Wooden architecture has developed over the centuries in many countries. Today, for the construction of warm and durable houses, various types of logs and logs are used, which have successfully proven themselves in the northern regions of Russia, Canada and Norway.

Timber and rounded logs are widely used as building materials - strict geometric dimensions simplify and speed up the assembly of the log house, since a template can be used to mark the connecting grooves. Construction from chopped debarked logs is noticeably more difficult, since each connection is adjusted individually.

When it comes to houses made of wood for the private sector, we mainly mean either frame structures or ready-made turnkey log (timber) buildings. Is it possible to build log houses on your own, the way our ancestors did? The answer is unequivocal - yes, cutting a log house is within the capabilities of any skilled owner . You will learn about all its nuances from this article.

The construction of any building is a complex of various activities, including both preparation for construction and the phased implementation of individual technological operations. We will not consider them all, starting from the “zero” cycle, since the subject of conversation is precisely the felling of a log house. But one remark will not be superfluous. It concerns the most expensive part of the structure, the foundation, the costs of which can reach ⅓ of the estimate.

Which type should I choose? Considering the relative lightness of buildings made of wood, it is advisable to limit ourselves to a shallow-depth tape or a pile-grillage foundation. For any log house it is quite enough, if the presence of a technological (basement) floor is not an indispensable condition. Although in this case there is a good solution - to “raise” the house by installing a higher base.

The general order of work is unchanged: installation of the foundation - lower crown - laying wood samples in rows (from bottom to top) with simultaneous arrangement of openings for doors and windows. Next is the ceiling and rafter system. But what does “cutting a log house” mean? This is the connection of all blanks into a single structure with a preliminary selection of material at the designated “points”. The construction of the walls of a building is impossible without reliable fixation of all elements, therefore, when working with wood, cuts (cuts) are made in certain places of the log (timber).

But there is a difference in how the samples are fastened together. There are several ways to cut log houses. Each of the methods has both advantages and individual disadvantages, so we will give a general overview of the ones most used when doing DIY work, since there are quite a lot of them. And which one to choose is entirely at the discretion of the master.

LONGITUDINAL SLOTS

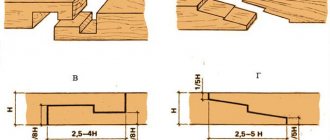

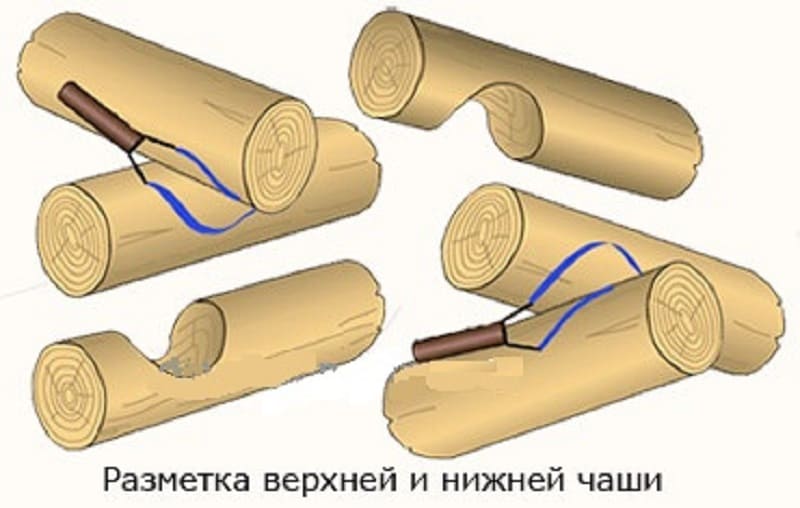

To build walls without gaps, longitudinal grooves are cut into the logs. The width of the groove should be from 12 cm if frosts in the region reach -30°C and from 14 cm if the temperature drops to -40°C.

After applying the markings using an ax, a notch is applied to the log and a semicircular (moon) groove is selected along the entire length. It is recommended to make a groove in the lower part of the logs that are laid on the previous crown - in this case, the risk of moisture penetration into the joint between the elements of the log house is reduced.

For rigidity of fastening, wooden (usually birch) dowels are used, and insulation is laid between the crowns. Wooden tenons 12-15 cm long and 2.5 cm in diameter are staggered in increments of 1-1.5 m. The nest for the tenon is made with a depth reserve of 1-2 cm, so that as a result of shrinkage of the log house, no cracks form in the wall between the crowns.

To achieve a perfect fit of the crowns, pay attention to the size of the moon groove. If the radius of the groove is slightly smaller than that of the log itself, it is adjacent to the adjacent crown with its ribs, and in the space between the convexity of the log and the concave part of the groove there is space for insulation. The edges are protected with a heat insulator from moisture.

As the wood shrinks, the log cracks on the inside of the groove, the edges move apart, and the upper crown fits tightly onto the lower one. This creates a sealed joint. If the initial size of the groove corresponds to the size of the log in contact with it, as a result of cracking of the log as it dries out and changes in the geometric dimensions of the groove, gaps appear between the rims, and they need to be additionally insulated.

Chopping in the paw

This type of cutting has one significant difference - you can use all 6 meters of logs (standard length), which allows you to minimize the amount of waste during construction. Features include the fact that the rooms are more spacious due to the absence of “outtakes” (or “exhausts”), which are technologically necessary when cutting into a bowl. The disadvantages clearly include its low thermal insulation properties, therefore, when making a log house from a round log into a claw, the outside must be additionally insulated and sheathed, which affects both the aesthetic perception of the log house and, to a greater extent, eliminates the savings in the production of the log house.

CORNER JOINTS

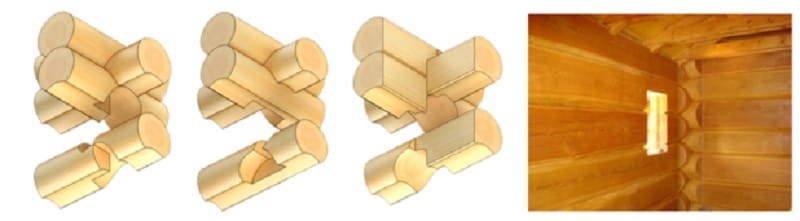

When classifying the types of log cutting, first of all, pay attention to the principle of fastening the crowns in the corners. There are two types of connections: with a remainder (with elements protruding at the corners and intersections of walls) and without a remainder.

Corners chopped with a remainder (with release) have a number of advantages:

- the level of heat loss in the premises is reduced, the corners do not freeze and are not blown through;

- The log house looks colorful and attractive.

The disadvantage is the loss of usable space, since the standard length of a log or timber is limited to six meters.

Corners chopped without residue allow you to make maximum use of the length of the log. Such connections are easier to make, but they have a significant drawback - they are blown through and freeze without additional insulation. To prevent the house from losing heat during the winter, and the corners from freezing and becoming damp, the outside is insulated and sheathed with boards or other finishing material.

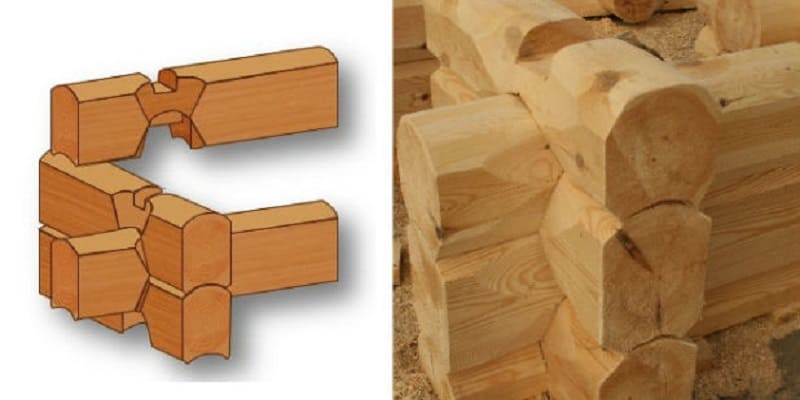

LOBBY IN THE PAWS

This is one of the types of cutting corners without residue, which is used in the construction of houses from timber or logs. There are two main cutting methods - straight paw and dovetail (the second name is oblique paw).

STRAIGHT FOOT

The end of the log is trimmed to give it a smooth rectangular shape. If non-profiled timber is used for construction, no special manipulations are required; the crowns are simply laid on top of each other, alternating the arrangement of the ends.

When hewing chopped logs, first of all, a straight paw is formed at the thin end of the element. It is important that the surfaces of the connecting parts are smooth and ensure a tight fit, otherwise the corner will be blown out. When forming a paw on the thick end of a log, it is necessary to correctly determine the height of the element so that the crowns lie flat.

When assembling a log house, the crowns in the corners are strengthened with dowels, since a simple paw is a weak connection. When hewing a paw at the end of a log, a rectangular root tenon is formed on its upper plane, and a corresponding groove is formed on the lower plane.

OBLIQUE FOOT

At the end of a log or beam, a connecting element is hewn out in the form of a trapezoid, the planes of which are inclined. The dovetail configuration allows you to create a strong connection that is resistant to blowing. To increase the rigidity and reliability of the structure, the oblique paw is additionally equipped with a hewn tenon.

This is a complex and labor-intensive corner connection that requires the skill of the performer. To speed up the work, it is recommended to use a template taken from the first completed batten. The geometric shape and dimensions of the connecting element depend on the diameter of the logs and are regulated by GOST 30974-2002.

CANADIAN CUTTING

According to the principle of execution, a corner joint is similar to a fat tail cut; the main difference is the shape of the bowl. Canadian felling involves the formation of a trapezoidal bowl at the bottom of the log, in which a tenon is left. In the upper part of the log, cuts are made at an angle to fit the bowl and a groove is selected for the tenon of the transverse element of the crown.

The Canadian bowl is a sealed and reliable connection that does not blow out or freeze. The configuration of the lock has the following feature: it self-jams when the frame shrinks, which makes the connection even tighter over time, unlike a smooth bowl.

When building a house using this technology, it is enough to lay the thermal insulation material once and no longer worry about caulking the inter-crown joints, since as the logs dry out, no gaps appear between them.

With this technology, unlike others, the sapwood is preserved. This is a superficial, soft layer of wood in which, in addition to nutrients, various resins are concentrated. Their presence protects the log from rotting.

pros

— The heat loss of a log house is lower compared to other cutting methods. — In such a structure it is easier to maintain a constant microclimate. — Increased protection of the corner parts of the log house from freezing and moisture penetration. — The durability of wood with sapwood is much higher. — A log house built using the “Canadian” logging technology does not need caulking. Anyone who understands how troublesome this task is and how often it is carried out will appreciate this advantage.

NORWEGIAN CUTTING

The Norwegian chopped corner with the remainder is created according to the same principle as the joint commonly called Canadian felling - the bowl with the tenon has a trapezoidal shape, notches are made in the transverse log and a groove is formed for the tenon. But the fundamental difference is the shape of the log itself.

The material used for construction is a carriage - a log with side parts trimmed along its entire length. The cross section of such a log is an oval. Thanks to the use of a carriage, the walls in the house have a flat surface, and the usable space of the premises increases.

Log houses made from gun carriages look powerful and stylish; Norwegian log houses are suitable for building a heat-efficient house, since the corners are windproof and resistant to freezing. When shrinking, the structure self-compacts.

The peculiarity is in the form of “locks”. They are wedge-shaped, and during the drying process of the wood, the joint is compacted as much as possible.

pros

— The risk of wood twisting is minimal. — Significant savings on interventional insulation.

The technology is in many ways similar to the previous one. The difference is in the preparations. With this method of cutting, the logs are pre-processed so that the cross-section becomes an oval. The presence of openings and tenons in the grooves ensures spontaneous jamming of the “lock” during the shrinkage process.

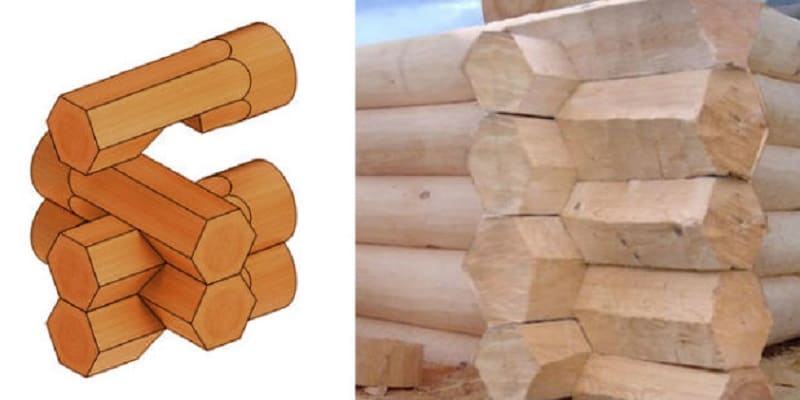

SWEDISH CUT

And here the difference is in the shape of the log section.

The advantage is obvious - such a log house looks great. The downside is that this cutting takes a lot of time and is quite complex. You will have to trim each log with high precision, strictly maintaining the dimensions of the edges.

TO THE HOOK

There are two options for constructing log houses, which is called hook felling.

Option 1. The bowl is selected only half the diameter of the log relative to its axis. To the remaining part from above, select a through quarter. The ends of the logs receive a complex hook shape. The “hook” angle turns out to be windproof and durable, but in terms of execution it is a difficult option.

Option 2. The log from the inside along its entire length is trimmed to a quarter of its diameter. A tenon-presec is formed on the transverse log, the size of which must correspond to the size of the hem. The room has walls with a flat surface, which increases usable space.

This cutting method is considered one of the most difficult.

Only a master with sufficient practical experience can build a log house using this technology with his own hands. But as a result, you can get a very strong, reliable and warm corner connection. There are 2 varieties of this technique, differing in the way the bowl is arranged (up to half a log or through)

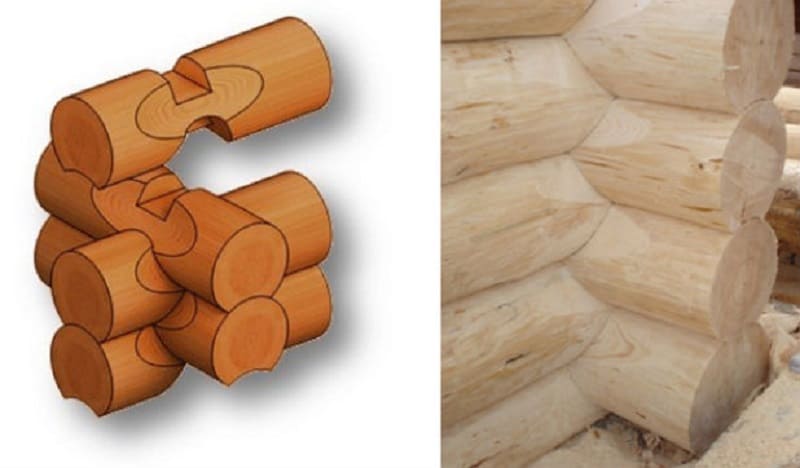

INTO THE BOWL

There is an intermediate option between felling in the chopping block and chopping in the chopping block. A moon groove is cut into the top log to prevent moisture from flowing between the crowns. At the same time, a lower bowl is made in the corners to simplify and speed up the assembly of the log house.

One of the simplest cutting methods, which has several options.

pros

— Ease of processing logs. — Time saving compared to other methods.

Minuses

— The need for regular caulking. — Risk of liquid getting into the bowl (precipitation, condensation). The result is constant dampness, rotting of wood and heat insulation. — The need for high-quality insulation of the log house. The absence of locking connections makes the structure ventilated even after caulking.

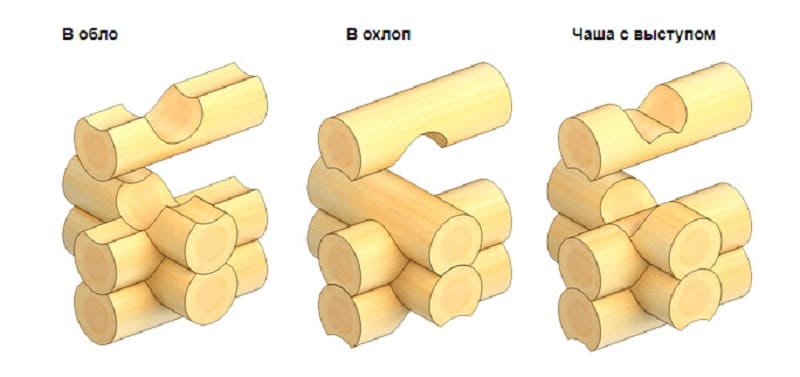

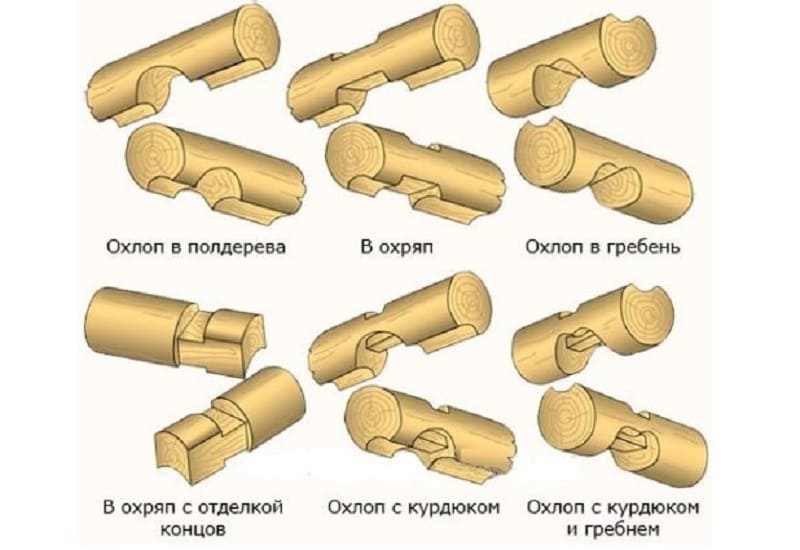

IN OHLOP

A log house, the corners of which are cut into clapboards, is more durable compared to the previous version. The “Siberian bowl” is an inverted version of the classic, lower bowl. Due to this, moisture from rain and snow does not get into the gap between the crowns and into the corner joints.

Installation of such a log house is more difficult and time-consuming, since each log is turned over many times during the cutting and fitting of the moon groove and the bowl itself. Disadvantages also include insufficient rigidity and ventilation of corners with smooth bowls.

The difference is clear from the figure. The same bowl, only upside down. This method of felling protects the log house from the accumulation of water in the lock joint. The difficulty is that the workpiece will have to be turned repeatedly, so this technology takes more time.

IN OBLO

An ancient technique of Russian architecture, thanks to which the construction of a log house is carried out at a rapid pace. A semicircular (lunar) groove is cut down in the upper part of the lower log. Indented from the edge, at the corner joint, a semicircular cutout is made - a bowl into which the transverse crown element is placed.

The advantages of the method include a minimum number of steps - the production of recesses is carried out on a log laid in the wall, it does not need to be removed and reinstalled. The main disadvantage is the penetration of moisture flowing down the walls into the cut out bowls and moon grooves during the operation of the log house, which reduces the durability of the building.

Corner joints assembled into a clapboard are blown out and frozen; they require caulking after the frame shrinks and regular replacement of the insulation as it deteriorates under the influence of moisture.

TO KURDIUK

This option is an improved bowl. When creating a bowl, a rectangular tenon is formed in it, and a groove of suitable dimensions is cut out in the lower part of the transverse log with an allowance for insulation. This corner connection is resistant to blowing and adds strength to the log house.

Corners cut into tails can be mounted up or down with the bowl. The connection is labor-intensive, but widespread due to its high performance characteristics.

The presence of a tenon increases the strength of all connections and eliminates blowing of the log house. Such felling is quite within the capabilities of any owner when building a log house with his own hands.

AT OKRYAP

Rectangular tenons and grooves for them are formed in the logs. But simple-shaped recesses do not allow for tightness and high strength of connections, so this option is used for the construction of auxiliary buildings for utility purposes.

Anyone can do cutting this way.

However, professionals do not recommend practicing it when constructing a residential building. A log house built using this technology can be ventilated even with insulation, so it is used mainly for utility buildings.

IN THE SADDLE

A simplified version of the Canadian felling . The bowl is made in a trapezoidal shape, there is no tenon and, accordingly, no groove is cut in the upper log. This technology for constructing a log house makes it possible to construct a durable structure, but the thermal insulation properties of its corners are noticeably lower.

Insulating walls with moss: recommendations

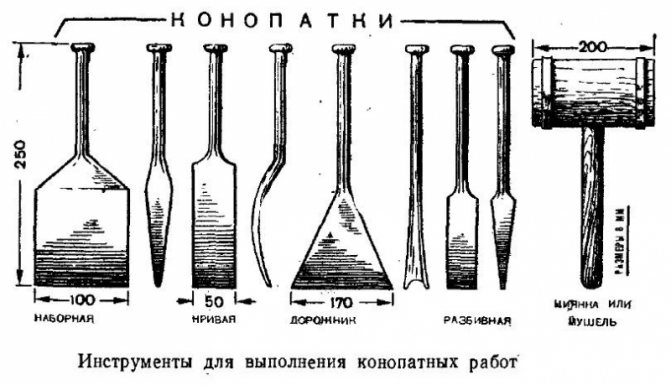

Laying moss between logs is done with special tools.

The next step will be insulation with moss. In windy weather, to prevent the insulation from blowing away, use an ax to stick it along the fibers. Why moss? In terms of characteristics, it is better than oakum, since it is the most durable, smells like incense and will improve the air in the house for a long time.

Related article: Types of wooden floor beams - calculation of beams for bending, strength and load

Logs filled with moss are placed on protruding dowels. Once they fall into place, they are knocked on with a wooden hammer until they settle completely. Tapping must be done with care so that the log sits evenly and does not break the dowels. The blows are given to them one by one.

The final caulking is done after the furnace is installed, but it is better to do it before the onset of winter. Caulk is made of wood and has the shape of a spatula. If it becomes dull, it is trimmed with an ax, after which it can continue to work.

Further laying of logs in the log house is carried out using ropes, which facilitates the installation of the upper crowns. When a log house is cut on a separate site, it is divided into two stacks according to height. One of them is closed in the center of the window openings with through elements, and after they are installed in place, they are cut out to fit the openings.

When cutting a log house, the work is carried out by two people, one at each corner. It takes two people to fit the logs, but one person works when removing the gutter. While the sampling is being carried out, other workers are preparing other elements of the frame for lifting, making dowels and performing other work.

So, the assembly of the log house “into a cup” has been completed. Thanks to the use of natural materials, such houses do not require additional finishing. But to extend the service life of the logs, it is recommended to treat them with antiseptics, as well as a thin layer of varnish. This will protect the wood from the influences of the natural environment, and then the house (log house) will delight you with its warmth and comfort for decades.

The best posts

- Advantages of children's playgrounds for summer cottages

- How to disassemble an interior door handle without the help of a technician

- DIY foundation made of plastic pipes for a veranda

- Installing door locks with your own hands: step-by-step instructions (video)

- Do-it-yourself ceiling made of plastic panels - instructions (photos and videos)

- How to insulate a metal entrance door with your own hands

- Install a lock on an iron door: technology

- Rock garden in the garden: DIY Alpine slide (30 photos)