Most owners of private houses and summer cottages have a bathhouse; we read about building a bathhouse from timber. For the proper functioning of any bathhouse, a drainage hole must be equipped. However, in order to equip a drainage hole, you need to choose the right place for it.

Shower floor in a wooden bath

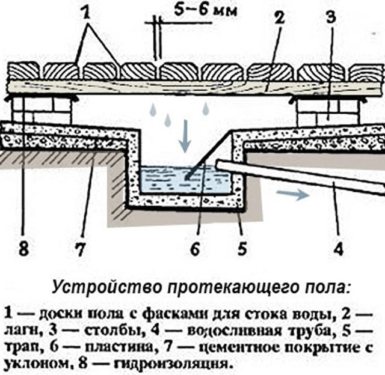

This floor base design is one of the simplest and most cost-effective ones because it uses inexpensive materials. For the plank floor of the bathhouse, you can use edged boards of grade I or II. In this case, the floor structure looks like a flooring, between the elements of which gaps of 5-10 mm are left. It is these gaps in the floor that allow water to drain under the subfloor and into the sewer system. It’s not difficult to make such a flooring in a bathhouse with your own hands.

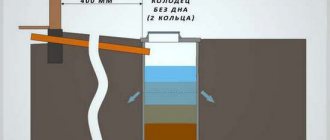

But as for such elements as drainage and drainage of water, there are certain restrictions. If the soil on the site is sandy, then the bath itself may not be drained. Water will be perfectly absorbed into the sandy soil, gradually reaching the groundwater layers. This is a simple drain.

Attention! With this method of draining and draining water in the bathhouse, care must be taken to ensure that no unpleasant odor is formed inside the bathhouse premises. Therefore, if the foundation is slab or strip, holes are left.

If the soil on the site is clayey or loamy, then such a drainage system will not be suitable. Here you need a well-thought-out drainage with the organization of a water collector. What can you offer?

- The first option is to build a so-called pit outside the bathhouse. In fact, this is an ordinary pit into which water will be drained. It is half filled with coarse sand or gravel; this is a kind of filtration layer. Dirty water, entering the collection, passes through the filtration layer, is purified and penetrates further into the groundwater. You don’t have to put sand in the hole, then you will have to periodically pump water out of it. As for the drainage system, you will have to make a groove under the floor of the bathhouse, which is finished with clay or concrete mortar. The soil under the bathhouse floor is made with a slope towards the groove.

- The second option is to completely concrete the soil under the floor with a slope towards the pit. Of the two options, this is optimal in terms of long-term operation.

Attention! For any options for draining water in a pouring floor, one requirement must be adhered to. The distance between the flooring and the ground surface should not be less than 1 m.

Installation of a pouring floor in a wooden bath

Floor requirements.

- First, an underground base is installed, which is responsible for draining dirty water.

- Logs are installed with a slope of no more than 10%. To do this, it will be necessary to make a 2-3 mm cut from one edge.

- The gap between the floorboards is at least 5 mm, taking into account the swelling of the wood.

- The boards are not attached to the joists so that they can be lifted and taken outside for drying.

- The planes under the joists are protected with a double layer of waterproofing.

In small wooden baths, logs are installed on the foundation of the building. If the room is large enough, you will have to install support posts under the joists. They can be raised from brick or concrete blocks. The size of the columns is 25x25 cm; be sure to add sand underneath them and lay roofing material. The supports themselves are plastered. The distance between them is 80-100 cm. It is better if the logs are made of larch.

A very important point is the waterproofing of the subfloor. Usually all planes are treated with bitumen mastics, preferably in several layers. This will provide not only protection, but also ease of washing off waste from soap procedures. The flakes are easily washed off with water pressure.

As for the boardwalk, as mentioned above, the boards are not attached to the joists. The best option is to use a 40 mm thick board made of hard wood, for example, larch. Floor elements are not treated with protective mastics, but joists must be treated.

Dry water seal for a bath

Until recently, for most summer residents there was a problem of how to dry the drain in winter, and thereby preserve the pipes and shutter of the bathhouse during the period of frost. Most often, water was simply drained from the water seal elbow through an additional fitting. The solution to the problem was to use a dry shutter for the bath.

Pendulum or leaf shutter mechanism

The design of a dry water seal differs from the ladder or float version only in the presence of two plastic curtains suspended above the outlet window on a pendulum suspension.

The petals do not create obstacles to the flow of water moving from the bathhouse through the window into the sewer pipe. In the opposite direction, the mass of water presses the curtain against the window and blocks it. As a result, the internal cavity remains dry and impermeable to gases from the sewer system.

Controlled type of water seal

Used in bathhouses not connected to a centralized sewerage system. The design of the water seal is almost identical to the drain drain design. The only significant addition is the presence of a controlled valve. At the top of the grille there is a ring, by clicking on which you can snap a ring petal that covers the window into the drain pipe.

In this case, the water is drained directly into a container for collecting dirty water. After completing the procedures, the water seal opens or closes, depending on whether the bathhouse needs to be dried or not.

In this case, the waste collection container can be equipped with an improvised valve according to the diagram below.

It was on this principle that drainage pipes were installed in the Sandunovo steam rooms and baths in the last century.

For example, if a bathhouse is used all year round, then in winter a wet-type water seal can cause failure of the drain and the receiving flank of the sewer pipe. Dry transoms for a bathhouse turn out to be too capricious. The controlled drain option requires no worries at all. Even in winter, after a bath, there is no need to blow out and dry the drainage part. It is enough to open the valve and leave it to dry until your next visit to the bathhouse.

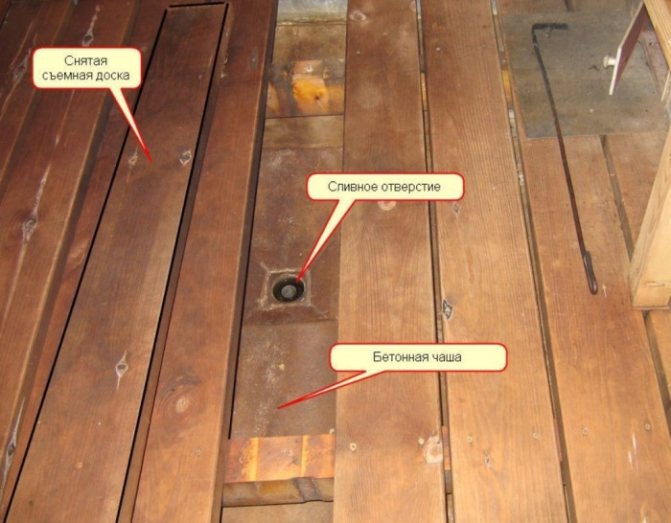

Drain in a wooden bath and its features

Some systems for draining and draining water have already been mentioned, but I would like to dwell in more detail on one interesting option. It consists of a specially made flooring that is laid under a wooden floor. This is not a concrete screed. The flooring can be made from a metal sheet or several sheets. You can use sheet-type polymer materials, corrugated sheets, second-hand ones, and so on.

In essence, this underground flooring is an additional floor that is laid in the underground floor of the bathhouse. It is installed with an inclination towards the drain outlet leading to the catch basin. What are its advantages?

- It can be easily washed by lifting the boards.

- This is a 100% guarantee that water will not seep into the ground under the floor.

- This is an opportunity to additionally protect the structural elements of the bathhouse from the negative effects of moisture and water.

- The flooring can be made in the form of a removable structure, which will allow you to remove it, if necessary, for drying and repair, or for complete replacement.

The question is how to attach this structure. In principle, there is nothing complicated here. There are plenty of mounting options. For example, secure it to the joists with self-tapping screws, observing the slope. You can use staples rather than self-tapping screws, which will simplify the removal process. You can make and install hooks and so on.

Dry water seals

The most pressing issue for a bathhouse with a drain into the sewer is not so much the choice of drain design as the laying of the line itself. Any ready-made version of the drain from the store, including the “dry” one, contains a water seal with a water column of 30 mm or more, so that with regular use of the bathhouse, no problems with drying out the water plug will arise . And anyone who knows that the bathhouse will not be in use for a long time can simply plug the drain.

For those who want to forget and not remember about the dried siphon, there are so-called dry drains.

There are two types of dry water seal.

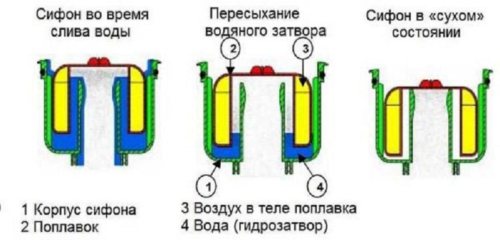

Float type

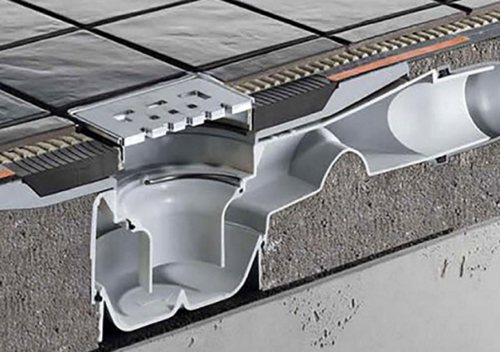

It is best to consider a specific sample, for example, the Austrian HL 310 NPr.

Vertical drain. The top element is cut to the required size from 12 to 70 mm and embedded in the screed.

The polyethylene body is designed for waste water temperatures up to 85 degrees. The installation procedure for different cases is described in the passport.

The float, when the water dries out, simply lowers and closes the pipe. The height of the water column of the valve is 50 mm (corresponds to Austrian city regulations).

The principle of operation is clearly visible in the picture.

In the working position, the water raises and holds the float at the same level and the system works as one of the water seal options. If the bath is not used for a long time, then the water from the valve evaporates , and the float closes the drain hole before the water has completely evaporated.

Craftsmen have come up with an option that can work no worse than the factory one. The main difference from this scheme is that such a float in the form of an inverted glass is fixed so that its bottom is higher than the drain hole than the diameter of the drain pipe. And the hole itself is covered by a light ball with a diameter larger than the drain one - it acts as a float.

Pendulum type

The photo shows a specific example - a dry shutter for 100 mm drains in the neck - Viega 583255.

Below, near the shutter, two curtains are visible, suspended at an angle to the vertical - this is the pendulum shutter. The curtains are closed due to their own weight, and the water opens them when drained. The height of the water column of the water seal is 32 mm - quite enough for a country bath. In Germany itself, which is declared as the manufacturing country, when designing a sewerage system in city houses, it is assumed that plumbing fixtures in apartments have a water column height of the water seal equal to 50-60 mm, but not 32!

If the force of gravity that closes the curtains is replaced by the force of a spring, then you will get different versions of spring-type dry shutters with wider capabilities.

Of course, all of the valves listed contain some version of a siphon.

There is another type of dry closures, for which sometimes too abstruse names are invented, such as cellular memory of the material. Usually they are a stocking made of flattened rubber , which begins to let water through under low pressure. This is unlikely to be of interest for a country bathhouse.

Skillful owners, even with very limited funds, can easily reproduce and, possibly, improve any type of water seal.

How to make a drain with shower trays?

A standard tray from any shower stall is a ready-made system for collecting and draining water. It has a waterproof layer, a drainage system with a funnel and a pipe for connecting to the sewer.

A notable feature is that the shower tray has a water seal (siphon). Using a ready-made shower tray is the easiest way to ensure water drainage in a bathhouse with your own hands. Compared to a system where the water drain in the bathhouse is organized in the floor, the shower tray is less convenient.

The bath tray for draining water is purchased separately from the shower stall. Many stores offer this service. It is advisable to purchase large pallets. They are more convenient to use.

Having a booth in the washroom doesn't hurt either. Everything here is determined by the budget, the total washing area and the chosen design style. Manufacturers of shower trays offer a large selection of materials:

- Plastic acrylic;

- Fiberglass;

- Cink Steel;

- Stainless steel;

- A natural stone;

- Fake diamond;

- Porcelain, ceramics.

The most widespread are pallets made of acrylic and other cheaper types of plastic. The production method is casting in metal molds under pressure, so they can be of any size.

Galvanized shower trays are extremely rare and are mainly made handicraft for summer cottages. Pallets made of natural and artificial stone are not installed in baths due to their high cost. They are more suitable for luxury bathrooms.

Drain pipe wiring

Pipes must be laid sparingly in length and without making unnecessary bends. It must be remembered that a simple structural device not only saves on construction, but also convenient operation and maintenance. The drain will not become clogged. Unfortunately, this is not always observed. In many pictures you can see floors with a drain, where water stagnates in the trench and gutter.

The best way to lay a pipe in the floor is to lay a straight section at an angle.

The pipe runs from the funnel to the outer surface of the foundation.

There is also the option of connecting the drain to other sewer pipes under the floor.

The entrance in the center of the floor funnel or under an inclined gutter near the wall is shaped like a cup.

This cup is located completely under the front plane of the floor and at its lowest point.

The cup in the floor is covered with a fine grate. It must be protected especially carefully if there is no exposed wooden flooring on the floor. For a bathhouse this configuration is rare, but for a sauna it is the most common.

In a bathhouse, as a rule, several plumbing fixtures are used, so proper pipe wiring is very important. This is discussed in a separate article on our website.

Wet valves

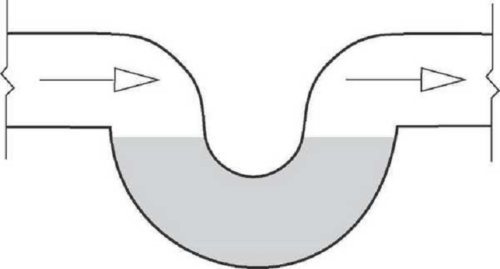

If you choose a water seal for a bathhouse based on the efficiency of locking, then the best option would be a hydraulic circuit with a curved U-elbow, or an annular chamber with a concentric partition.

Eternal knee

A water seal in the form of an elbow requires a free space of at least 150 mm in height for pipes with a diameter of 50 mm and an overhang of 250-300 mm for a full drain with a cross-section of 100 mm. Therefore, knee bellows are used primarily for bathhouse projects on stilts or columnar foundations. To reliably lock the pipe, the height of the water column must be at least one and a half diameters of the channel.

The main advantage of a water seal is its simplicity of design; it is quite possible to make such a siphon for a bathhouse with your own hands from parts of sewer fittings and pipes. It turns out not as beautiful as industrially made drains, but for a bathhouse it is more important that the structure is easy to repair and simple to maintain. The knee can be easily cleaned, either with a brush or with specialized attachments, rotating brushes and even chemicals such as “Mole”.

This type of drain can work in a properly constructed bathhouse for a couple of decades, until someone uses a cable to punch a hole in the plastic elbow of the water seal.

Flat water seal

For a bathhouse installed on a strip foundation, it is best to use a trap water seal. Its height usually does not exceed 10-12 cm, so the drain box can be safely mounted into the floor screed, and no additional fastenings are required for connection to the sewer.

For example, the “CENTER AQUAPA” model consists of two halves. In the bottom part of the water seal there is an annular cavity with water, which, after installing the top cover, will be divided by a partition. The result is the same bellows, but with a gate height of only 15-20 mm. The drain body is simply put on the receiving hole of the compensating adapter of the sewer pipe of 110 mm.

The box-shaped design turned out to be quite reliable and easy to maintain; the only drawbacks include a small level of water in the water seal. In summer, the water in the drain evaporates, and, accordingly, odors from the septic tank will break into the bathhouse within a couple of days. Whereas in the bellows elbow the water seal will last 3-4 days.

In winter, in a country bathhouse, the drain drain may freeze, but this does not affect its operation in any way. There is little water left, so the risk of damage is minimal. A water seal with an elbow can actually be crushed by frozen water.

Float device for organizing a drain in a bathhouse

Structurally, the water seal with a float is very similar to the previous version of the water seal. The only difference is that in the ladder version, the outlet hole is blocked by raising the water level, and in the float version, the same window is blocked with a foam liner.

Float valves very tightly and reliably block the drain passage even with a minimum amount of liquid. In practice, the drain in the bathhouse can be reliably blocked within 10-15 days from the date of the last visit to the steam room. Among the disadvantages, one can note the sensitivity of the water seal to contamination. After soapy water, the float must be washed with clean boiling water.