In this article we will discuss the pressing question of whether it is possible to pour concrete in cold weather and how to do this with the least damage to the quality of the final result. It is no secret that the use of cement-containing mortars in winter is practiced in industrial construction, since the construction of individual low-rise buildings can be mothballed until the onset of the warm season.

However, there are exceptions to this rule, and concrete has to be poured into the formwork at sub-zero temperatures. Let's consider how this can turn out and how to avoid such consequences.

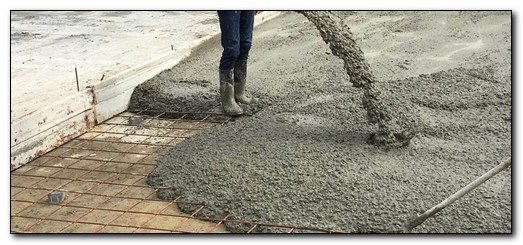

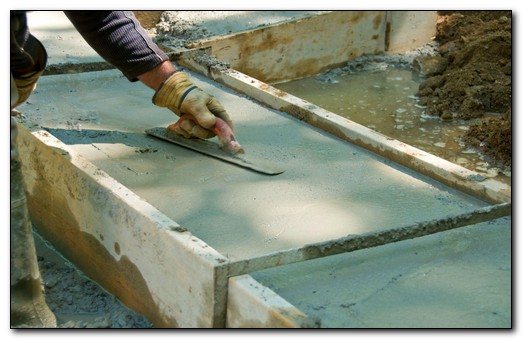

In the photo - laying the foundation at sub-zero temperatures

A set of concrete care measures

The finished mixture begins to harden after pouring into a mold or trench, and lasts approximately 28 days. During this time, it gains strength and requires careful treatment.

The maintenance and protection process includes a number of measures, we list them:

- protection against rapid drying;

- ensuring the required temperature;

- exclude physical impact;

- prevent the influence of the external environment - sun, frost, rain, snow;

- protect the water in it from freezing;

- provide hydration in sub-zero temperatures.

The optimal temperature for gaining strength is 20 degrees, air humidity 80%.

Two main stages of hardening

To achieve the declared qualities, it is necessary to maintain the correct proportions when mixing the solution. Only in this case will the desired strength be achieved. About an hour after pouring the mixture, the process of changing its structure begins. This stage is called setting. How long does it take for the cement mortar to harden before further work is continued?

After a day, the mass becomes so strong that you can walk on it. But it is still far from the declared brand strength. This was only the first stage, called grasping. Next, the hardening process begins. After two days, the mixture gains about 50% strength in the warm season.

It is recommended to begin full operational load and operations for the further construction of the next floor no earlier than 28 days, when the concrete strength approaches 90% as stated. Particular importance is attached to time during the construction of load-bearing structures.

If possible, it is better to pour strong foundations a year before the start of main construction. During this time, almost all processes of structure change occur. There will be no significant changes to the geometry of the structure. It is difficult to determine the exact time for complete hardening of a particular cement mortar. It can last for years, but after 12 months these changes do not affect the quality of the building.

Why is care needed?

When the mass hardens, the mineral components of cement turn into hydrates, which create a strong crystalline structure. The reaction is regulated by the water present in the composition, and heat is released. With uneven evaporation, hydration slows down; with complete drying, the mass hardens unevenly, resulting in cracks appearing inside and on the surface. As a result, the object or structure will quickly collapse. When hydration slows down, the strength gain schedule is also disrupted; it decreases by 40-50% with all the disastrous consequences.

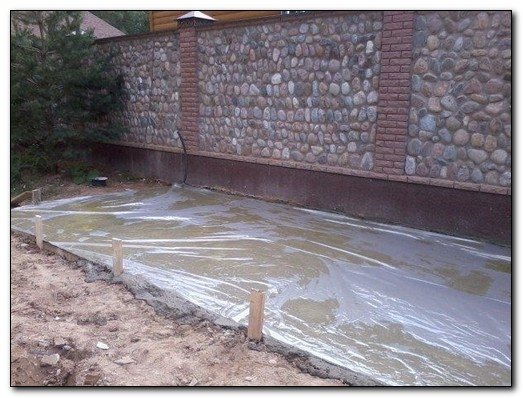

The question is often asked: does concrete need to be covered with film? The poured mass is covered with film during the cold season to warm it up. This will eliminate rapid freezing, which is fraught with consequences. In summer, the film is used in cases of strong wind or precipitation to prevent washout and disturb the surface layer.

Composition of cement and its hydration

The reaction of converting a dry mixture into a solid mass starts after introducing water into its composition. Clinker minerals, being silicates, actively begin to form spatial bonds. The process is irreversible, since coagulation of particles leads to a complete change in the structure of the material. How long an ordinary cement mortar with sand dries depends on the chemical composition of the dry mixture. The high silicate content speeds up the process.

High-strength grades, such as M 400, M 500, have a small amount of impurities, and the setting time of the cement mortar is faster than when using less durable materials.

The mixture first becomes plastic, which makes it possible to form an element of the required shape from it, and then it hardens, acquiring the necessary strength. It is recommended to use the liquid solution within the period indicated on the package. Typically it ranges from 30 minutes to 4 hours. Then it is possible to restore the plasticity of the hardening solution without loss of quality. At low temperatures, minor adjustments are allowed in the direction of increasing the period. Then the manufacturer guarantees the declared qualities and hardening time of the cement mortar in standard values.

The reaction is called hydration, where the first part of the word means water. The process is unique and differs fundamentally from the setting and hardening of gypsum-based mixtures, where air is needed for a full reaction, which proceeds many times faster and gains the declared qualities in the very first hours.

Caring for concrete in winter and summer

As soon as the air drops to 0 degrees, hardening stops; with a further decrease in degrees, water freezes. When frozen, it turns into ice, expands and breaks the mass. Therefore, at subzero temperatures it is important to prevent water from turning into ice; concrete must have time to gain the required strength. High-quality concrete is obtained when the entire mass dries slowly and evenly. The rapid hardening process is accompanied by unwanted shrinkage and volume changes, which is also undesirable.

The heating method is prescribed at the design stage for future work.

In winter, the thermos method is used to heat concrete, i.e. If possible, insulate the filling and protect it from the cold.

The second option is a combined one, the concrete mass is poured with heated water during the preparation process, and after pouring it is covered with available materials. During the hydration process, concrete heats itself and after 3-5 days it will have time to gain more than 50% of its strength.

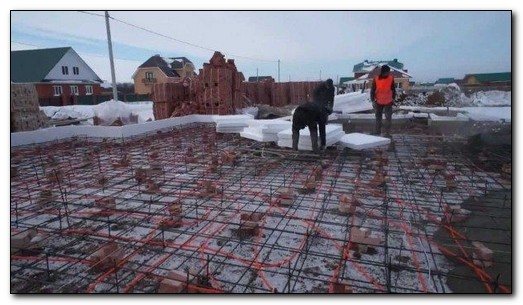

The electrical heating method is also often used in construction. It is easy to use—special heating wires are laid around the perimeter and connected to the generator. In this case, all wiring must be grounded, and the ends of the wires must be carefully insulated. With a combined option, a thermos plus electric heating, the current supply can be reduced. On average, heating is done for three to five days, at an average temperature in the solution body of at least 40 degrees.

The hydration process is accompanied by the release of heat - the concrete heats itself, therefore, in hot weather, it is important to consider a method for cooling the mass. As a rule, in the summer, special chemical additives are added to the solution to prevent rapid uncontrolled drying of the material.

Protecting the surface from drying out moisture is a major important process. After pouring, in hot sunny weather, it should be covered. Any available materials are suitable for this - tarpaulin, film, large sawdust, grass, bags...

After reaching a minimum strength of approximately 0.5 MPa, further care should consist of moisturizing and frequently spraying water over its surface. If the concrete is covered with sawdust, it can be watered with a light stream of water; high pressure is undesirable.

After removing the formwork, the entire surface must be thoroughly moistened to prevent cracks from forming. Water until moisture completely evaporates from the surface of the material. If the air temperature drops to 5 degrees, watering can be stopped.

In large volumes, film-forming additives are added to the concrete solution, which retain moisture in the drying concrete.

When can you pour the foundation in the spring?

Those who decide to start building a foundation in early spring (before April) should exercise caution. First you need to wait for the soil to thaw and warm up, when the temperature at night does not drop below 0 °C. It is also necessary to take into account the “drying out” of roads, which lasts one to two months, during which heavy equipment (concrete pumps, scows, toners and other vehicles) are restricted from moving on regional roads. Without the listed transport, it is impossible to build a monolithic foundation. From April, the cost of consumables begins to rise.

In the spring, the roads wash out, so heavy equipment cannot pass along them.

Unexpected frosts can cause irreparable damage to the structure, so when the weather forecast is unstable and work has already been planned, it is recommended to insure yourself by purchasing anti-frost fillers. Even at an air temperature of 23 °C, concrete gains standard strength only after three weeks. At lower temperatures, the time period increases noticeably; as a result, you cannot rush to lay the walls after pouring.

How to prevent chipping and cracking

Concrete care begins with its delivery or mixing at home. The delivery time of the finished solution should be minimal, no more than 1 hour. Filling of the solution must occur immediately after its delivery. It is better to order the mixer in the morning or in the evening, after pouring it, cover it and insulate it.

To avoid cracks in the concrete, it is necessary to equip the correct cushion; it is made using sand or crushed stone. Sand for the pillow needs a medium or coarse fraction, clean, preferably river sand. It is advisable to use granite crushed stone for the base, it is the most durable. The pillow must be carefully compacted - this will prevent shrinkage and subsidence of the structure.

For concreting, medium and large crushed stone with low flakiness is recommended for use. The cube-shaped surface is compacted and does not leave empty spaces in the solution, due to which, in the future, cracks occur.

Another aspect is reinforcing the concrete mass with wire or metal mesh. The reinforcement will not allow the mass to spread out or shrink.

A mistake that all beginners make is adding more water to the cement mixture than is supposed to, supposedly to make mixing easier. This leads to a disruption of the concrete structure, which will negatively affect the quality of the object, its strength and durability. An extra liter of water reduces the quality of the solution by 40%! Concrete that floats is too wet; if it crumbles, it is too dry. The correct consistency resembles high-quality sour cream - a homogeneous, dense, impurity-free, soaked mass.

If a crack does appear, it can be easily repaired with a special compound that is available in hardware stores, or you can repair it yourself. First, the repair site must be cleaned and moistened, and the surface next to the crack must be checked for strength. Mix the required amount of solution, pour and insulate from heat or cold.

Despite the unique characteristics of artificial stone, this material needs protection and care after reaching maximum strength. It is advisable to treat the external elements with special hydrophobic materials to protect them from the external aggressive environment.

How to influence the drying time of cement M 500

The strength, durability, and compliance with the declared characteristics of the mixture are influenced by several factors, including how long the cement hardens.

This process can be regulated in two ways: temperature and choice of binder brand. An important factor for determining how long the cement mortar dries is temperature. The optimal value for this operation is the range of 15-25° C. At lower temperatures, the time increases significantly. Values above 30° C also do not have a very favorable effect on the quality of the hardening mixture. It is necessary to apply additional measures to prevent premature drying and control the process.

The fastest and highest quality hardening of concrete occurs when using the technology used in enterprises producing reinforced concrete products. How long does it take for cement to harden when forming, for example, floor slabs? After 12-18 hours, concrete gains 90% of its declared strength. Such a drying speed is possible only with special equipment that ensures sealing of the product, the required temperature, the specified strength grade and some other conditions. Precise dosage of the composition, vibration treatment, heating the product with steam, eliminating moisture loss are essential conditions for the manufacture of reinforced concrete products.

It is impossible to achieve such indicators on a construction site. Therefore, you can know exactly how long cement hardens under normal conditions on the product packaging. The recommended proportions, temperature conditions and hardening time of the mixture are indicated there. The manufacturer may introduce additives into the composition to obtain special qualities, so the exact time may differ slightly even for the same brands of cement.

You can speed up the hardening process of the mixture by maintaining an optimal temperature. The average daily value is calculated and if it is below 15-20° C, then additional measures must be taken to heat the material. In this case, dehydration of the mixture must not be allowed. Cement has a tendency to dry out on its own. Lack of moisture does not allow hydration reactions to occur, causing the quality of the material to deteriorate.

Winter concreting methods used

Where would you prefer to live: in a private house or apartment?

When performing concrete work in winter, the following methods are used:

- increasing the temperature of the concrete mixture through the use of preheated water;

- introducing plasticizing additives and modifiers that significantly reduce the freezing threshold of water;

- increasing the temperature of the solution using special methods of electrical and infrared heating.

Let us dwell in detail on the features of each technical technique.