Entrance doors in a log house, as in any other building, perform several important functions. Firstly, they provide reliable protection against intrusion by strangers. Secondly, they prevent dust, dirt and precipitation from getting into the house from the street. In addition, the entrance door serves as a heat and sound insulating barrier, providing more comfortable living conditions.

Features of installation of door frames for metal entrance doors

Installation work begins with preparation. The box is installed together with a protective film, and if it is not there, it is covered with masking tape. The room and furniture must be protected from dust. Peeled plaster is removed from the wall surface, defects and irregularities are eliminated. Then the base is plastered.

Entrance metal doors and frame frames are not trimmed, so if the dimensions do not match, the opening has to be modified. You can only shorten the U-shaped structure by adjusting the height of the canvas. To reduce the size, install a metal frame from a channel or corner and attach it to the wall with anchors. To widen the opening, cut off part of the wall to the required size using a grinder. You can drill a series of holes and try to break out the concrete in sections. Using the impact method, especially on aerated concrete partitions, can lead to cracking of the wall.

Metal doors have significant weight, so if the wall’s load-bearing capacity is low and the strength is insufficient, a monolithic concrete portal is cast for installation. Additionally, it is connected to the wall with reinforcement. In addition, according to GOST, steel doors with frames cannot be installed in walls less than 150 mm thick. If the walls are thin, you will have to thicken them.

It should be borne in mind that an iron door puts a significant load on the floor. In this regard, it is necessary to check its condition and the strength of the coating. It is recommended to replace wooden beams and bricks with concrete gravy.

Methods for installing door frames under metal doors

- Using mounting plates. For this purpose, the design provides 3 protruding lugs on each side. The door frame is placed in the opening so that the plates are adjacent to the wall on the inside. The technological gap is left 10–20 mm. Holes for fasteners are drilled in the partition to 2/3 of the thickness, but not less than 100 mm. Anchor bolts are inserted through the holes in the eyes and tightened. They can be replaced with fittings with a diameter of 12–16 mm. The top of the pins are spattered or welded.

- With fixation through holes in the frame. It is used for wide walls, which allows you to form slopes. It is important that the wall thickness is at least 150 mm to prevent damage. Holes to a depth of 100–150 mm are drilled through the mounting holes in the box at the fastening points. The fasteners are inserted into them and tightened with a key. It is important to maintain a gap from the wall of at least 10 mm.

- By concreting. In this case, the hollow door frame is filled with concrete mortar. It is first leveled and anchored to the wall with anchors. They remain until the solution has completely hardened. The method provides a monolithic, ultra-rigid installation and is performed in walls of any curvature.

At its location, the door frame of the front door is aligned in the vertical and horizontal planes using a building level and a plumb line. The position is corrected using wedges. It is important to avoid distortions, otherwise the door will not function properly. The number of attachment points along the long side must be at least three. Technological gaps are filled with foam. After a day, when it hardens, the excess is cut off with a knife, as are the protruding parts of the wedges.

Types of pigtails

By material

Combined. This is the cheapest and most common option. For the window sill, a type-setting glue board is used, the remaining parts of the box are made from solid boards. Typically, pine is used as wood.

Glue. During the manufacturing process, blanks from type-setting boards (glued lamellas) are used, which are fastened with micro-spikes and also placed on an adhesive composition.

Array. All parts are made of solid (solid board) while maintaining the original texture of the material.

By execution

Finishing (with sampling). As a rule, it is not done under a window, since surface finishing is not provided for wooden buildings. This is precisely one of their advantages.

Draft (without sampling). Such a box is installed in openings if the external decoration of the walls is planned with some kind of facing material.

By type of windows

- For wooden frames

- For PVC products.

Features of the pigtail

The width of the box components is no more than 25 mm. If this condition is not met and the value of this parameter is increased (for example, “because it’s better this way”), there is no guarantee that any side of the casing will not “spread” with cracks. And no one needs to explain what a longitudinal split of a board is.

The permissible minimum wood moisture content for a box is 12%. If you use dried workpieces, then further deformation of the “dry” board under the influence of shrinkage of the house will lead to internal breaks in the structure of the material, consequently, to subsequent intensive destruction of the casing.

For each opening, the frame is made individually, in accordance with its linear parameters.

During installation, the casing is not “rigidly” fastened to the wall material. When assembling the box, metal fasteners (nails, screws, etc.) are not used.

Insulation is placed in the gap between the deck and the wall, but it must be soft - tow, mineral wool, flax wool and the like. It is impossible to use solid heat insulators (for example, polystyrene foam) or foam (after drying this mass hardens) the cracks, since due to shrinkage the window frame itself can be deformed, and, therefore, the whole point of its installation is lost.

How to dismantle a metal door frame

Installation of a new door begins with dismantling work. The canvas must be removed from the canopies, the trim and trim on the slopes must be removed using a hammer drill. Then you need to remove the threshold to make it easier to work with the sidewalls.

Unscrew the fasteners holding the box in the opening. If they do not give in or steel pins were used for fixation, then they are cut off with a grinder with a cutting wheel. The gap between the wall and the frame should provide access to the fasteners. Otherwise, it will have to be expanded by installing a lance in the hammer drill chuck. Using a tool, the plaster is carefully removed at the attachment points, and the polyurethane foam is cut out with a knife.

Trimming should begin from the bottom and gradually move upward to avoid the beam spontaneously falling out and causing injury. First you need to dismantle the side posts, and remove the horizontal part last. The beams may have to be cut in several places and pryed up with a crowbar or scarpel. The cuts must not pass through the lock mate.

Why do you need a door frame?

The door frame is an additional support, a wooden frame that will take on the entire load when the wooden house shrinks and will prevent the door leaf from skewing during operation. The requirement for a frame is important not only for new houses, but also for old, established ones, since the wood begins to dry out over time, and the walls and floor can change their position along the horizontal and vertical plane.

How to expand a metal door frame without removing it

The expansion of the door frame has to be done when the thickness of the wall is greater than the size of the frame. To do this, use additional strips matched to match the door trim, plasterboard sheets, solid wood slabs, MDF panels or laminate. The finish is quickly installed, masks installation defects and gives the entrance area an aesthetic appearance. The width of the slats is 70–400 mm. The thickness of the skin should be 15–25 mm to withstand the loads during operation. For fastening, liquid nails, polyurethane foam, building mixtures or lath lathing are used.

Types and sizes of pigtails in a wooden house

What is a pigtail and why is it needed?

PROMO Do you need casing installation?

Our specialists have extensive experience in constructive work on home improvement and internal organization of premises in country houses and apartments.

Construction and installation department Lesobaza.rf

Finish casing

To avoid disturbances in the openings of a wooden house and to protect future windows and doors from deformation, wooden casings are installed.

PROMO Our carpentry factory produces false beams from solid wood and MDF. L/P/O-shaped, different sizes.

We also brush them (artificially age them) and paint them in a color to match your interior. Many years of experience and a variety of products give us the right to be considered one of the leaders in this area. And our painting is of furniture quality! See for yourself!

Joinery factory Lesobaza.rf

Window casing

The pigtail performs a restraining function, strengthens the tightness between structures, and holds the crowns of the log house.

Wooden opening in a timber house

The casing (window) is made of wood, in the form of a box and then inserted into the window or doorway. The log is held and gives minimal load, the future structure will remain intact. Any casing options must be strong, so a wooden beam is perfect for making various types of casing.

casing of the pigtail

Installation in the opening, regardless of the choice of window frame, is carried out in a house that has been standing for more than a year. Why is this being done? Everyone knows that a log house must sit for some time in order for the log to shrink. More often, this rule applies to log houses, where logs are selected according to caliber and are preserved in their natural, original form. For the construction of a house, material is used that has natural moisture, as well as material that has already been dried in production. Also, some casing options are used in frame and other houses. What types of casing are there in a wooden house?

7

Casing in a wooden house

3

Casing

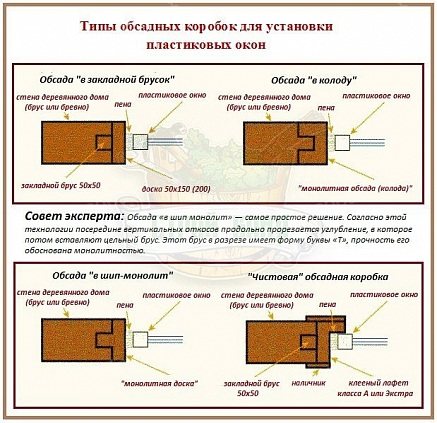

To begin with, casing boxes with an expansion gap are installed. This is due to the fact that wood tends to swell and shrink depending on weather conditions, and this can continue for about six years. At this stage, the selection of the pigtail begins. Types of casing: - with embedded beam; — tenon casing; — casing in the groove; And also the types of sockets in a wooden house can differ into rough and fine.

Okosyachka houses

Basic rough casing is used in houses where further finishing is expected. This is a fairly economical option, which involves the further use of finishing materials to create an aesthetic appearance. For rough cutting, edged timber with natural moisture is used.

Window frame in the house

Edged board

If your house is made of logs or timber, then in this case you should immediately install a finishing casing. First of all, dry, planed material is used for it. In our online store Lesobaza.rf you will find all types of wood that you may need to make your own casing.

Opening - house casing

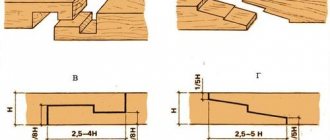

Let us examine in detail the types of casing. Casing with embedded timber. For vertical sliding of the casing, a groove 5 cm deep and wide is cut in the inner side of the log and a block of square cross-section is placed in the groove. Next, they actually assemble the pigtail from a regular straight board and insert it into the opening. All joints are insulated with jute or flax fiber. It is important to leave a gap between the top board and the main block; the distance is approximately 6-8 cm. The casing is attached to the embedded bars and to the lower crown.

Houses made of timber

1

Casing installation

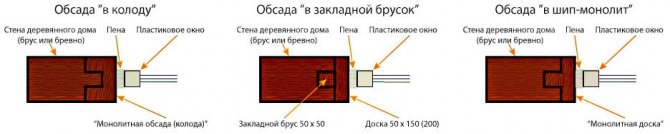

Casing in a tenon. The cross-section resembles the same as in a casing with an embedded beam, only the design is made immediately as a T-shaped one. The installation principle differs in that, first, the T-shaped sides are installed in pre-insulated grooves and pushed apart by the bottom board or window sill, and only then the structure is secured with a top. The casing in the groove resembles a U-shape. A protrusion is cut out of the log, after which side logs are mounted on it. The protrusions serve as guides along which the casing will move. Further installation, as in the tenon, the principle does not change. In all cases, leave a gap along the top edge into which to lay the insulation.

24

Types of casing

3

Casing for a house made of timber

2

Manufacturing of casing

The dimensions of the frame are matched to future windows and doors. It is more profitable to use standard sizes, rather than customize and order individually for the opening. In the online store Lesobaza.rf you can order the production of finishing casing of any type by professional carpenters; you will only need installation on site. For any questions, please contact the specialists of Lesobaza.rf

Door casing design

The door frame casing includes the following elements: sidewalls, top, threshold. In production, chamber-drying solid wood or laminated veneer lumber is used. There are two main types of casing for doors: Embedded block, or rough casing , is used as a temporary option or for finishing. In the opening, a groove is cut out on the inside, into which a block is inserted, to which the rough box is in turn attached. This design is easy to install, inexpensive in materials, but has the main drawback of an unpresentable appearance, which requires additional finishing. A “tenon” pigtail , here the embedded block and the sides of the box are made from a single block in the shape of a “t”. A groove is cut out along the inside of the doorway, part of the block is inserted into this groove, and the crossbar serves as the sidewalls. A transverse strip is applied on top. In the “deck” , the casing is performed according to the opposite principle than in the “tenon”, the groove is created on the side of the box, and the tenon or comb is created on the side of the inner wall of the doorway.