House made of double timber on a pile foundation

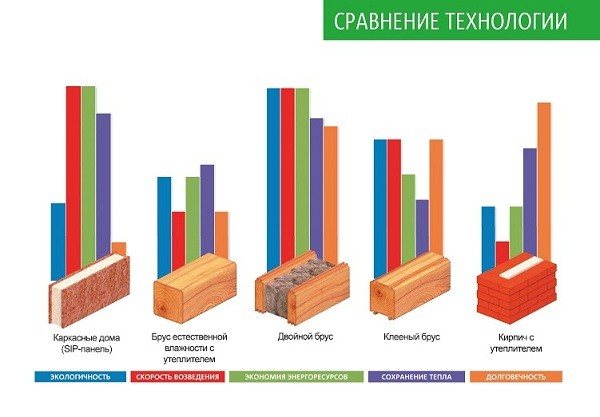

The technology of building houses from double timber has been used in Europe for a long time. In Russia, they began to build houses using double beam technology relatively recently, but the buildings have proven themselves to be very economical and energy efficient.

The technology for building a house from double timber came from the Finns; they were the first to lay two beams in a mirror image, laying insulation between them.

Disadvantages of double timber

Experts also note the disadvantages of houses made of double timber:

- Uneven shrinkage of a wooden structure. This happens due to the difference in temperatures inside the house and outside.

- Replacement of sections of walls damaged during operation. They are discovered both at the construction stage and during the operation of the home.

- Only qualified specialists achieve high quality assembly, and they do not value their work cheaply.

These are the disadvantages of construction.

Technology of constructing a dwelling from double timber

Despite the fact that the thickness of the walls can vary within any limits, the territory of the Russian Federation is located in several climatic zones with known operating conditions and negative temperatures in winter. Therefore, for the convenience of developers, several standard options are usually used:

| Options for external walls of wooden houses made of double timber | ||||

| For seasonal buildings and internal partitions - for a garden house without heating and non-load-bearing walls of a cottage, cottage, it is more rational to use 44 mm or 70 mm tongue and groove boards without insulation | ||||

| warm climate, “mild winter” - wall thickness 188 mm or 238 mm from 44 mm boards and 100 mm, 150 mm ecowool layer between them, respectively, the option is also suitable for partitions The thickness of the insulation is 100 or 150mm. The total thickness of the house wall is 188 and 238 mm, respectively. This option is used for the manufacture of walls and partitions of residential wooden houses. This design has become most widespread in the construction of residential wooden houses. | ||||

| harsh climate, critical levels of negative temperatures - 240 mm or 290 mm walls made of 70 mm calibrated boards on both sides and 100 mm or 150 mm of insulation inside the warm timber | ||||

Production of houses from double timber

provides the developer with a house kit, that is, a set of marked boards from which the building box must be assembled on the erected foundation without errors.

Therefore, the “Double Beam” technology

is complex, combining the construction of a log house and the classic “frame” with minor differences:

- instead of a log or beam, the crowns consist of two parallel boards installed on an edge

- the corners retain cuts, but the crowns have a hollow structure like a frame without posts

- after the construction of all floors to the mauerlat and gables to the ridge, the space between the boards double timber houses

filled with ecowool

It is the last stage that is considered the most important, affects the operational life and can become a source of increased operating costs when insulating independently. The fact is that specialists from specialized companies use professional technologies:

- industrial equipment for the production of ecowool and its supply under pressure of 2 kg/cm2

- calculation of the density of the heat insulator depending on the height of the “frame structure”

An individual developer who does not have such equipment will be able to insulate double beams

commercially available thermal insulators:

- extruded polystyrene foam - does not meet fire safety standards, according to SP 4.13130, the wall perimeter adjacent to window/door units should be insulated only with non-combustible materials

- basalt wool - complies with fire safety standards, however, with high wall heights, it is guaranteed to shrink without vertical fixation to load-bearing structures

- glass wool - similar to the previous case, the owner will receive crumbling insulation from below and empty space at the top of the wall after 4 - 7 years of operation

That is why the production of houses from double timber

their assembly at sites must be carried out by specialized companies.

Stages of building a house

Building a house using double timber technology consists of several stages:

- a project (sketch) is developed, a construction and architectural plan is selected;

- a working version of the project is created taking into account the wishes of the customer;

- preparation of parts for the timber kit;

- construction of the structure.

Double log houses do not require the use of glue or nails. Connections and nodes are clearly adjusted. This ensures durability and high strength of the structure.

It’s easy to build a log house with your own hands, but you need experience in constructing this kind of structure.

Advantages of houses made of double timber

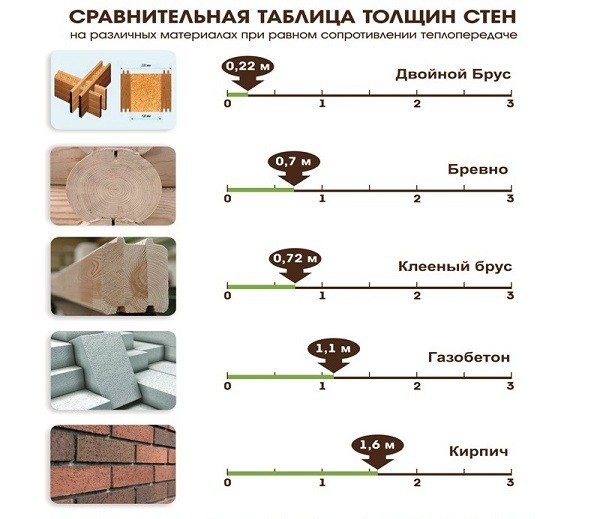

Houses made of double timber are distinguished by high thermal insulation properties due to the use of natural warm material. Such a house will be warmer than a log house; it will be cool in summer and warm in winter. During the heating season, the cost of heating the room is minimal. The thermal insulation characteristics of a house made of double timber are the same as that of a brick house with a one and a half meter wall, which does not require further insulation and finishing.

Wood is an environmentally friendly material. The production technology does not use glue, as in laminated timber.

The main advantage of houses made of double timber is the fairly low price. The cost will depend on the design of the house and the insulation chosen. Mineral wool is much cheaper than ecowool, but ecowool has a longer service life. In terms of cost, a house made of double timber will be the same as an uninsulated log house.

Advantages of Ecowool

The material has high fire resistance. The boards are treated with fire retardant compounds, and non-combustible materials are used as insulation.

Has excellent soundproofing properties.

The timber is manufactured on high-tech lines in the factory. The board is dried in chamber dryers to a humidity of 13% - this humidity is optimal, while the molecular bonds in the material are broken and it does not accumulate more moisture than it gives off.

Double timber is lightweight. A house built from such material does not need a strong foundation - an inexpensive pile or shallow strip foundation will do. This results in significant cost savings.

Communications are carried out during the construction process. They can be hidden inside the walls.

A house made of timber can be built in one season. Does not require additional standing until complete shrinkage. After construction, you can immediately begin finishing work.

Easy to install. It is built without the use of construction equipment. But the construction of such houses must be carried out by professionals, otherwise the thermal insulation characteristics may decrease.

If all the work is done correctly, the house practically does not shrink. The maximum possible shrinkage is 1-2%.

Only dry boards are used in the production of timber. Thanks to this, the building is not subject to shrinkage and deformation.

When the heating is turned off, a well-heated house stays warm for more than 15 hours.

A house made of timber breathes. Does not require additional vapor barrier measures. The wonderful pine scent lingers for a long time.

It is believed that living in houses made of coniferous timber has a beneficial effect on health, in particular on the respiratory system.

The boards used in construction using double beam technology are processed with high quality. Thanks to the tenon-groove connection, they fit perfectly against each other without the formation of gaps or cracks.

Attention! Construction using double beam technology can only be carried out in dry weather. In rain and snow, the material gets wet. You cannot build from wet timber. When it rains or snows, the building is covered with plastic film and work is temporarily stopped. The timber is stored under a canopy in packaging.

Laying the foundation

The foundation is laid for a timber house after a thorough examination of the soil, the depth of soil freezing and its moisture level. The thickness of the base depends on the area of the future structure.

The foundation formwork also needs to be installed correctly. Its quality depends on this. Several steps are expected to be completed:

- The heat-insulating material (glassine) is spread evenly;

- fittings with a diameter of 12 mm or more are attached;

- asbestos-cement pipes are laid, acting as ventilation passages;

- the frame is strengthened with knitting wire;

- Concrete is being poured.

Leave the choice of foundation type to a specialist. One-story buildings are often erected on a strip foundation. It has its advantages:

- withstands timber construction;

- installation costs are saved;

- Ecowool, which does not shrink, is used as insulation;

- the boards are connected with tenons that fit into grooves, which ensures the rigidity of the structure;

- insulation is placed in the gaps;

- the inner side is covered with a vapor barrier film.

One-story houses made of this material are favorably energy efficient. Heating requires little fuel, since the walls retain and save heat well. Their thermal conductivity is equal to the thickness of brick walls.

Heat loss during winter operation of the house for each type of timber

Heat escapes through walls, windows, and roof. Some heat is lost through ventilation. The most significant heat loss is through the walls of the house. Their value is higher, the greater the temperature difference between the house and the street. The amount of heat loss directly depends on the thermal insulation properties of the material from which the house is built. The thermal conductivity of a material directly depends on its density: the higher the density, the lower the thermal conductivity.

The wood species from which the blanks are made have different densities. You need to know this when calculating heat loss in winter. When calculating the heat loss of a house made of timber, the term heat transfer resistance is used - a value that characterizes the heat-protective properties of enclosing structures. This characteristic demonstrates how much heat is lost for a given temperature difference through a square meter of wall. Calculation using the formula: Q = S * ΔT/ R,

where Q is heat loss; R – heat transfer resistance; S is the area of the structure; ΔT is the difference between the temperature in the house and outside. The value of the variable R is in construction reference books - SNiP II-3-79.

Final touches

Having built a log house with your own hands, you need to treat the surface with protective agents, remove visible damage, and begin sanding.

The technology for grinding timber is simple. An important condition is not to put pressure on the grinder and not to linger in one place.

The device should be held at a slight angle to the surface. Horizontal and vertical movements must be constantly alternated. In places where the material is laid unevenly, sanding the timber house is performed repeatedly.

During the work, the surface is leveled, the slightest differences in the crowns and partitions of the walls are eliminated. Also, by grinding the surface, the lint that appears after treating the walls with antiseptic preparations is removed.

Warming up of the building is carried out slowly; temperature changes should not be allowed, otherwise cracks will appear. When installing heating, specialists take into account the characteristics of natural wood and the options for its possible deformation.

The specific operation of houses built from double timber requires a lightweight rafter system and roofing so that the load on the walls does not become excessive. For roofing material, it is advisable to choose flexible and lightweight tiles.

One-story country houses made of double timber are a profitable investment. When constructing a building, building material is saved. And you can enjoy its beauty and comfort for many years.

Hello, my name is Tatyana. In June 2020, my husband and I began building a house on the territory of SNT within the city of Chelyabinsk.

When choosing materials for the house, we chose between full timber, gas block and double mini timber.

The beam shrinks greatly. Heating an aerated block requires large resources; in SNT only electricity is available - there is no gas.

The content of the article:

Therefore, the choice fell on the “double beam” or mini-beam technology. The technology allows you to get a warm house for a relatively low price, and assemble it in a few weeks.

The house was built by two people - my husband and his brother, I helped a little. None of us had much construction experience.

Features of the structure of a bathhouse using Finnish technology

A bathhouse built using double beam technology will be an excellent place to relax and spend time. It will perform all the necessary tasks several times better, because it will be possible to achieve low thermal conductivity and high thermal insulation. Such a bath will not cause a lot of expenses, since the heat in it will be retained for a long time.

It is possible to order the construction of a bathhouse from double timber or buy a basic package. Using the latter option, you can significantly save on installation costs. For them you need to pay at least 10% of the cost of the bathhouse set. You can independently build a house from timber or a bathhouse in just a few weeks.

So, the basic set sauna includes the following elements:

Fundamental basis:

- Pile-screw device for installing the base;

- Strapping timber pre-treated with an antiseptic. Anchors to piles;

Floors:

- The first layer of the floor (rough). Edged board 2 grades;

- Waterproofing and vapor barrier;

- Floor joists. Installation should be carried out at a distance of no more than 600 mm;

- Ecowool;

- Facial floor. tongue and groove board;

Walls:

- Elements using double timber technology;

- Ecowool as insulation;

- Partitions, internal walls

Window:

- Windows made of metal/plastic, double glazing.

Doors:

- Entrance door made of metal;

- Interior paneled doors.

Roof structure:

- Rafters made of timber with natural moisture;

- Mineral wool;

- Vertical type lathing;

- Horizontal sheathing;

- Vapor barrier, waterproofing;

- Metal tiles, cornice;

Each element is marked on the reverse side, so building a house from laminated veneer lumber or a bathhouse from a double version will not be difficult, even without special skills. For greater confidence, it is recommended to watch a video of professionals installing a structure made of double timber, where the bathhouse is assembled in a short time.

Double timber technology is an assembly of massive walls. They consist of three layers, each of which performs a specific role. When building a bathhouse using this technology, it is important to correctly assemble thick boards immediately at the construction site. They are fastened together by tongue-and-groove joining, just like building a house from profiled timber.

After erecting the walls and rafter system, it is necessary to embed beams and ceilings into them. They are needed for greater strength and aesthetics. And the last step in carrying out construction using this technology is the use of a vapor barrier film in the overlap areas.

All stages of construction can be seen in more detail in the video:

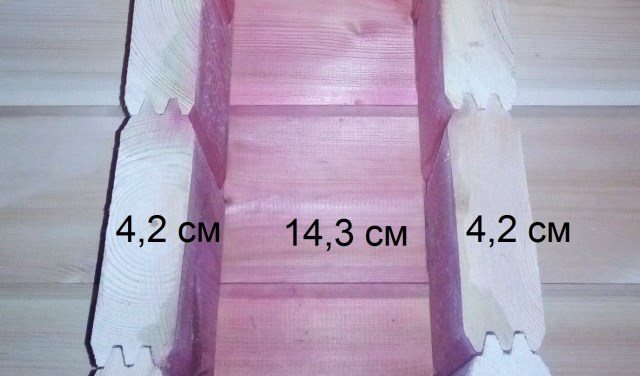

About construction technology

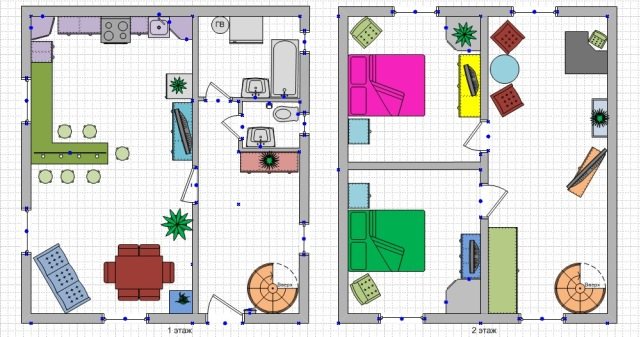

What is a mini-beam? Strictly speaking, this is not a timber, but a dry profiled board 137x42 mm. The wall of a house assembled using this technology is double - it consists of two boards and the space between them for insulation. The total wall thickness is 227 mm.

The house is assembled like a standard log house, only with an external and internal contour. All parts are numbered for convenience, instructions are included.

First, the first crown is assembled: parts of one plane are attached to each other in a tongue-and-groove manner, then the second plane is assembled, then assembly continues according to the diagram.

The space between the beams is filled with ecowool.

Before designing, we decided on the approximate layout and number of floors. According to the plans, it was supposed to be a one-story house with a residential attic, with a total area of just over 100 sq.m.

This is the layout we wanted

Prices

The cost of a double timber bath will depend on several provisions. The area of the selected project plays a big role. The insulation used has an impact; today you can find mineral wool or ecowool, and their cost varies significantly. The price will depend on the selected set – “Basic” or “Standard”. The latter option has several advantages.

So, the cost of purchasing a kit for building a bathhouse or ordering construction from different companies:

| Company/City | Cost of the set per 1 sq.m. (rub.) | Cost of a house per 1 sq.m. (rub.) | ||

| "Base" | "Standard" | Home construction | Turnkey construction | |

| "ELBA LTD"/ St. Petersburg | From 6800 | From 11000 | From 14.600 | From 17.200 |

| "StroyDrom/Moscow | From 7000 | From 11200 | From 14.760 | From 17.350 |

| “NGS. Dom/Novosibirsk | From 6300 | From 11400 | From 14.900 | From 17.800 |

| "Green Wood"/Ufa | From 6200 | From 11400 | From 15.200 | From 18.100 |

| "Stroy Banya"/Perm | From 7100 | From 12200 | From 15.050 | From 18.000 |

Since double beam technology has recently begun to be practiced, not all companies have been able to study it. However, the companies mentioned above not only succeeded in studying, but were able to achieve success in the construction of similar structures.

Design. House kit cost

We found a manufacturer of house kits with a good reputation in the neighboring region. Together with the manager, we drew up a sketch, after which we signed a contract for the design of the log house.

3D model of a house

We were completely satisfied with the finished project. The price of a cube of finished timber from the company is 17,500 rubles; according to the report, it should have taken 28.98 m3 per house.

- Design RUB 16,500

- House kit 507,000 rub.

We could only wait until the specialists prepared the material - sawed it, dried it, cut grooves and tenons, and cut out cups. The manufacturer reported a readiness time of 1 month.

Communications: well and sewerage

During the production of the wall set, we laid communications.

A drilling company was invited to construct a well. In our area, the water lies at a depth of 25 meters. After drilling the well, the pump was lowered inside. Then, using an excavator, they dug a hole around the hole in the ground to install a reinforced concrete ring. A hatch with a cover was installed on top of the resulting structure. They laid a water pipe to the house. Spent 1 day.

- The water well cost 48,000 rubles.

Specialists were also called in to install the sewer system using an excavator. The first step: we dug a trench from the point of entry into the house to the cesspool. Second step: we dug a hole 1.5×1.5×3 m to install reinforced concrete rings. Third step: installed reinforced concrete rings with a bottom on a concrete solution in the pit. Fourth step: coated all seams with bitumen mastic, installed a hatch with a cover. A HDPE sewer pipe was laid in a dug trench on a sand bed. A 20 cm layer of sand was poured over the pipe. Then everything was covered with soil remaining after digging the trench and hole (3 cubic meters).

- 23,800 rubles on sewer installation

- Communication costs RUB 71,800.

Practicality and cost of building a house (capital costs for construction)

Regular timber is the most affordable. This is due to low manufacturing costs and relatively simple technology. Environmental friendliness and low cost are its advantages, however, a house made of such material needs insulation and finishing. Profiled timber (which also includes vertical timber) is manufactured using complex technology in several stages. This type of lumber meets strict parameters; cutting accuracy in production is maintained within 1 mm. This technology increases the speed and quality of building a house, but at the same time increases the cost. The manufacturing technology of laminated veneer lumber is complex and time-consuming. It improves utilitarian characteristics, but increases cost. The downside is the deterioration of air circulation and the presence of adhesives. Double timber is cheaper than laminated timber and warmer than profiled timber. The price per square meter of double timber is comparable to the cost of solid wood from 150*150 mm logs, but without insulation.

Name of timber

pros

Minuses

glued

strength; no deformation; resistance to fungus, high humidity and insect damage; does not require finishing.

high price; the use of adhesives; due to the poor quality of some of them, delamination of the wood is possible.

double

high heat saving; minimal shrinkage; relatively low price.

shrinkage of insulation. However, this problem can be solved by using ecowool.

vertical

short shrinkage period; good thermal insulation properties; possibility of self-installation; you can build a round house.

the formation of cracks that are more difficult to seal than when laying logs horizontally; The entire wall may rot. To prevent this from happening, vertical beams are installed on a base of horizontally laid logs coated with bitumen.

profiled

Strength of connections between workpieces; Simplicity and high quality of assembly; Minimum costs for insulation.

If the raw materials were used with natural moisture, the shrinkage period is extended; The appearance of cracks, especially on square beams.

ordinary

Low cost; Good thermal insulation; environmental friendliness

Additional protection from moisture and fungus is required; Finishing work is required.

Typical mistakes in building a log house

Our website presents a number of log house projects, for example: Or you can see all prices for log houses. You can calculate the house or bathhouse you need with maximum accuracy using our log house cost calculator. To order and buy a log house, call:

- Vologda

- Moscow,

Comments

No comments yet.

Foundation and floor

Since a house made from double timber is quite light, a capital foundation is not required; a pile foundation is sufficient. We used a drilled foundation. Its construction required: a hole drill, metal reinforcement, asbestos-cement pipes and concrete.

To begin with, we calculated the number of piles (20 pieces, it could have been less), marked the future house using wooden pegs, and leveled them. Next, they called a hole drill, and in the marked places the specialist drilled holes of the required depth (2 m).

Pipes were installed in the holes, 3 rods of reinforcement each, and filled with concrete. After the mixture had hardened, the piles were brought into one plane using a laser level, and the excess was cut off using a grinder. Metal square heads were installed on the upper part of the support, secured with concrete, and covered with waterproofing.

- Foundation RUB 46,200, 2 days

For strapping, a dry board (50*200 mm) treated with an antiseptic and fire retardant was used. Processing and material – RUB 32,200.

OSB boards served as the base of the floor - RUB 100,000.

- Strapping and flooring RUB 132,200, 2 days.

Projects and their implementation

A house made of double timber is designed and installed by companies that specialize in this type of construction. To reduce the cost of the estimate, you can purchase a standard project adapted to your area and, if desired, make minor changes to it. Individual drawings are drawn up based on site research, but the price of such work will be much higher. Construction companies offering their services provide a package of services, which includes:

- creating a sketch;

- development of a draft working scheme;

- production of a set of parts;

- installation work.

At the first stage, the construction technology involves drawing up an architectural plan, drawing a diagram of the house, and outlining the main work. The most important and complex process is the production of the installation kit, from which the structure will be erected, and it is also the most lengthy – it takes up to a month. The connection of structural elements occurs according to the locking principle. The construction process here is similar to the installation of a formwork structure, and the internal and external walls are erected simultaneously.

Delivery and assembly

Delivery of the finished set of walls to our city using a truck cost 21,000 rubles. (200 km). The manufacturer packed the finished parts into pallets using a tie; for unloading, the services of a manipulator were required - 5,000 rubles.

- Delivery 26,000 rub.

After delivery, we read the instructions - the manufacturer provided a plan for the axles and rims.

We started assembling (we assembled it ourselves).

To begin with, using iron corners, we attached the boards of the first crown to the OSB floor. Next, using rubber mallets, we attached the boards of the 2nd crown to the 1st crown. When assembling, it is important to carefully punch each beam along its entire length, otherwise the house may become deformed and blow out. Next, the assembly continued along the crowns.

After assembling the 1st floor, the ceiling was installed. We used a dry treated board 200x50 mm, pitch - 0.45 m. For the subfloor - 25x150 mm.

- Flooring and flooring RUB 25,000, 1 day

Next, we made a rough staircase from scraps of boards, taking one day to complete.

Then the second floor was assembled according to the design.

Assembly of the 2nd floor

After completing the assembly, we installed a regular advertising banner instead of the roof to prevent moisture from getting inside.

In total, the assembly of the walls took 4 days.

Want to create a site? Find Free WordPress Themes and plugins.

Double beam. This technology consists of two profiled chamber-drying timbers. They are dried to a state of 10-12%. Ecowool insulation is blown between them. The thickness of the insulation can be from 50 to 200 mm. 150 mm is the most optimal thickness for our strip.

Advantages of technology.

The most important advantage of this technology is its thermal insulation properties. It has no equal in terms of thermal efficiency!

What is its advantage? First of all, it's a tree. The role of timber here is played by a dry planed board with a thickness of 44 to 70 mm and a height of 140 mm, placed on an edge or laminated timber 75 and 80 mm. Its seating edges are profiled using a tongue-and-groove system, which makes it possible to achieve tight contact and protect the seam from blowing. Another important element is the labyrinth wind lock. It is very important so that there are no gaps in the “cuts”. The thickness of the insulation for our latitudes should be 150mm for timber 44mm, and 100mm for timber 70mm and above.

The wall thickness with a 70th beam is 290 mm, with a 45th beam – 240mm. If you compare it with brick, you will need 2 meters of it. Glued laminated timber - 300-400 mm. A frame house is approximately the same in terms of body efficiency, but it is inferior in structural rigidity.

In a double beam, the spatial rigidity of the structure is achieved due to the corners connected by the “cutting” method, when a groove is cut in the joined boards to half their height.

A house made of double timber shrinks only about 1-2%. If we take a log or timber with natural moisture for comparison, they shrink 10-12%, laminated timber 3-5%. This means that in houses made of double timber, you can immediately after construction do the finishing touches and fully use the house.

A very important aspect for houses made of double timber is the quality of production of the house kit and its assembly. Despite the apparent ease of installation, this technology has its own nuances. And only specialists who have experience in building these houses will be able to build you a high-quality house.

When constructing a building from wood that is not impregnated with harmful synthetic resins, the most correct decision would be to use insulation that is safe for health.

Of all the thermal insulation options, ECO WOOL, consisting of natural cellulose, is optimal for this. It does not rot, does not shrink and does not support combustion.

A very important point when insulating walls made of double timber. Many companies, in pursuit of cost reduction, insulate walls with mineral slabs, synthetic insulation, etc. But only ECO WOOL is suitable for this type of construction.

This is the only insulation that is used without a vapor barrier. The mineral slab will settle over time, which will lead to the appearance of cold bridges. In order for ECO WOOL to serve you for a long time and correctly, you need to follow several rules:

— Buy ECO WOOL only from large factories that have a certificate for their products. Small “handicraft” productions, as a rule, skimp on quality and do not add any antiseptics or fire retardants. Essentially, when buying ECO WOOL from such manufacturers, you are simply buying shredded paper.

— ECO WOOL needs to be blown out with a special installation under a pressure of at least 65-70 kg per m3. Only in this case it will not shrink. Under no circumstances should you simply fill it up, fill it up and compact it, or even come up with different installation methods.

If you do not follow these rules, you risk being among those people who are disappointed in the Double Beam technology, only through your own fault or the fault of unscrupulous builders.

Did you find apk for android? You can find new Free Android Games and apps.

Electrical wiring

Since the power grid in the SNT territory is “weak”, they decided to connect to the city network. I had to install a pole on the site.

- Supplying electricity costs 16,500 rubles, the process took almost 2 months (due to red tape with the energy company).

The electricity was turned on after all, and all we had to do was install the wiring inside the walls of the house.

Used:

- more than 300 m of cable and corrugated HDPE/NG;

- 100 installation sites;

- distribution boxes;

- socket boxes, small consumables.

- Posting RUB 34,000, 2 days.

Insulation

Next, the walls were insulated using ecowool (finely shredded paper with the addition of boric acid and fire retardant).

Before starting work, we installed door and window frames and used the material left over from the ceiling and framing.

We calculated the insulation taking into account the required density (55-65 kg/m3). The volume of the walls is 30 m3, 30*65 = 1950 kg of wool. The mixture is sold in briquettes of 15 kg, 1950/15 = 130 briquettes.

- The price of insulation is 33 rubles/kg, 1950*33 = 64,350 rubles.

- To blow in the cotton wool, we rented a unit for 6,000 rubles and insulated the house for 3 days.

Roof structure

The next stage was the installation of rafters, sheathing, corrugated sheeting and roof insulation.

For the rafters we used a 50x200 mm board, for the sheathing - 15x100 mm (treated with OBZ).

- Boards 20,000 rub.

The rafters were attached to the side walls and the ridge wall using metal corners, in increments of 0.6 m. The sheathing was screwed on top of the rafters using self-tapping screws.

Next, corrugated sheeting for the roof was attached to the rafters.

- Corrugated sheeting and fasteners RUB 40,000.

We attached waterproofing from the inside and laid Izospan insulation (roll, 200mm).

- Roof insulation RUB 25,000.

- Total cost 85,000 rubles, time – 3 days.

Installation of windows and entrance door

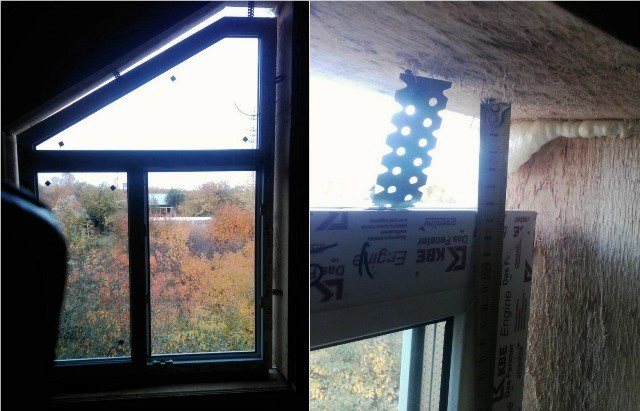

Since the attic windows are non-standard, the order had to wait longer than usual (3 weeks); mounting plates and foam were used to secure the windows.

One side of the metal plate was attached to the casing, the other to the window, the space between was filled with polyurethane foam

- Windows 61,000 rub., 1 day.

We ordered a metal door. The installation didn't take long. The door was secured with wood groins to the casing, and the remaining space between the jamb and the frame was foamed with polyurethane foam. We assembled the door hardware.

- Door 15,000 rub., 3 hours.

Finishing

- The ceiling on the first floor was covered with clapboard 13,000 rubles, 1 day.

Double timber does not require finishing as such; it is necessary to lightly sand the surface and cover it with oil or paint. We chose a 2 in 1 impregnation – antiseptic and transparent strengthening paint.

- Impregnation 15,000 rubles, 2 days.

- The floor of the 1st floor was covered with linoleum, 20,000 rubles, 1 day.

Heating and plumbing

For heating, we purchased a 9 kW electric boiler (3 heating elements of 3 kW each, can be used separately), a pump, metal-plastic pipes, bimetallic radiators, fastenings, and fittings.

We stretched the pipes along the 1st floor, attached radiators to the walls, and connected them to the boiler.

We installed a pressure maintenance station and a water heater, laid pipes for cold and hot water.

- Heating 50,000 rub., 1 day.

- Water supply RUB 25,000, 1 day.

Technology Basics

For more than 20 years, Western European countries have been practicing the construction of houses from double timber (CPSB) using Finnish technology. The popularity of the technology is explained by the fact that the finished country house is not only comfortable, but also energy efficient. As a result, the low thermal conductivity of load-bearing walls allows for more economical heating of rooms.

Low heat loss is ensured by the configuration of the building material. If we consider the double beam in cross section, we will see a complex structure consisting of two external parallel wooden partitions.

The thickness of the partitions is selected in accordance with the climatic characteristics of the region where construction will take place. On average, this parameter is 7 cm. Between the wooden partitions there is one or another heat-insulating material.

Thus, external partitions made of natural wood protect the heat-insulating layer from the negative effects of environmental factors, while a layer of ecowool or similar fillers performs the function of insulation and sound insulation.

The feasibility of using a complex double beam structure is also determined by the moisture content of the building material. For example, during operation, the humidity of the outer contour of the beam can be 22%, while the humidity of the internal partition does not exceed the original 12%.

The low humidity of wooden surfaces inside the house guarantees the absence of cracks, which, for example, is typical for ordinary timber. In addition, mold and areas of rot will not appear on the surface of dry lumber.

Construction companies

However, it is important not only to assemble the structure correctly, but also to purchase a high-quality kit. Today it is difficult to find a company that would optimally combine the price of a product and its quality. Below we will present construction companies that sell high-quality and reliable kits for building a bathhouse using double beam technology.

"ELBALTD"

Construction specializes in the construction of strong, reliable and high-quality buildings. That is why it is practiced in the construction of houses and baths using double beam technology. This Finnish technology was first used about twenty years ago, and has already gained popularity. In terms of its qualities, this material is superior to simple timber, and construction from it is cheaper.

The construction company also offers to purchase a double-timber bathhouse kit for self-construction. Doing this yourself is not so difficult, because the kit includes drawings, instructions and recommendations. You can save on installation work and build a bathhouse yourself, which will be in no way inferior to a structure made of simple timber. On the contrary, this bath will have a number of advantages.

A bathhouse made of double timber shrinks by only 0.5-1.5%, so the structure can be used immediately after construction is completed. The included effective insulation has vapor permeability, so you don’t have to waste time and effort on installing a vapor barrier film.

Construction is located at the address: St. Petersburg, Vyborg highway, 212. For questions, please call.

"StroyDrom"

The recently introduced double beam technology has managed to captivate a large number of people, and now it is one of the popular construction methods. It builds buildings efficiently and quickly using this method - construction. The company employs only specialists and builders with extensive experience.

You can purchase a bathhouse set from this company at an attractive price. The low price is due to the presence of our own production base, due to which it is sold at cost. Ecowool impregnated with borax is used as insulation.

Customers are offered a choice of two sets – “Standard” and “Basic”. Unlike the basic set, the standard set provides additional materials for construction, lighting elements and other details, with the use of which the construction process will become easier and simpler, and the bathhouse will look better.

You can purchase the kit by visiting the following address: Moscow, st. Sushchevsky Val, 43, office 101.

“NGS. HOUSE"

Since last year, it began production of house kits using double beam technology. She came to Russia from Finland, and has already become famous. And this is not just so, because it has a lot of advantages that are superior to simple timber in use. With its use it is possible to achieve maximum energy efficiency. The savings on heating a bathhouse built using this technology are colossal.

What does a “double beam” look like? At the ends of the beam there are attachments made of wood, so the material is no different from laminated veneer lumber. The walls of the house are assembled from thick and massive boards, right at the construction site. Walls made of double timber, due to high-quality and correct processing, can give the building a unique appearance. In terms of their appearance and characteristics, these baths are absolutely not inferior to buildings made of laminated veneer lumber.

The office is located at: Novosibirsk, st. M. Gorky, 34. For questions, please call: 20-20-791.

"GreenWood"

A strong and high-quality structure can be erected using double timber technology. For several years now, it has been selling kits for the construction of baths. Ecowool is used as insulation, which is blown into free space using special equipment.

The walls consist of three layers, resulting in a massive structure. It does not allow moisture, wind or heat to pass through. Self-construction using a kit justifies the effort expended, because a large amount of money would have to be spent on installation work (from 10% of the cost of the kit).

The big advantage of using a building kit is the absence of mandatory finishing. Beautiful wood texture and proper processing can give the bathhouse a real Russian look. The structure will not only look beautiful, but also have excellent properties.

is located at the following address: Ufa, Industrialnoye shocce, 44/1. For questions, please call: 8-960-800-6-777.