of a metal furnace must be lined. The lining is made with refractory bricks, using a special clay refractory mortar.

In order not to bother you with the intricacies of preparing this solution, I will say that it is easier to purchase it in the store as a dry construction mixture and knead it according to the instructions.

Typically, lining is done by laying refractory bricks on the floor of the firebox, with a grate embedded in it, on an edge along the walls. In some cases, the upper part of the firebox is also lined.

Since it is difficult for a home craftsman who is not knowledgeable in the furnace business to line the top of the firebox, we can recommend covering the top of the firebox with a thick sheet of stainless boiler steel 12Х18Н10Т, which was mentioned earlier. This sheet will not burn out very soon, and you can save money by making only one of the most important parts in your furnace from this steel.

You can also use a heat dissipation grille at the top of the firebox, which is not in direct contact with the overlying sheet metal. It will burn out first from the action of fire, and it can be easily replaced if necessary.

If the firebox is small, about 200 mm wide, then it can be simply covered with one row of bricks across. Therefore, it is often necessary to make the compartment under the firebox in an iron sauna stove narrow and high enough so that more logs can be placed there or placed there, given the small width of the chamber itself.

Smoke circulation is designed to increase the area of contact between the surface of the stove and the gases that escape from the fuel during combustion and exit into the chimney. This increases the efficiency of the stove, since less heat will escape with the smoke.

It is optimal for a sauna stove to perform one or two smoke rotations. If you use smoke passing through stove stones as described earlier, you can do without them altogether.

If there are smoke circulations, due to the small dimensions of the stove, it is most rational to place them horizontally above the combustion chamber so that the stove is larger in height and not in length. The dimensions of the stove are a fairly important characteristic for a not very large bathhouse.

In some cases, smoke circulation is made in the form of a hog passing through the bathhouse, for example, under a stove bench. Although this is more typical for a Turkish bath, many will certainly like this design, where you can lie on a warm bed covered with mosaics.

The hog is made exclusively from brick. It must be remembered that to ensure good traction through the hog, you need to install a pipe of greater height.

Chimney. Quite an important part of the stove, although many do not attach importance to it. The stove pipe for an iron sauna stove is usually also made of iron.

The material here can be used as a piece of ordinary water pipe, since if the stove is made correctly, nothing will burn out in the pipe, and it will be protected from high temperatures.

The chimney must have one very important property - it must have good thermal insulation from the outside air. This is especially important for large pipe heights.

Otherwise, the air in the pipe will quickly cool as it passes through, and will press down, as a result, the draft will disappear, and during combustion, the smoke will escape into the bathhouse. For thermal insulation, you can use mineral wool wrapping the chimney.

It is best to wrap not only the attic, but also the part that faces the street. The outside of the wrapped pipe must be protected with fiberglass or other material to prevent rain and sleet from getting on the mineral wool.

You can use standard metal structures for the pipe, which are produced immediately with insulation and external insulation in the form of a layer of roofing sheet. Unfortunately, immediately placing this structure on the stove is unlikely to be a good solution, since there is a problem with humid air in the steam room, due to which the mineral wool can become damp.

According to fire safety rules, the distance from the chimney to the combustible parts of the roof and ceiling must be at least 25 cm. For a sauna stove, by the way, the same standard applies.

Typically for a brick pipe this space is filled with otter and fluff. For a metal pipe, it is common to place an asbestos gasket around the pipe, and then a metal sheet that fills the area between the pipe and the wooden roof and ceiling structures.

To increase traction, it is customary to equip the pipe with a deflector. This is a device, like a small “roof” over a pipe. The deflector also prevents rain and snow from entering the chimney.

Do-it-yourself iron stove for a bath (see photo with a pipe below), where the deflector is made of various designs, in the form of a rectangular recess, or even with patterns made of tin. The simplest version of the deflector is to make a cutout in the pipe itself using a gas cutter or welding, leaving two legs, and weld a metal plate-cover on top of them.

At the base of the chimney there is usually an important part such as a valve. When the wood in the stove burns out and only coals remain, the valve is closed. The coals smolder slowly, retaining heat for as long as possible, and without releasing it into the atmosphere through the chimney.

Feringer oven models

This brand produces both sauna stoves - with a closed heater, and sauna stoves - with an open one.

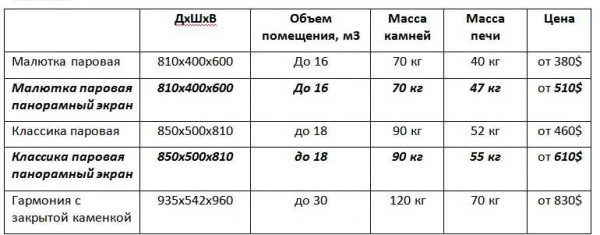

The category of sauna stoves is called “steam stoves” by Fehringer. There are five options. Their technical characteristics are presented below. The price is indicated approximately in dollars due to exchange rate instability.

Furnace models

If we talk about modifications of stoves to create a Russian bath mode, then there are three models:

- Feringer Malyutka Steam for small steam rooms up to 16 cubic meters;

- Feringer Classic - for medium volumes - up to 18 cubic meters;

- Feringer Harmony for steam rooms up to 30 cubic meters.

All of these ovens have the same internal structure, only the dimensions differ. The stoves can be equipped with solid cast-iron doors, doors with glass or a panoramic screen (the result is a fireplace stove).

Lamel stoves are included in a separate category.” They also create the atmosphere of a Russian steam room. They are made entirely of AISI 430 stainless steel, 3 mm thick.

This is what the lamellas look like

In this option, you can order a stove with an open heater and a closed one, with a stacked lamella (from several pieces) or a solid one. The stone used is soapstone, serpentine, jadeite, marble and numerous combinations thereof. Moreover, the thickness of the finish can be different. Therefore, overall dimensions are not indicated.

Technical characteristics of Feringer Lamel sauna stoves (to enlarge the table, right-click on it)

In an open heater, the top of the container can be trimmed with metal or stone. The screen can be a regular size, or it can look like a fireplace portal. So the prices here are really “from” - the cheapest option.

These stoves have an open heater. In the catalog they are located in the “Golden Ratio” section. The table summarizes the main technical data; the price is indicated for the option with a standard door with transparent glass. It is possible to install a panoramic screen.

Technical characteristics of Ferniger sauna stoves (to enlarge the table, right-click on it)

How to drown

Due to the unusual design - without grates, fuel loading and ignition in Feringer sauna stoves are different.

The firewood used is of short length, but they are stacked on top of each other, filling 3/4 of the volume. The firebox of the Mini model can accommodate logs up to 270 mm long, for Optima and MaxI - 310 mm. Both whole logs with a diameter of up to 18 cm and chopped into large and small pieces are used.

Before filling, the following are opened: the upper damper on the door, the damper on the chimney. Closed: the lower gate on the door and the heater purge valve (if there is a network). Coarsely chopped firewood is placed at the very bottom of the firebox. You can put one whole log in the Optima and Maxima fireboxes, and surround it with medium-sized fragments.

After the wood starts to burn, a hum is heard. It means that there is too much oxygen, the combustion is too strong. Therefore, the gate at the top of the door must be gradually closed. With the optimal amount of air, the hum disappears. If the chimney in the bathhouse turns out to be very high (above 8 meters), then the adjustment is carried out with a chimney damper (until the hum is eliminated).

If there is an economizer on the pipe, after reaching normal combustion mode, you can begin to humidify the air and activate heating of the steam room. To do this, boiling water is poured into the economizer tray. The oven is left in this mode until the desired temperature is reached. The duration of warming up depends on how correctly the stove is selected, how it is installed, and how the steam room is insulated.

Boiler structure. Methods of heating water

Boiler for water in the bath

A boiler in an iron stove for a bath is usually installed outside the stove.

Typically the boiler material is also metal.

Most often, it has a lid for pouring cold water into it, and a small tap for taking water from there and using it.

Since, unlike a brick stove, the walls of an iron stove have a much higher temperature during operation, you can simply place the boiler close to the stove, or fix it on the wall of the stove.

In this case, the water will heat up better if the boiler has one flat wall, as close as possible to the wall of the furnace.

Therefore, it is better to use a “cube” type structure welded from sheets of metal, rather than a round metal barrel adjacent to the stove with only a small surface area.

It is better to use stainless steel as the material for the boiler. If there is none, you can use regular black one. You can also use enamel containers.

You cannot use aluminum or plastic for the boiler, as they can be destroyed by the temperature outside the stove, especially if there is no water in the boiler. The thickness of the walls of the boiler made of stainless steel can be from 1.5 to 3 mm, of black - at least 3 mm. You can use galvanized steel if you are not using the boiler to heat water for food purposes.

If you are unable to place the boiler inside the steam compartment due to its large dimensions, you can place it in the dressing room. In this case, use the old method of heating water.

When firing a stove-heater, after the stones have heated up, you need to take several hot stones and put them in a bucket. Bring the bucket to a container of water, or even a wooden or plastic one, and pour these stones into the water. Hot stones will give off heat to the water, and it will become warm.

What types of wood are most often used?

You need to understand that different types of wood material are characterized by their density and heat output. These indicators directly affect how much fuel is needed to achieve the required temperature level. We will consider trees that grow in Russia. The hornbeam produces the most heat, the poplar the least. As a result, you will need very little of the first type, and an impressive amount of the second.

Obviously, hornbeam does not grow everywhere, so sometimes you will have to replace it with what you can find in your area. In this case, you need to take into account the fact that not the first tree you come across will do. The most common species are alder and birch. They burn excellently, and what is important, when heated, they release aromatic essential oils. Pine wood is also ubiquitous, but its problem is that when it burns, it releases resin, which will clog the chimney.

The choice of wood is important, but you still need to figure out how to properly heat a sauna with wood. We will also dwell on this topic in detail further.

The best options to consider as fuel are:

- Hornbeam is an ideal option. It burns for a very long time and produces very little smoke.

- Acacia - is characterized by the fact that it allows you to maintain a constant level of heat in the firebox.

- Linden - it is not very dense in its structure, so it burns quickly without leaving behind hot coals.

- Oak is an excellent option; it fills the room with a pleasant aroma while burning and gives off enough heat. The cost of such firewood is high, however, they can be stored for a very long time and do not change their qualities.

- Birch - burns quickly and evenly, releases substances into the air that allow you to clean the steam room from harmful microorganisms. It is better to use those logs that were prepared quite recently. Watch the amount of firewood thrown into the stove; when there is a lot of smoke, tar begins to be released, which clogs the chimney.

- Pine or spruce. They should be used as a last resort, when there is simply no other material. Resin contaminates the walls of the smoke exhaust pipe quite quickly. When figuring out what kind of wood you can’t use to heat a bathhouse, this option is first on the list.

We invite you to read How to knit brooms for a bath: instructions for beginners

Once you have decided on a specific type of fuel, all that remains is to learn how to prepare it correctly. Of course, this option is more relevant for those who prefer not to buy ready-made logs.

How to light a stove correctly

If you heat a sauna stove, you need to take care of the quality of the firewood. It is best to use birch logs. They should be of such a size that several pieces can easily fit into the combustion chamber.

It is better not to burn with spruce or pine wood. They create a lot of soot and your chimney will quickly become clogged. Also, you should not heat the stove with aspen or alder wood. They also produce a lot of soot and do not burn well.

For kindling, it is best to use crumpled newspaper and splinters. Place the newspaper in the gap between the logs at the bottom, stick a few splinters between it and the logs and light it with a match.

If the firewood is damp, you can try putting only two logs in the firebox, and between them put newspaper and more logs. When these two logs flare up, add more firewood.

Fault diagnosis

You can diagnose the condition of the stove yourself, without involving a professional stove maker. Troubleshooting methods include:

- inspection of external damage;

- assessment of the operation of a flooded furnace.

Diagnosis of faults begins with an external examination. The joints in the masonry, walls, foundation, firebox, chimney in the house, attic and roof are subject to assessment. The condition of metal parts and components (hob, valves, firebox door, grate, firebox lining) is checked.

Reference. A stove in need of repair has one or more external signs of malfunction: cracks in the masonry, in the foundation, in the chimney, in the seams between the bricks. Fragments of burnt bricks are visible inside the firebox. The door is loose, broken, the hob and grates have cracks.

Then the furnace is flooded and its “in operation” condition is assessed. The heating structure is faulty if:

- the stove cannot be lit due to poor draft (or lack thereof);

- smoke comes from cracks in the masonry, from the door, through the gaps of the hob, through the holes for the valves;

- Carbon monoxide (CO) accumulates in the house.

You cannot heat a stove whose foundation is deformed or tilted.

In this case, the chimney, walls, and cutting are under stress, which can lead to sudden destruction of elements of the house or stove. If this happens while burning wood, a fire may occur.

It is especially difficult to determine the accumulation of carbon monoxide in the home, which causes fatal poisoning of people and animals.

This gas is heavier than air, it accumulates underground, near the floor in rooms. The gas has no odor; it accumulates in the house if the firewood is not completely burned out (they no longer emit smoke, but the fire glows in the ash) and the valve is already closed. Carbon dioxide can accumulate if a bucket of hot ash is left in the house overnight. Coal ash is especially dangerous.

Important! Deep, long cracks in the body of the furnace indicate its destruction. This device needs a major overhaul.

Do-it-yourself minor repairs: how to cope without disassembling the entire stove

After detecting defects and malfunctions, repairs begin. Small corrections are made within a few hours.

To clean the chimney from soot you need:

- aspen or alder firewood;

- a trowel with sharp edges for removing knockout bricks;

- a scraper and a narrow blade for removing soot from the chimney;

- clay masonry mortar (not cement) to seal the knockout bricks in place;

- plaster, lime for whitewashing.

The chimney is cleaned of soot by heating the stove with aspen or alder logs. They burn quickly, create good draft and high temperature and burn off soot.

The effect is enhanced if the burning logs are sprinkled with table salt. In this way, chimneys and chimneys are cleaned. It is recommended to clean two or three times a month.

If burning wood does not help and there is too much soot, the chimneys are cleaned manually by removing knockout bricks. They protrude slightly from the wall.

They are taken out by scraping off the plaster with a trowel. If the chimney is blocked by burnt bricks, the pieces can be removed through the same holes.

Important! The fall of pieces of brick into the smoke channel indicates that the oven began to collapse from the inside.

Summing up

In this article, we talked in detail about how to light a sauna and what kind of wood is best to heat it with, and looked at all the features of this process. Now all you have to do is prepare a sufficient amount of material and properly prepare the heating device for operation. If you have any additional questions, you can always ask the specialists at the time of purchasing the stove.

They will explain to you in detail all the intricacies of the device of a particular model and tell you how to make the product last as long as possible. Modern metal structures are made with high quality; it is enough to follow basic rules such as timely cleaning of the firebox from ash, regular inspection of the chimney and compliance with operating techniques.

Please note that this article is for informational purposes only and under no circumstances constitutes a public offer as defined by the provisions of Article 437 (2) of the Civil Code of the Russian Federation.