Wood-burning stove with water circuit: the best heating system option

4. Fireplace.

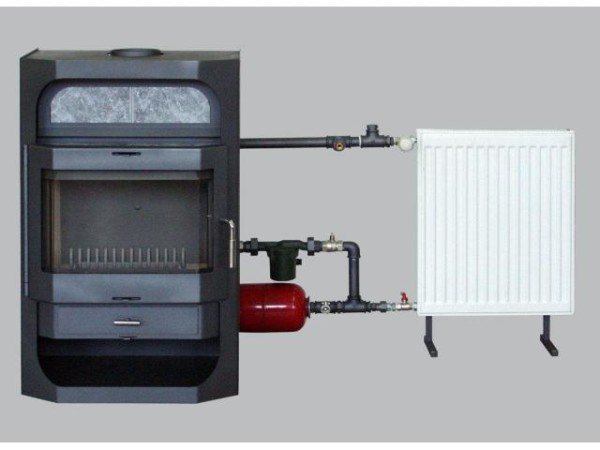

This furnace is characterized by simplified installation. During operation, heat is transferred to the heating system, thereby significantly reducing fuel consumption. Integrating the stove into the heating system

https://www.youtube.com/watch?v=Waxg6VSKkXQ

The process of implementing a furnace with a water circuit is quite simple. Such a stove can successfully replace a heating boiler. Modern stoves usually do not have a reservoir filled with water. Instead, they are equipped with a built-in heat exchanger that does not limit the amount of heated water. The stove models on the market are suitable for providing a private home with sufficient heat and hot water. Not only traditional firewood can be used as fuel, but also its modern analogue - pellets made from wood granules.

Requirements for pipes

As a rule, the heating system is characterized by natural circulation of the contents. To do this, it is necessary to take into account the dimensions of the pipes used in construction. The spill pipe must be at least 32 mm in diameter and increase depending on the length of the pipeline. The diameter of the connection to a specific heating device is usually no more than 20 mm, which is quite enough.

Selection of coolant

Since we are talking about furnaces equipped with a water circuit, it is necessary not only to create the system itself, but also to select the coolant with which it will be filled. This issue needs to be approached as responsibly as possible because, for example, at dachas in winter, heating is not always required, which requires filling the system with a liquid that does not freeze during cold weather. This technique allows you to avoid burst pipes without emptying the entire system every time before leaving.

Water circuit option

There are several options for liquid that can be used to fill the system:

- antifreeze - most of them are non-toxic, have a viscosity higher than that of water, and the specific heat capacity is low.

- Glycerin-containing liquids are expensive, do not require draining and replacement, and do not freeze to -30 degrees.

- salt solutions are a budget option that allows you to vary the temperature at which the liquid will not freeze.

In general, wood stoves have a number of undeniable advantages:

- Availability of fuel, which can be found directly on site if necessary;

- Compactness;

- No difficulties during operation and maintenance;

- The fuel for such stoves is harmless to humans and nature; the combustion process is accompanied by the release of a minimum of harmful substances compared to other types of fuel;

- Independence from the availability of other resources (for example, electricity);

- The strength of the materials used, ensuring a long service life without the need for repairs;

- Possibility of equipping a hob, the heating source for which is also a flame.

Despite significant advantages, such stoves, like any other heating system design option, also have their drawbacks. These include:

- Low efficiency compared to boilers using diesel or gas as fuel;

- The inability to automate control, the need to control fuel supply and temperature maintenance.

To summarize, we can conclude that heating systems using wood as fuel are a very popular option for organizing heating of a private home or cottage. It can be used as primary or backup. Sometimes it is the only possible one due to the impossibility of using another type of fuel.

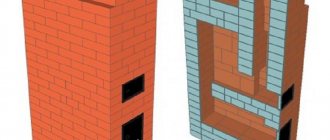

A furnace with a water circuit differs from a conventional one only in the presence of a heat exchanger - a vessel through which water is pumped and in which it is heated.

At first glance, it may seem that equipping a heater with a heat exchanger is an extremely simple task that any home craftsman can handle. Indeed, it is not difficult to embed a water tank into the body of the heat generator.

It is much more difficult to correctly answer several related questions:

- In which part of the furnace is heat removed? There is no definite answer: if you heat water with a body, the process may take too long; if the heat exchanger is placed in the firebox, this can lead to an excessive drop in temperature and, as a result, deterioration in the characteristics of the stove (incomplete combustion of fuel, drop in efficiency, large amount of soot); An attempt to remove heat in the chimney without proper calculation will lead to overcooling of the flue gases, resulting in deterioration of draft and the formation of a large amount of condensate.

- The second question stems from the first: how much heat can be removed so that both the furnace works properly and the water circuit is efficient?

- Which heat exchanger design can be considered optimal, taking into account its installation location?

As you can see, in order to create a sauna stove with a water circuit that is perfect from the point of view of thermal engineering, it is necessary not only to perform complex calculations, but also to experiment a lot with prototypes.

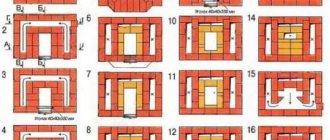

Coil

A long coiled tube is installed directly in the firebox, but in such a way that contact with the flame is excluded. Thus, the water heats up very quickly and at the same time the heat exchanger is protected from burning out.

This solution has the following advantages:

- the heat exchanger is very simple to manufacture and therefore cheap;

- Preparing hot water takes minimal time.

But there are also disadvantages: too high a hydraulic resistance of such a heat exchanger excludes the possibility of water circulation due to convection alone (natural circulation) - it has to be pumped with a circulation pump. Thus, this type of water circuit is volatile.

An analogue of a coil can be considered a plate heat exchanger, which today is equipped with some models of wood-burning stoves. It is also installed in the firebox and has the same advantages and disadvantages as the coil, except that it is more difficult to manufacture.

Such a heat exchanger is a series of parallel U-shaped tubes, the ends of which are welded to two collectors - inlet and outlet.

From the point of view of mass production, a register heat exchanger is more complex to manufacture than a coil. But at home, on the contrary, it is easier to do. Like a coil, it provides rapid heating of water, but does not allow you to regulate the intensity of this process.

Sauna stove with heat exchanger

An important disadvantage of a tubular heat exchanger is the following circumstance: in the absence of circulation, the water in it can boil, which will lead to rupture of the walls by steam pressure. To prevent this from happening, furnaces with a water circuit of this type are equipped with the following devices:

- safety valve that relieves excess pressure;

- system of automatic regulation of the damper position depending on the water temperature.

When there is a threat of overheating, the damper closes, thereby reducing the intensity of fuel combustion.

Boiler

Part of this heat exchanger covers the firebox on three sides in the form of a water jacket, while the main volume of water is located above the firebox.

Pipes can be installed inside the vessel through which flue gases are removed - the so-called fire tube heat exchanger.

The boiler itself is made of sheet steel.

When connecting, it is important to comply with the main condition: cold water must be supplied through the lower pipe, and hot water must be taken in through the upper one.

The strengths of this solution include:

- significant thermal inertia;

- the ability to accumulate an impressive supply of heat;

- Possibility of operation in natural circulation mode.

The disadvantage is that such a heat exchanger greatly reduces the temperature in the firebox and thus has a noticeable effect on the combustion process.

A variant of a tubular heat exchanger, which is located around the combustion chamber and partially around the chimney. It has a number of advantages:

- the water heats up at a sufficient speed, but smoothly;

- it is possible to regulate the heating temperature;

- heat extraction does not lead to overcooling of the internal space of the furnace;

- the risk of the coolant boiling is almost eliminated;

- the system is capable of functioning in natural circulation mode.

Because of such an impressive list of advantages, this type of water circuit is most often used in modern sauna stoves.

All of the heat exchangers described above use the heat of the combustion chamber, as a result of which the stove heats the sauna and heater less efficiently. It is easy to understand that it is much more profitable to use the heat of flue gases to heat water, which is still released into the street. With this scheme, the efficiency of the furnace immediately increases by 10%.

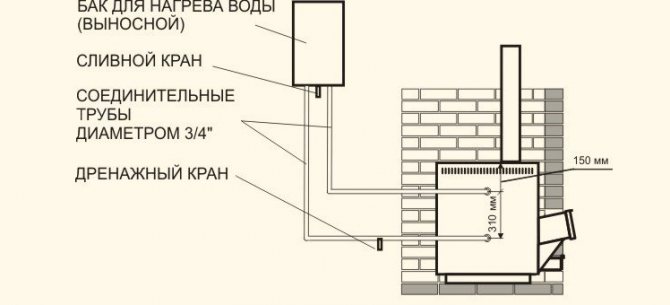

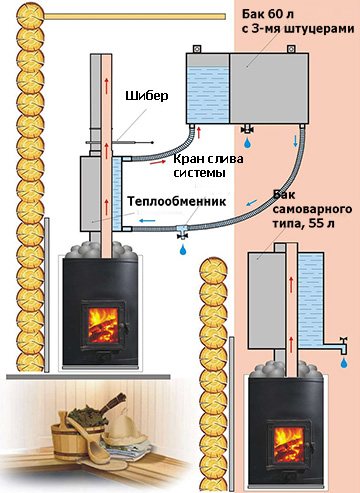

To implement this, the heat exchanger is installed on the chimney, and there are two options for its design:

- A tank covering the chimney. The advantage of this solution is the ability to operate the water circuit in natural circulation mode.

- A coil wrapped around a chimney. Such a heat exchanger is easier to make, but due to its high hydraulic resistance it will not be able to work without a circulation pump.

Since this type of water circuit does not affect the combustion mode, it can be equipped with almost any stove. However, even in this case, heat must be taken in moderation: if the flue gases are cooled too much, condensation will form abundantly and the draft will deteriorate.

Some models of wood stoves are available in a combined design, that is, their water circuit consists of two heat exchangers connected by pipes: one is located in the firebox area, the second is on the chimney.

Principles of installation, connection and safe operation

- Installation options depend only on the choice of location of the exchanger. The most difficult thing will happen if you decide to place it inside a finished oven , where it was not originally planned. For this you will have to disassemble the case and make holes. It is much easier to use a hanging structure or put a coil or a “samovar” on the chimney pipe.

- As for the pipes that connect the heat exchanger to the tank, for a gravity-flow design it is important to observe slopes, and also remember that the fastening of the pipes should not be rigid - allow them to “walk” freely during thermal expansion.

- The material for pipes is best copper , and connections are brass . When purchasing seals, pay attention to their ability to withstand high temperatures.

Operating safety depends on your awareness. The main thing is not to forget about two things:

- when leaving the bathhouse, you need to drain all the water from the system;

- You should not start heating without making sure that the storage tank is full of water.

If a brick oven with an internal water circuit is flooded and you forgot to add water in time, it is better not to do this when the oven is heated.

It is also important to prevent the liquid from boiling in the system.

Which heat exchanger is better for a sauna stove?

In addition to heating the steam room to the required temperature, for a comfortable visit to the bathhouse or sauna you need a large amount of hot water. They solve the problem in different ways: by installing a boiler or instantaneous water heater. Judging by consumer reviews, a heat exchanger for a sauna stove is considered the most economical and heat-efficient solution. The device, depending on the design, meets the needs for hot water and allows you to fully heat adjacent rooms: washing room and dressing room.

The design of a furnace with a heat exchanger has proven itself so well that various heat removal design options have emerged, with varying degrees of efficiency. The most common:

- Classic coil.

- Built-in flat-plate heat exchanger (similar to two hollow plates connected to each other).

- Samovar heat exchanger installed on a chimney.

A water jacket surrounding the combustion chamber is used extremely rarely and is found in only 1-2 models of factory-produced stoves. Meanwhile, sauna stoves with a heat exchanger have become the subject of consumer debate. Some argue that the application is not practical, others, on the contrary, point to convenience and comfort during operation. What does a built-in or samovar heat removal device provide?

- A heat exchanger in a sauna stove is needed to produce hot water for washing. This task was the main one when designing the structure.

- The possibility of heating the bathhouse from a stove with a water circuit - in fact, a metal stove becomes a kind of heating boiler. During combustion, enough heat is released to warm up the coolant and heat the required volume of hot water.

The operating principle depends on the device used. Efficiency is determined by several parameters:

- Reliability.

- Sufficient heat dissipation.

- Possibility of operation without the use of a heat exchanger.

According to their design, all water heating devices can be divided into built-in and built-on (samovar type).

Popular furnaces with heat exchangers

Cast iron stoves are deservedly popular among lovers of Russian baths, but how are they combined with heat exchangers? As it turns out, they combine perfectly.

Cast iron stove

To get started, we recommend visiting the Petrozavodsk website. Among the products offered to visitors are components, among which there is a disk-shaped heat exchanger, apparently attached to one of the walls of the furnace. Thus, you can purchase both a stove and an exchanger at once. As an option, they also sell mounted tanks for the chimney.

Cast iron stove with heat exchanger for a bath. Photo source

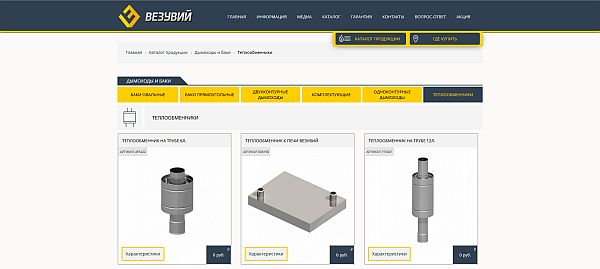

Vesuvius stove

Vesuvius stove with heat exchanger for a bath

also provides the opportunity to simultaneously purchase a stove (and in its catalog you will find both steel and cast iron stoves) and a heat exchanger . The buyer has a choice of three models - two “samovars” for the chimney, differing in capacity, and one rectangular heat exchanger, which takes heat from the stove wall.

photo of heat exchangers on the Vesuvius website

Stoves for baths "Termofor"

There is a message on the Termofor website that the manufacturer took into account customer preferences and produces the most popular models - Tunguska 16 and Tunguska 24 - with already installed heat exchangers , which require an external location of the storage tank. The material of the exchangers is high-quality food grade stainless steel, 2 mm thick . Depending on the buyer’s choice, the placement can be varied by installing it either on the right or on the left wall of the stove.

Useful video

Termofor sauna stoves with a heat exchanger may be built well, but there are negative reviews. Watch the video and see what it looks like:

Advantages and types of wood stoves

There are several heating systems for country houses, saunas, and other premises. Wood-burning stoves, despite the emergence of modern, technologically advanced ways to maintain a comfortable microclimate, have not only not become a rarity, but are successfully competing with other options for maintaining “the weather in the house.” What, if not a real wood-burning stove, with smoke, the smell of logs, dancing tongues of fire, will give you living, real warmth?

A little history

It is probably difficult to say definitely when, by whom and where the wood-burning stove was invented. In Rus', black-fired chicken stoves were used for a long time. Classic Russian, used not only as a means of heating a hut, but also as a place to relax, sleep, serve for cooking, and even as an alternative to a bathhouse, has existed for several centuries.

Modern wood stove in the interior

This “sauna” was very popular. Interesting fact: children were placed in the stove for washing, sitting on a wooden shovel. Is it not from this that in Russian fairy tales the main character, having visited Baba Yaga, did not perceive it as unusual to use this household item as a means of transportation to the oven?

In Ancient Rome, wood-burning ovens were used to prepare traditional pizza several thousand years ago. They were also found in Ancient Egypt, Europe, wherever the preparation of bread was known, and it was possible to use firewood as fuel.

About Scandinavian wood stoves

In a modern house, the main task of such a stove is heating, and it copes with it well, making do with a small amount of firewood. First of all, given the design, the use of such a stove is justified in small spaces. The application depends on the material from which it is made, as well as how often it is used.

Mass produced metal wood burning stove

Any wood stove has the following advantages:

- rapid heating of the room;

- simplicity of design, both the stove itself and the heating system of the house as a whole. It is quite possible to do without installing radiators or installing pipes;

- economic benefit in the absence of connection to the gas main or other heating sources. Procuring and using firewood can cost less than using electricity for space heating;

- The combustion of a furnace requires the provision of draft, which means the supply of fresh air. This improves heat exchange between the street and the room, regulates the humidity in it;

- some versions of stoves allow you to cook food, and even arrange a kind of shelter for relaxation, although both of these are now rather exotic;

- Kindling is carried out as needed.

The latter is also a disadvantage. A stove, wood-burning or powered by coal, peat, etc., is not an autonomous device and requires constant attention. It needs to be cleaned, ignited, maintained and regulated from time to time, and it also requires the preparation of firewood and a special place for storing it.

Metal furnaces

Made of metal, wood-burning stoves are often compact, simple in design, and allow you to install them yourself, with your own hands, without the expense of specialists. You just need to place it in the prepared place and install the pipe.

Note: Install the oven on a non-combustible base, the area of which is 1.5-2 times larger than the area of the oven. This will prevent coal falling from the firebox from getting onto the floor, carpet, etc. The fire should be inside the oven, not outside it.

New format metal wood stove

A wood stove can be made using different metals, which may determine its characteristics.

About the Milano II oven

Which stove-fireplace to choose for a bath

The modern choice of sauna stoves is so large and varied that it can confuse an inexperienced person. The units have different power and heat output, and are heated by electricity, gas or wood.

Bathing traditions largely determine consumers’ preferences for wood-burning fireboxes. But progress has not spared lovers of light steam. Among them, more and more people want to combine bath procedures with subsequent relaxation by the fireplace.

One of the important elements of such a combined unit is the glass-ceramic fireplace door. It turns an ordinary heating device into a sauna fireplace stove. The popularity of products in this class is constantly growing, judging by the reviews of connoisseurs and connoisseurs of steam baths.

In order for the firebox to produce heat of the required intensity, heat the stones to create steam and delight you with the sight of burning logs, it must be made of durable and fire-resistant metal. The properties of heat-resistant high-alloy steel meet all the specific requirements of the room:

- ensures rapid heating of rooms and stones,

- long service life of the firebox is guaranteed,

- the convection characteristics of the equipment are improved.