The most thoughtful buyer of a sauna stove is a man slightly over 55. He confidently walks along the orderly rows of various stoves and with his gaze selects the mouth of the chimney with the thickest metal. Having discovered such an instance, he taps on it with his finger for a long time and subtly listens to the sound, like a cat to the movement of a mouse. Having “sipped” the stove with both hands, appreciating its fullness, he soon quickly left, shouting loudly at the sales assistant’s suggestions: “don’t teach me how to live.” Such people, as a rule, do not buy a stove at all, but order it from a neighbor in the garage who does welding work. For them, the thickness of the metal is sacred. Probably, products under the loud name Tsar-stoves would satisfy them, after all, a full-weight 8 mm firebox body, or even as much as 10, if you wait.

Types of iron stoves for summer cottages

Modern stoves, which run on wood and are made of metal, bear little resemblance to a “potbelly stove”. Metal stoves for the home are usually divided into two groups:

- Classic ones that operate using a direct combustion system.

- Heating units designed for long-term combustion.

This or that system may be present in steel ovens that are intended for cooking or heating. There are a large number of such stoves on the market, among them the following are worth noting:

- A bell-type stove is a heating stove; it uses the principle of convective movement of gases that move through channels and then exit into the chimney. Instead of a hob, an open oven is installed, which is located directly under the hood. This helps keep food hot for a long time. Firewood is loaded horizontally; the firebox door is made of fire-resistant glass.

- Direct combustion furnace. Most often these are small-sized models, for example, Termofor or Cinderella. The design performs two functions at once - it heats the room and helps in cooking. The thermal power of such a “baby” is 4 kW or a little more, which allows you to heat a room up to 50 m2. There are models that are equipped with electricity generators, which increases the voltage production and power of the furnace. For example, the Indigirka cooking stove, which runs on wood, not only heats the house, but is also suitable for charging gadgets.

- Gas generator furnaces. They are perfect for summer cottages, since the designs are economical and compact in size, and have a high level of efficiency, which reaches 80%. For long-term operation of a stove of this type, it is necessary to equip a chimney and burn it with high-quality firewood. Gas fired stoves work by loading wood (or another type of fuel) into the combustion chamber, igniting it, and then closing the door. Fresh air flows through the telescopic pipe, which drops lower when the amount of firewood decreases. The air supply process is regulated by a damper. The operating life of the furnace is, on average, three days. If gas generator stoves have a water heating mode, you can save on the use of firewood.

What does the manufacturer promise?

As always, the manufacturer promises everything, a lot, and for an incredibly low price.

Let's take the Emelya Premium oven as an example. We present its main characteristics in a summary information table:

| Characteristics of the indicator | Meaning |

| Volume of heated steam room | 9 - 14 cubic meters |

| Time to reach temperature 65 - 85 degrees Celsius | 40 - 50 min. |

| Recommended weight of stone backfill | Up to 70 kg |

| Possibility of installation under a wall | Eat |

| Type and thickness of steel grate | Built-in, 8 mm |

| Furnace roof thickness | 8 mm |

| No deformation of the combustion chamber | For 15 years |

| Overall dimensions, width x height x depth | 450×630×790 mm |

| Possibility of regulating air flow through an adjustable hole in the ash pan area | Eat |

| Length of logs to be laid | Up to 600 mm |

Now let’s look at the above facts with an objective, evaluative look:

- The time to reach operating temperature is indicated “in the range” of 65 - 85 degrees Celsius. As they say in Odessa, 65 degrees and 85 degrees “are completely different things.” Such fundamental things as steam room acceleration need to be indicated more clearly and accurately, without such extended indicators.

- The manufacturer promises the absence of not only burnout, but even deformation of the combustion chamber for 15 years, but the guarantee, however, is only 5 years.

- The practical use of stoves of this type shows that despite the high combustion vault indicated in the design and the non-direct flow of combustion and flue gases, which theoretically should lead to a certain combustion efficiency and increased efficiency, in fact, the consumption of firewood during standard combustion is quite high.

- Low-carbon structural steel has a low scale formation temperature, so thermal corrosion will occur in any case, although not as critical as in the case of lightweight systems. In addition, oxidative processes are accompanied by the participation of atomic oxygen in the internal atmosphere of the steam room, which, with a large array of steel, will require good supply and exhaust ventilation. Otherwise, users may encounter such an unpleasant phenomenon, which is commonly called “oxygen burnout.”

- The massive design of the stove provokes a high threshold of infrared radiation, which in the area of immediate proximity to the sauna shelves can cause extremely uncomfortable sensations. Unpleasant phenomena can be reduced by installing a “brick case” around the body of the furnace, which will cut off infrared wave radiation.

- Finally, such stoves produce hard, sharp steam, which is significantly inferior in terms of conditions to the steam generated by sauna stoves built from mineral building materials.

What is additionally upsetting and alarming

Whatever the manufacturer claims regarding the use of special steels in the production process, the large thickness of the metal during welding requires a very high production culture, which the domestic manufacturer, with rare exceptions, never had. During operation, the most loaded element is the welding seam. Thick metal, especially when special boiler steel is used, is poorly welded and various welding defects are common, the most dangerous of which are hidden cavities.

Home stove models

Buleryan

This is a Canadian designed and built oven. It is quite easy to use and has a simple design. The main part of the stove (firebox) is made in the shape of a steel cylinder, the thickness of which is 5-6 mm. The hole for supplying coal (door) is made at the end of the furnace. Adjacent to the main part are round (or rectangular) pipes that are hollow inside. After heating, these pipes create the necessary transfer of warm air in the desired direction.

A grate for maintaining coal (grid) is made at the bottom of the firebox. At the top of the firebox there is a fence that divides the main part of the stove into two halves. This is done so that it can be heated with both coal and gas. The smoke exit hole is located on the back side of the door and is combined with the firebox, allowing smoke to escape safely to the street.

Butakov stove

It was tested in extreme conditions of a cold climate, not meeting the expectations of the owners of the patent for this invention. This brand has several varieties. The models, which are planned to be used around the clock, are improved with glass barriers. The stove consumes 12 times less fuel than a potbelly stove, and two times less than conventional brickwork.

Model "Student"

This happens due to the fact that in such a furnace the fuel does not burn, but smolders (pyrolysis process). The only negative is that the chimney pipe is not sealed enough and water may drip from there during the transition of steam into liquid. There are 6 types of such stoves. “Gymnasium student” is the most convenient in size.

Breneran

Russian model of the Buleryan stove. The oven is not heavy and compact. It is suitable for both living space and garage. Testing of such a stove was carried out in the mountainous areas of Tajikistan, where border office premises are equipped with stoves of this type. Breneran stoves come in 5 sizes, with a power of up to 35 kilowatts.

Teplodar-Matrix

This is a successful combination of design and functionality. In stoves of this type, it is possible to burn continuously for 8 hours (with one fuel supply). The convection compartment housing creates uniform heating and protects against negative radiation. The depth of the smoke exhaust compartment and the compact design of the stove saves space and creates additional advantages during installation - the chimney can be made in the direction in which it is necessary or convenient. This manufacturer has a fairly large selection of models, so you can choose the best option based on your needs and preferences.

Teplodar-Matrix 100

Teplodar-Matrix 200

Suitable if you need to heat a room up to 200 square meters. For garage premises, the best option is the Teplodar T series. For kitchen areas, a Vertical fireplace stove is ideal. If uniform heating of the living space is of paramount importance, it is better to choose the Vesuvius model.

Termofor

High-quality domestic stoves for heating areas with an air volume of 50 to 250 cubic meters. The power of such furnaces reaches 13 kilowatts. Suitable for heating both residential and non-residential premises. Some models have added fans for better dispersal of warm air. A large number of different models are presented - Ermak, Normal, Indigirka, Cinderella, etc. These stoves are compact and have an efficiency of up to 90%. Some models have glass shutters.

What else can be made from an old font and how?

Brazier

It is in demand among summer residents and those who like to combine outdoor recreation with eating dishes cooked over a fire. Advantages of a barbecue from a bathtub:

- cast iron alloy retains heat from coals for a long time;

- ease of manufacture;

- can be divided into zones for different dishes or use separate grates.

From two baths it is possible to make a grill with a lid, which will be a full-fledged version of the stove.

To get a simple version of a heat-resistant grate with a bathtub base you need:

- Make a pallet on which the cast iron trough will be installed. This can be a masonry of bricks or a stand welded to size from pipe scraps. The point of the action is to isolate the bathtub from the ground to prevent heat loss. If the factory legs are still there, think about how to provide additional stability.

- After welding the corners, place a grid of suitable size. It should be removable, like in a regular barbecue.

To attach the second bath as a lid, use strong door hinges, as well as vertical stops on the sides to prevent the heavy trough from tipping forward and backward uncontrollably. For ease of opening, attach a handle to the top.

garden furniture

Advantages of garden furniture from a bathtub:

- ability to withstand weight more than 100 kg;

- minimal susceptibility to wear and tear;

- strength and durability;

- color design and decoration to your taste.

Depending on the direction of cutting the bath, you can get:

- a sofa or bench, if you cut off the side along the longitudinal side;

- 2 armchairs if you cut the bath crosswise.

Before you start making garden furniture from a bathtub, you need to prepare:

- welding machine;

- tools for cutting and grinding metal;

- primer, brushes and paints for external work;

- gloves;

- means for protecting the organs of vision and breathing from metal dust.

Process steps:

- Remove all unnecessary parts from the font - this makes priming and painting easier.

- Mark the cutting lines according to the plan with a marker and cut the cast iron.

- Seal the drain hole and coat the surface with primer according to the instructions.

- Paint furniture, legs and decorative elements in the desired colors.

- Attach the restored factory legs back or change the seat height using your own.

- For insulation, use a mattress and pillows.

Water

The idea will be appreciated by lovers of solitude and contemplation. For a pond/fountain, you can choose a beautiful frame of living plants and populate it with aquatic inhabitants and even birds.

The advantage of using a cast iron bathtub in home pond construction is the strength and durability of its walls, which will keep the soil around the edges from shedding and collapsing. In addition, there is no need to spend money on additional waterproofing materials.

Sequencing:

- Decide on the location, dig a hole.

- Remove excess parts from the trough, seal the drain hole, cover chips and scratches with waterproofing paint.

- Compact the bottom of the pit with sand, place the font, fix its location with sand, soil, and stones.

- Reinforce the inner surface of the bath with steel mesh and cement mixture.

- Install a pump for the fountain (optional) and begin landscaping.

Flowerbed

The Internet is full of ideas on how to make a flowerbed from a variety of things that have lost their value - beds, carts, shelves and even shoes. It’s not difficult to follow the same path with a bathtub - just fill in the soil and plant the plants. The advantage of using an old font in creating a flower bed should take into account its strengths:

- ability to withstand heavy weight;

- corrosion resistance;

- strength of shape and walls.

These advantages come in handy when creating a weighted structure, for example, not just a flower bed, but a greenhouse flower bed that has a lid. It is practical to plant capricious, heat-loving varieties of flowers, seedlings or strawberries in such a mini-greenhouse.

Design Features:

- the cover can be made removable;

- There is no need to plug the drain hole so that excess water can drain freely.

The main amount of work in this option falls on the creation of an arc dome on a wooden frame. Attach it to the bath using door hinges.

The benefits of using an unwanted bathtub as a fireplace are:

- no need to make a special foundation and hood;

- minimum dirty construction work;

- easy installation;

- stability and durability of the structure.

Basic steps to get a home fireplace:

- Protect floors and walls at the installation site layer by layer with materials for thermal insulation, waterproofing, and reinforced cement screed.

- Make a base for a cast iron fireplace from non-combustible materials with thermal insulation properties - brick or foam concrete blocks.

- Cut off 1/3 of the tub from the drain side and work with the remaining 2/3. At a height of 20 cm from the cutting line on the bottom side, cut out a door for storing firewood. Place on the hinges and attach the handle.

- If the fireplace is installed in the corner of the room, then weld 2 sheets of iron on the back side at right angles to each other and to the sides of the trough, leaving space for installing the chimney.

- After installing the ventilation, perform finishing work - plaster, veneer.

We suggest you familiarize yourself with How to weld a sauna stove

Advantages of wood stoves

The main advantages are:

- The presence of a casing that has holes for air or a combustion chamber with a system of pipes that exhaust air.

- The casing absorbs all the radiation, and when it heats up, it releases heat into the room.

- You can regulate the flow of fresh air into the firebox.

- The presence of several partitions located above the combustion chamber. As a result, the gases do not exit directly into the pipe, but first give off heat and only then go into the pipe.

- A long period of operation, which is associated with the use of refractory bricks in furnaces, the use of hobs made of cast iron, steel or other metal.

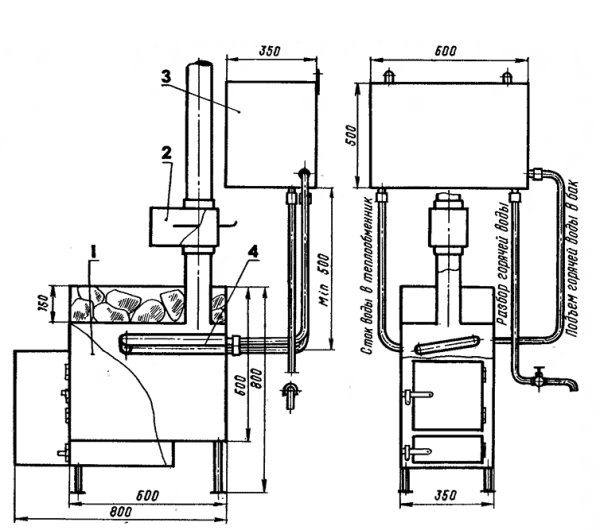

- The presence of heat exchangers that heat water, but such systems are only available in a few models.

- The so-called afterburning process of pyrolysis gases that are released during combustion occurs.

- The wood in the stove produces electricity.

- Wood-burning metal stoves release smoke to the right place, which allows you to regulate the heat balance in the living room. As a result, the rooms can maintain a stable temperature for 24 hours.

Other advantages of metal stoves, the operating principle of which is based on wood, include environmental friendliness, safety, and affordability. In particular, this applies to firewood, which is considered an environmentally friendly type of fuel. And its price is lower than for coal or peat. It is worth considering that firewood supplies must be replenished and placed in a specially designated place.

Required materials and tools

To build a stove from a cast iron bath yourself, you will need to stock up on the necessary tools.

Here is their exhaustive list:

- grinder (angle grinder), as well as discs for it (cleaning and cutting);

- electric drill and set of drills;

- equipment that allows gas cutting of metal elements (if available);

- wrenches of different sizes, hammer and pliers;

- crowbar and shovel;

- container where the solution will be mixed;

- spatula and trowel;

- tools for taking measurements: building level, plumb line, tape measure, metal corner;

- a welding machine (will be needed to install the chimney), as well as electrodes for it and a protective mask;

- hacksaw for woodworking.

We suggest you familiarize yourself with How to make a foundation on piles

The main element of the stove is a cast iron bath. However, the stove has significant weight, so it must have a foundation. For its construction, a certain amount of sand, cement mortar, brick, as well as clay and water is required.

Making a stove from a cast iron bath is much cheaper and more profitable than buying a new one

In addition, you will need:

- corner (metal);

- metal sheet (4 millimeters);

- a grid of a certain size;

- pipe required for the manufacture of a chimney (length - from 2 to 3 m, diameter - from 10 to 12.5 cm, wall thickness - from 3 mm);

- hinges for doors;

- Rabitz;

- polyethylene film (necessary for waterproofing the foundation);

- board (thickness - from 2 to 2.5 cm);

- slats (2 by 2 cm);

- nails.

You will need tools for metal processing and masonry construction. To cut a cast iron bathtub, sand its edges, and make holes for fasteners, you will need:

- laser level, plumb line, tape measure, marker - for marking;

- grinder with a set of circles (for cutting metal - 125 mm in diameter and 1 mm thick, for grinding);

- files with coarse and fine notches, sandpaper;

- electric drill, drills 9-11 mm;

- hammer, pliers, metal cutters.

In addition to metal parts, there will be brickwork at the base of the structure, so you will need a nozzle for mixing cement mortar, a container for it, a trowel, and a spatula.

If you do not use an angle grinder all the time, you can rent it

Disadvantages of metal stoves

No matter what high-quality stove model that is suitable in size and functionality is chosen, it must be remembered that any stove, no matter how ideally it fits, always has disadvantages.

Metal stoves are inferior to brick stoves in terms of heat retention. When heating a room with such models, warm air is retained in it for only a couple of hours, and in the morning there will be no heat. But we can solve this drawback if we buy a metal stove that operates continuously. After purchasing and installing it, you can forget about adding fuel for 8 hours.

The operation of metal furnaces can last up to 20 years. According to statistics, much earlier than this, the metal in the firebox burns out and requires replacement.

When buying a metal stove, you need to think about who will service it and how. If you plan to install it for residential premises, then it is worth considering the presence of people with chronic diseases of the respiratory tract or cardiovascular system. In addition to the fact that such stoves create powerful radiation, they create the effect of “dry air.” This problem can be solved if you cover the metal base of the stove with bricks (calculate whether the floor can withstand the additional weight). This will greatly reduce the operating time of the stove and void the product warranty. The heating rate will become slower, but the heat capacity will increase.

What you will need

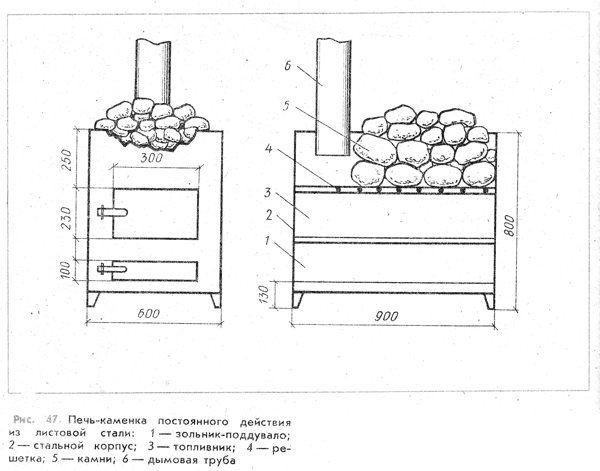

Ready-made diagram of a metal furnace.

It is not necessary to implement the idea yourself “from start to finish”; you can find ready-made drawings of a metal stove in a bathhouse by wandering around the Internet.

A good option is to contact specialists, they will create a project for you based on the features of the building and its area.

In any case, a thorough approach to the issue will give a positive result. Once you have collected everything you need, you can get to work.

Materials

- Metal sheets with a thickness of at least 8 mm.

- Grinder and welding machine.

- Iron pipes with a diameter of 60 mm.

- Door flaps.

- Valve and grate.

- Spare parts for chimney.

- Of course, the process begins with choosing a place for the stove and its size. The instructions warn about compliance with fire safety measures. Too large a stove in a small sauna can lead to trouble. The dimensions of the device must be such that there is enough heat to cover the entire area of the room.

Stages of work

Now we will look at the simplest design of a stove made from a pipe.

Drawing of a simple metal stove.

- Find a pipe 1.8 m long and with a wall thickness of 5–10 mm. Cut it into lengths of 60 cm (for the tank), 90 cm (for the firebox and heater), the rest will go to the doors of the firebox and blower.

- Holes for a firebox with a blower are cut in a 90-centimeter section. For the latter, the dimensions are 50–60 mm in height and 180–200 mm in width. A metal plate is welded above it with a hole cut out in the center, into which 4 eyes are welded for fastening the grate.

- You can purchase a grate in a store, depending on the size of the future oven. The plate for its fastening should be no thinner than 12 mm.

- We make the doors from the remains of the pipe. We cut out a fragment 300 mm wide and 200 mm high for the firebox. A plate with a cutout in the center is welded on top, and iron bars with a cross section of 10x10 mm for the heater are then placed on it.

- It doesn’t hurt to buy a special grate for the grate; it has a low price, just like the grate. In the heater compartment we cut a 250x300 mm hole for the door.

Grate: appearance

- You can make a tank for heating water. To do this, an 8 mm plate with a hole for a chimney 120–150 mm in diameter is welded to the top of the heater. Then a pre-cut piece of pipe for the tank and the chimney pipe are attached to the required places. It is advisable to make the hole for the pipe close to the back wall of the stove.

- The fragment of the tank on the side of the chimney pipe is covered with a steel semicircle with a hole for the welded chimney pipe. The second compartment of the tank will serve as a container for water. A lid with a handle is made for it.

- If a brick pipe is installed on the roof of the bathhouse, then a platform of 300x300 mm is welded to the chimney, under the masonry, at a distance of 350 mm from the tank lid. A pipe under the tap is welded into the wall of the tank.

- Some drawings of homemade metal stoves for a bath include lining the finished structure with brick. But if you have a relatively small room area and you use it infrequently, additional finishing is not necessary.

- Many people mistakenly believe that a lightweight metal stove can be installed directly on the floor. The average weight of the kit is about 150 kg, therefore, a special foundation is needed.

- A pit is dug, filled with crushed stone and compacted. Next, the site is filled with concrete mixture and left to harden. Roofing felt is laid on the almost finished surface, and only after that can the stove be installed.

- Typically, the drawings and dimensions of metal sauna stoves are designed so that part of the heater will go into the adjacent room - a dressing room or washing room. This is necessary to maintain warmth, because you don’t want to go out into the cold vestibule after warming up in the steam room.

Features of metal furnaces

Wood-burning metal stoves for summer cottages are considered super economical because they consume a small amount of oxygen during combustion. While they smolder, heat is released and the room is heated.

You can try to find models that have an additional combustion chamber designed to burn carbon monoxide. To reduce the amount of firewood and oxygen consumed, it is necessary to properly stack the firewood in the firebox. The fewer gaps remain between them, the longer the tree will smolder. Considering that oxygen in heating furnaces is supplied to places of smoldering and not combustion, the process is prolonged several times.

Particular attention should be paid to the design of the chimney, which is needed to create draft and remove combustion products. In metal home stoves that burn wood, it is necessary to install round chimneys so that they do not create air turbulence, characteristic of rectangular models, and it is difficult to clean such a structure. Round chimneys are excellent for cleaning from soot and soot. There should be no bends in the pipe, or their number should be kept to a minimum. The chimney is installed before the stove itself is installed.

About the requirements

Homemade modifications often compete well with factory products. They are also economical, compact, have a decent appearance, and are also easy to maintain.

Model with water heater

Liquid fuel, firewood, peat, and charcoal can be used as coolants here. Other energy sources are also possible.

When choosing, you must meet certain requirements:

- the thermal power must be regulated over a wide range, because the heat sufficient to warm up a bathhouse made of timber may not be enough to heat frame buildings;

Sauna stove design

- a heat accumulator and a steam generator are required to freely control heat and moisture;

- the presence of means regulating convection (energy transfer by gases) is mandatory;

- There should be no surfaces with temperatures above 150°C.

In addition, the stove firebox must comply with fire safety rules. Other parameters are also important.

How to install the stove correctly

- The first priority is choosing the installation location and measuring the area. Everything must comply with safety regulations. The stove should be installed at a distance of at least 60 cm from the plaster and 80 cm from the wallpaper.

- The stove must stand on a concrete slab (at least 0.7 cm), asbestos or basalt cardboard.

- The furnace elements are assembled according to the instructions, after which it is necessary to check the tightness of the assembled structure.

- A protective element must be attached above the stove, on the ceiling.

- Installation of a chimney (it is better to choose a round option - rectangular ones have worse draft).

- If you want to paint the stove, then any paint will not work for this. You need to choose special enamels (silicate or organic).

- Call a fire inspector who will check the correct installation.

- Test check of the entire system.

Tips for use

- The more densely the wood is stacked in the stove (this increases the smoldering time), the greater the fuel savings.

- Regular chimney cleaning is an essential safety measure.

- To ensure that no one touches the stove or gets burned on the structure, you can install screens or cover the metal body with bricks.

- If the oven door is glass, then it will constantly turn black from soot. It is better to clean before the glass has cooled, otherwise you will have to deal with resin. Cleaning can be done with regular glass cleaner and a sponge or newspaper. You should not use metal scrapers as they will cause scratches.

- Make sure that the metal parts (especially the grate) do not burn through. They need to be changed in a timely manner.

- The ash pan needs to be inspected and cleaned regularly.

A metal stove for a wood-burning home is an effective solution to the heating problem, which is popular due to its intuitive operating principle and easy maintenance. When choosing from the presented options, you should take into account not only the cost, but also the technical characteristics and reviews of owners who already own one or another model.