To ensure comfortable conditions and hygienic standards, waterproofing of the bathhouse is carried out in full without fail. Thanks to this measure, the floor, walls and ceiling in the room remain dry, there is no mold or mildew, and the insulation lasts longer.

We will talk about how to do this below and, in addition, as a supplement, we will watch a thematic video in this article.

>

Waterproofing for a bath made of foil polyethylene foam

Traditional waterproofing of a bathhouse floor

There is traditional and penetrating bath floor insulation. Traditional insulation is, in turn, divided into two types - pasted insulation and coating insulation. Their use depends on the type of materials and purpose of the structure. Let's consider the question in more detail.

Laminated waterproofing of bathhouse floor

Traditional waterproofing creates a reliable moisture-proof layer, but reduces the height of bathhouses by 5 cm.

The advantages of adhesive insulation include its low cost and ease of installation, thanks to which anyone can handle the job without professional training or construction experience. Adhesive floor waterproofing is carried out in the following sequence: first, 2-3 layers of bitumen mastic are applied to a clean, prepared floor surface, then a roll of waterproofing material is laid, and finishing material or wooden floor joists are placed on top of it.

Polymer films, glass roofing material, hydrostekloizol, reinforced concrete and others are used as roll materials for bathhouse floor waterproofing.

The main disadvantage of adhesive waterproofing of bathhouse floors is the unpleasant smell of bitumen that is released during the work.

Coating waterproofing of the floor in the bathhouse

Bitumen-polymer materials containing synthetic additives are inexpensive, but require a concrete screed. Coating waterproofing also includes single-component cement and cement-polymer materials. They are applied to the surface using brushes, brushes and rollers.

Liquid glass for waterproofing:

Treatment of a bath floor with liquid glass is almost identical to the silicification of concrete buildings. The method is cheaper and simpler than others. When using liquid glass for moisture insulation of a bath floor, we imitate penetrating insulation. When liquid glass hits concrete products or bricks, it creates a crystalline substance, filling the rigid base.

Liquid glass

The consistency of liquid glass is similar to melting rubber, which helps create a moisture-proof layer. Poured onto the foundation and subfloor, the mass forms a barrier to air and water.

Liquid glass consists of calcium or sodium silicate, soda and quartz sand. After the substance hardens, the mass has the following properties:

- moisture-proof;

- antiseptic;

- chemically neutral;

- fireproof;

- antistatic;

- with high adhesion.

Such waterproofing lasts only 5 years, because the substance has the property of self-destruction. It is worth noting that with a thicker layer the insulation lasts longer. The substance will last even longer if covered with protective paint.

You need to know that liquid glass hardens very quickly, so you need to prepare the solution in small batches in order to have time to pour it. Half an hour after aiming, the glass will harden and nothing can be changed.

Author of the article

Professionals have learned to mix liquid glass with other substances and have obtained new materials. If you mix 10 parts liquid glass and 1 part cement, you get an excellent mixture for repairing foundation cracks. It is important not to disturb the ratio, otherwise you may not have time to pour - the substance will harden very quickly, and in the worst case, the mixture can break the foundation at the pouring site. Liquid glass can be stored in finished form, but only in an airtight container.

For better contact of liquid glass with concrete, you need to vacuum the surface. The substance must be applied in equal stripes, evenly distributed over the surface. When working with liquid glass, bubbles may form in the solution, which must be removed.

The result should be a uniform layer of waterproofing with a thickness of 3 to 5 mm. The layer turns out transparent, it is important not to miss uncovered areas of the floor.

After drying, the liquid glass waterproofing layer is coated with varnish.

When working with any waterproofing, it is important to follow safety rules and regularly ventilate the room.

Penetrating waterproofing of bath floor

It is divided into several types: concreting, inorganic cement, seamless, polymer cement. These types of insulation have distinctive physical, mechanical and operational properties. Features of using penetrating waterproofing:

- Concrete waterproofing has high density and resistance to low temperatures. It is used in the construction of concrete structures.

- Inorganic waterproofing is used in rooms with high humidity levels.

- Polymer cement materials are environmentally friendly, have high strength and good adhesion. They are universal and suitable for waterproofing concrete and wooden floors. When applied layer by layer using a reinforcing mesh, such compositions, in addition to protecting against moisture, can act as a screed.

- Seamless waterproofing is most effective. It can be used in any premises.

Work on protecting floors begins immediately after waterproofing the walls and ceilings of the building is completed.

All types of waterproofing materials must be applied to a floor that has been cleared of contaminants over a previously primed surface. The primer composition must be allowed to dry. The technology for doing your own waterproofing of a bathhouse floor depends on the material it is made of. In the steam room and washing department, you can install a concrete floor, since wood is susceptible to rapid rotting in conditions of high humidity and insufficient ventilation. The plank floor can be laid in the rest room or dressing room.

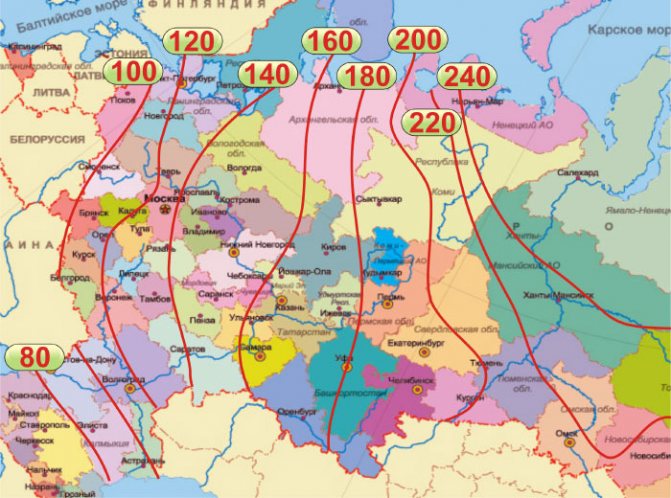

About groundwater

Before building a foundation for a bathhouse, it is necessary to conduct geological exploration to accurately determine the depth of groundwater, since if it is close to the surface, the building will certainly sag. Waterproofing is especially important in those regions of the country where the ground freezes. Sudden temperature changes can damage the base.

Groundwater map

If you plan to build a bathhouse with your own hands, without resorting to the help of specialists, then work with the foundation must be carried out with special care. This is especially true for buildings located near bodies of water.

Soil freezing depth

Note! High-quality waterproofing will take approximately 4% of all construction costs. This is quite a lot, but you will be sure that the structure will stand for many years without repair.

Waterproofing a concrete floor in a bathhouse

Coating waterproofing is most popular for protecting floors from moisture. Its surface is leveled to an ideal state and polymer or bitumen mastic is applied to it. When applying several layers, they are applied in a perpendicular direction to each other. Another option for protecting the floor is to cover it with roll materials:

- Plywood is fixed to the subfloor, on which the waterproofing is laid. This product is made of cellulose asbestos cardboard treated with petroleum bitumen.

- The edges of the material are brought onto the walls under the loose lower ends of the front cladding.

- The joints of foil wall material and floor waterproofing are insulated using aluminum tape.

- Then a reinforcing mesh is placed on the waterproofing sheets, which is filled with a cement screed.

- Floor tiles are laid on top of it.

In a log bathhouse, the floors can be poured only after the frame has settled, after one to two years.

Otherwise, the floors may crack. Advice: ideal protection can be provided by coating waterproofing of a concrete floor in a bathhouse, applied as an additional layer to the surface of a cement screed.

Practical advice from professionals

The depth of soil freezing can be different, it depends on the climate of the region and the temperature in the bathhouse itself. Sandy and rocky soil are classified as freezing rocks, which is why the foundation on them is laid only below the freezing level.

If there is a basement under the bathhouse, and the groundwater level is higher than its floor, then special measures must be taken. We are talking about insulating the floor and walls, and especially their joints. There it is advisable to install an elastic lock made of tow impregnated with molten bitumen.

To protect against surface water, it is necessary to make a blind area 70 cm wide around the bathhouse. This should be a “pillow” of clay 20 cm thick, covered with a layer of gravel. The blind area is filled with concrete mortar and laid with tiles. You can also install a drainage system around the foundation.

This is not a complete list of all possible ways to waterproof the base of a bathhouse. But if you strictly follow the instructions, the desired result will certainly be achieved.

Video - Waterproofing the foundation with technoelast

Waterproofing a wooden bath floor

Waterproofing protection of a wooden floor is of paramount importance, since wood has extremely low resistance to moisture. Wooden flooring in the bathhouse is designed in the form of leaking floors and non-leaking floors. Depending on the type chosen, their protection technology is implemented.

Waterproofing a leaking floor in a bathhouse

Their design provides for the natural flow of water between the cracks of the floorboards and its removal to the outside. The type of soil under the bathhouse determines whether it is absorbed by the soil through a prepared layer of crushed stone or discharged into a sewer or drainage pit. The advantage of leaking floors is that they are simple and inexpensive to install. For a long service life, the logs of such floors are treated with an antiseptic, the log supports are insulated with roofing felt or glassine, and the floorboards are thoroughly impregnated with drying oil. It is recommended to install effective ventilation under the floor - thanks to it, the floors will dry faster.

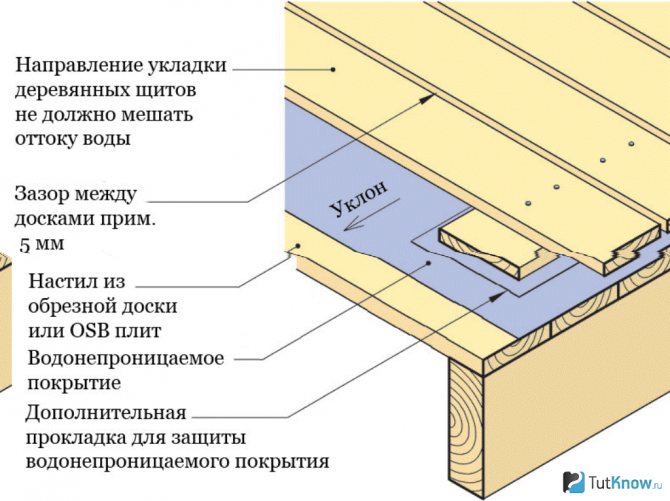

Waterproofing a non-leaking bath floor

Support bars are placed on wooden joists, on which the subfloor is laid. Then it is covered with plastic film or two or three layers of overlapping roofing felt. The edges of the roofing material are coated with melted bitumen, and the joints of the film are insulated with tape. On top of the roofing material there is a layer of thermal insulation made of expanded clay granules or mineral wool mats. The insulation is covered with roofing felt in three layers, which are coated with hot bitumen.

The waterproofing of the wooden floor performed in the bathhouse must be protected by finishing flooring boards. An air gap is required between the finished floor and the insulation layer to ventilate the underground space.

Ceiling and roof: some recommendations

The ceiling is not the wettest place in the bathhouse; vapors and condensation do not represent a flow of water. However, this is the problem - with poor insulation of the upper space and frequent use of the bathhouse, there is a risk of moisture accumulation, rotting and destruction of the roof structure, as well as corrosion of the roof from the inside. Therefore, it is worth taking care of this when installing the upper joists.

The easiest way to waterproof against steam is to use liquid clay. This is also the cheapest option. But it is only suitable for flat roofs. Clay mixed with sawdust is poured onto tightly knit boards of the top covering and left until completely dry. If the attic space of the bathhouse will be used for anything else, then a layer of roofing material or other covering is laid on top of the clay layer before installing the attic floor.

But if the owners of the bathhouse are adherents of progressive methods, then glassine or types of vapor barrier films are offered to choose from. They are attached in the same way as in the case of walls - with a stapler and tape.

And some types have self-adhesive surfaces. Waterproofing in the form of mastics or films is also applied to the roof. Otherwise, corrosion from the inside cannot be avoided if metal materials were used for coating.

Any waterproofing work is carried out simultaneously with insulation, because one without the other is ineffective. Complex work will allow you to use the premises immediately and for as long as needed. They are quite labor-intensive, but not complicated. And if the owners built the building themselves, then insulating or sealing it will be easy.

What materials are best to use

When building a bathhouse, many cannot decide how best to treat the foundation from moisture. Today, waterproofing additives, rolled materials and coating mixtures are very popular.

- Roll materials. They are presented in a wide range: roofing felt, ecofleck, isoelast, antechamber, krembit, etc. They have different components and differ in manufacturing technology. They attract with an affordable price and high levels of strength, ductility, elasticity and tear resistance.

- Coating mixtures. They are made on a bitumen basis. Reliably bonded to surfaces due to excellent adhesive properties. They also suppress vibrations of the building foundation, since the structure of the mixture is quite elastic.

- Waterproofing additives. They are divided into different types:

- Liquid – reduce the degree of porosity of the foundation;

- Elastic additives – increase the viscosity of the solution and improve water resistance;

- Dry - penetrate into the deep cracks of the foundation, ensuring its safety.

All of the listed materials are complete components for waterproofing. To ensure the most effective protection of the bathhouse foundation, it is better to combine several waterproofing materials.

Horizontal method of laying roofing felt

Let's consider the main stages of waterproofing using the example of horizontal laying of roofing felt.

- Preparatory work.

When waterproofing a foundation that has been built for a long time, it must first be freed from the soil and given time to dry. Then the walls should be cleaned of turf, soil, dust and other contaminants. Then level with cement mortar, removing roughness, chips, potholes and other defects. Carrying out preparatory work contributes to stronger adhesion of the waterproofing material to the wall surfaces of the foundation.

- Installation of waterproofing material.

A layer of heated liquid bitumen or hot mastic should be applied to the foundation. Without allowing the bitumen to cool, a sheet of roofing material, also heated over a fire, is laid on it. The sheets must be overlapped, and the width of the overlap should be at least 10-12 cm. Then the edges of the sheets of roofing material must be coated with the same bitumen or mastic and glued together, passing along the seams with a construction roller or a small roller.

Horizontal waterproofing with roofing felt

Professionals recommend laying roofing felt in at least two layers. This will increase its service life, increase protection and provide more thorough waterproofing. This method is especially popular in regions with highly humid climatic conditions.

- Final works.

After the bitumen-roofing felt layer has completely cooled, the foundation must be covered with soil. This must be done very carefully so as not to damage the resulting waterproofing layer with sharp stones, debris from work and other objects. For additional protection, you can line the foundation walls with plywood sheets or hardboard sheets.