The main room of any bathhouse or sauna is, naturally, the steam room, and in the steam room the main role is played, of course, by the heater . To be fair, let’s make a small digression and present interesting facts about the baths and saunas of the peoples of the world: Japanese, Turkish and Irish baths do not have sauna stoves at all.

Today, brick stoves for baths are rarely used; they have been replaced by factory stoves for Russian baths. Such heaters are produced by different manufacturers and in a variety of models, which differ in many parameters. But before choosing a specific model, you need to decide the main question: will you have a wood-burning sauna stove or an electric one?

IN THE ARTICLE:

- Wood or electric?

- Features of the microclimate

- Ease of use

- Economic expediency

- What to choose?

Features of modern stoves

From time immemorial, people living in Russia in past centuries massively used solid fuel stoves to heat their homes. In those days, the stove was a universal piece of furniture in the house: it was used to cook food and heat the home. Even in modern homes, the stove has not lost its heating functions. As a source of heating, stoves are now in great demand. Various manufacturers offer a wide selection of heating systems to suit every taste.

Modern heating stoves are superior to their predecessors of past times in efficiency, versatility and improved characteristics, and have a beautiful design. As an example, we can cite the most famous convection ovens; the latest inverter ovens are gaining popularity.

Functional differences between furnaces

Stove heating is designed to heat rooms of various sizes, as well as to create the appropriate temperature in a bathhouse. Based on their functional differences they are divided into groups:

Heating. This type of stove is designed for space heating. It is known that modern models are much more efficient than their predecessors and have high efficiency (about 90%). This is due to improved air supply technology. Although the operating principle of an air-heated furnace is quite simple, the furnace constantly heats cold air, releasing heat to the outside.

Cooking and heating. One of the modern heating stoves with very high efficiency. In addition to heating, they are used for cooking. In such a stove, the cooking device is located on top of the combustion part. In most cases, they are installed in rooms with a small area. There are models that have several burners or the burners are replaced by a convenient oven. Additionally, to heat the water, you can attach a coil.

Heating stove with hob

Specialized. They are used in heating baths, saunas for heating stones inside stoves.

Furnace design

Based on design differences, furnaces are divided into:

- Forced-air stoves are a widespread unique stove that has advantages and disadvantages, with a simple design and operating principle. Installed in greenhouses to maintain a constant temperature. It has a pipe through which smoke is exhausted. Along with the smoke, heat loss is observed, which significantly reduces the efficiency.

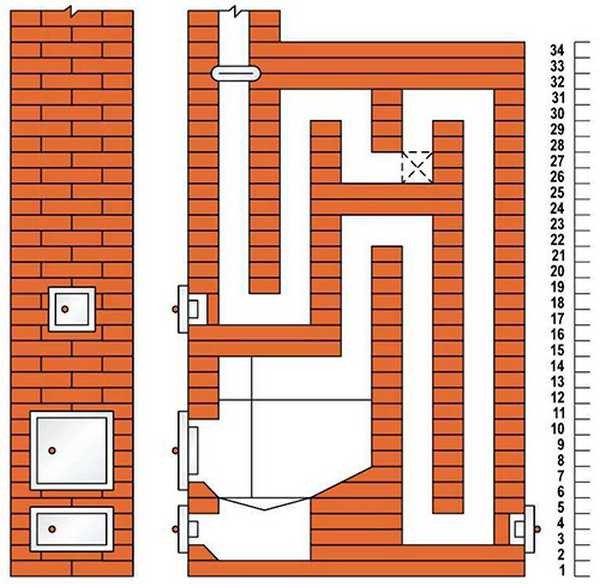

- A duct stove is a good and reliable source of heat. It has a complex design, which contributes to the release of cold smoke. Smoke does not enter the chimney immediately. Before this, it circulates through internal channels, giving off heat to the furnace. This operating principle guarantees high efficiency.

Sectional view of a duct furnace

- Bell furnace - made on the basis of furnaces used in metallurgical plants. Now this stove model is used in other areas, in particular for heating a home. It gained popularity due to its ease of operation - the generated hot air rises, reaches the hood and returns back to further generate heat.

It is worth considering that when choosing a stove, you should pay attention to the differences. For example, a channel stove needs a special draft to light it, while a bell-type stove does not. A bell-type stove generates less smoke than a channel stove. The efficiency of a channel furnace depends on the length of the pipes that are inside it. The longer the pipes, the better.

Wood-burning

Pros:

- Low spending. The maintenance of such a stove is cheaper than an electric one, because... no need to pay for light.

- Atmosphere. Wood burning in the stove creates a pleasant aroma and maintains a good atmosphere in the bathhouse.

- No dependence on electricity. The device can work at any time, because does not depend on electricity.

Minuses:

- Preparation of firewood. To operate the stove, it is necessary to prepare and store firewood in advance, which is not always possible.

- Need for cleaning. It is necessary to carry out regular cleaning of the wood stove and chimney, because... There is a lot of garbage left there.

- Fire hazard. Modern wood stoves are manufactured to all standards, but this does not eliminate the risk of fire.

Necessary building materials

Modern stoves for heating homes are made mainly from materials such as brick, cast iron, and steel.

Combination ovens

Combined brick stoves are popular due to their ease of use and have a number of advantages. It is known that the larger the oven, the more heat is released:

- The first advantage of a brick oven is its large dimensions.

- The second advantage is the ability to use various materials to start a fire: briquetted fuel, peat, coal for heating, ordinary firewood.

- The third advantage is the ability to increase the heating area when releasing smoke. The smoke released during combustion passes through pipes, which absorb heat, creating an additional source of heat.

- There is no specific standard for the shape, quantity and size of pipes.

Combined brick oven

The disadvantage is that due to its large dimensions, this heating system is not suitable for use in small rooms. To build a brick oven, it is better to use bricks that are resistant to high temperatures. A brick oven takes quite a long time to heat up, but after finishing work it retains heat for a long time.

Cast iron stove

An excellent heating product with high efficiency. The conversion of air into warm air is carried out according to the principle of conversion. The cast iron stove is also used for heating saunas. The design of a cast iron stove is based on special elements that ensure fairly fast ignition, long and active combustion, and high heat transfer. The Finnish stove has these properties, which is widely used in ordinary homes. Such a stove has a very large weight (made of cast iron), but it is small in size and quite easy to use, which is why it is widely used.

How to choose a stove for a bath. Wood or electric?

Choosing a stove for your own sauna or steam bath is not so easy. It is important to know the basic selection criteria here.

Below we will describe how to choose the right stove for a bath and calculate its dimensions. What types and designs of stoves are there, and what is ideal for a home steam room.

When choosing a stove, it is important to take into account all factors - technical and operational. You should not neglect minor points; you need to take into account the material of the walls in the bathhouse, the mode of its use and the average number of people visiting it.

How to calculate the power of a sauna stove

Manufacturers offer their customers a fairly rough calculation, in which it is necessary to take into account only the internal volume of the steam room. To determine it, you need to multiply the height of the floor by the perimeter; if the door is glass, then 2 m3 is added to the resulting volume; if the walls are not thermally insulated, then another 1.5 m3 is added to each square meter of the wall. If the bathhouse is a separate building, which was erected from a log frame, or was not lined with clapboard inside, then the volume is multiplied by another 1.5.

It is considered more correct to perform a thermal calculation of a sauna building that has adjacent and external walls. It is necessary to take into account the thermal conductivity of materials, thermal insulation of the floor and ceiling. If you have a Russian bath, then the final calculated temperature is 70-75 degrees, if you have a dry sauna, then 90-100 degrees. The result of the calculation will be the total heat loss, to which the additional heat capacity of the heater is added.

Making the main choice in favor of a larger oven power is not always correct. With a high productivity of the stove, it will be difficult to stay in the steam room, and if the supply of firewood is reduced, the required temperature for steam formation will not be obtained.

Tunnel firebox and its features

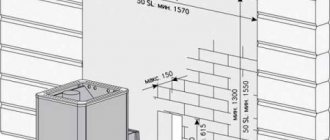

Choosing the right stove design for a bath begins with deciding on the type of firebox. There are two options here - regular and remote (extended, tunnel). The latter type is suitable for a bathhouse, in which next to the steam room there is an adjacent room from which firewood is stored. Stoves with ordinary fireboxes are not so comfortable; they “consume” a lot of oxygen, disrupt heat exchange and attract fresh low-temperature air. And also in a clean steam room there is no place for logs and firewood.

You can choose stoves with a fireplace door if you plan to remove the firebox from the dressing room.

Video: how to make a sauna stove with your own hands

Type of heater, setting, how many stones needed

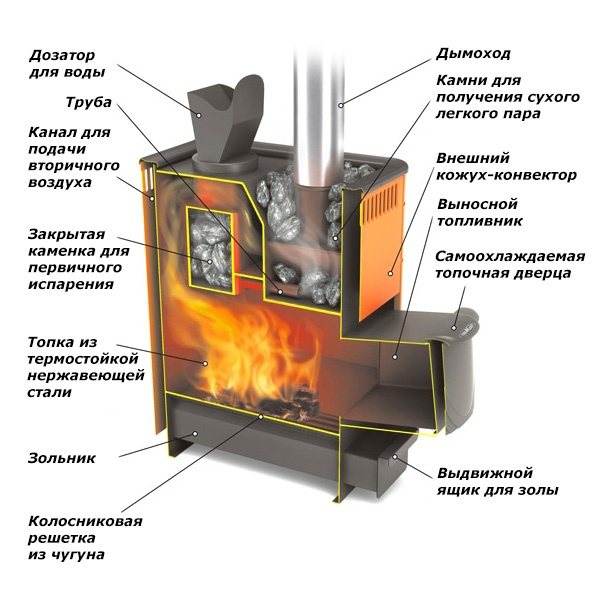

High-quality steam in a bathhouse is considered to be light, which is formed at temperatures above 500 degrees. In this state, water breaks down into tiny molecules. If the oven is heated to this temperature, it will be impossible to stay inside the room. Stones are used for this purpose.

There are two types of heaters, each of them has its admirers. A closed heater is found in a traditional Russian bathhouse; it is rare to see an iron stove with it. Stoves with open heaters remain popular; here steam is more difficult to generate and many more stones are required.

The number of stones that can be placed in the heater is determined by the stove manufacturers. This is determined by the design of the latter. You can calculate the mass of stones yourself, approximately 15 kg for each cubic meter of the bathhouse, add 15 kg per visitor.

It is not easy to find a stove with the right number of stones and the required power. You can independently increase the open volume of the heater by building side fences for stones.

Combined heater or steam generator

Some stoves have a heater just for show. And the entire steam generation system is produced in closed channels located inside the casing. Here the temperature reaches 600 degrees and the steam is light.

Often the steam generator fails quickly due to scale formation. In this case, it is better to opt for combined heaters.

Furnace material and design

Cast iron is considered the best material for the walls of the firebox and heater. However, it is rare; it is replaced by alloy or chrome steel. The heat capacity of new materials is lower, and the temperature of scale formation is high.

In a high-quality furnace, the steel of the firebox and main heat exchanger should contain about 13% chromium. It is better to choose stamped elements or high-quality plasma welded parts. If there are additional ribs inside the firebox, then the stove is really high quality.

Internal channels determine the efficiency of the furnace; thanks to them, maximum heat and minimum soot are generated.

Tank and heat exchanger, application

Residual heat must be used rationally. For example, heating water. It is very useful. For example, in stoves with built-in tanks you can heat about 100 liters of water.

The water is used for washing, watering stones, and even for heating adjacent buildings. Such functions are performed by furnaces with additional heat exchangers. When choosing a stove, it is important to consider the heat consumption required to heat water.

Video: which sauna stove to choose

Convection oven

Poor-quality stoves create unpleasant conditions for visitors - a high difference in temperature between the ceiling and floor. This is explained by the lack of convection, air circulation, which accumulates in the upper layers.

Ovens with convection ducts do not have these disadvantages. Thanks to them, the air warms up perfectly. As a result, the steam room heats up much faster, and the lack of oxygen in it is not acutely felt.

Taking into account all these principles, you can choose the ideal stove for your sauna or steam room.