A bathhouse made of larch is truly an excellent option, since this building material has excellent performance and aesthetic characteristics.

Larch for a bathhouse is strong enough, which allows it to withstand significant temperature changes and high humidity that prevail inside a bathhouse building. In addition, this type of wood is not susceptible to attacks by various living organisms, provided it is properly processed. These qualities determine the durability and reliability of larch as a building material.

>

This is what a bathhouse made from larch beams might look like.

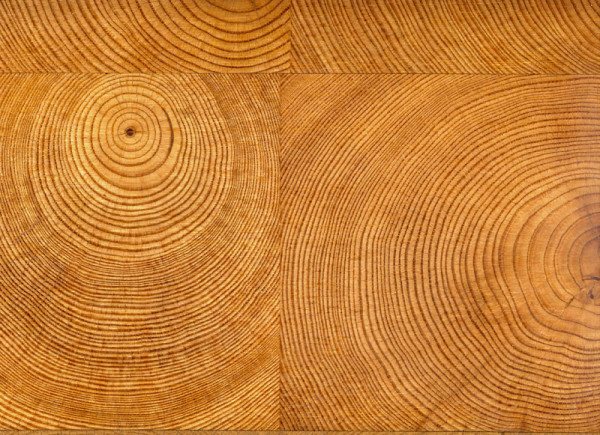

Larch lumber is recognizable by its special pattern.

The price of larch is in optimal harmony with its advantages, which is an excellent motivation for building a bathhouse from this wood.

In this article we are going to talk about building a bathhouse from the specified building material. The reader will be provided with brief installation instructions, corresponding photos, and we will also watch a video in this article in addition to what has been said.

Larch foundation technology

Despite the fairly high load-bearing capacity, columnar foundations made of larch are usually used for the construction of wooden rather than brick houses. First, preliminary soil studies are carried out. If you have a substantial construction budget, you can order special surveys, but if you don’t have a lot of money, you’ll have to do it yourself. Experts advise digging holes at the corners of the future house. If there is clay there, this is not very good: the soil is heaving. In loams this quality is less pronounced, and in sand it is very weak.

Be sure to check to what depth the soil freezes. This indicator depends on the area. The length of the piles and the depth of the foundation are determined taking into account soil freezing. The larger this value, the deeper the piles should be driven. In the conditions of Moscow and the region, the length of the underground part should be from 75 to 155 cm. To this you need to add at least 25 cm of the above-ground part.

To make a wooden columnar foundation, larch trunks are pre-processed (we’ll tell you how to do this a little later) and placed in the corners of the future building, as well as along all walls - both external and internal. By the way, in heated houses it is enough to deepen the internal pillars by only 50-70 cm.

Holes for a wooden foundation can be dug manually, but it is more convenient to use drills, especially when buried deep. A layer of sand ten to twenty centimeters thick is poured into the bottom of each pit. The sand cushion must be compacted. Pre-prepared (impregnated and waterproofed) pillars are lowered into their designated places and perfectly aligned along the axes of the walls. For marking, cords and lighthouse poles are used, which are placed in the corners and at the intersections of walls.

In large buildings or on heaving soils, the base of the pillars is often installed not directly on the sand, but on a special cross. A spike is made in the lower part of the log, and a nest is made in the upper part of the cross, then the structure is connected with staples and lowered into the hole. The crosspiece allows you to increase the supporting area, which contributes to better load distribution.

The supports are carefully leveled vertically, and then the holes are filled with crushed stone, gravel, broken brick or sand. This must be done in stages: after filling the 15-20 cm layer, the layer is carefully compacted, and so on until the very top. Then all the ends of the logs are cut down at the same height using a tensioned cord. All that remains is to insulate them with roofing felt, membrane materials or birch bark, and the larch columnar foundation is ready!

Action plan

The process of building a bathhouse consists of several phases:

- First of all, you need to choose a suitable place where the desired structure will be erected. Next, you need to design the building itself, as well as calculate the amount of building materials that will be needed to implement this idea.

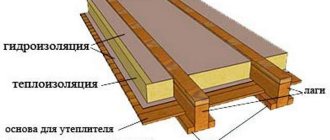

- Next, the foundation is poured, on which the walls and roof of the structure are erected. Along with this, work is being carried out to heat and waterproof the bathhouse premises.

- The next step towards your dream is laying the floor. At the same stage, facing manipulations are also carried out.

- After completion of construction and testing of the heating unit, the bathhouse can be put into operation.

First phase

The location for the construction of a larch bathhouse must be chosen carefully and taking into account all existing rules. These rules state that buildings of this kind, operating with maximum intensity, must be located at a sufficient distance from other structures located on a specific site, as well as on neighboring land holdings.

Thus, the minimum distance from the bathhouse to any other building should be twelve meters.

The choice of construction site must be taken seriously.

In the case where the concentration of smoke in the surrounding atmosphere is relatively low, the previously mentioned distance is reduced to five meters. But, by and large, a bathhouse, which will obviously emit a relatively small amount of smoke, can be freely constructed as a kind of extension to a living space.

However, due to the fact that this design must be provided with an optimal drainage system for spent liquid, experts recommend erecting such structures on small elevations of natural origin.

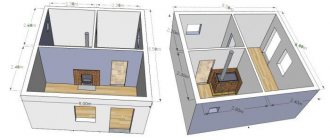

Of course, the design of this design is a personal matter, but it is worth noting that the most popular are bathhouses that have three internal rooms:

- The dressing room is also a rest room.

- Washing room.

- Steam room.

Project of a bathhouse made of larch.

When designing a dressing room, you can provide for it with sufficiently large dimensions in order to arrange a rest room in this room. The rest of the space must be planned taking into account its purpose and characteristics. If the steam room is given a rather large size, it will be poorly heated, which will significantly reduce its functional qualities.

It is not recommended to combine a steam room and a sink, since taking water procedures in such conditions will be devoid of comfort. But the entrance to the steam room must be done directly from the washing room - this is the most profitable and convenient.

Second phase

Any construction begins with laying the foundation.

Speaking about the foundation, it should be noted that the ideal option is a concrete foundation, since it is easiest to build if the work is done with your own hands. In this case, it is necessary to dig a pit, the parameters of which must correspond to the approved plan.

Advice! A special bedding made of crushed stone should be placed at the bottom of this recess, and a reinforced frame should be mounted on top of it. Next, you need to build a wooden formwork, then prepare and pour a sand-cement mixture into the pit.

When the concrete mass is completely dry, the formwork should be removed, and the resulting foundation should be treated with bitumen and covered with roofing felt.

Never neglect waterproofing your foundation.

Third phase

- Before starting installation and construction operations using larch, this building material must be thoroughly processed using special protective substances.

Proper processing of the material is the key to the durability of the structure

Advice! Here we need to draw the reader’s attention to the fact that it is much more convenient to use wooden beams for the construction of a bathhouse than logs, since they have a rectangular cross-section.

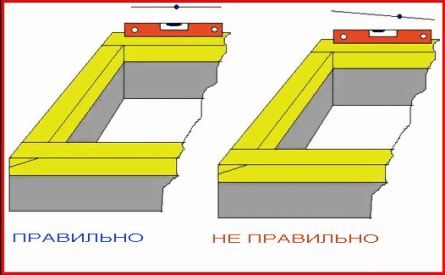

- Construction begins with the laying of special slats on top of the foundation, excluding direct contact of the beams with the base (photo). The purpose of this action is to ensure the safety of the tree through ventilation.

Take care of ventilation of the structure from below.

- Next, the first crown is mounted, which must have a strictly horizontal orientation. This can be checked quite easily using a building level. The mounted crown is covered with insulation on top.

The strict horizontality of the structure is determined using a building level.

The first crown is usually not secured. The weight of the building will already fix it quite reliably.

- The second crown is secured with wooden dowels or pins made of metal. The latter are attached through appropriate perforations, which must be provided in advance. The size of these holes should ideally match the size of the metal pins.

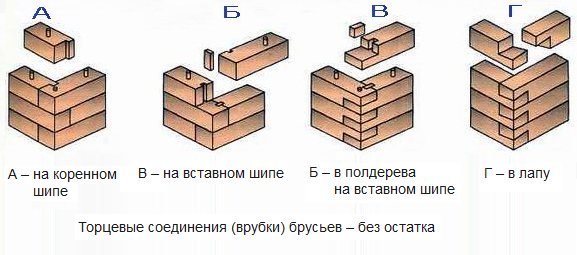

Methods for fixing timber to each other.

The two upper beams remain unfixed until the structure shrinks. This is due to the fact that the bathhouse ceilings are installed only after the walls have shrinked. This process involves removing just the two upper crowns.

Advice! When constructing a structure, it is necessary to leave openings for doors and windows. It should be noted that the boxes for the mentioned elements can be installed after the construction of the log house or directly during the construction of the walls.

- Next, the bath structure is insulated, after which the roof is installed.

Fourth phase

As for the stove, the most convenient option is to install a finished metal structure. However, before this it is necessary to carry out all the finishing work, since testing the stove presupposes the presence of all interior elements that will be present in the room during its operation.

A ready-made metal stove for a bath is the best option.

Preparation and processing of wooden posts

If you have ever been interested in the properties of Siberian larch, then you know that its wood is considered the leader among European species in terms of resistance to moisture. The substances contained in the resin also have antiseptic properties, so treatment, in principle, is not necessary. But if you consider that you are going to build a house that will last forever, it is still better to pre-treat the wood.

To protect wood from rotting, two methods are used. The first one can be called classic. It involves firing that part of the pillars that will be underground. The wooden foundation will not rot after this treatment, but it will take time to properly burn the logs. Before firing, the logs are coated with a layer of clay, and the processing is carried out using a blowtorch. It is important that the layer of burnt wood is no thicker than 2 cm (with the recommended diameter of the pillars being 20 cm or more).

The second method of treating piles involves impregnation with special chemicals, optimally oil-based, then they will dissolve less in water. The method is faster, but requires costs, so choose for yourself what suits you best.

To waterproof a wooden foundation, piles are often covered with “stockings” - covered with roofing felt or roofing felt and coated with bitumen mastics. The stocking is also needed to reduce the forces of frost heaving. Please note that impregnation, firing and waterproofing with bitumen are carried out not only for the underground part, but also in the area that will rise above the ground. It is considered that 25 cm of above ground insulation is sufficient.

Advantages and disadvantages of wooden foundations

Let's start with the disadvantages: you won't be able to arrange a basement or basement. A stone house that is too heavy will still have to be built on a concrete foundation, because a wooden one is not so “hardy”. Due to the danger of horizontal displacement, a powerful grillage will have to be made.

It may seem that a house on stilts has more disadvantages than advantages, because logs do not look as impressive as concrete slabs or blocks. But sometimes a pile foundation is the best option. It is ideal for soils with deep freezing depth and unstable foundations.

Wooden piles made from Siberian larch do not require strength building, unlike concrete foundations, so work can continue without delay. True, you will have to invite specialists who know how to work with wood, but you won’t need special equipment.

You can order Siberian larch logs for a columnar foundation on our website. The standard sizes and costs of lumber that will be needed during construction can be found directly in the catalog.

Features of a wooden foundation

If you install a larch pile foundation, the house will be left without a basement or ground floor. A wooden base is only suitable for a wooden house. A heavy brick or block house cannot be placed on it.

The foundation is ideal for moving soil with a large freezing depth. It does not have the same strength as concrete and there is no need to wait to start building walls.

The main thing is that the installation of larch piles is carried out by professionals, then you don’t have to worry about quality.