Why cover with brick material?

Any work must be done thoughtfully, and before execution it is necessary to understand the reasons. The designs are easy to install, heat up quickly and are accessible to everyone due to their low price, but they have a lot of disadvantages.

In addition to the high heating rate, the surface is a source of infrared radiation, which is unpleasant for humans and burns the skin at a considerable distance.

Steel heaters dry out the air, which prevents the creation of the correct conditions in the bathhouse necessary for a comfortable procedure. When heating quickly, such a stove instantly gives off heat and has to be heated regularly, which increases the consumption of firewood and creates a lot of inconvenience.

Brickwork acts as a protective screen, allowing you to retain heat for a long time and rid you of infrared rays. Covering a sauna stove with bricks is inexpensive.

What else is the highlight of Hephaestus?

Economical - The stoves are designed with two combustion chambers, the first is the main firebox, the second is the gas afterburning chamber, making the efficiency higher than that of stoves with only one firebox. Fresh heated air enters this afterburning chamber along the technological path and the gases that have not burned out in the furnace are burned out. The afterburner also allowed Hephaestus to meet European standards and be in demand in Europe.

Factory warranty - Thanks to high-quality materials and successful design, the factory is confident in its furnaces and provides a 5-year warranty on the product, and an estimated service life of more than 30 years, with proper operation.

Door with glass - If you purchase a stove with a door with glass, keep in mind that special ceramic glass from the German company Robax is installed at the factory. The door itself, like the entire oven, is made of cast iron. An air control valve is located under the glass; it regulates the air supply to the firebox.

Remote combustion tunnel - All models come with a distance of 200 mm from the door to the firebox. If necessary, you can purchase an extension of the combustion tunnel (it is called a combustion tunnel adapter) with a width of 100 mm, if you have a wide ceiling and 100 mm is not enough, then by purchasing another such element, you can lengthen the portal by 200, these elements are joined to each other and so This way you gain the desired length.

Equipment - All stoves are equipped with a starting cast iron chimney element, 234 mm long (working size 111 mm). The first chimney pipe is always the most thermally loaded, and made of cast iron, it lasts as long.

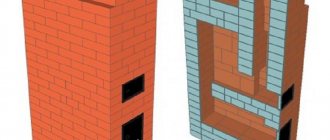

Convection operating scheme - Hephaestus stoves heat the steam room not only by thermal radiation, but also by convection. Regardless of whether you line the stove with brick or buy it in stone, the design of the stove provides convection spaces; they help remove heat from the walls, cooling them and, as a result, the air heats up faster.

Furnace lining – factory lining of furnaces is made only from natural stone from Karelia and the Urals, soapstone and coil stone are used. Both stones are volcanic rock, confidently withstand temperature changes when cold water hits heated surfaces, the stone does not crack or fly into fragments.

According to their characteristics, the stones differ primarily in color, one is green, the other is gray. Serpentinite, also known as coil, is more durable in its structure and, as a result, lasts longer and this point is reflected in the form of a higher price. In terms of heat capacity, soapstone chlorite is ahead of the coil, but since the volume of stone in cast iron stoves is significantly less than the bricks used in a Russian stove, this volume of stone will not retain heat in the steam room for a long time, so this plus is not significant.

There is also a difference in the technical properties of the stone, but these points primarily affect the processing of the product and for the common man they are also not significant. In general, choose the color and service life of the stone.

Functionality - according to operating experience and testing results, the Hephaestus stove heats the steam room to 80 degrees in 40-60 minutes. In this case, the stove operates in forced mode, i.e. You open both dampers - one on the door, the second on the chimney and burn with medium-sized dry firewood, in this case you effectively use the available firewood.

Wet firewood does not produce as much heat as dry firewood. Large wood burns longer, but produces less heat; it is better to use it to maintain the temperature in a heated steam room. After you have warmed up the steam room, you need to switch the oven to economy mode, i.e. close the air supply on the door and slightly cover the damper on the pipe, in this mode the stove uses wood economically and maintains the temperature in the steam room.

Hephaestus sauna stove with closed heater

This line of stoves is marked with the mark ZK; it differs from all other stoves by the presence of a cast iron lid that covers the heater. This gives the effect of finer and heated steam. This modification of the stove is recommended for bathing gourmets.

Assembly of Hephaestus furnaces

The assembly process is described in detail in the accompanying passport for the stove. Everything was assembled without bolted connections according to the assembly diagram; there are only 19 oven elements (in the PB 04 oven). During assembly, all joints and grooves are coated with heat-resistant sealant. The resulting design is confident and rigid.

We suggest you familiarize yourself with How much clay is needed for laying a stove

Calculations for choosing a base

For the correct distribution of parameters, knowledge of the basic parameters is necessary:

- dimensions of the furnace and its weight;

- weight of stones in the heater;

- the mass of the container for heating the liquid and the volume of water (further calculations are based on the condition that a liter weighs 1 kilogram);

- the weight of the brick wall (depends on the type of stone, but standard fire brick = 4 kg).

When all the information is received, the specialist can easily carry out the necessary calculations. He will need to add up the weight of the stove, stones, brickwork, container and liquid. 20% is added to this amount to create an additional safety margin. It should be remembered that pressure is applied constantly, and if the boards do not meet the required characteristics, then sooner or later they will be pressed through.

If the resulting number does not exceed 600 kilograms, you can line a metal stove in a bathhouse with bricks without manipulating the foundation. For detailed calculations, you can use the information below.

How to line a sauna stove with bricks without involving specialists

The fate of the entire bath structure depends on how well the stove in the steam room is made. It is uncomfortable to be in a cold or overheated room, which means that the bathhouse will be empty most of the time. If you decided to build a stove in a bathhouse with your own hands, you will probably need a couple of tips on what it means to line a stove in a bathhouse with bricks.

An iron stove in a bathhouse has long been the standard equipment for a steam room; it is the most favorite option for a stove in a bathhouse. It has a lot of advantages compared to other types of stoves:

- A metal stove is easy to make, install and maintain on your own. Even lining the stove in a bathhouse with bricks does not present any particular difficulties if you follow the basic rules of the work;

- A stove made of iron sheets is easy to “start”, quickly heats up and maintains a high temperature in the combustion chamber, which allows you to fully burn wood with good draft, without “exhausting” smoke into the steam room.

But there are a couple of disadvantages that force you to install an iron stove in the steam room as far as possible from benches and water. High performance and good heat transfer quickly heats the room, but the stones used to produce steam heat up much slower than the air in the steam room, primarily due to good air convection and strong heat radiation through the iron walls.

This is how, for example, a household infrared heater works, capable of heating an ordinary room to a comfortable temperature of 20-23°C in 15-20 minutes. So it turns out that the air temperature is under 50°C, and the heater is cold. Therefore, in such a situation, they try to cover the stove in the bath with various kinds of shields made of tin, steel, or even bath basins, and thereby even out the heating rate.

Before you decide to line it with bricks, you should carefully examine the base and foundation of the iron stove. The main difficulty of lining an iron stove with bricks in a bathhouse lies in three main problems:

- The covering brick lining will have significant weight and will require a foundation. If for some reason your iron stove does not have a stone base and sits on a thick layer of thermal insulation, reconstruction should begin with the foundation;

- In addition to the foundation, the brick lining will require a layer of good heat insulator, which will reduce the loss of heat coming from the iron furnace directly into the soil and foundation;

- The lining of an iron stove must be strong and stable. Heating-cooling cycles should not lead to the mortar spilling out of the joints and the destruction of the brick itself.

Advice! When calculating the load, use at least one and a half times the safety margin of the supporting structures; this will allow you to maintain the integrity of the brick lining and iron stove even in extreme situations.

Metal stoves are easy to use and reliable, but they quickly cool down and dry out the air in the steam room. Hard radiation from hot metal walls negatively affects people’s well-being; moreover, there is a risk of getting burned on a hot surface. Eliminating all these problems is very simple - just cover the stove with bricks.

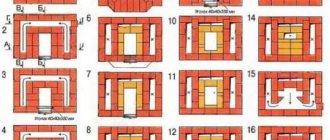

Brick screen diagram

When erecting a brick screen, it is necessary to fulfill all the conditions specified in SNiP 21-01-97 (Fire safety of buildings and structures).

Covering a sauna stove with bricks is a very common technical move among owners of metal sauna stoves.

The fact is that in addition to the obvious positive aspects, using devices made of metal for heating also has its obvious disadvantages. The operation of lining such a stove with brick is intended to correct such shortcomings.

Experienced stove makers advise installing metal stoves in bathhouses for several reasons. The most common of them are the following:

- the ease of manufacturing such a stove compared to a stone one;

- a high degree of mobility of such a design, since a metal stove can, if necessary, be moved to another room or building;

- the possibility of autonomous operation, especially when the metal stove is powered by pellets or runs on gas.

We suggest you familiarize yourself with Building a bathhouse with your own hands.

However, as an addition, the same stove makers suggest supplementing metal stoves with a special brick casing. Firstly, thanks to this you optimize the distribution of heat in the room, since metal heats up quickly and cools down quickly, while brick retains heat for a long time.

Thus, at any point in the steam room you will feel pleasant warmth; a stove that is not lined with bricks will only warm the room around itself, while the rest of the area will remain unheated.

Secondly, metal furnaces become heated as the temperature increases, resulting in a sharp increase in the risk of fire. Brick is an absolutely non-flammable material, and if it protects the metal, such a risk can be reduced to zero. In addition, you cannot get burned on it, which is very important when you have small children in your family.

Thirdly, if you know what brick to line the stove in the bathhouse with, you can achieve a very good design effect. Besides the fact that a brick stove is in any case more advantageous to wear out in a bathhouse, bricks on its façade can be used to lay out real paintings or, in extreme cases, geometric shapes that are pleasing to the eye.

There are other advantages to such a solution, and only an experienced stove specialist can evaluate all of them. Therefore, in any case, before starting work, you should contact him. In addition, it also makes sense to carefully study the architectural and construction design of your bathhouse for the possibility of carrying out the above operation.

If, according to preliminary calculations, you still have to build a new foundation for the lined furnace, you need to decide on its type. To equip furnaces, 2 types of foundations are used: columnar and strip. At the same time, the strip type, as the easiest to construct, is the most common.

If you are going to brick a stove already installed in a bathhouse, you will have to dismantle some elements of its floor. In addition, you will need to carry out excavation work and select trenches for the foundation. Next, crushed stone and sand are placed on their bottom, which are spilled with water and compacted.

After compaction is completed, the foundation can be poured with concrete, although for greater strength it can be pre-reinforced. The resulting foundation should be buried at least half a meter into the ground and protrude above it by about the same amount.

After building the foundation, it will be necessary to move on to other preparatory work. For example, this includes the preparation of the necessary facing material. If you do not know what kind of brick to line an iron stove in a bathhouse, you should consult on this issue with an experienced stove maker before starting work. He can also tell you how to properly line a stove in a bathhouse with bricks, because this process has its own subtleties and nuances.

As a general rule, refractory bricks are used for lining metal furnaces. At the same time, there are special bricks intended for laying stone ovens. You can buy them, but it’s still better to limit yourself to purchasing ordinary refractory bricks, since they are more affordable.

Many homeowners are wondering what to line the stove in the bathhouse with besides brick? Here we can recommend using fireproof tiles. It has the same characteristics as fire bricks, but looks better. In addition, you can line the stove with heat-resistant artificial grant. It will also look good indoors.

The preparatory stages of work on lining a sauna stove are preparing the mortar for masonry, selecting tools, and marking the location of the future masonry.

Having decided which brick to line the metal stove in the bathhouse with, after the preparatory work, you can proceed directly to laying out the brick. If you do not have experience in carrying out this type of work, it makes sense for you to study in advance the information on how to line a metal stove with bricks in a bathhouse.

In this case, it is recommended to either read specialized literature or browse specialized sites on the Internet, for example, on construction. They often contain a large amount of information on how to line a sauna stove with refractory bricks.

The masonry itself begins with mixing the mortar. To do this, sand and clay are taken in a 50:50 ratio, and 100 g of ordinary salt is added to the mixture. Fireclay clay or glue for porcelain tiles is also added. This mixture is poured with water and kneaded. You can also purchase a ready-made mixture for stove work, sold in construction stores.

Immediately before laying, the distance between the stove wall and the wall of the bathhouse is checked. The minimum distance should be 5-10 cm. To give greater strength to the masonry, the bricks are placed in water before work. The masonry itself is done in a checkerboard pattern, with the rows being folded and adjusted using a trowel or a wooden hammer.

To give the luggage strength, each row is laid with reinforcing mesh. In this case, such a grid should not extend beyond the border of the masonry. After all its rows have been laid, it will be necessary to finish the seams with the remaining mixture. It is the finishing stage that completes the process of lining a metal furnace with refractory bricks.

Before you begin finishing, you will need to let the rows of masonry dry. They usually take several days to dry. Finishing calls for removing traces of mortar on the surface of the brick, as well as giving the finished masonry a pleasant appearance. You can mechanize the process of such cleaning by using a drill with a special attachment.

As for the secrets of lining a metal stove with bricks, the laying should be a maximum of brick thickness. In addition, in the first row of masonry it will be necessary to leave a half-brick hole, which will improve ventilation and provide better heating of the room. By the way, if you decide to equip the stove with additional elements, this can be done while lining it.

Calculation of dangerous load on floors (kg/m2)

To assess how much load your floor can support, the technician needs to know what kind of joists are used. In the table below you can see the capabilities of different types of joists to support weight in kilograms per square meter.

| Section (cm) | Beam length between supports | ||||||

| 2 m | 2.5 m | 3m | 3.5 m | 4 m | 5 m | 6 m | |

| 10×5 | 734 | 585 | 490 | 420 | 367 | 325 | 293 |

| 15×5 | 1650 | 1321 | 1101 | 942 | 827 | 733 | 665 |

| 20×5 | 2930 | 2347 | 1955 | 1675 | 1464 | 1303 | 1172 |

| 20×10 | 4867 | 4690 | 3910 | 3353 | 2933 | 2733 | 2607 |

| 20×20 | 11730 | 3987 | 7821 | 6705 | 5866 | 6215 | 4691 |

| Cylindrical shape 20 | 6912 | 5528 | 4608 | 3950 | 3456 | 3070 | 2765 |

| Cylinder. f. 22 | 9200 | 7360 | 6132 | 5256 | 4600 | 4090 | 3682 |

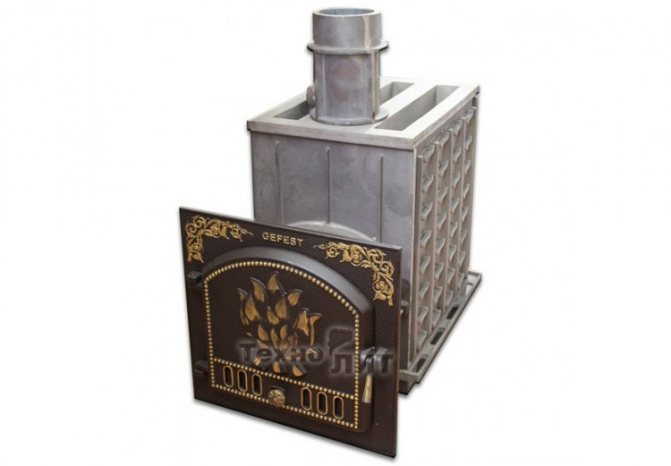

General technical specifications

Hephaestus sauna stoves are superior to those of competing companies with their high speed of air heating. The temperature regime requires one hour for the surface of the equipment to reach 7000°C, and the smoke to reach 3500°C. Thanks to the built-in flame arresters, the equipment consumes fuel economically. This occurs due to good air circulation over the surface of the walls of the unit; the process is considered additional heating of the equipment.

Steam rooms of the traditional Russian type are famous for their high humidity, which the Hephaestus cast iron sauna stove will help to realize. Using this technique, you can easily achieve the formation of light steam. In addition, cast iron material is heavy, due to which it is able to maintain a given temperature for a long time. The maximum retention period for a certain temperature regime is 4 hours.

The body is made of cast iron, wall thickness 6 mm

Their main advantage is their compact size and weight. All equipment is equipped with a remote portal and a combustion tunnel of different lengths. The body is made of cast iron with a minimum wall thickness of 4 mm, which guarantees more than 15 years of regular use and long-term heat retention.

When heated, cast iron does not emit toxic substances, but becomes very brittle. It is not recommended to fill a hot stove with cold water or cool it in any other way.

Model range and prices for Hephaestus sauna stoves

Hephaestus cast iron stoves are made of durable, fire-resistant material and are available on the market in the following modifications:

- Hephaestus sauna stove with an additional mesh, which can be used to line it with brick or natural stone;

- With a ready-made design solution for cladding - an economical option that does not require brick lining;

- Premium sauna stove Hephaestus, with heat-accumulating stone cladding;

- Mini series. The device is used in country houses, used for cooking and heating the room.

Cast iron stove for bath GEFEST PB-02MS up to 35 m 3

The main advantage of the equipment is its compact dimensions, which can significantly save the usable space of the house. A series of mini-equipment is produced in three types:

- gas oven,

- cooking panel,

- combined option, which includes a hob and electric oven.

Currently the company operates in 2 main areas:

Cast iron stoves for rooms up to 45 cubic meters

- Hephaestus PB 01

- Hephaestus PB 02

- Hephaestus PB 03

- Hephaestus PB 04

Cast iron stoves for rooms from 45 to 120 m3

- Hephaestus PB 80 M

- Hephaestus PB 80 MS

- Hephaestus PB 120 M

- Hephaestus PB 120 MS

The most popular are the Hephaestus PB 04 and PB 03 sauna stoves.

VIDEO: Review of all cast iron stoves. Vesuvius, Hephaestus, Kalita, ATB

For rooms up to 45 cubic meters

All models presented below are supplied unassembled. Installation and assembly are carried out according to the instructions included with the equipment.

Hephaestus PB 01

The main advantages include insulation of hot steam so as not to injure people in the steam room, lining with soapstone (a natural decorative material consisting of talc, magnesite and chlorite) and instant heating.

Price – 70500-82000 rub.

Type

Dimensions, cm and weight, kg

Peculiarities

Classic version of a cast iron stove

It is allowed to increase the length of the combustion tunnel by 10 cm

Convection channels are made on both sides of the body, which increases the rate of heat transfer

Each variation of the PB 01 series holds up to 300 kg of stones.

Hephaestus PB 02

Designed for rooms up to 15 sq.m. Price 55900-65000 rub.

The series includes more than 10 models, but only 3 of them are popular:

Type

Dimensions, cm and weight, kg

Peculiarities

The set includes heat-resistant glass on the firebox door, designed for temperatures up to 12000°C.

The body is extended to accommodate two rooms at once

There is a heater on top that can withstand up to 300 kg of stones for quick heating of the steam room and dressing room

Extended body, allowing it to be installed in 2 rooms at once. The firebox should be structurally located in an adjacent room.

Two operating modes - wet steam and dry air

Hephaestus PB 04

The unit is a closed-type wood-burning system with a power of 8 kW. It has small dimensions of 39x56x65cm and, despite its compactness, is capable of heating 15m3. The system is equipped with double combustion technology, a waste (ash) container, and a chimney. The attached type device consists of cast iron material, the door is made of durable glass.

The average cost of equipment is 34,000 rubles.

Hephaestus PB 03

Small-sized equipment is of the convection type. Power - 12 kW, efficiency varies between 84-88%. With this power, the Hephaestus PB 03 sauna stove has the ability to heat up to 25 m2 by burning wood or wood briquettes. Thanks to the presence of a flame divider, the flow of hot air is distributed evenly throughout the equipment body, and the stones reach the set temperature much faster.

Type

Dimensions, cm and weight, kg

Construction on foundation

If a metal sauna stove lined with brick is not suitable for installation according to the table, then in this case it is necessary to make a foundation. This task is simplified if you have just started building a building with your own hands and you do not need to dismantle the stove and floors.

To build a foundation, a hole about half a meter deep is dug around the perimeter of the masonry and filled 3/5 with crushed stone or a mixture of gravel and sand. It must be taken into account that contact with the bathhouse foundation is unacceptable.

After laying the cushion, a cement screed and a layer of waterproofing are made, after which formwork is made, which is filled with concrete mortar. For such a product to harden properly, it must be regularly moistened with water to avoid cracks.

The next stage is the construction of brick pillars that serve as support. It is recommended to do the masonry using clay mortar. All work must be carried out taking into account the level, avoiding distortions.

When everything is ready, the metal product is installed and covered with brick.

What is interesting about Hephaestus stoves for a bath, the main advantages

The most valuable thing about Hephaestus stoves is the body made of thick alloy cast iron with an extremely long service life. Now in stores there are stoves made of black and stainless steel; in 90% of cases, their lifespan is limited to 8-10 years, if you steam once a day off. Cast iron Hephaestus lives without problems for 30 years or more, with proper use.

We suggest you read: How to repair a furnace firebox with your own hands

How is this ensured?1. The actual wall thickness is from 10 to 60 mm; having such a thickness of the firebox walls, in these furnaces there are no such concepts as *started the firebox*. Iron stoves have a thickness from 2 mm (chromium steel with 13-17% chromium) to 10 mm (regular black steel). 2. The production uses cast iron grades SCh20-25 and ChH10, which combine such properties as increased ductility, resistance to corrosion and reliable resistance to temperature changes.

When cold water gets on the furnace elements, these materials can withstand temperature changes without any problems.3. The furnace elements are manufactured using a tongue-and-groove system, which minimizes problems with thermal deformations; the design does not have connections in the form of nuts and bolts, as well as welds.

Floor base

If the weight of your structure does not exceed the established standards, you can place the stand directly on the surface. If the bathhouse is many years old, the technician will still have to open the floor and inspect the joists and boards for damage. You also need to remember that the brick base also has its own weight and will put pressure on the floorboards.

If the wood is not suitable for the job or is not in perfect condition, it is not necessary to replace it. It is possible to reinforce them with a metal channel or additional wooden beam. It is worth considering the distance between the beams. If they are located more than a meter apart, the specialist will need to install additional ones so that the clearance between them is about 600 mm.

To lay the base, floorboards are placed ten centimeters larger than the size of the structure with the lining. On the firebox side, it is necessary to increase this distance to avoid burning elements from hitting the wood. Then a sheet of refractory material is placed on the marked area, on which brickwork is made about 200 mm high.

It is recommended to use refractory bricks without hollow sections for these purposes. You need to use a clay mortar, to which you can add a little cement mixture. All actions must be performed using a level. After preparing the base, you can think about how to properly brick a stove in a bathhouse.

Model range of sauna stoves Hephaestus

The Hephaestus company offers customers equipment capable of heating a room from 15 to 120 m³. therefore, various models can be found in both private and public baths. What should you pay attention to when choosing?

In this category there are four powerful models designed mainly for heating large rooms. Namely:

- Hephaestus PB 00 M - dimensions 1171*726*1100 mm. The weight of the structure is 700 kg, the output is 35 kW, it is possible to heat rooms up to 80 m³.

- Hephaestus PB 00 MS - the model has identical technical characteristics of the previous stove. The difference lies in the weight of 720 kg, as well as the dimensions of 1171 * 950 * 1200 mm. In both cases, the outlet for the chimney has a cross-section of 200 mm.

- Hephaestus PB 000 MS and M - used for steam rooms with an area of up to 120 m³, the productivity is 45 kW. The weight of the finished structure when fully equipped is 950 kg. The only difference between the models is the difference in case size and design. The height is the same 1382 cm. The width and length of the MS are 726*1100; M - 926*1200.

| Hephaestus PB 00 M | Hephaestus PB 00 MS | Hephaestus PB 000 M | Hephaestus PB 000 MS | |

| Steam room volume | up to 80 m³ | up to 120 m³ | ||

| Chimney diameter | 200 mm | |||

| Power | 35 kW | 45 kW | ||

| Height | 1171 mm | 1382 mm | ||

| Width | 726 mm | 950 mm | 726 mm | 926 mm |

| Length | 1100 mm | 1200 mm | 1100 mm | 1200 mm |

| Weight | 700 kg | 720 kg | 950 kg | |

| Efficiency | 87 % | |||

This line of stoves also includes four models with a total output of 18 kW and enough power to heat 45 m³. When choosing the model you like, you should pay attention to their features:

- Hephaestus PB 01 M - the stove is made of soapstone. A special feature of the design is a system that prevents steam from entering the feeder. Design dimensions 711*495*887. Installation weight 350 kg.

- Hephaestus PB 01 C mesh heater - has a remote portal that allows you to heat the stove from the adjacent room; if necessary, the combustion tunnel can be increased by another 10 cm, thanks to special inserts (included in the basic package). Stove dimensions 800*600*967.

- Hephaestus PB 01 MS - this model is designed for quick heating of large steam rooms. The heater holds 300 kg of stones; special convection valves are installed on the sides to promote rapid heat transfer.

We invite you to familiarize yourself with drawings of a metal sauna stove: do-it-yourself iron sauna stoves, design dimensions, diagram of a homemade metal stove, manufacturing

| Hephaestus PB 01 | Hephaestus PB 01 M | Hephaestus PB 01 C | Hephaestus PB 01 MS | |

| Steam room volume | up to 45 m³ | |||

| Chimney diameter | 150 mm | |||

| Power | 18 kW | |||

| Height | 711 mm | 800 mm | ||

| Width | 495 mm | 600 mm | ||

| Length | 887 mm | 967 mm | ||

| Weight | 350 kg | 360 kg | ||

| Efficiency | 87 % | |||

Hephaestus brand stoves under the index PB 02 are capable of heating rooms up to 35 m³. To date, at least 9 modifications in this line are being manufactured. The most popular stoves are:

- Hephaestus PB 02 M - the design of the model allows you to heat two rooms at once: a steam room and an adjacent room into which the fuel tunnel will go. Subsequent finishing of the structure with brick is mandatory. The package includes a combustion door with glass that can withstand 1200 degrees. Case dimensions 645*458*855.

- Hephaestus heater PB 02 C - a mesh is used - an open type heater. Thanks to the special design, the convection of heated air between the stones is carried out unhindered, which significantly improves heat transfer and promotes uniform heating of the room.

- Hephaestus PB 02 MS is a model that allows you to create optimal conditions for both a Russian bath (hot air with high humidity) and a sauna (dry air with virtually no moisture). It is possible to fire the furnace from the adjacent room. Weight 310 kg.

| Hephaestus PB 02 | Hephaestus PB 02 M | Hephaestus PB 02 C | Hephaestus PB 02 MS | |

| Steam room volume | up to 35 m³ | |||

| Chimney diameter | 150 mm | |||

| Power | 15 kW | |||

| Height | 645 mm | 750 mm | ||

| Width | 458 mm | 600 mm | ||

| Length | 855 mm | 955 mm | ||

| Weight | 300 kg | 310 kg | ||

| Efficiency | 87 % | |||

Furnace equipment for heating air in rooms with a maximum area of up to 25 m³ is represented by the PB 03 series. Although there are about 10 different models in the line, you can focus on the three most popular and productive of them.

- Hephaestus PB 03 M - heats the air in the room in 10-20 minutes. Maximum heating is achieved within 50 minutes after the start of combustion. The simple design makes it possible to brick the equipment yourself. Body dimensions 590*418*755, weight 195 with empty heater.

- Hephaestus stove-heater PB 03 C - this model is equipped with an open grid-heater. The design provides for the possibility of extending the remote fuel channel. The weight of the equipment is 205 kg. The weight of the stones when fully loaded is at least 200 kg. The main distinguishing feature of this model is the completely sealed combustion chamber door.

- Hephaestus PB 03 MS - quick heating of the room is carried out thanks to the unique design of the heater. The weight of loaded stones is at least 200 kg; after full loading, the weight of the product will be 400 kg. The case dimensions are identical to the previous model 700*500*855.

| Hephaestus PB 03 | Hephaestus PB 03 M | Hephaestus PB 03 C | Hephaestus PB 03 MS | |

| Steam room volume | up to 25 m³ | |||

| Chimney diameter | 130 mm | |||

| Power | 12 kW | |||

| Height | 590 mm | 700 mm | ||

| Width | 418 mm | 500 mm | ||

| Length | 755 mm | 855 mm | ||

| Weight | 195 kg | 190 kg | 205 kg | 200 kg |

| Efficiency | 87 % | |||

We invite you to familiarize yourself with the Chimney for a waste oil stove

One of the most popular series of furnace equipment is Hephaestus. The PB 04 line is designed for heating air in rooms with an area of up to 15 m³.

- Hephaestus PB 04 M - runs on wood, is intended for heating water and air in the steam room and adjacent rooms. Can be used both in baths and saunas. Definitely requires brick lining. The weight of the finished structure is 110 kg.

- Hephaestus PB 04C with an open-type heater - design features ensure quick heating of the room without the presence of cold zones. It is possible to fire an adjacent room using an external combustion chamber. If necessary, the fuel channel can be extended. The weight of the product with an empty heater is 125 kg.

- Hephaestus PB 04 MS - the design includes a steam generator, which allows you to work in the “Sauna” and “Bath” modes. The volume of the heater allows you to put 150 kg of stones into it, which after laying increases the weight of the product to 270 kg.

| Hephaestus PB 04 | Hephaestus PB 04 M | Hephaestus PB 04 C | Hephaestus PB 04 MS | |

| Steam room volume | up to 15 m³ | |||

| Chimney diameter | 115 mm | |||

| Power | 8 kW | |||

| Height | 489 mm | 600 mm | ||

| Width | 394 mm | 400 mm | ||

| Length | 645 mm | 745 mm | ||

| Weight | 115 kg | 110 kg | 125 kg | 120 kg |

| Efficiency | 87 % | |||

All Hephaestus furnaces have a high efficiency rate of 87%. Convenient separation and marking of stoves allows you to choose the required model without unnecessary difficulties.

If ready-made stone cladding for Gefest stoves made of soapstone is not affordable, you can choose a more economical option and cover the structure with brick or natural stone. The following recommendations must be taken into account:

- The distance from the convection openings to the wall must be at least 50 cm.

- The body is specially designed for cladding work. It is quite easy to line the stove with brick using the manufacturer's instructions.

- A brick-lined stove can additionally be lined with heat-resistant ceramic tiles, marble or granite.

- When working, it is necessary to use ready-made mixtures that include fireclay clay.

Installing and covering a Hephaestus cast iron stove with bricks in a bathhouse with your own hands is a fairly simple process. Of course, subject to compliance with the manufacturer's requirements and the master having minimal construction skills.

Construction process

If you plan to cover it with bricks on all sides, then it will be a full covering, if only some sides are partial. When completely surrounded, it is possible to control the movement of warm air masses. To do this, doors are made at the top and bottom of the screen to stop the movement of air when closed.

The model, completely covered with masonry, creates an ideal microclimate typical for a Russian bath. If at least one open wall remains, it will be more like a sauna, and the stone will protect you from burns and accumulate heat.

Screen construction options

To determine the answer to how to line a metal sauna stove correctly and with what kind of brick, it is necessary to consider all existing classifications.

By distance:

- solid - interferes with circulation, which reduces the heating rate;

- randomly - the brick is placed with holes, this type reduces the quality of shielding;

- a screen with doors at the top and bottom is an ideal option with the ability to adjust convection.

By arrangement of bricks:

- in size - increases the heating time of stones and consumes a lot of raw materials during construction;

- half a brick - the most suitable option with a durable wall and rapid warm-up;

- in a quarter of a stone - has good heating characteristics, but the strength of the masonry is reduced.

It is worth noting that an overly unstable option can be corrected using reinforcement with a special network, but still, a thin-walled lining should not be erected without good preparation.

What kind of brick to cover a stove in a bathhouse

Before the main procedure, you must first prepare all the materials. On the modern market you will find a huge variety of bricks, varying in size, aesthetic qualities and properties.

The choice of brick must be made based on the distance from the metal to the screen being built. If it is less than 250 mm, then this will lead to strong heating of the masonry and therefore it is better to use fireclay.

The optimal is 500 mm. For such buildings, an ordinary fire-resistant red stone is perfect. If you plan to install vents from below, then this material can be used closer.

Characteristics of building materials

You can calculate the main indicators that a brick has for lining a metal or iron stove in a bathhouse using the following table:

| Options | Facing | Textured | Raised | Ceramic |

| Strength | M-250 | M-250 | M-250 | M-200 |

| Size, cm | 25×12×6,5 | 25×12×6,5 | 25×12×6,5 | 25×12×6,5 |

| Frost resistance | F35 | F35 | F35 | F75 |

| Moisture absorption,% | 8,5 | 8,5 | 8,5 | 6 |

| Weight, kg | 4 | 4 | 3,8÷4 | 4,1 |

| Thermal conductivity, W/(m×°C) | 0,61 | 0,61 | 0,61 | 0,72 |

Bricks for lining furnaces

A further description of the process of installing a brick casing is made using the example of a metal sauna stove - Sahara 16. The advantage of this unit is that heating occurs in about half an hour. However, there is no need to talk about uniform heating of the air. Therefore, the air in the room near the stove can be both warm and scalding hot.

In fact, in the bathhouse you need to get soft air, which will provide deep warming and have a beneficial effect on the human body. The reason for such poor heating is the difference in the time it takes to heat the stones and the stove itself.

The metal structure heats up to the limit, but the stones themselves do not create the required steam. Solving this problem turns out to be quite simple: you need to line the metal stove in the bathhouse with bricks in order to improve a number of operational characteristics.

For laying, you can only use solid refractory bricks and in no case standard construction bricks. The brick can have either a regular red surface or an original textured one, which is used for decorative purposes.

Typically, the lining of a bathhouse stove with bricks is carried out using the following types of binder mixtures:

- cement mortar with the addition of fireclay clay;

- a mixture of clay and sand;

- cement with glue for laying porcelain tiles.

The masonry is created in a standard way with the placement of bricks in a checkerboard pattern: each next row is shifted by half a brick. To save money, you can place the brick for lining a metal stove in a bathhouse on an edge, but in this case the wall will be thinner and its efficiency will decrease. It is best to lay the brick completely across the entire width.

It’s worth explaining right away that lining a sauna stove with brick is done in such a way that a gap of 1 to 10 centimeters thick is maintained between the screen and the stove structure. Naturally, when choosing a thickness value, you can only focus on the availability of free space in the room.

If the gap is less than the designated range of values, then the furnace will become excessively hot during operation, which will reduce its service life, and if it is larger, then the brick will not warm up well enough.

During the process of laying bricks, each product must first be soaked in water, which will significantly improve the adhesion of the mortar used. The joints in the masonry must be grouted using the same solution.

In some rows, small holes should be left to ventilate the gap between the brick screen and the walls of the oven. Usually four small windows are enough for each of the brick walls.

Speaking about how to line an iron stove in a bathhouse with bricks, it is worth considering the method of strengthening the masonry. To do this, cut metal mesh for reinforcement is laid on even or odd rows of bricks.

However, this precaution is not necessary, since properly executed masonry will last a very long time without reinforcement.

After covering an iron stove in a bathhouse with bricks, you need to wait a day until the solution initially hardens, and then begin removing stains. Although the stove is essentially a technical structure, it will look clumsy against the backdrop of the beautiful interior of the bathhouse if the brickwork is dirty.

You can use a regular drill with a brush attachment for cleaning, but only to remove excess, but stains can be washed off with a stiff brush and soapy water. As a result, you will get not only an effective, but also a very beautiful sauna stove, with which you can take photos and post them on specialized construction sites!

A metal sauna stove lined with brick has the following operational advantages over open structures:

- The air in the room is heated evenly, since first the thermal energy is accumulated by the brick screen, and only then the air masses are heated from the masonry. And for the human body such air seems much more pleasant, even if its temperature is very high.

- The stones in such a furnace also heat up very quickly, and therefore there will always be plenty of wet steam during the procedures.

- The volume of thermal energy accumulated in a brick screen when heated is enough to steam for several hours in a row without adding fuel.

- The masonry also performs an important protective function. If, while going to the bathhouse, you touch a bare area of skin to the hot metal of the stove, then a severe burn is guaranteed, and the brick does not heat up to that temperature.

An increase in the heating time of the entire complex can be considered a disadvantage, but in fact, even an hour is a fairly short period of time for such a procedure as lighting a bathhouse. In a modern bathhouse there is somewhere to spend this hour. You can arrange gatherings in the relaxation room, or prepare everything you need for tea after visiting the steam room.

The article describes in detail the process of creating a brick screen for a metal furnace. If you act correctly, the performance of the heating unit will increase, and visiting the bathhouse will become a much more enjoyable process. If you wish, you can entrust the construction of the screen to a specialist who will take responsibility for all stages - from purchasing the necessary materials to their installation and putting the furnace into operation.

Not everyone is suitable for a heater. Sand-lime brick is not suitable. It will collapse very quickly due to temperature.

If you want a long-lasting stove, use a fireproof one (made from fireclay clay). It is more expensive than the usual one (red), and it doesn’t look very good. But for decorative masonry, the outside can be lined with ordinary brick with a textured surface (hollow brick will be somewhat preferable, since it accumulates heat better). There are two types of fireproof: hollow and solid. Choose a full-bodied one.

But if fireclay is not affordable, take red (and also full-bodied).

Choice of solution

The most common option for carrying out such work is clay. It is mixed with sand, adding a little cement. A cement mixture with the same clay ratio is also used. For the cementless option, make a clay mixture with twice the amount of sand, which is diluted with water to the desired consistency.

Fireclay powder is best used for refining seams, because it binds bricks less firmly.

A simpler option is to purchase a special mixture. It is inexpensive and easier to use. Thanks to a wide selection of similar products, you can easily select the optimal solution. It is worth noting that the diluted mixture must stand for some time before use so that the substances contained in it dissolve better and the solution takes on the necessary properties.

Fencing an iron stove in a bathhouse

Before starting construction, it is recommended to thoroughly wet the bricks with water for 12-13 hours. This will allow them to achieve the desired level of humidity. Otherwise, they will dehydrate the solution.

The quality of the mixture is checked as follows: it is applied to a new brick, and if it does not spill or crack, then the specialist has created the correct consistency.

Now you can begin the laying process itself. It is important to check each row for evenness using a level.

If you are interested in what to line a stove in a bathhouse with (except for brick), you can always find a replacement. There are special casings that are cut to suitable dimensions. They are made from different rocks, are easy to install, and you will definitely find the right option for yourself.

Model range of sauna stoves Hephaestus

Hephaestus wood-burning sauna stoves are supplied in parts, disassembled, this makes them easier to install and assemble right on site. The finished product can weigh from 110 kg (PB 04 M stove) to 950 kg (PB 000 MS stove), so it is easier to assemble the structure directly in the steam room. One or two people will be needed to complete the installation work.

We invite you to read step-by-step instructions for installing a stove in a bathhouse

The manufacturer of cast iron stoves, Hephaestus, thought out the design in such a way that its installation would not be difficult even for a non-professional. In addition to technical characteristics, all models can be divided into two categories, which will determine the features and nuances of installation. Namely:

- Hephaestus stoves in the lining - for their installation you will need to connect a smoke exhaust system and prepare a solid base. These models also include Hephaestus bath stoves in soapstone (a stone with unique healing properties). For the convenience of the consumer, you can familiarize yourself with various methods of finishing performed in the factory. The options for covering the Hephaestus stove depend on the chosen model.

- Stoves designed for finishing with bricks. In models for brick cladding, the finishing depends on the owner himself. After installation, the stove is usually lined and made like a Russian stove.

The Hephaestus stove lined with stone or brick increases heat transfer by 20-30%.

The experience of using Hephaestus cast-iron sauna stoves shows that they should be heated exclusively with firewood and special fuel briquettes. The use of coal and wood waste is not allowed. The optimal solution is to heat the stove with hardwood firewood.

The decision to burn with wood has another advantage: the Hephaestus stove with soapstone releases beneficial substances when heated, which, together with the smell of wood, have the most effective effect similar to aromatherapy. Hephaestus wood-burning stoves in stone are also distinguished by their ability to uniformly heat the room, which makes visiting the bathhouse comfortable and enjoyable.

From the inventory you need to prepare galvanized buckets.

In order for the brick walls to be laid according to the rules and the furnace insulation to be as effective as possible, you need to prepare the following equipment:

- tray for mixing the solution;

- galvanized buckets - 2 pcs.;

- tape measure, plumb line, level, rule;

- a hammer-pick and a hammer with a rubber nozzle for forming masonry.

Finishing

After setting, you need to make a lining so that the sauna stove, lined with brick, becomes a real decoration.

It is most convenient to remove excess solution using a drill with a special attachment. It is important to use personal protective equipment during the process. If after this procedure there are stains left on the brick, they can be removed with a brush dipped in a solution of laundry soap.

In order for the stone to retain its appearance for a long time, it is better to melt it slowly for the first time after lining, allowing the material to gradually warm up. Otherwise, the mortar may crack and the brick may lose its aesthetic qualities and properties.

Brickwork looks very beautiful regardless of the interior style. It does not require decorative finishing, and a huge selection of facing building materials will satisfy the most sophisticated tastes. All you need to do is keep it clean and protect it from damage.

Now you know how to cover an iron stove and boiler in a bathhouse with bricks. Regardless of the masonry method you choose and the materials used, you will immediately feel the pleasant comfort of the updated stove.

Masonry mortar

Invented more than a hundred years ago, the potbelly stove is still popular today due to its positive properties:

- Light weight;

- Long service life;

- Compactness;

- Mobility;

- Fast heating of the room;

- Easy to install.

It has few disadvantages:

- Poorly retains heat;

- The surface becomes very hot during combustion.

To eliminate these phenomena, brick walls are laid around the metal structure.

As a result, the oven receives new positive properties:

- When burning fuel, a metal stove quickly heats up and gives off heat. As soon as the fire goes out, the stove quickly cools down and the temperature in the room drops. The bricks surrounding the surface of the furnace heat up and, unlike metal, release thermal energy slowly. Lining the stove with brick maintains a comfortable temperature in the room longer.

- When fuel burns, the metal becomes so hot that touching it can cause a burn. The surface of the brick does not heat up to such a high temperature. The heat from the heating device becomes softer and more evenly distributed throughout the room.

- Brick gives the stove an attractive appearance. Thanks to its qualities, it can turn a simple stove into a decorative element that decorates the interior.

- The brick shell “breathes”. During the heating process, moisture from the brick evaporates into the room and is absorbed during cooling. As a result, the microclimate improves - the air will not be too dry or too humid. There is no dampness or mold in a room with a brick stove.

We suggest you read: How to cover cracks in a stove between bricks

Before starting masonry work, it is necessary to prepare the base and install heat-resistant thermal insulation on the walls (if they are made of flammable material).

Often, cast iron bath stoves with a brick lining are installed in the wall of the steam room so that the fire door opens into the dressing room. Since the entire steam room is made of wood, special attention must be paid to thermal insulation. At the points of contact between brick and wood, a double layer of heat insulation is laid.

What you need to pay attention to:

- Thermal insulation of walls is carried out with asbestos boards or similar non-combustible material;

- The heating device and chimney should be located no closer than 20 cm from the wall;

- A gap of 10 cm is left between the metal surface and the masonry for air circulation;

- For the movement of convection currents that quickly heat the room, holes (vents) are left in the masonry; they are made two at the top of the masonry and two at the bottom, on the side walls;

- When lining the front wall with doors, you need to make sure that the brick does not interfere with their opening;

- Remove any mortar that comes out of the joints immediately before it dries.

It is easier to understand the technological process using a specific example. Let's look at how to line a sauna stove with bricks. The metal stove will be installed on a concrete foundation. A brick casing will cover four walls; a window is provided for the door on the lintel from the corner.

The entire process of lining an iron stove can be divided into several stages.

Stage 1 Foundation

The most important stage of any construction is the installation of the foundation. The durability and strength of the entire structure depends on the quality of its installation. If during the initial construction a foundation was made for the stove, then in order to cover the metal firebox you will not need to construct a new foundation.

Foundation construction procedure:

- After the issue of where to install the stove has been decided, it is necessary to cut floorboards around the perimeter of the structure, taking into account that the size of the foundation should be 10–15 cm larger on each side.

- Next, you need to dig a pit up to 40 cm deep.

- Then it is necessary to build wooden formwork according to the size of the pit and the planned structure.

- The next step will be to waterproof the foundation.

- Then we pour a cushion of sand and crushed stone of the middle fraction to retain moisture.

- We fill the foundation with cement mortar and be sure to lay a layer of reinforcing mesh on top. We use a building level to check the evenness of the surface.

- Then you need to wait time for the concrete screed to completely harden.

- After the foundation mortar has completely hardened, you need to lay out the base in one row of brickwork.

- We check again with a building level that the surface is horizontal.

- We lay a layer of roofing material to waterproof the base.

- It is necessary to lay a sheet of iron on top, which should exceed the size of the brickwork by 10 cm around the perimeter.

- Then we install a metal stove.

A mixture of cement and clay will serve as an ideal mortar for lining a metal firebox with bricks. Experienced stove makers advise determining the proportion of these components by appearance. It is believed that it is necessary to take the same amount of cement and clay, while adding up to 30% river sand to the solution.

The main thing when preparing the solution is to achieve a homogeneous mass, without pebbles and lumps, reminiscent in appearance of thick sour cream. To check the quality of the prepared masonry mortar, you need to apply a little of the mixture to the brick. A high-quality mortar should not flow or slide off the brick. If the mixture is not very thick, you can add a small amount of sand.

To complete this stage of work, it is necessary to soak a selected number of bricks for masonry in water for 12 hours. This action is required to ensure that the brick does not absorb moisture from the mortar during laying. When using old bricks, it must be cleaned of sand and old mortar.

The average height of the structure will occupy 13–15 rows of masonry. Therefore, it is advisable to divide the entire work process into two stages. First you need to lay 7-8 rows and let them dry. The next day, after checking the shrinkage, we lay the remaining section of the structure.

Brick finishing process:

- You need to build a row starting from the corner of the structure, not forgetting to control the horizontal laying with a building level. Checking the correct angle should be carried out using a plumb line or a protractor.

- It is necessary to spread a reinforcing mesh on the second row to increase the strength of the structure.

- On the same row you need to start creating air gaps through which heated air will flow into the room. This operation must be repeated on rows 6 and 8. It is not advisable to make many holes. Two at the top and two at the bottom will be enough.

- The third row is laid out in the same way as the first.

- In the place where you plan to install the door for fuel and the blower, you need to lay a metal corner.

- The last row is laid out randomly.

An important stage is the preparation of the manufactured structure for its further operation. Do not immediately heat the oven to maximum temperature. It is necessary to perform 2-3 preliminary fires, which use a minimum amount of fuel. Such actions will allow the solution to dry thoroughly. Remember that there are a large number of schemes and methods for lining a metal stove with bricks, which you can learn about in detail on many construction Internet portals.

Durability depends on its quality.

Sand. It should be fine without impurities and poured through a sieve with a mesh of 1.5 mm.

Clay. Pour into a container and fill with good water (not musty), then stir. After kneading, the water should cover the clay. The mixture is left to “sour” for 2-3 days. Then filter through a sieve, rubbing out lumps. Add a new portion of fresh clay to the container and soak again. And so on until the required volume of paste-like consistency is formed.

Clays have different fat content. Particularly oily ones are “neutralized” by adding sand (otherwise they dry out and crack). The proportion of added sand ranges from 0.5 to 1.5 by volume. A good solution is to use fireclay clay. Some craftsmen add heat-resistant glue. However, I will not recommend it because the results may vary.

The craftsmen say that the stove must be covered with half a brick. This is the optimal solution. You can do it in brick, but it will take longer to warm up.

The masonry is done in such a way that the bricks must be tied. Each top one should lie on the two bottom ones, overlapping their vertical joint in the middle of its length. The same order is followed when bandaging the corners.

If you have doubts about the foundation, you can ensure the strength of the masonry with reinforcement mesh. Just cut the pieces to the desired size in advance. It is laid on the surface of each new row, but so that it does not protrude beyond the boundaries of the masonry.

The oven is lined in rows. First, each brick is laid out dry. In this process, adjustments are made (trimming, trimming) so that the vertical gaps are within 5-10 mm and ensure the evenness of the outer row, the verticality of the corners and the symmetry of the smoke and ventilation ducts.

Each brick is numbered and a sequential diagram of the future masonry is formed. After numbering and fitting, the ceramic bricks are soaked in ordinary water. This is done until the release of air bubbles stops. After which they begin laying.

Fireclay brick, immerse in water for a moment. The task here is not to moisten, but to wash away dust from the surface. It must be laid quickly, since fireclay quickly absorbs the moisture of the solution. During work, a plumb line and a building level are used.

We suggest you familiarize yourself with: Vapor barrier for the walls of a wooden house, which side