Caulking a log house is a labor-intensive and expensive process; its effectiveness largely depends on the properties of the selected sealant and the quality of the work.

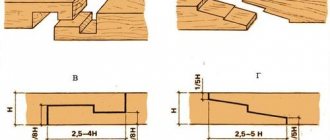

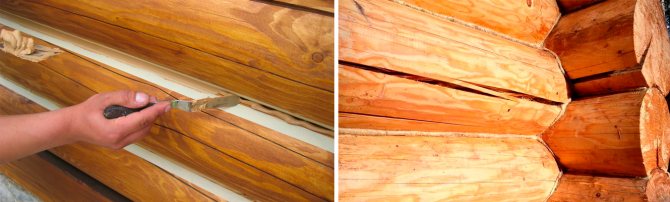

It is carried out at least twice: at the collection stage (inter-crown insulation) and at the end of shrinkage. In both cases, the optimal insulator is jute fiber materials, produced in the form of combed tow, tapes of different thicknesses and densities, or thin rope.

The thickness of the layer is determined by the evenness of the treated wood and the depth of the gaps; on average, upon completion of the work, the height of the walls increases by 5-15 cm.

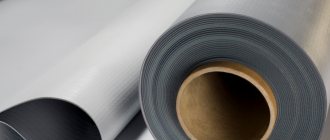

Features of the caulking tool

In construction, the term caulking is used, which refers to the process itself and the tool for its implementation. This process is the sealing of gaps and cracks that arise for various reasons when installing log houses. A special tool is also called a caulk. This could be a wooden tool or a metal spatula.

A caulk is a handle with a blade. Additional tools are also required for caulking.

Useful tips

Regardless of what exactly is used to seal cracks - homemade putties, putties or sealants, there are uniform rules.

Knowing the rules, the work on sealing cracks will become better and more durable:

- Carry out such events in the warm season, at above-zero temperatures.

- Before applying any composition, thoroughly clean the surface to be treated from debris, dirt and dust.

- Make sure that the tree is not wet after rain. Choose dry weather for such events.

- If the split is serious and large, pre-glue its edges with masking tape. This will prevent the composition from reaching other places.

- If sealant is accidentally spilled on the surface, wait until it dries and carefully clean the area with sandpaper.

- After finishing the work, the former crack is moistened with water and leveled (you can use a brush). This will give the log a neat and smooth look.

What means would you use to repair cracks in logs?

People's Professional

When planning to build a cottage, house or bathhouse from a log house, select only high-quality logs. It is better if they come with pre-treatment with antiseptic compounds and after prolonged drying. This will protect the wood not only from splitting, but also from the appearance of mold and fungal colonies.

Selection and use of caulk

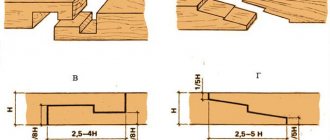

To work, you also need a flat caulk. The very name of the instrument speaks for itself. It is used to install insulation using the kit method. This means that the material is twisted into a single thread using a series of loops. The loops are pushed with a tool into the cracks and gaps between logs or beams. Well-known requirements for a blade:

- It is better to use a tool that has a metal main working part. Iron should not bend easily. In this regard, high-quality steel is preferable.

- The handle of the tool should fit well in the hand and be comfortable. Handles made of corrugated rubber or rubber handles have proven themselves to be the best.

- You need to hit the end of the handle with a mallet. The end should be a knob with a cap.

It is better to use a caulk with a blade measuring 100 mm and a thickness of 5 mm.

In addition, other tools are used for caulking a log house. They are presented in a wide range, which allows you to choose a copy that is convenient to use.

Correct caulk

How to properly caulk a house made of timber?

Any person dreams of living in comfortable conditions, the list of which includes a comfortable home, a pleasant and stable microclimate. In such buildings, special attention is paid to high-quality insulation of the building. This stage is of great importance for owners of log houses. How to properly caulk a house so that you don’t have to redo the constructed creation in the future? A large number of private developers are trying to find the answer to this question.

Caulking a house made of timber is necessary for its insulation.

Having searched for a sufficient amount of material on this topic, you can come across the statement that it is not necessary to use a similar method of insulating a building. Such arguments are justified by the following fact: wood undergoes special treatment before use, and buildings erected from it should not shrink. This means that the appearance of cracks in timber buildings is excluded.

Despite this point of view, profiled beams occupy a central place in the ranking of building materials, and they also have a reasonable price. Any beam is a wooden base with all its inherent characteristics. It can dry out if a material with a natural degree of humidity is chosen for construction.

Despite the fact that insulation can be laid between the logs, this will not prevent the wood from shrinking, as a result of which its dimensions will noticeably decrease and the gaps will become more noticeable. If you do not caulk the log house, the warmed air from the room will end up on the street. Timely work will prevent the appearance of dampness on the walls and rotting of the surface.

Features of a wooden instrument

This tool is something like a wooden spatula. It can be made on your own. It may seem that there cannot be any special difficulties. You just need to plan a wooden blade and start insulating it. Slowly tap the instrument with a wooden mallet, sealing the seam with tow.

Some craftsmen even try to use an axe. They just try to stick the tow inside the seam.

Insulation is not an easy process. In ancient times, self-made blades of different widths and sharpness were used to perform it. But this was not entrusted to everyone, but only to a recognized craftsman.

A caulk is a tool that must have the following necessary qualities. It must be made from hardwood. If the material was unsuitable, it lost its qualities after just a couple of meters of sealed seam. The blade could become covered with burrs and become completely unusable.

If the hammer for hammering is made of metal, then the caulk must also have a metal handle.

The purpose of the application is to fill the seam as tightly as possible with insulation. When using low-quality logs in the construction of a log house, it will be necessary to seal fairly wide seams. This circumstance will allow you to fill them out without any extra effort. When finishing a log house with thin logs, you will need to use a metal device.

Using a caulking chisel

A caulking chisel is a metal version of this tool. Today you can buy it in a store without any problems. Branded products are offered by the best manufacturers.

A good quality chisel can also be adapted under certain conditions. It should not be particularly thick and have a blade less than 5 mm thick. A regular chisel is too narrow. They will have to carry out insulation for an unreasonably long time. The process will be speeded up by a 100 mm spatula. It is this device that needs to do the job. This tool is called a caulking tool.

Chisels are used to perform specific operations. They have different lengths and blade thicknesses. It is necessary when sealing seams and grooves of different sizes.

Using caulk with a hammer drill

A caulk with a hammer drill will significantly speed up the progress of work. In this case, the quality will be worse, since there is a high risk of damage to the logs of the log house. The load becomes uncontrollable. This is due to its shock nature. Manual execution requires the master to make only 1 blow per width of the blade of the device.

The insulation is placed at a given depth. Using a hammer drill involves frequent impacts that the worker cannot accurately assess. The insulation is laid unevenly, the seams are insulated poorly.

A significant positive aspect of using a hammer drill is the speed of the operation. Professional caulkers prefer not to use a hammer drill because they value their own reputation.

Mallet for performing insulation

A wooden hammer or mallet is simply necessary when insulating a log house. A good master with experience and significant experience usually has his own large set of mallets of various modifications. It is preferable to use a mallet of the same type of wood as the log house that needs to be caulked. This is not always essential, but it is desirable. Mallet has other names. Some masters call it a mushel, a beater.

A curved caulk will be very useful in this work. In a log house there are a large number of rounded sections, the ends of the logs. This type of caulk has a narrower blade than a flat caulk, its size is 50 mm with the same thickness of the blades of both modifications of the tool.

A road worker is also used. This tool has a fork-shaped appearance. It is necessary for forming rollers in the most convenient way. A road builder is used when caulking a log house using the stretch method. It should have a width of 170 mm. The recess in the road construction must be selected in accordance with the dimensions of the grooves. An experienced master always has at least 3 tools of this type with him. They are used for seams of different sizes.

It is equally important to have a breaking caulk on hand when caulking a log house. It is necessary to widen an excessively narrow groove. The breaking caulk has a wedge-shaped blade, which makes it possible to expand the space. It will have to be filled with material using another device.

Why are cracks dangerous?

Water easily penetrates into the cracks formed in the logs and moisture accumulates. Which inevitably provokes internal rotting of the tree. And this is dangerous:

- gradual destruction of the structure;

- significant deterioration in thermal insulation qualities;

- the appearance of dangerous mold and fungi inside the building.

It was noted that the largest number of cracks appears in the first year of construction and subsidence of logs.

The explanation for cracking is simple: the outside of the wood material dries out much faster than the inside. And when solid wood remains dry on the outside and damp on the inside, this situation automatically “stretches” the outer layers of wood, while the inner ones shrink. The result is the rupture of wood fibers and the formation of cracks on their surface. Moreover, the faster the tree shrinks, the more cracks appear on it.

Execution of work

Caulking of log houses or beams is a labor-intensive task that is performed entirely by hand. There are no devices that mechanize such work. This process is long and quite difficult; the master performs it only with his own hands.

Caulkers are a special specialty in wood construction. The caulking team consists of several physically resilient and strong men who perform caulking exclusively.

Since these masters are not involved in other types of work, they reach the pinnacle of mastery in their specialization and have the highest qualifications. If possible, you should definitely use the services of such a team, since everything is done quickly and with the highest quality.

It is quite clear that a team of caulkers has at its disposal the entire necessary set of tools to carry out caulking of a log house of any complexity:

- in the presence of any material for sealing the seams of the log house;

- different sizes of seams;

- different types of wood for wooden buildings;

- the need to seal seams in complex elements.

Every stage of work is important. It is impossible to neglect caulking, on which the warmth and comfort of living in the house depends. It is impossible to do without it in wooden construction.

What to choose: jute, fiber or other material

Synthetic-based sealants are quite suitable for sealing joints: acrylic, silicone, latex, alkyd, bitumen and polyurethane, but their use does not allow the wood to breathe; whenever possible, preference is given to natural insulation materials. As an alternative to jute, the following are used:

- white and red moss is an environmentally friendly material with antibacterial properties. The advantages include affordable cost, low thermal conductivity, the ability to absorb moisture and withstand temperature changes without harming the structure of the fibers, the disadvantages are being pulled apart by birds and the complexity of installation (for secondary and subsequent caulking, it is better to purchase a different type).

- flax in the form of tow, felt or batting, without foreign additives. This insulation is superior to pure jute in elasticity, but inferior in water resistance.

- combined materials from flax, jute and recycled products. In this case, the characteristics are determined by the percentage of components; for high-quality brands, the proportion of regenerated fiber does not exceed 10%.

Any of the above natural materials will provide a good microclimate inside a wooden house, the main thing is to choose the right density and perform the work efficiently. Moss and combed tow are cheaper, but their installation takes more effort and time, and it is difficult to achieve uniform density. Linen insulation does not always harmonize in color with wood and cakes after a few years. Therefore, experts advise choosing jute, even despite its high price; it definitely wins in decorativeness, durability and convenience of caulking.

For primary inter-crown insulation, it is recommended to purchase strips of compressed fiber 4-5 cm wider than the radius of the logs, to seal small cracks - combed tow or soft thin strips, to hide large cracks - cord. When purchasing, carefully study the composition; it should not contain waste from the textile industry, flax dust or the addition of coarse particles. Good jute has a uniform structure and color, does not crumble and does not smell.

Sealant or caulk for log house

Our website presents a number of log house projects, for example: Or you can see the full list of prices for log houses. You can calculate the bathhouse you need with maximum accuracy using our log house cost calculator. To order and buy a log house, call:

- Vologda

- Moscow,

Samofalov Alexander Gennadievich

Comments

No comments yet.