Advantages

Cast iron wood-burning sauna stoves have positive properties resulting from the original production material - cast iron.

- Environmental friendliness. Iron, carbon, graphite contained in cast iron ensure their safe and environmentally friendly use. Iron, carbon, graphite.

- Durability. By choosing cast iron, you provide heat in your home for at least 30 years. The material is reliable and resistant to corrosion. The design does not require welding; the absence of irregularities and seams significantly increases the service life of the product, outperforming brick and steel products.

- Heat resistance. Cast iron is not afraid of deformation due to high temperatures and changes.

- Easy installation and portability. Thanks to its small size and relatively moderate weight, you will not need to make any extra effort to install the stove. If desired, the unit can be easily transported and installed in another location. The structure is made of individual elements fastened to each other using locks. Therefore, if parts break, they can be easily replaced with new ones.

- Excellent heating. Cast iron heats up quickly, accumulating heat and takes a long time to cool down. Therefore, during long-term operation, the device melts a large bath within 2-3 hours. A one-time stack of firewood heats the room for 8-9 hours.

- Safety. The “cast iron” cannot catch fire: the wood burns completely, and there is no chance of a fire.

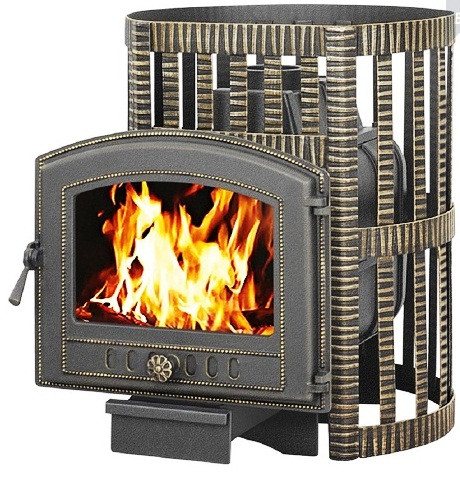

- Aesthetics. Wood-burning cast-iron sauna stoves do not take up large areas; they fit beautifully into the interior of any sauna. The main fuel for cast iron stoves is wood. And this, in turn, is a pleasant and familiar smell, creating an excellent atmosphere in the bathhouse.

Manufacturing of furnace equipment

You can assemble a simple stove for a black sauna with your own hands. To do this, you need to come up with a design, draw up a drawing, prepare tools with consumables, and perform assembly.

Drawing up a diagram

The first stage of self-construction of furnace equipment is drawing up a diagram. In the drawing you need to note the dimensions and design of the stove, indicate the location of the stones. After preparing the drawing, you can calculate the amount of consumables.

Preparation of tools and materials

After drawing up the diagram, you need to prepare tools and consumables:

- Stones that will accumulate heat will not be destroyed by temperature changes or exposure to moisture. It is better to use jadeite.

- Set of locksmith tools.

- Metal rods.

- Fireclay bricks.

- Boards, fittings, wire.

- Container for mixing masonry mortar.

- Trowel, spatulas of different sizes.

- Bayonet, shovel.

- Welding machine.

- Hammer.

Dimensions and location of the structure

To calculate the dimensions, you need to choose a place for a homemade stove and adhere to some rules:

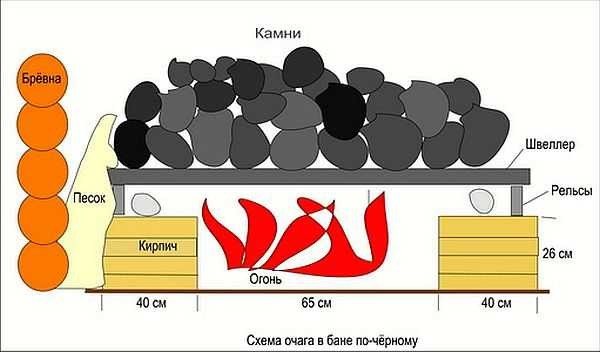

- For a steam room with a volume of 10 m3, the following equipment dimensions are suitable - 150 by 100 cm, height up to 50 cm.

- The optimal shape is rectangular. Thanks to it, the room will warm up evenly.

- It is better to install the structure opposite the door. This way the cold air will spread heat throughout the room.

Foundation

A homemade stove for a black sauna will weigh a lot. Therefore, you need to build a foundation for it. Foundation construction process:

- Dig a pit 60 cm deep.

- Place a 15 cm thick layer of sand at the bottom of the hole.

- Pour a second layer of expanded clay 15 cm thick and compact it.

- Lay two layers of roofing felt on top of the expanded clay.

- Tie a metal frame from reinforcement and place it in the hole.

- Put together the formwork. Make it so high that its height exceeds the bathhouse floor by 50 cm.

- Mix the cement mortar and pour it into the formwork to the required height.

Wait until the base hardens (7–10 days), disassemble the formwork.

Construction of the structure

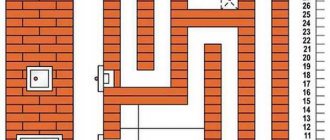

Oven assembly process:

- Place 2 layers of roofing felt on the base for waterproofing.

- Mark the dimensions of the structure.

- Mix the masonry mortar. To do this, you need to mix 5 parts clay with 1 part cement.

- Lay out the first row of fireclay bricks and check it with a building level.

- The next rows are laid so that the seams do not coincide.

- Stop at the 4th–5th row and install a grate made of thick reinforcement.

- Leave space for a combustion hole through the row of bricks.

- Secure the grate on which the stones will be laid.

- Make the last row of fireclay bricks.

You need to start laying out the stones from large to small.

Types of devices

- Cast iron sauna stove with open heater. The most common type. The stones are located in a niche above the firebox: the surface of the hot walls heats the stones, which in turn release heat into the room. An open-type heater not only saves firewood, but also heats up faster.

- Stove with a closed heater. It takes longer to heat up than an open one, but the heat is distributed evenly. The steam that comes out is lighter and thicker. The main advantage: the unit has to be heated less often. A closed heater ensures fire safety and heats larger areas compared to an open one.

- Sauna stove made of cast iron with a water tank. The tank can be suspended or built into the device itself. The second type is not very convenient to use: you cannot control the amount of remaining water.

How to heat properly?

To make it comfortable to steam in a black sauna, you need to follow a number of rules:

- Use birch wood for kindling. Solid fuel with chemical elements is prohibited.

- Before heating, you need to open the doors and windows in the bathhouse and check how the vent is positioned.

- Before adding firewood to the firebox for the second time, you need to fill a bucket with cold water and pour it over the walls and shelves.

- You can start steaming after a crimson tint appears on the surface of the stones.

- Before you start steaming, you need to remove the coals and ash from the bathhouse.

Before starting bath procedures, it is recommended to splash 2-3 cups of herbal infusions on the stones.

Black baths have long lost popularity, giving way to modern buildings with chimneys. Sometimes people want to feel how their ancestors steamed, but they don’t know how to assemble a stove according to the old model or carry out the procedures. To do this, just follow simple rules and assemble homemade oven equipment. The procedure itself is no different from modern soaring. The main thing is to wait until the smoke comes out of the steam room.

Key characteristics when choosing

Having chosen cast iron, you need to compare the parameters of the product with the bathhouse in which it will be installed.

Working properties:

- Productivity, characterized by the area of the room heated by the unit.

- Fuel type. Most often, buyers prefer wood stoves.

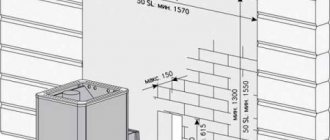

- Type of firebox (standard or extended). The extended one is mounted in the wall. You can heat the sauna directly from the steam room or from the dressing room, which is very convenient.

- Material. There are several variations of cast iron. The service life of the unit and the thickness of the furnace walls depend on the correct choice.

- Wall thickness. Best option: gray cast iron.

- Availability of a water tank and its type. There are two types: built-in and suspended. In use, preference is given to hanging tanks: it is easier to fill in water and control the level of the remaining water. The mounting location of the tank is also important: at the back or on the side. Depends on where you will install the unit.

Design and principle of operation

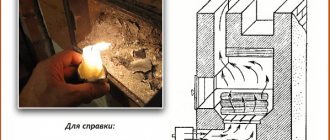

You can still find squat, small bathhouses in which you can steam in the black. Why is this method called this way? This type of stove does not have a chimney. Essentially, this is a fireplace burning in a room, the smoke from which is released through slightly open doors and windows.

Principle of operation

Soot and soot cover the walls and ceiling of the bathhouse, which is why it is called that. Ovens are usually made of stones and refractory bricks. You can make a simple base made of brick and cover it with a powerful lattice that can withstand the weight of the stones, which are laid in a thick layer. In this case, the heat spreads evenly throughout the room, and the stones accumulate it. Now, in order to increase the temperature in the steam room, it is enough to pour water on the stones and the steam room will be filled with steam.

Opposite the stove at the bottom of the wall, several closing grooves are made, with the help of which you can regulate the access of air into the bathhouse; it is important for the combustion of fuel in the hearth.

Stove example

The best cast iron stoves for saunas

Domestic manufacturers offer a wide selection of reliable and cheap devices. After reading the list of the best units, you will find out which cast iron stove is best for a bathhouse.

- "Hephaestus." Hephaestus stoves are rightfully considered the best on the market. Among their main advantages: high power, thick walls and safe operation. The design of the furnaces is monolithic, i.e. there are no fasteners or welding seams. The risk of damage to such a stove is reduced to zero. Convection fins located on both sides of the side walls provide rapid heating and high heat transfer. The efficiency of Hephaestus is the highest among its competitors: 90%. Hephaestus allows you to save on firewood and reduces soot levels. The cost of stoves starts from 25,000 rubles.

- "Vesuvius". Thanks to its one-piece design, it is highly durable and not prone to wear or damage due to temperature changes. Buyers note the good design of the stove, the presence of many modifications. The tank is located around the chimney. The walls of the firebox are thin, so the sauna quickly heats up to the required temperature. The oven capacity is up to 160 stones. The efficiency of Vesuvius is 70%. The assembly has a convenient compartment for ash, which helps in cleaning the stove. The average price for Vesuvius is 20,000 rubles.

- "ATB". Sauna stoves with a cast iron firebox "ATB" are prefabricated units - the design can be modified and faulty parts can be easily replaced. Some find this a drawback - cast iron is less durable compared to solid counterparts. Despite this, the ATB has thick walls and a convenient water tank with a capacity of 60 liters. The efficiency of the stove is 60%. "ATB" has a limitation on heating volume; the unit is not suitable for baths with an area of more than 20 cubic meters.

- "Magnum". These ovens have a high degree of safety. Thanks to the stone cladding, there is no chance of getting burned if used carelessly. The cast iron sauna stove “Magnum” is a conscious choice of buyers.

- AITO-AK. This stove is produced in Finland. They are not inferior in quality to domestic analogues and are highly valued by summer residents. The main advantage of the stove: clean steam. The stones are heated to a high temperature of 500 degrees and do not leave soot. Consumers note extremely fast heating and heat retention for up to 11-13 hours.

- "TORNADO". "Cast iron" produced. If desired, the buyer can independently do the stone or brick cladding. Prices are significantly lower than competitors. It is relatively light in weight and very large in size. Which means the walls are thinner than their analogues. It is known from the manufacturer that heat-resistant cast iron is used in smelting.

Features of operation

When operating cast iron products that are subject to strong, constant heat, it is necessary to remember fire safety rules and carefully follow them. This will help not only avoid fire, but also extend the life of the stove.

The main disadvantage of cast iron is that it is susceptible to corrosion. Therefore, the installation of the product is carried out in a room devoid of sources of moisture. If damage has been caused or there are cracks on the product, they must be repaired in a timely manner to avoid damage to the unit.

You should also use the correct fuel for your stove. In Russia, summer residents most often lay firewood. There is no point in buying peat or pellets, since firewood is the most affordable type of fuel.

The type of logs must also be taken into account. Firewood should not protrude beyond the firebox, as this can lead to fire and untimely damage to the stove.

It is imperative to monitor the level of ash and clean the unit from it as often as possible. This extends the life of the cast iron stove and helps keep it looking beautiful and presentable. A cast-iron wood-burning sauna stove with a water tank requires careful treatment and it is highly not recommended to clog it with ash, dirt and debris.

The cast iron sauna stove is very easy to install and is ready for use immediately after installation. It significantly outperforms its brick and steel counterparts due to its strength, quick heating and independence from the season, which is ideal for use in our conditions.