Hello, dear visitors of our site!

We offer to build for you a real Russian bathhouse from:

- Rounded logs with a diameter of 18 to 26 cm. Larger log diameters are available upon request;

- From debarked log , when only the bark is removed from the log and the protective layer of wood is preserved, which increases the greater strength and stability of the materials. Logs do not rot longer and are not negatively affected by insects.

We build bathhouses from logs on a turnkey basis or for shrinkage:

- Shrinking. The foundation is made (pile, strip, slab - at your request), the frame is assembled and placed under the roof. Any roof covering - temporary roofing made of roofing felt, ondulin, galvanized or painted corrugated sheets, metal tiles.

- Full construction. Thanks to the assembly on spring force units, the assembly of the log house can be carried out immediately on a turnkey basis, that is, windows and doors are inserted, finished floors are laid, and interior finishing of ceilings and walls is carried out.

Construction technology:

- Number of floors: one, one and a half, two or three floors;

- The height of the first floor is from 2.10 to 3 m according to your desire;

- The diameter of the logs is from 18 to 26 cm;

- Foundation according to your wishes: piles, tape, slab;

- Inter-crown seal: jute tape. If desired, it is possible to use natural moss;

- The floor and ceiling are insulated with Rockwool stone wool in 2, 3 or 4 layers of your choice;

- The roof gables are made of logs or covered with blockhouse (imitation logs) at your request;

- The corners of the log house are cut into a bowl, into a paw, or Canadian felling. Cutting into a bowl is carried out on production equipment with high precision;

- The logs are assembled on spring anchors (force units), this absolutely eliminates heat loss due to the drying out of the logs during operation.

Typical log bathhouses (floor height 2.4 m)

| Size, m. | Price | Assembly | Log diameter, cm |

| 3x3 | 57 | 17 | 20 |

| 3x4 | 70 | 21 | 20 |

| 3x5 | 76 | 23 | 20 |

| 3x6 | 82 | 24 | 20 |

| 4x6 | 114 | 34 | 22-24 |

| 5x6 | 121 | 36 | 22-24 |

| 6x6 | 133 | 40 | 22-24 |

| 6x6 with gazebo | 190 | 57 | 22-24 |

| 6x9 five-walled | 230 | 68 | 22-24 |

IMPORTANT! All sizes of log houses are indicated by the length of the log. The cost of installation is indicated with our material. Log houses for a bathhouse have a height of 2.4-2.5 m. At the request of the customer, outfalls up to 3 m long can be made. All of the above log houses are without a rafter system, partitions are calculated separately.

Advantages of debarked logs

The most important advantage is the preservation of the natural biological protective layer + maximum preservation of the outer layer - which increases the service life of the log house by 30%. The consumption of timber in the manufacture of crowns for construction is minimal compared to rounding; at least 25-30% more wood is saved in the log!

We also get other benefits:

♦ increased heat resistance of log walls – i.e. lower heating and cooling costs (in summer);

♦ due to the preservation of denser layers of wood, shrinkage is significantly less than, for example, a rounded log;

♦ reduced need to use antiseptics, i.e. maximum environmental friendliness;

♦ minimum number of cracks that appear during the drying process of the log;

♦ natural beauty, unique pattern and relief of wood allows you to do without additional internal and external finishing, sept.e. minimizing costs for finishing work;

♦ after assembling the log house, unlike chopped logs, minimal sanding of the walls is required;

♦ Houses and bathhouses made from water-barked logs have a unique appearance, each log retains all its curves, they attract with their individuality and natural closeness to nature.

Flaws

- Of course, there are disadvantages of a wooden house:

- the log changes color over time;

- even a correctly selected log requires long-term and proper drying as part of a log house;

- Long construction;

- There are few specialists left who can process a log without an electric planer and a CNC milling machine.

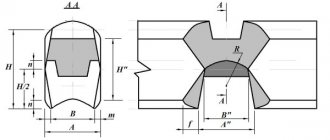

Chopping method - in a bowl or in a paw

Log house chopped into paw |

Log houses, chopped into a paw and a bowl |

Log house chopped into a bowl |

A log house cut into a bowl is smaller in internal dimensions than one chopped into a paw. For small-sized log houses, the internal size in the bowl is approximately 80 cm smaller, and in the paw by about 50 cm. Large-sized log houses require more

larger indentations from the edge of the log, so the internal size of the finished log house is correspondingly reduced. Also, the size of the foundation depends on the type of log house, do not forget about this.

We make log cabins in both bowl and paw sizes.

We only cut rounded logs into a bowl.

Read more.

Log house made from debarked logs

A debarked log is a log obtained by hand cutting and removing only the top thin layer of bark. For such work, a tool called a stapler is most often used. This type of log processing is considered one of the oldest; craftsmen passed on their experience from generation to generation.

Let's look at the main advantages of debarked logs:

— environmentally friendly and safe;

— thanks to good air exchange in the rooms there is always a comfortable microclimate;

— has good thermal insulation properties, so such a wooden house does not need to be insulated;

— the light weight of the log house does not require a bulky foundation;

- due to its natural properties it will emit a pleasant aroma and have a beneficial effect on health;

— exterior finishing of the house is not required;

- due to its texture, the house will turn out to be in the style of Old Russian architecture;

— the top layer of the log is an excellent protection against mold, mildew and harmful insects;

— with high-quality material (Arkhangelsk forest), fewer cracks form when the building shrinks;

- the material is durable, strong and reliable.

The choice of material for construction requires careful attention when inspecting and selecting the diameter of the log. Diameter 240-260mm is perfect for building a summer house, veranda, gazebo. For a permanent permanent residence and bathhouse, the log diameter will require from 220 to 300 mm, depending on the construction area. For log houses, it is best to use winter timber harvesting; it is less susceptible to mold, rot, and insects. Before constructing a building, logs can be treated with antiseptic agents and must be treated with fire retardants. When erecting walls, it is imperative to caulk the cracks with jute, moss, flax or felt.

The main disadvantage of using debarked logs is considered to be the correct choice of a team of builders to build a house; the reliability, quality, durability and beauty of your home will directly depend on this, since this material is very difficult to assemble into a box. And accordingly, due to the presence of manual work and good qualifications of specialists, the construction of such a house is more expensive than, for example, from cylinders or timber.

If you want to build a house from debarked logs, then you can use existing turnkey projects; to do this, you just need to go to the company’s websites and look at drawings, diagrams and pictures of finished houses along with price lists, or order an individual project, according to your wishes. Our specialists will help you choose the right solution by selecting one or more home options.

What is the log diameter needed?

The diameter of the rounded log must be selected depending on the purpose of the finished building. We produce rounded logs from spruce or aspen with a diameter of 16 to 26 cm and above. The larger the diameter, the more expensive the finished log house.

If it's a bathhouse

or a cottage for a summer residence, in which only summer residence is planned, then a diameter of 16 to 22 cm is needed. It makes no sense to use a thicker log, because the cost will only increase.

If this is home

, then choose a log diameter of at least 22 cm so that the wood retains heat better. The optimal diameter, both in thickness and price, is 24 cm.

When calculating the height of the building, keep in mind that the inter-crown groove reduces the height diameter of the log by about 2 cm.

Saunas made of debarked chopped logs

Due to the constant questions “What does a bathhouse made from an ordinary log look like?”, we decided to improve our website a little and posted a photo so that you can roughly imagine what we are talking about.

The construction of bathhouses from debarked chopped logs in Perm from Kama-Dom is offered today in several options, each of which we will consider below. These are bathhouses made of planed, calibrated and polished logs. These types have between can mean the same thing. For example, a bathhouse made from calibrated logs can be planed or sanded, or all together: first, planing, and after the log frame shrinks and dries, finishing sanding before painting.

Planed baths

logs

So, what is a bathhouse made from planed chopped material? It's hard to describe, it's easier to look at the second photo. I think you will agree that the bathhouse looks quite aesthetically pleasing. Before cutting the log house, the round timber was completely processed with an electric planer (before cutting, not after!). A planed log combines the beauty of rounding and the naturalness of a simple chopped log. It is believed that this material is much more durable than rounding, since it has an intact upper protective layer. To view details, you can go to the section by clicking on the photo.

Saunas made of calibrated logs

The name comes from the word "caliber". This means that before making a log house, all round timber is carefully sorted by diameter, and timber of equal diameter is selected. Thanks to this, the log house ultimately turns out much smoother and more beautiful than from a simple log. Calibrated logs can be planed or sanded; the difference will not be noticeable to a non-professional at first. In villages, calibrated logs are rarely used for felling due to cheap timber. In the city, log cutters - manufacturers of log houses carefully count every cubic meter of wood, so they carefully select logs of the same diameters just to reduce material consumption and, accordingly, reduce the cost of a log house.

Saunas made of polished logs

It is difficult to see any difference between the planed log house in the second photo and the polished one. But in fact the difference is significant. A well-polished log house sparkles in the sun and has a perfectly smooth wall surface. It is advisable to order wall sanding from professionals if you do not want to ruin your bathhouse. It’s better to book a bath in advance from professionals. Since polished walls should not be exposed to various harmful influences, they must be properly impregnated with protective compounds.

Projects, costs, photos, equipment for log baths can be viewed here (you should select the required size of the bath):

Do you need a five-wall?

The five-wall is the fifth wall inside the building. In the bathhouse it serves to separate the washing and steam compartments. In a house - to strengthen a long wall, separate the residential and non-residential parts of the house, or divide the house into apartments. For log houses smaller than 3×5, it does not make sense, because The size of such a log house is already small, the fifth wall will reduce the internal dimensions to critical. If desired, the wall in such a log house can be made of a thick board (block), bars or boards with insulation between them.

Discussion of the article here.

Look at the prices and equipment of 3×3 and five-wall 4×6 log houses. All prices are in the Prices section. Call to calculate the price for a log house in your case.

What material to choose for a log house

Planed log is an ordinary log processed with a hand plane. Pros - it has a beautiful appearance, the inside of the bathhouse is lighter. Cons – less protected from weather, protective treatment required. The cost of such a log house is higher, because manual work is used. Such a log house can be cut into either a bowl or a paw.

Rounded log is a log processed on a special machine (rounded). Pros - it has a beautiful appearance, a neat, uniform diameter along the entire length of the log. The logs are the same size along the entire length of the log. The production of the log house is carried out on a machine, so all the bowls are also neat and of the same size. Disadvantages - less protected from weather, protective treatment is required, but this is not critical. Such a log house can only be cut by us into a bowl. We make a cut on top of the log, so when it dries out, the crack passes mainly in this place, the log becomes more protected from weather conditions. In addition, it is not visible, because it is covered by the groove of the upper log. Rounding made in winter is of higher quality, because Frozen wood is better processed. In addition, we produce it in winter at last year’s prices; in summer it will cost more. We treat all cylinders with protective impregnation free of charge.

A beam is a square log in profile. Pros - low price, identical dimensions along the entire length and each crown. Disadvantages - more difficult to assemble, since each crown needs to be strengthened with special dowels, drilling holes with a special tool. We only ship the required amount of timber, and you do the cutting and assembly yourself, or you order it from us for a separate cost.

Despite the material of the log house, any wood still needs to be processed so that it retains its beautiful appearance for a long time. Any log house will still last a long time; it will last for your lifetime.

What wood to choose for a log house

We make log cabins from winter forests, using pine, spruce or aspen. Winter wood contains less moisture, so when it dries out it produces fewer cracks. We also specially treat the cylinders so that the cracks are sealed from bad weather.

Spruce is a traditional wood for making log cabins. Suitable for both baths and home.

Pine is a denser wood, more expensive because it's harder to cut it. Suitable for both baths and home.

Aspen is used only for rounding. It is believed that the spirit in such a bath is “lighter”. Not recommended for home use.