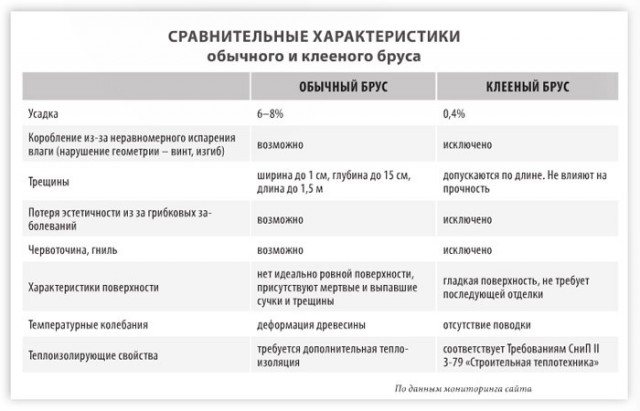

Wood is the traditional material from which baths are assembled. But progress does not stand still and lumber is constantly being modernized and improved. Thus, profiled and laminated timber appeared, from which it is easier and faster to assemble any structure. But is it possible to build a bathhouse from laminated veneer lumber? Experts and ordinary netizens are actively discussing this issue. We have analyzed most of the reviews on the Internet, and we will also try to answer this question not as sellers trying to advertise their product and show it only from the best side, but as specialists ready to help their readers choose the right material for a bath.

Bathhouse made of laminated veneer lumber, turnkey construction.

Advantages of laminated veneer lumber for the construction of a bathhouse

If we compare the heat-shielding properties of laminated veneer lumber and solid timber, the former wins. This is due to the fact that the glue connecting the lamellas of the product prevents the transfer of heat between them. Therefore, a bathhouse built from laminated timber better maintains the temperature of its premises. In addition to the above, this material has a number of other advantages:

- There are virtually no bends, shrinkage or cracks;

- Simple and quick installation;

- Durability;

- Smooth surface;

- One hundred percent tightness of connections;

- Resistance to mechanical stress - abrasion, shock, etc.;

- Excellent moisture resistance due to adhesive impregnation;

- A design that does not require additional finishing work - cladding and other things.

Unlike simple wood, laminated timber is not afraid of changes in humidity levels. This is due to the technology of its production: when gluing timber, the wood fibers of its components are directed in opposite directions in relation to each other. This greatly increases the strength of the product and guarantees the preservation of its shape.

Choosing laminated timber for a bath

Regarding the correct choice of laminated veneer lumber for building a bathhouse, experts advise the following:

- You should only purchase northern forest from trusted manufacturers.

- You can only cooperate with a company that guarantees that the walls of the building are treated with a special compound that counteracts the appearance of insects and rot. Such an antiseptic must itself be environmentally friendly, this is important.

- When making timber, an adhesive composition is used to connect the lamellas. It is worth paying attention to its brand. The AkzoNobel composition, which has an environmental certificate, has proven itself to be the best.

- A high-quality timber includes from 3 to 7 lamellas - no more, no less.

- The end part of the beam must be protected from cracking by impregnation with a special solution.

- When purchasing, they often give preference to Finnish laminated veneer lumber, which is slightly more expensive than its local counterpart, but is of better quality.

How to choose quality timber

The quality of the future bath depends on the correct building material. When choosing laminated veneer lumber, it is recommended to pay attention to the performance characteristics of the material and the presence of defects.

- It is better to choose wooden beams only from reliable suppliers who guarantee high quality of the product.

- The wood must be well dried, treated with an antiseptic and a special impregnation against cracking.

- The surface of the timber must be flat and smooth, without defects or deformations. In addition, it should be free from rot and damage caused by insects and other wood pests.

- The adhesive used to connect individual lamellas must be of the appropriate brand and quality.

- In high-quality laminated veneer lumber, the number of lamellas is strictly limited and amounts to 3–7 pieces. The thickness of the material depends on the number of lamellas.

It is better to dispose of low-quality or contaminated areas of wood immediately to prevent further contamination of healthy parts of the timber.

Undamaged areas with minor defects are recommended for use in the manufacture of door or window frames, slats, floor boards, gazebos and benches.

When choosing laminated veneer lumber, it is important to consider the type of wood from which it is made. So, it is better to use larch for the lower crowns, and coniferous species for the remaining elements.

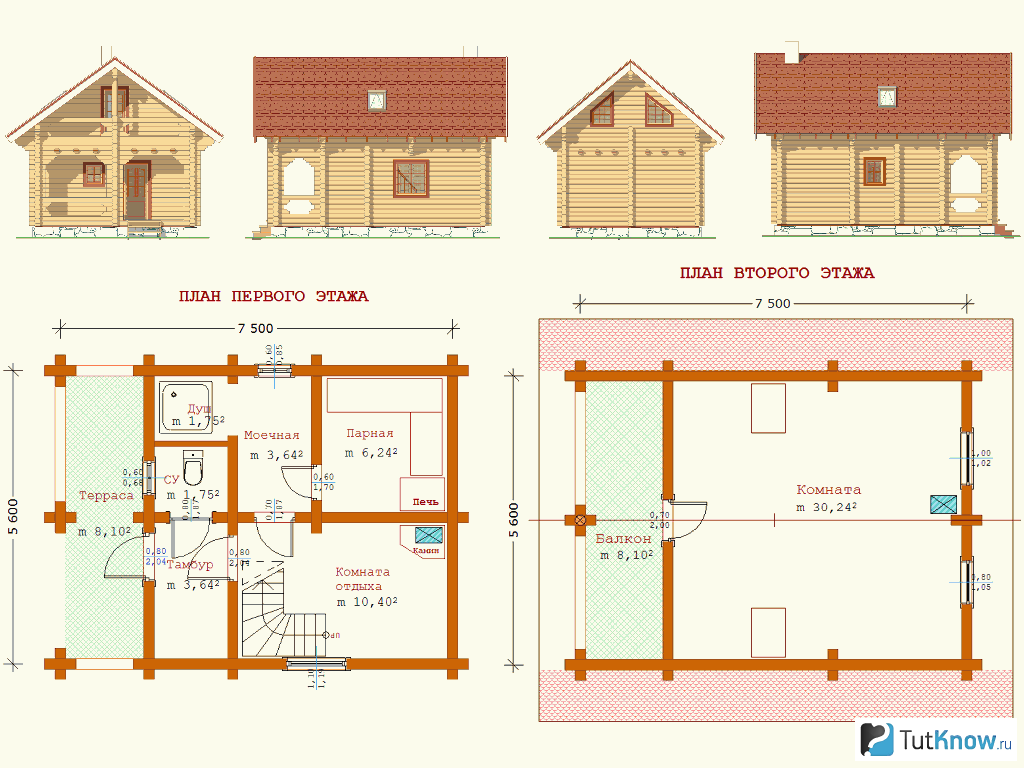

Designing a bathhouse made of laminated veneer lumber

But the construction of a bathhouse has a distinctive feature: the need to take into account the humidity and exposure to hot air in its premises. Before starting construction, it is necessary to think through all the elements that will make up the building, so that the finished structure does not need to be rebuilt later. To do this, we advise you to familiarize yourself with information that can help you optimally choose the appropriate material, or consult with professionals. You can find various photographs and ready-made designs of bathhouses made of laminated veneer lumber, find out what they look like, choose the right sizes, roof shape and much more.

It is worth paying attention to the location of your future building. The bathhouse must be built on the leeward side of other buildings. Thanks to this placement, it will be closed from slanting rains, which adversely affect the safety of wooden structures.

At the planning stage of upcoming construction work, it is necessary to determine:

- Types and quantities of tools needed;

- Specification and cost of materials for the bath;

- Total construction cost.

If you have difficulty doing this work, you need to involve estimate masters. If you have a ready-made project, you can purchase a bathhouse kit for it at the factory in the form of its parts. After their delivery, the bathhouse can be simply assembled. If all the materials are available, a bathhouse made of laminated veneer lumber can be erected in a month and a half.

Construction of a foundation for a bathhouse made of laminated veneer lumber

Its type and depth no longer depend on the purpose of the building, but on its weight, as well as on the depth of soil freezing in your region. Many builders like to build strip foundations. There are several reasons for this: endurance, durability and simple installation of the concrete strip without the use of cranes and other construction equipment. The work on installing a strip foundation can be divided into several stages:

- Planning and marking of the site for construction.

- Digging trenches with the required depth of soil freezing in winter.

- Installation of a sand cushion 150–200 mm thick at the bottom of the trenches.

- Assembly and strengthening of formwork for strip foundations.

- Production of reinforcing frames and linking them to formwork.

- Pouring the resulting structure with concrete to the design level.

- Covering the foundation with waterproofing after it has hardened.

The bottom of the foundation should be located 200 mm below the freezing point of the soil to avoid its deformation destruction during the winter-summer cycles.

Less commonly, a pile foundation is used to build a bathhouse. Its installation is advisable on soils with subsidence or at the bottom of a reservoir.

Construction of walls from laminated timber

Each row of such elements is called a “crown”. The frame of a house with such walls is called a “log house”. Wooden structures are connected to each other in many ways: “into the paw”, “into the bowl”, “dovetail” and dozens of others. To build a wall from laminated veneer lumber, you need to cut a groove at the bottom of each element. This part of the beam is laid on the plane of the previous element with jute insulation 1 cm thick. The lower part of the first crown is isolated from contact with the foundation by built-up waterproofing.

The sauna log house can be made from solid timber. In this case, the elements are connected with dowels with a cross-section of 25x25 mm and a length of 350 mm. They are installed in increments of 2 m. Corners and joints are often assembled “into a tongue” or “into a tongue.”

The length of timber walls should not be more than 6.5 m, otherwise vertical compressions are installed. After installing the timber walls, all grooves are caulked. This procedure must be repeated a year and a half after the final settlement of the walls.

Windows for saunas made of laminated veneer lumber

To do this, special grooves are made at the ends of the window frames to suit the size of the slats. With this design, the windows move freely up and down. Then thermal insulation is laid into the grooves and trims are installed. Do not use softwood materials to make steam room windows. At elevated temperatures, such wood releases resin. The beams of the wooden floor of the bathhouse are attached to the wall with a reliable notch, imparting rigidity to the overall structure.

WHAT CLAN TO COVER THE STEAM ROOM?

Pine, spruce or larch should not be used to upholster the walls of a steam room. Coniferous wood is especially dangerous in a steam room - it contains a large amount of natural resin in the structure of the tree. When heated, sticky resin is released from the mass, burns the body and causes dizziness.

To cover the steam room, it is necessary to use materials that retain heat for as long as possible and at the same time remove excess moisture naturally. Not every lining can withstand 10-15 years of use without darkening, rotting and repairs. Experienced bath attendants recommend using three types of lining:

- Aspen lining is the strongest of inexpensive lumber. People call aspen a “vampire tree”, which takes away negative energy and improves the emotional background. The lining made from treated aspen does not heat up, which prevents the appearance of burns on the skin. Washing in an aspen steam room has a positive effect on the treatment of bronchitis and joint diseases. The bitterness from the aspen core relieves inflammation and has an anthelmintic effect.

- Linden lining is a material that does not swell when exposed to water and is not covered with fungus. It is not inferior in properties to the famous abashi tree, but is much cheaper than its African competitor. Pay attention to the fact that due to the small number of knots, it is quite easy to cover the steam room with linden clapboard. The air in the steam room, lined with linden boards, has a pleasant honey aroma of moderate persistence. Inhalation of linden vapors has a beneficial effect on the liver and has an anti-cellulite effect.

- Alder lining is a beautiful white-pink material. If you want to make your steam room “rich” and surprise your guests with the sophistication of the interior, alder lining is perfect for solving this problem. Alder is also a water-resistant wood species, which is used for the construction of small piers and wells.

The lining should be mounted on a horizontal sheathing with a step convenient for installing a mineral wool mat or other insulation. To secure the lumber to the sheathing, you must use nails or clamps.

Finishing a bathhouse made of laminated veneer lumber

But if you wish, the walls can be sanded and painted. For a therapeutic effect, the steam room is lined with clapboard made of linden, alder or aspen. When heated, these woods release aromatic essential oils that are very beneficial for health. The floors in the bathhouse can be made of wood on joists with mandatory ventilation in the underground space. Insulation and insulation of ceilings is carried out with basalt mats, polyethylene film and aluminum foil. Non-flammable materials are good for roofing: metal tiles, profiled flooring, slate or ondulin.

LINING THE BATH WITH CLIPPING INSIDE

Aspen lining is the lightest among sauna lumber. Thanks to its whitish tint, it can be safely used for finishing ceilings and walls. White color with vague light brown spots will visually increase the height of the room and bring a touch of freshness and cleanliness to the steam room and dressing room.

Aspen lining does not crack, burst, overheat, or darken, and if properly processed, does not accumulate condensation on its surface. The material can withstand water loads in baths, wells and cellars. Aspen lining does not burn the skin and kills mold and fermentation fungi. Air saturated with aspen vapor relieves headaches - this was noted by Vladimir Ivanovich Dal himself, a famous writer and lexicographer.

An equally popular material for lining a bathhouse is alder lining. This type of wood is resistant to dampness, heats up slightly, and does not split for decades. It will not only keep the room warm and dry, but will also give the interior a rich reddish-chocolate hue. Oleshnik does not absorb moisture, so it is used for laying floors.

Construction of a roof for a bathhouse made of laminated veneer lumber

They are quite reliable and easy to manufacture. They consist of a rafter system, sheathing, vapor barrier, insulation and finishing material. There are two types of roof rafters - inclined and hanging. Inclined rafters can span a span of up to 7 m without intermediate supports. For larger spans, hanging rafters are used. After installing the entire system, you can install the cornice flooring and trim the gable. Then a sheathing of boards is installed on the supporting structure. We will attach the roofing material to it. Each of its types has its pros and cons, let’s consider each of them:

- Shingles, for example, although durable, are heavy. To support it, powerful rafters and lathing are required. Therefore, tiled roofing is more suitable for a home than a bathhouse.

- A slate roof is lighter, but it will last about 15 years, no more. For a bathhouse, this is a completely acceptable option, because the slate can then be replaced. When installing such a roof, the overlap of one sheet on another follows the length of one wave.

- The lightest covering is metal flooring. Its sheets are fixed to the sheathing using special metal strips, which are located in the places where the sheet is closed and in its middle.

Don't forget to provide the roof of your bathhouse with drainpipes, eaves and gutters so that when it rains or melts snow, water does not flow down the walls.

COVERING THE WASH COMPARTMENT WITH LINKING

Not only PVC, but also linden lining is suitable for lining the washing compartment. The main thing is to install a ceiling hood and treat the boards against mold to avoid the appearance of black spots and insect nests. For this purpose, transparent antifungal agents are used for linden and other types of wood. The water-based coating does not in any way affect the smell inside the room and does not contain dangerous impurities.

In order for the air to circulate naturally under the linden paneling, technological holes are drilled in the board. Don't forget to install sliding guides under the cladding board. They will prevent deformation of the material during the shrinkage of the log house.

Engineering communications in a bathhouse made of laminated veneer lumber

Water supply, sewerage, electricity, ventilation and heating networks must be present in it. When installing utilities, the following recommendations should be taken into account:

- The power supply of saunas and baths is considered a high-risk facility. Therefore, materials and devices used for electrical installation must meet electrical and fire safety requirements.

- Wiring is laid on wooden walls only in a metal sleeve.

- In the steam room, the electrical wiring must be behind a vapor barrier and be adapted to work at elevated temperatures.

- Lamps for baths are made in explosion-proof design.

- Sockets and switches are not installed in rooms with high humidity.

To operate the ventilation system, it is necessary to calculate the air exchange of bath rooms, lay air ducts, install ventilation grilles and valves in the technological windows of the boxes.

We also recommend watching a video about finishing and communications in a bathhouse made of laminated veneer lumber:

[media=https://www.youtube.com/watch?v=E44KAkNu1_s]

By and large, building bathhouses from laminated veneer lumber is not a particularly difficult task. Many stages of the work can be completed independently. You can always involve professionals in a matter that is unfamiliar to you. But you always need to learn, experience is priceless!

WHERE TO BUY LINING FOR COVERING BATH AND SAUNA?

If you want to buy lining made of alder, linden or aspen, consider purchasing from a reliable supplier -. The company specializes in the production of finishing materials and furniture for saunas and baths. By purchasing goods from a specialized company, you can rest assured of the quality of lumber and their compliance with the declared characteristics.

The manufacturer supplies lining made of aspen, linden and alder directly from the base on various types of transport: GAZelle, Valdai cars, Euro trucks and containers. The prepared material is packed in shrink film and delivered to the client with all the necessary documents.