Home / Articles / Installation of a bathhouse made of profiled timber. Features and main stages.

August-20-2018

The bathhouse is traditionally used for hygiene procedures and health promotion. Many owners of suburban areas plan in advance the place for its construction, and then invite workers or independently erect a log house for the future steam room. This article will focus on what you need to know about installing a turnkey bathhouse from profiled timber with your own hands.

The price of a 6x8 bath is turnkey and shrinkable

| Description of equipment | ∅ 90x140 mm Wall: 9 cm. | ∅ 140x140 mm Wall: 14 cm. | ∅ 190x140 mm Wall: 19 cm. |

| Log house for shrinkage Bathhouse without finishing | RUB 384,000 | 417,000 rub. | 461,000 rub. |

| Turnkey made of natural moisture timber | 488,000 rub. | 536,000 rub. | 601,000 rub. |

| Turnkey made from kiln-dried timber | 540,000 rub. | RUB 594,000 | 667,000 rub. |

- Project: B-46

. - External dimensions of the bath: 6x8 meters

, area:

48 m2

. - Material in stock: in stock

. The walls of the bathhouse are made of profiled planed timber. - Construction time for a bathhouse on your site: from 4 to 12 days

.

Material properties

Profiled timber is made from spruce, pine, larch, and cedar. This lumber undergoes careful processing on a four-sided six-spindle machine, due to which the elements have a special shape and tongue-and-groove connection.

Profiled timber is used in the construction of private and country houses, as well as in the installation of bathhouses. This is due to its following qualities:

- reliability. Compared to aerated concrete and foam blocks, the timber can withstand significant structural loads and does not deform;

- environmental friendliness. Natural material does not harm the human body. Even with prolonged use and when heated, it does not emit toxic substances;

- thermal efficiency. A material 200 mm thick with self-expanding insulation is comparable in this indicator to a rounded log with a diameter of 300 mm. Correct installation of a bathhouse made of profiled timber will ensure its comfortable use at any time of the year;

- resistance to fungus and mold. Treating wood with antibacterial impregnations in production will prevent it from being damaged by pathogenic flora;

- availability. Almost every owner of a suburban area can afford to install a bathhouse from profiled timber with his own hands. The low cost of building materials, savings on fasteners and construction work will allow you to optimize your budget.

It should be noted that wood is not the easiest material for construction. One mistake when installing a sauna from profiled timber with your own hands can reduce all the advantages of the array to zero. For this reason, anyone undertaking construction should pay special attention to preparation.

What's inside? Interior of a timber bath

Petrov Sergey (construction specialist)

I’ll tell you about the equipment, prices, ordering methods, choice of foundation, delivery, how much it costs, technology for constructing a timber bathhouse.

Request a call back

We include in the price the cost of material supplied at our production base in the Novgorod region, and the construction of a bathhouse by a team of experienced carpenters and roofers on a turnkey basis.

At your request, changes and additions can be made to the standard bathhouse design with appropriate cost adjustments. Moving partitions without increasing the material, changing the location of windows and doors will not affect the price of the bathhouse.

Since the bathhouse is assembled at the Customer’s site, this provides complete freedom to implement various layouts and any other of your wishes.

Project development

Initially, you should decide on the size of the building and think about the layout. The depth of the foundation is determined by the level of soil freezing and requires careful calculation, since the log house can create a significant load on the foundation.

Also, when designing, pay attention to the following nuances:

- efficient location of the furnace. When drafting, position the heat source so that it heats as much of the available space as possible. It is advisable that there be enough for a shower, steam room and relaxation area;

- presence of a window in the steam room. Required to regulate the humidity level in the room;

- think about ventilation. Otherwise, even with proper installation of the bathhouse, done independently, mold and mildew will quickly appear on the walls made of profiled timber.

Bathhouse projects

Number of projects 683

Mini square barrel bath project

- To favorites

- 4.2² Total area

- 2 x 2m Building area

from 80,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bani Elena project

- To favorites

- 42² Total area

- 6 x 8m Construction area

individual calculation

Construction period individually

Amazon Baths Project

- To favorites

- 43² Total area

- 8 x 8m Construction area

from 580,500 rub.

Construction period 35 days

- 1 room

- 2 bathrooms

Project Baths Gloria 7*13

- To favorites

- 68.4² Total area

- 7 x 13m Construction area

from RUR 813,857

Construction time individually

- 1 room

- 2 bathrooms

Bathhouse project "Riga"

- To favorites

- 81.5² Total area

- 12 x 10m Construction area

from 1,630,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Project Baths Jupiter

- To favorites

- 30² Total area

- 6 x 6m Construction area

from 405,000 rub.

Construction period 24 days

- 2 rooms

- 2 bathrooms

Bani Vasilek project

- To favorites

- 60.62² Total area

- 8 x 5m Construction area

from 818,370 rub.

Construction period 37 days

- 3 rooms

- 2 bathrooms

Russian Steam Bath Project

- To favorites

- 108² Total area

- 8 x 9m Construction area

from 1,458,000 rub.

Construction period 45 days

Quad bathhouse project “Standard”

- To favorites

- 2 x 4m Building area

from RUB 179,900

Construction time 1 day

- 1 room

- 2 bathrooms

Project of a garden house-sauna "Vasto"

- To favorites

- 25.5² Total area

- 6 x 5m Construction area

from RUR 344,250

Construction time 3 days

Bathhouse project “Russian Steam”

- To favorites

- 36² Total area

- 6 x 6m Construction area

from RUB 420,968

Construction time individually

- 1 room

Bathhouse project "Nega"

- To favorites

- 16² Total area

- 4 x 4m Building area

from RUB 178,550

Construction time 1 day

- 2 rooms

- 2 bathrooms

Project Baths Wave 9.5*6.5

- To favorites

- 85² Total area

- 10 x 7m Construction area

from RUR 1,031,442

Construction time individually

- 1 room

- 2 bathrooms

Yantarnaya Baths Project

- To favorites

- 55.1² Total area

- 9 x 7m Construction area

from RUR 743,850

Construction period 35 days

- 1 room

- 1 bathroom

Oval sauna project “4x4”

- To favorites

- 4 x 4m Building area

from RUB 319,900

Construction time 1 day

- 1 room

- 1 bathroom

Bani B-10 project

- To favorites

- 5 x 4m Building area

from 325,000 rub.

Construction time 10 days

- 1 room

- 2 bathrooms

Bath Pagoda Project

- To favorites

- 123² Total area

- 15 x 9m Construction area

from 1,660,500 rub.

Construction period 30 days

- 1 room

- 1 bathroom

Project Baths Cozy

- To favorites

- 29.3² Total area

- 7 x 5m Building area

from RUR 395,550

Construction time 23 days

- 2 rooms

- 2 bathrooms

Bath Capella project with attic

- To favorites

- 71.72² Total area

- 6 x 7m Construction area

from 968,220 rub.

Construction time 42 days

- 1 room

- 1 bathroom

Project of a garden house-bath "Theano"

- To favorites

- 45.5² Total area

- 6 x 9m Construction area

from 614,250 rub.

Construction time 3 days

View all projects

A bathhouse made of profiled timber is an improved Russian wooden bathhouse. Every resident of a large metropolis dreams of such a building, because after a stuffy and dusty city, taking a steam bath is the best end to the work week.

There are standard and individual projects for turnkey baths made of profiled timber, prices for which vary from several tens of thousands to half a million.

The price of a full-fledged bath complex can exceed the cost of a small house Source teremsibiri.ru

Each structural element has a groove and a tenon, which make it possible to join the beams as tightly as possible. Construction technology has its own characteristics and nuances. Therefore, only specialists will do the work quickly and efficiently.

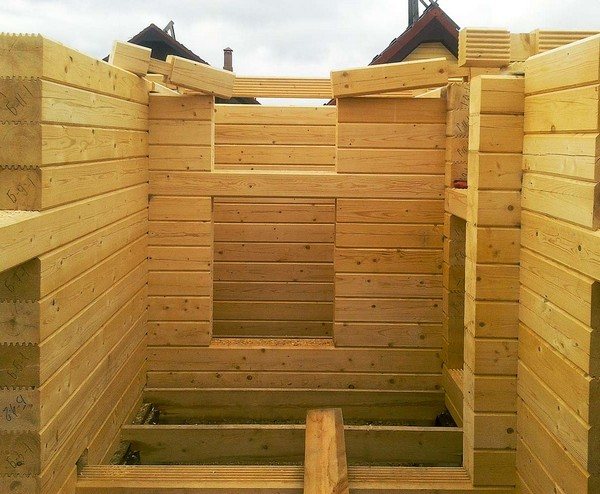

Construction of a bathhouse from timber

Construction of a bathhouse from timber

Building a bathhouse from timber with your own hands is a relatively simple process compared to building a brick bathhouse or a bathhouse from a log house. It should be noted that timber manufacturers can immediately provide you with the construction of a bathhouse by specialists from their company for a fee. This is not to say that this is a bad option, because... the bathhouse will be built quickly, efficiently, and most importantly according to the design you have come up with.

We also draw your attention to the fact that the process of constructing a bathhouse from timber with your own hands can take a lot of time. This is due to the 2-3 week hardening of the foundation, as well as the shrinkage of the timber, after which it is allowed to decorate the interior of the bathhouse with decorative materials.

The technology for building a bathhouse from timber with your own hands is not very convenient to provide in writing, because Visual information is easier to perceive and remember. That is why next we will provide you with a video tutorial on how to independently build a bathhouse from timber with your own hands, and now we will tell you a few tips that will be useful when building your own bathhouse.

Tips for building a bathhouse:

- Choose the right foundation. Although a timber bathhouse is a lightweight building that can be erected on a columnar or pile foundation, a lot depends on the properties of the soil. For example, if the soil on your site is heaving, then even a light bath will require the construction of a slab or strip foundation.

- If you decide to lay the timber yourself, do it with additional insulation of the inter-crown space using log caulking materials (jute or flax).

Caulking timber - Be sure to provide high-quality waterproofing and insulation of the bathhouse. The durability of the building, the cost of heating the steam room, as well as the comfort of staying in the bathhouse will depend on this.

- Carry out all finishing work only after the timber has shrunk, because within 5-6 months after the construction of the bathhouse, the structure can settle by 5-10 cm and damage the lining of the bathhouse.

Calculation of the amount of timber for a bath

When building a bathhouse from timber, you need to consider the following: they sell wood materials by the cubic meter. Since the geometry of the timber (regular, profiled or glued) is almost ideal, the same volume of material produces a larger area of the finished product (walls in this case) than from logs of the same volume. Add to this the saving of time and labor when constructing a box from timber, as well as the ability to leave the building without exterior or even interior decoration, and the high price of timber, ultimately, does not greatly affect the overall cost of construction.

When building baths from profiled timber, much less waste is generated

It is also necessary to take into account that timber has thermal conductivity characteristics similar to wood, and for the construction of a log house from timber in central Russia, material with a cross-section of 150x150 mm is sufficient. Walls of this thickness retain heat well in winter and coolness in summer, and everyone knows about the ability of wood to regulate air humidity in rooms (with the exception of laminated veneer lumber - when using it, a well-thought-out ventilation system is required).

Since the material of this cross-section weighs little, it does not create significant loads on the foundation. If you are building only a bathhouse, and not a house with a bathhouse, then in most cases the foundation can be made columnar. It can cope with such a load, but it is built faster and, as a result, is cheaper. On some soils, a strip foundation may be needed (read about choosing the type of foundation and stages of construction here). It requires more materials and time, but can withstand heavy loads. In any case, you will need less materials, money, time and effort than a similar brick building. This also makes the final cost of the structure less.

Bathhouse made of profiled timber - photo of one of the typical options

How to count

The amount of timber needed to build a bathhouse (and a house too) is calculated after the size and layout have been decided. You also need to already know the cross-section of the lumber you will use. Next, the total perimeter of the walls is calculated, taking into account all the partitions being erected (if they are all made of timber of the same section). We multiply the perimeter by the height, then by the thickness of the timber in meters. We get the required volume.

Let's give an example of a calculation. We want to build a bathhouse 6*6 m with two partitions 6 and 4 m. The height of the walls is 2.5 m, the timber is 150*150 mm. The order is:

- We calculate the total perimeter of the walls: 6*4 + 6 +4 = 34 m;

- we determine the wall area 34 m * 2.5 m = 85 m2;

- we find how much timber will be needed 85 m2 * 0.15 m = 12.75 m3

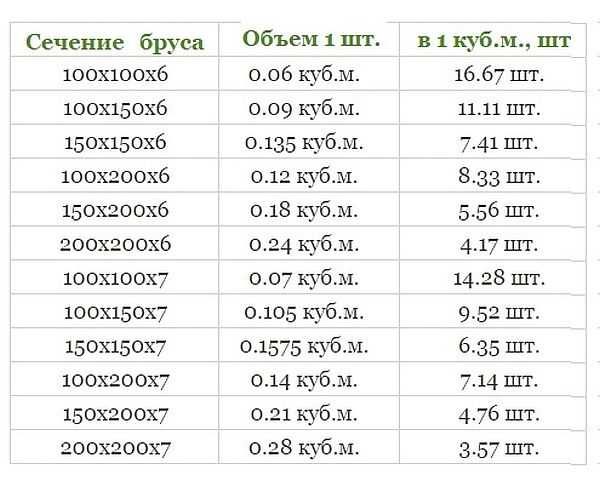

The table shows the volume of one 6-meter bar and the number of pieces in one cubic meter

But this is an approximate calculation; it will be necessary to add a couple of cubes, “just in case,” and also on the fact that if the length of the wall or partition is less than 6 meters (this is the standard length of lumber), then its remains are unlikely to be available anywhere apply. Therefore, it turns out that the calculated amount is less than required.