Recently, due to the saving of raw materials, Kuznetsov furnaces have become very popular, drawings of which can be found on the Internet. Kuznetsov furnaces have found very wide use in Russia and other countries due to their special design. Since 1962, the parent of these furnaces I.V. Kuznetsov was developing a better model of the furnace. Success followed his brainchild from the very beginning - satisfied customers spread positive reviews, and the popularity of the blacksmith's furnace grew.

Kuznetsov's inventions - bell-type stoves are worthy of close attention, since they have an interesting design and perfectly heat the room.

Economical stoves are the result of many years of development

A pressing problem that has been solved by inventors for centuries is still relevant today - the efficiency or efficiency of the furnace. The same goal was pursued by I.V. Kuznetsov, I am constantly improving the design of my inventions. On his website on the Internet, the author demonstrates many designs that have improvements in different projections. Some of them have improved heat-saving capabilities , an improved firebox or additional equipment.

The “horse” of blacksmiths is a special gas movement system that allows warm air to stay inside a kind of cap longer, and allows cold air to quickly escape through a special recess. So, hot air retains heat, but cold air does not have time to cool the brick, quickly being sucked out through the chimney. Inside the structure, a cap-like structure is formed that articulates the hearth and the lower segment.

This design gave these furnaces the name “bell-type” furnaces . It is this cap that is the separating point for gases of different temperatures, where hot ones rise into the cap and accumulate heat, staying there. Due to the fact that the combustion temperature increases, the efficiency of the bell-type furnace reaches 95%. This is an extremely high figure for a brick kiln - the same Russian stove produces an efficiency of up to 40%.

Multi-bell furnaces

Often a conventional bell-type furnace is made as a multi-stage furnace. Each cascade consists of two caps with an opening at the top. The presence of three cascades allows us to call this furnace a classic one, since there is a free flow of gases. In almost any combustion mode, such equipment has a very high efficiency, reaching 97%. In this case, the fuel used practically does not matter. It could be fuel oil, coal or anything else.

Typically, an even number of caps allows 90% efficiency to be achieved. Much depends on the combustion mode and the fuel used. However, the main disadvantage of this method is that the ovens are quite difficult to maintain. Problems often arise when cleaning carbon caps. In addition, the first cap (if the number is even) is very small, the temperature under it will be about 1500 degrees, as a result of which the metal will not withstand it, and the lining in weight is unreliable.

Well, we have already figured out what Kuznetsov bell furnaces are. Order is often built at home. Let's see how to do this and what to pay attention to.

Advantages of the Kuznetsov bell furnace

This stove has many advantages due to the natural movement of gases:

- Uniform heating and heat transfer;

- Lack of soot and smoke - therefore much less cleaning;

- High efficiency or efficiency – negligible heat loss;

- Durability of masonry;

- Interesting design (among more than 150 models there are also round options).

The question of many who want to have this marvel at home is whether it is possible to make it with your own hands? Yes, but to get an economical working stove you need to follow the diagram exactly and use high-quality material.

Required material

It is extremely important to choose high-quality material, in particular, refractory bricks. It must withstand high temperatures. So, fireclay bricks are used for interior masonry. Its quantity is determined according to the drawing. Often there are structures made of ordinary brick, which is done in order to save money. This is acceptable, but the durability of the masonry is reduced. For external masonry, M150 is suitable - clay brick.

You can’t do without 100-130 kilograms of clay. It's better to spend a little more money and pay for quality material. In this case, when crimping, the clay will not crack and will serve for quite a long time. You will need sand twice as much as clay. For approximately 500 bricks, it is necessary to make a mixture of clay and sand in a volume of 0.2 cubic meters.

All that remains is the metal fittings. This includes a valve, steel angles, a grate and two doors. Well, now we will look at how the Kuznetsov heating and cooking stove is made.

Do-it-yourself Kuznetsov heating stove

I.V. Kuznetsov has developed many options for furnaces for various purposes:

- for heating;

- for cooking food;

- for a bath;

- for the street (barbecue);

- with a bed and many other options.

When you decide to install the stove yourself and have decided on the option, the main thing is to get competent drawings for ordering . The order of the Kuznetsov kiln is an instruction that shows the method of laying out each of the rows of bricks and their sequence. Drawings of Kuznetsov’s stoves are easy to find on the website of the creator himself, who kindly shares his achievements with those who like to do everything with their own hands. The order itself is somewhat reminiscent of step-by-step instructions for assembling a complex construction set, so with effort, anyone can figure it out.

If you are faced with stove masonry for the first time, then all your attention should be focused on maintaining order.

Materials

Kuznetsov’s furnaces are much smaller than standard ones, so the material required for its manufacture is up to 2 times less. But this is also a great responsibility, since the lightweight structure must be executed with scrupulous precision.

So, materials for the oven:

- Refractory brick (fireclay);

- Brick for the furnace body (external masonry);

- Fireproof clay (about 100 kg);

- Clean sand;

- Metal wire;

- Steel corner;

- Cast elements: valve, doors for the firebox and ash pan, grate, hearth plate.

Sand: it must be cleaned through a sieve with 1.5 mm holes. It is best to take mountain sand, which contains almost no debris. The simplest option is to buy a ready-made mixture of clay and sand specifically for stove masonry at a hardware store.

Brick: fireclay brick should be taken grades ShB-8 or ShB-5, and ceramic bricks should be at least grade M150. The dimensions of clay brick are 250/120/56 mm, fireclay ShB-8 is 250/123/65 mm, ShB-5 is 230/114/40 mm. The amount of brick you will need can be calculated using an ordering scheme or another method.

Foundation

But the very first task is the foundation, which is easier to plan immediately when building a house. The foundation must be 10 cm larger than the size of the stove around the entire perimeter . It will support quite a lot of weight, so you need to approach it with the utmost rigor. To do this, you must comply with the following standards:

- The stove foundation should not be connected to the foundation of the house;

- If the stove is located near one of the walls, then the stove foundation must be at least 5 cm away from the main one, and the void between them must be filled with sand;

- It is important to ensure good waterproofing for the foundation. To do this, form a sand layer at the bottom of the pit, and wrap the frozen foundation with roofing felt;

- It would be good if the foundation was reinforced with reinforcement – a metal frame.

The upper level of the furnace foundation is flush with the main one. They build up to the required level with bricks.

Bricklaying and floating firebox

The firebox is made of fireclay brick, and the body of the stove is made of ceramic, which means that they behave differently when heated and cooled. Therefore, the firebox itself must be floating ; for this purpose, a special dry seam is made around it. This is done to ensure that fireclay and ceramic bricks, which have different physical characteristics, do not break during operation.

“Dry joint”: between the fireclay and ceramic bricks, the masonry mortar must be removed, and mineral cardboard must be inserted into the resulting void.

One more rule must be strictly observed - protrusions made of fireclay masonry should not fit into recesses made of ceramic masonry, and vice versa. Thus, we get a completely independent firebox.

Attention: you may not notice this in the drawings, but fireclay brick laying is done only on edge . But ceramic bricks are laid at the master’s discretion, this applies to columns and internal walls.

Wire for reinforcement

Metal wire should be used for every third row to strengthen the masonry. You will need approximately 5 meters of such wire. Not all articles contain this small detail, but it is very important.

Accessories

Metal parts are included in the masonry, maintaining a gap of 5 mm for brick expansion due to heating. This gap is filled with fireproof wool.

Recommendations for beginner stove makers

Here are some more useful tips for beginners from professionals:

- The channel between the first and second tier is laid in a quarter of a brick to increase the length of the firebox.

- On the 17-18th row, the top overlap of the caps is made.

- On the 21st tier, leave two passages along the side inner walls.

All this is shown in the drawings and usually does not cause difficulties during operation.

Having finished laying, carry out the first kindling. Use a minimum of fuel so that heating is slow and gradual. During this fire, the furnace is fired, its operation is checked, the tightness of the seams in the places where doors and valves are installed. If you find deficiencies, eliminate them.

As you can see, it is possible to build the simplest Kuznetsov heating or sauna stove yourself. If the work seems very labor-intensive and complicated to you, or you want to install a multifunctional stove, contact professional stove makers. They will do the job quickly, taking into account all the nuances, and the finished stove will be of high quality and beautiful.

Is this real - do-it-yourself blacksmithing?

It must be said that laying a blacksmith requires not so much skills as the presence of good diagrams and drawings, as well as extreme care. Even a non-stove maker, but a skilled house owner can master this task. On the website of the author I.V. Kuznetsov has many freely available ideas and diagrams for the Kuznetsov stove, drawings and clear instructions that are allowed to be taken for personal use.

It will be easier for those who already have valuable experience in bricklaying, then the only thing you will need to do is quietly and peacefully lay the rows, following the pattern. But there are several secrets that are not described in the diagrams, however, in this article you will find most of them.

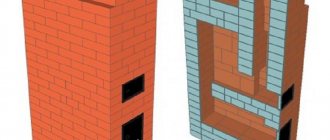

General idea of the design of a two-bell furnace

Furnaces that operate using the principle mentioned above have a fairly simple design. This is a pair of caps placed one above the other or next to each other. The cap, in this case, is a brick glass turned upside down. The latter is supported by walls and columns made of brick. The cap has a couple of holes in its lower part. One of them is the input. Heated gases flow through it. The second is on days off. This is where cold gases come out.

The considered scheme has a cap located on top. The role of the hole for removing gases, in this case, is played by the entrance to the exhaust pipe. Exhaust gases flow from the lower hood to the upper hood through a special vertical channel. In the same bell, a design such as a two-bell stove is equipped with a firebox, laid out in strict accordance with existing rules. High-temperature gases cool down as they move, giving off their heat to supporting structures and walls.

The main properties inherent in this operating principle

- The bell that the bell furnace has can be given any volume and shape (there are realized designs with volumes of 5.0 m³);

- Thermal energy moves due to natural physical laws;

- Gas turbulence forms inside the hood structure;

- Gases with the highest possible temperature are collected under the arches of the bell;

- Cold gases enter the transition channel;

- An increase in temperature under the hood leads to an increase in pressure;

- In each arbitrarily selected horizontal section, the walls of the bell are heated equally. The heating index increases when moving from lower to upper horizons;

- The source that emits thermal energy can be placed at any point in the lower zone of the 1st bell. This does not affect the heating pattern;

- Multiple heat sources are acceptable;

- If the scheme of sequential placement of the 1st and 2nd caps on top of each other is implemented, uniform heating of the structure is achieved over all horizontal sections of the structure. The cap located below absorbs more energy given off by heated gases than each next one.

Taking these properties into account allows you to correctly calculate and design furnaces of the mentioned design.

Features of work

Blacksmiths are multifunctional. All models have bottom heating. Regardless of the type of energy carrier (wood or electricity), the same heating pattern is achieved. The entire structure warms up completely. At the same time, it is possible to implement the operation of an open fireplace, which allows the possibility of cooking pancakes in a frying pan over coals (without the need to turn them over) or kebabs, or a Russian hotpot. In the latter case, you can cook any food.

Another characteristic of such stoves is technical quality. The longer a conventional stove is heated, the higher the temperature to which the chimney walls are heated. Accordingly, the amount of heat that can be absorbed by them from the exhaust flue gases is reduced. Accordingly, they are removed hotter, which reduces the efficiency of operating furnaces.

In two-bell furnaces, increasing the firing time does not have a noticeable effect on reducing efficiency, since all excess heat is accumulated in the bag of the upper bell.