Wood is the material most often used for construction. But it is very susceptible to such adverse influences as moisture; insects and rodents do not bypass it. To protect wood from such adverse effects, it is necessary to use special processing methods, which include the use of antiseptics. The technology for their application can be very different, it all depends on the processing conditions and the further use of the building material.

Today there are many such methods; the simplest is immersion in large baths and manual surface treatment. More complex methods are also used, such as pressure impregnation.

Wood is the most popular building material and will rot if not taken care of.

What it is?

Impregnations for wood

– these are special solutions designed to protect against the aggressive effects of the atmosphere, fire and biological damage. They are made on an oil, water and volatile organic compound basis.

Based on their purpose, they can be divided into several groups.

- flame retardants;

- antiseptics;

- against weather influences;

- combined formulations.

Fire retardants

Fire retardants

are designed to protect wood from fire and combustion processes.

They contain special substances that melt when the temperature rises and create a thin film on the surface. Thanks to this film, it is difficult for oxygen to reach the wood, the flammability threshold increases and the intensity of combustion decreases. Examples: DIAFOS-R50, Old Elm, Fire Retardant “PP”, etc.

Antiseptics

In the composition of impregnation for wood against rotting and other biological damage ( antiseptics

), includes biocides or, in other words, poisons that destroy microorganisms and insects and also prevent their occurrence.

Prevent the occurrence of putrefactive processes Aquatex, Biodecor, Neomid 430, Quintol, Biosept, Kram, Woodmaster Biosept, Biotonex, Tekotex, Biokron, VAK-48D, Actitox, Novotex,

etc.

Classic antiseptic brands are Tikkurila, Dulux, Pinotex

and

Senezh

.

The Tikkurila company produces Tikkurila Vinha antiseptic

. Pinotex's arsenal includes antiseptics

Pinotex Classic, Pinotex Aqva Plus

, etc. The Senezh brand is very popular in the Russian market.

The company produces the following antiseptics: Senezh ultra, Senezh ecobio, Senezh bio, Senezh impra

, etc.

Impregnations against weathering

Moisture impregnation for wood

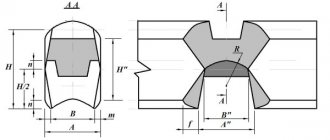

allows you to protect the wooden structure from deformations and cracks. They are dangerous because they worsen the appearance of the structure and reduce the quality characteristics of wood as a building material. The most effective, reliable, durable and most expensive way to protect wood from water is deep impregnation with special compounds. It is carried out under special conditions - in baths or autoclaves.

This mixture is a solution that protects the material from the destructive influences of the external environment. Examples: Tikkurila Valtti Color Extra glazing antiseptic, Tikkurila Valtti Aquacolor glazing antiseptic

etc. Thanks to the application of a mixture with a water-repellent effect, its strength and resistance to moisture are increased, and its service life is extended.

In the composition of impregnations against atmospheric influences

may include metal oxides. They protect the wood from ultraviolet radiation, which makes houses look grey. Colors can be very different: burgundy, green, blue and many other colors, and can also be transparent and translucent.

Combined formulations

Combined formulations

– these are products that protect the tree from the aggressive effects of several factors at once.

For example, antiseptic fire retardants protect the material from biological damage and at the same time increase the fire resistance of wood. These include Senezh Ognebio, Senezh Ognebio prof, Neomid 450, Healthy House Ognebio, Antibiokor-S, Pirilax, MIG-09

, etc.

Products that protect against biological damage: rot, mold, fungus, insects, and protect against precipitation, moisture and UV rays include Tikkurila Valtti Color Satin glazing antiseptic, Symphony Nordic Wood Silk glazing antiseptic, Healthy Home Aqualazur antiseptic, Tikkurila Euro Eco Wood antiseptic

and etc.

Characteristics of impregnations

Each type of wood impregnating composition has its own advantages and disadvantages.

Fire retardants

Treatment with fire-resistant impregnation

Fire retardants are a group of products that protect wood from fire damage.

The point is that such preparations contain components that create an airtight layer on the surface of a wooden product or structure.

When there is no oxygen available, it will not be able to ignite.

That is why fire retardant treatment is mandatory in wooden buildings, baths and saunas.

When processing a residential building made of timber, it is important to pay special attention to the room where the stove or fireplace is located.

Antiseptics

Antiseptic impregnations are a group of products that have an antibacterial effect on all layers of wood and protect it from damage by bugs, fungi and various infections that lead the wood to rot, corrosion and rottenness.

These impregnations are based on toxic components that destroy pathogenic microflora, kill existing parasites and prevent the appearance of new ones. Thus, impregnation completely protects the wood from harmful microorganisms.

Each type of impregnation has a degree of protection, consistency and color.

Some products are completely transparent, which allows you to preserve the natural wood color. There are also colored impregnations that process the product and at the same time give it the desired shade.

Anti-atmospheric impregnations

Anti-atmospheric impregnation creates reliable protection against the effects of aggressive environments and atmospheric phenomena. The first step is protection from moisture (snow and rain), ultraviolet radiation and other influences.

It is best to apply impregnation by soaking the material. This way the wood will be completely saturated, which will guarantee reliable protection.

The disadvantage of this treatment is that the appearance of the timber is distorted; it loses its color, but this can easily be corrected with varnish, paint or colored decorative impregnation. This treatment increases the protective functions of wood against precipitation and direct sunlight, which allows you to preserve the quality and appearance of the building for a long time.

Metal oxide is added to some modern impregnations in order to protect the wood from drying out and cracking. Such impregnations have different shades, depending on the type of metal with which they are oxidized. Accordingly, the wood acquires this shade.

Universal

Universal impregnation has all of the above characteristics. It provides combined protection against several types of exposure simultaneously: from moisture and parasites, or from fire and fungi, or from moisture and fire.

The product is ideal for rooms with high levels of moisture and exposure to fire. For example, in a bathhouse, where constant steam adds moisture and heats the stove, which can lead to a fire.

There is also a separate type of impregnation, which is based on wax with acrylic in the composition. Such means are very expensive, so they are not often used in the construction of wooden houses. Such impregnation has a high level of protection and gives an excellent look to natural wood, emphasizing every natural pattern.

How to choose the right composition

When choosing a protective composition, you need to pay attention to some nuances. Water-based mixtures require additional drying, which in turn can lead to cracks and deformation of ready-made structural elements.

Linings for purlins, purlins, beams, partition panels, struts, joists, fillings between joists, bars, and transverse strips are subject to complete treatment with water-based antiseptic solutions. As well as racks and lower wall frames, crossbars, slats, liners, sheathing boards, flooring boards for basement and interfloor attic floors.

Oil-based impregnations have an unpleasant, persistent odor. They are flammable, prone to discoloration of wood, very toxic and slow down the subsequent drying process. Wood after this treatment is almost impossible to machine and paint. Therefore, it is recommended to impregnate with oily protective compounds only those products that are located outdoors and are constantly in contact with water.

Wood properties are an important component

Depending on the species and structure of the tree, there are four classes of wood resistance to rotting:

- Unstable

– linden sapwood, aspen, birch kernel, alder; - Low-resistant

- elm core, beech, birch, maple, oak sapwood; - Medium-resistant

- fir, spruce, larch and cedar sapwood; - Resistant

- ash, pine, larch and oak core.

Different types of wood absorb protective solutions differently. There are three groups of breeds:

- Difficult to impregnate

- spruce, oak, birch, ash, beech; - Moderately impregnated

- aspen, alder, sapwood of maple, linden, oak, pine core; - Easily impregnated

- sapwood of pine, beech and birch.

Features of use

Water-based products differ from salt and oil ones in their versatility; they can be used simultaneously for external and internal work. For application, you can use any convenient method. The product can be applied to trees with a brush or roller, spray or soaking method.

Water repellent

To prevent a timber or wooden product from cracking, it must be pre-treated with special products that have water-repellent properties.

Processing is required for all types of wooden products, be it a house, benches in the garden or shelves in an apartment.

Antibacterial compounds can destroy bacteria that have already appeared in the tree and are beginning to infect it, as well as protect against their appearance in the future.

Water-based wood impregnation for interior work can be used as an independent product, as a finish, or as an impregnation for painting.

There are several nuances in applying impregnation. In order to impregnate untreated wood, it is simply applied with a brush or spray.

For polished products, a little preparation is tedious. First, you need to sand the surface with fine abrasive sandpaper so that it better absorbs the composition.

Next, the product is not just applied, but as if “rubbed” into the wood. To achieve a high-quality effect, you need to process a wooden product several times with an interval of 6 hours.

How to do it yourself?

If financial resources are very limited, you can make the mixture yourself. It will cost much less than buying a finished product. For many years, craftsmen have been making a protective substance from bitumen.

Contains bitumen

They do it as follows: pour bitumen into an unnecessary bucket, put it on the fire and bring it to a boil. After this, remove the bucket of bitumen from the heat and gradually pour in diesel fuel. You need enough diesel fuel so that the mixture remains liquid even when cooled. This homemade antiseptic for wood penetrates into the wood structure no worse than commercial ready-made ones - the absorption depth is up to 6 mm. At the same time, the tree breathes and dries out.

If a faster-drying impregnation is required, bitumen is diluted with gasoline. However, in this case it is impossible to heat the solution. All you need to do is dissolve the bitumen with gasoline. After drying, the wooden surface treated with this impregnation can be coated with oil enamels and paints after priming. The use of nitro varnishes and nitro paints is strictly prohibited.

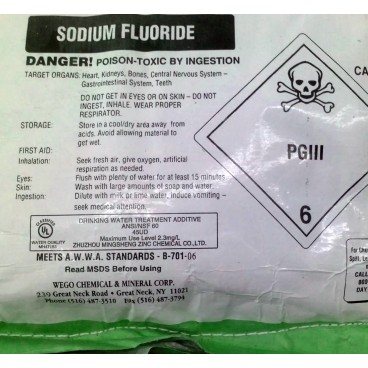

To make it, you need 25 kg of sodium fluoride (costs about 1,500 rubles). It is diluted in 400 liters of water and then, using an airless painting apparatus under a pressure of 200 bar, the entire frame is processed, simultaneously stripping off the top gray layer of wood. Then it is necessary to grind the angle grinder with a 40 flap wheel and carry out finishing treatment with oil, wax, varnish, etc.

How to make antifungal impregnation with your own hands

With large volumes of wood that need to be processed, a large amount of impregnated material is required, and this costs a lot of money. In order to save money, you can prepare your own impregnation for wooden products.

Bitumen

To do this, you need to pour bitumen into a metal container and place it on an open fire. When it boils, you need to remove and add solarium.

After cooling, the composition should have a liquid consistency. This product perfectly penetrates deep into the wood and provides deep protection against parasites.

If it is necessary for the logs to dry faster, it is necessary to add gasoline to the bitumen. Only in this case the composition cannot be heated. Most often, the resulting composition is used before applying alkyd or oil-based paints and varnishes.

Salt

Salt impregnation will also perfectly protect the wood from parasites. To prepare it, you will need to place 10 kilograms of sodium fluoride in 200 liters of water and stir until smooth.

The timber frame is treated with a product using a special high-pressure spray gun. After drying, the material must be sanded thoroughly to prepare it for treatment with varnish or paint.

The disadvantage of this impregnation is that it can be washed off with water, therefore a protective paint layer must be applied on top. But at the same time, it is non-toxic and less harmful, along with other methods of antibacterial wood treatment.

Prices

If you compare average prices in Moscow, you can see that Senezh

are the most economical, and the mixtures

Boritex Lazur and Shell Guard

are the most expensive.

Cost of various impregnations in rubles per liter or kilogram:

- Senezh ultra 50-60 rub./l.;

- Senezh firebio 50-60 rub./l.;

- Senezh bio 60-70 rub./l.;

- MIG-09 72 RUR/kg;

- Healthy House Ognebio 90 rub./l.;

- Zdorovy Dom antiseptic aqualazur 110 rub./l.;

- DIAFOS-R50 130 RUR/kg;

- Phenilax Fire and bioprotective composition 135 rub./l.;

- Pirilax Prime 163 rub./l.;

- Fire protection for wood Pirilax Biopyren 168 rub./l.;

- Elkon 180 rub./l.;

- Neomid 440 ECO 196 rub./l.;

- Antiseptic impregnation KRASULA for wood (reinforced concrete 0.95 l) 197 RUR/kg;

- Tikkurila Euro Eco Wood antiseptic 220 rub./l.;

- Belinka toplasur 226 rub./l.;

- Belinka toplasur 226 rub./l.;

- Pinotex Classic – antiseptic 265 rub./l.;

- Nordic Wood Silk 280 rub./l.;

- Tikkurila Valtti Color 280 rub./l.;

- Pinotex Ultra. 283 rub./l.;

- Pinotex Ultra 353 rub./l.;

- Tikkurila Vinha antiseptic 360 rub./l.;

- Dulux Weathershield Multi-Surface Fungicidal Wash RUB 490/l;

- Boritex Azure 1,020 rub./l.;

- Shell Guard RTU RUB 1,400/l.

Copper, brass and bronze products are degreased in a solution containing 100 g of trisodium phosphate and 10-20 ml of liquid glass in 1 liter of water. After degreasing, the product is thoroughly washed in hot water and immersed for 30-60 seconds in 5% hydrochloric acid to remove the layer of metal oxides, after which the product is washed again with water and immediately transferred to the coating solution. To “paint” copper products

in various colors, it is recommended to use the following recipes:17. Dissolve 4 g of sodium hydroxide and 4 g of lactose (milk sugar) in 100 ml of water, boil the solution for several minutes, and then add 4 ml of a concentrated solution of copper sulfate in small portions with continuous stirring. The fat-free product is immersed in a hot solution, and depending on the duration of treatment, its surface becomes colored from golden to green, brown or even black.

As a result of the redox chemical reaction of copper sulfate with lactose in an alkaline medium, gluconic acid is obtained and a precipitate of copper (I) oxide is released. First, a thin yellow Cu2O film is formed, which gives the copper surface a golden hue. With prolonged heating, Cu2O crystals enlarge and become dark red, hence the change in color of the coating

18. Prepare a solution of 2 g of nickel sulfate, 4 g of berthollet salt, 18 g of copper sulfate and 0.2 g of potassium permanganate in 100 ml of water. Treating copper products with a warm solution of this composition gives them a “ bronze”

" view

19. Dissolve 12.5 g of ammonium carbonate in 100 ml of water and add 4 ml of ammonia. The resulting solution is applied to the surface of the product with a brush and a greenish colored surface is obtained. When ammonia acts on the surface of copper in the presence of atmospheric oxygen, a complex salt is formed, which then reacts with ammonium carbonate, releasing a green precipitate of copper hydroxide-carbonate Cu2CO3 (OH) 2 on the metal surface.

20. Copper is blackened

weed liver solution. To obtain sulfur liver, 1 part (by weight) of sulfur and 2 parts of potash are fused in an iron can. After cooling, the glassy black mass is removed from the jar and finely crushed. Sulfur liver can only be stored in airtight containers. Make a 10-15% solution of liver sulfur in water, bring the solution to a boil and lower the parts into it. Blackening time 0.5 - 1 min. If the product is complex and consists of parts, then they are blackened and polished before assembly. 21. Brass is blackened in the following solution: 200 g of copper carbonate and 1 g of ammonia (25%) are dissolved in 1 liter of water. Parts are processed in a solution at a temperature of 30-40°C, processing time 3-5 minutes

22. «Rust converter

» turns it into a durable brown surface coating. Apply a 15-30% aqueous solution of orthophosphoric acid to the product with a brush or spray and allow the product to air dry. It is even better to use phosphoric acid with additives, for example, 4 ml of butyl alcohol or 15 g of tartaric acid per 1 liter of phosphoric acid solution. Orthophosphoric acid converts rust components into iron orthophosphate FePO4, which creates a protective film on the surface. At the same time, tartaric acid binds some of the iron derivatives into tartrate complexes.

23. An ancient ointment

to protect metal from rust is as follows: melt 100 g of pork fat, add 1.5 g of camphor, remove the foam from the melt and mix it with graphite, ground into powder, so that the composition turns black. Lubricate the metal with the cooled ointment and leave it for a day, and then polish the metal with a woolen cloth.

Padding

walls is an operation to create an intermediate layer (primer) that firmly adheres to both the plastered surface and a layer of putty, whitewash or paint. At the same time, the cracks are sealed. Drying oil primer mixtures. 24. Vitriol primer: dissolve 150-200 g of copper sulfate in 2-3 liters of boiling water, separately dissolve 200 g of wood glue in 2-3 liters of water. Add 25-30 ml of drying oil to the glue solution, filter and add a solution of copper sulfate, 250 g of planed laundry soap and 2-3 kg of chalk powder, and then add water to 10 liters. The mixture is filtered through a mesh cloth (for example, gauze)

25. Alum primer contains 150-200 g of potassium alum, 200 g of soap, 200 g of wood glue, 25-30 ml of drying oil and 2-3 kg of chalk powder in 10 liters of water, and is prepared in the same way as vitriol

26. Soap primer consists of 2-3 kg of slaked lime, 500 g of soap, 100 g of drying oil and water. First, dissolve the soap in 2-3 liters of boiling water and pour drying oil into this solution while thoroughly mixing. Then slaked lime is added to the resulting emulsion, mixed with a small amount of water until it forms a dough. The mixture is thoroughly mixed and water is added to 10 liters.

Treating wood with high-quality antiseptics can significantly increase its service life.

They are intended to effectively protect wooden structures from mold, rot and destruction, as well as to improve performance.

For this purpose, specially developed formulations that meet basic safety requirements are suitable.

Wood protection begins with choosing a suitable antiseptic.

Types of antiseptics and composition

Modern antiseptics are classified by composition, purpose and area of use.

Depending on the main components that were used to produce protective products, wood impregnation can be divided into the following types:

- Water soluble;

- Oil;

- Organic;

- Combined.

Water soluble

Water-soluble impregnation is intended for preventive treatment of various types of wood. Wood preservative is used to protect surfaces that are not exposed to water.

The following ingredients are used for the production of water-soluble antiseptics:

- Sodium silicofluoride;

- Sodium fluoride;

- BBK 3 (boric acid and borax).

Oily

The most popular and sought-after type of antiseptic, which is used to protect wooden structures from increased moisture. The basis of such products is oils - anthracene, shale or coal.

Wood preservative gives the wood a dark, rich shade.

It does not dissolve in water, but has an increased flammability coefficient and a strong oily odor, therefore it is used exclusively for external work.

Organic

Organic impregnation is not so popular and is often used to protect external wooden structures.

An antiseptic for wood of this type creates a thin protective film on the surface being treated, improving the moisture-absorbing and adhesive characteristics of the wood.

Disadvantages include the possibility of painting surfaces green and increasing their porosity.

In addition, such products have a negative effect on metal elements, promoting the development of corrosion processes.

Combined

Such antiseptic compositions successfully combine the performance characteristics of other types.

Purpose

Depending on the purpose, special wood protection is divided into two categories:

Based on the area of use, wood antiseptics are divided into two categories:

- For interior work. Impregnation of this type is used to protect structures and elements intended for interior spaces. Therefore, it is absolutely harmless and does not have a strong odor. It is important to remember that for each type of room you must choose the appropriate antiseptic.

- For outdoor work. This category presents antiseptic impregnations and finishing agents intended for treating external wooden surfaces. They are wear-resistant and resistant to aggressive influences. Compositions for external use have a specific pungent odor and are resistant to high moisture, low temperatures and ultraviolet radiation. It is better not to use them for interior work.

Types and methods of impregnation

By their nature, antiseptics are divided into oil-based, used in their natural form or in the form of mixtures with other antiseptics and diluents, and water-soluble, used in the form of aqueous solutions of certain concentrations.1. Oil antiseptics 2. Water-soluble antiseptics

1. Oil antiseptics

Oil antiseptics include mainly coal and shale impregnating oils. The former are obtained by fractional distillation of coal tar, and the latter - in the process of thermal processing of oil shale. Oil antiseptic ZhTK, made on the basis of oil industry products, has found distribution among certain groups of consumers.

The main and best oil antiseptic currently used for impregnating sleepers at wood impregnation plants is coal impregnating oil (creosote), supplied by the coke industry.

Coal oil is non-hygroscopic and very resistant to leaching from impregnated wood, is highly antiseptic towards wood-destroying organisms, does not reduce the mechanical properties of wood and does not corrode metal.

The negative qualities of coal oil as one of the best antiseptics: pungent odor, flammability and, in some cases, the impossibility of subsequent painting of impregnated wood.

Back to contents

2. Water-soluble antiseptics

Water-soluble (salt) are solid or liquid antiseptics used to impregnate wood in the form of aqueous solutions of varying concentrations.

The advantages of these antiseptics include the aesthetic appearance of impregnated wood (gray-green or light green shades) and the absence of odor during operation.

The disadvantages of water-soluble antiseptics are lower resistance to water washout from wood, which leads to a shorter service life of impregnated wood compared to impregnation with oils. In addition, some types of water-soluble antiseptics may contain toxic substances that are extremely dangerous to humans if the impregnation process is not followed.

Preparations based on copper and chromium compounds (hereinafter referred to as CM) have found very wide distribution throughout the world: in the USA, for example, since 1928, in England since 1926, in the USSR since 1958, etc. They are still used in significant quantities to this day.

In different countries this drug has different names, for example in Bulgaria MX-13, Romania - Romalit, USA and England Selkur, etc. Initially, these formulations contained 50 parts of copper sulfate, 47.5 parts of sodium bichromate and 2.5 parts of acetic acid. Later, acetic acid was replaced by chromic acid or boric acid and phosphates, as well as zinc chloride. In French patents, ammonium sulfate was added to copper sulfate and alkali metal dichromate, in Finland - chromium trioxide, in Germany - phosphorus compounds. In addition, chromium-copper-containing compositions may contain copper carbonate or copper hydroxide or copper oxide instead of copper sulfate; instead of alkali metal dichromate they may contain chromium oxide, ammonium dichromate and others. The XM preparation does not cause corrosion of metals, effectively protects wood from a wide range of fungi (with the exception of house fungi and especially Poria sp.), however, it is not effective enough against insects and sea wood borers, even in large quantities.

In different countries, copper-chromium-arsenic-containing preparations have different names. These are Erdalite, and Green Salt, and Tanalit S, and Tanalit SA, and Tanalit NSA, and SSA, and Boliden K-33, and Bolideng Bis, and Wolman SSA, and K 33, and Selkur AN, and Selkur A, etc. .

There is data in the literature on the high rate of fixation of copper-chromium-arsenic-containing preparations, as a result of which their diffusion ability decreases, which is especially important when impregnating hard-to-impregnate wood. Increased swelling and shrinkage of wood impregnated with these compounds is also noted, even with an absorption of 4 - 8 kg/m3. At higher absorptions, the effect on shrinkage and swelling is reduced, but the hygroscopicity of the treated wood increases.

ChM preparations also have, although lower, a fairly high rate of fixation in wood and therefore also have a low diffusion capacity. When carrying out impregnation and subsequent use of impregnated wood, it should be borne in mind that in addition to the optimal ratio of components in the preparation for complete fixation, a certain time is required for the interaction of compounds with wood and with each other, and the longer the lower the ambient temperature. At the same time, the duration of fixation of joints in wood is sharply reduced when the impregnated material is heated.

Back to contents

As for the harmfulness of drugs, the problem should be considered in several aspects:

- harmfulness of the drug manufacturing process,

- harmfulness of the wood impregnation process

- the harmfulness of the impregnated material for the personnel serving during operation and for the environment in which, for example, supports are installed, as well as the harmfulness of wooden structures that have expired or have failed due to decay.

The harmfulness of the impregnation process for our Russian conditions is of particular importance, since only those enterprises that have the appropriate equipment and protective measures that ensure the correct and safe use of such protective agents can use preparations containing arsenic compounds. In addition, enterprises must strictly adhere to the technologies of impregnation and fixation of the drug, since their violation can lead to the production of parts with incompletely fixed harmful compounds.

When using both drugs, ChM and MChM, it should be taken into account that chromium compounds are also highly dangerous (hexavalent chromium compounds according to GOST 12.1.005 belong to substances of hazard class 1). And with XM preparations that do not contain arsenic, in order to avoid cases of illness and poisoning, the technology of impregnation and fixation, as well as safety precautions during work, should also be strictly observed.

At the same time, it should be noted that the stages of production of preparations and impregnation of wood are harmful when using chemical preparations. After fixation and interaction of the components with each other and the wood, hexavalent chromium compounds transform into trivalent chromium compounds, which already belong to substances of hazard class 111 according to GOST 12.1.005, i.e. to moderately dangerous. And thus the impregnated pillars no longer contain hazardous substances of hazard class 1.

At the same time, when choosing drugs for specific conditions of use and service, one should take into account their characteristics and, in particular, the low effectiveness of the drug MXM in relation to some types of mold fungi, and in particular the fungus Penicillium brevicaule, as well as moderate rot fungi of the Soft rot type. the effectiveness of the drug XM in relation to house mushrooms and especially to fungi of the genus Poria. At the same time, in relation to the complex of fungi that develop in contact with soil, both preparations are highly effective and, when the required protection parameters are achieved during impregnation, are able to protect wood for a long time.

Back to contents

Choosing the best antiseptic

Effective protection of wood depends on which antiseptic was chosen. To choose suitable antiseptic compounds for wood, it is important to consider some factors:

- Manufacturer;

- Compound;

- Purpose and scope of use;

- Type of wood;

- Consumption per sq.m.;

- Effect on the human body;

- Quality certificates;

- Price.

A reliable antiseptic for wood should have a high toxicity rating against mold, mildew and harmful microorganisms.

No less important is the protective ability indicator. So wood protection can be ineffective, medium effective, effective and highly effective.

The finished product must fully correspond to the degree of damage to the wood. According to this characteristic, the antiseptic can be used on clean, uncontaminated, slightly contaminated and heavily contaminated wooden surfaces.

Impregnation for interior work must have an appropriate sanitary certificate indicating complete safety for indoor use. Preparations for external use must have high resistance to low temperatures and ultraviolet radiation.

What antiseptic drug is considered high quality? One that is well applied to the surface and is compatible with any paint and varnish material.

Before purchasing, you should carefully read the instructions for use and check the expiration date of the drug.

It is worth refusing to purchase antiseptics from unknown manufacturers that lack the necessary quality certificates, because high cost is not always an indicator of quality.

DIY antiseptic

You can prepare a protective antiseptic for wood yourself, which will be much cheaper than purchased analogues. Most often, homemade antiseptic compositions are prepared from iron sulfate and sodium fluoride.

Vitriolic

Pour 100 g of iron sulfate and 10 g of potassium permanganate into a large plastic container. Add 20 liters of water and stir thoroughly. Apply the finished composition to the surface to be treated using a brush or roller.

Sodium

To prepare an antiseptic you will need 25 kg of sodium fluoride and 400 liters of water.

It is better to apply the finished mixture to a wooden surface using the airless painting method. After drying, the wood is carefully sanded with a flap wheel and treated with finishing protective impregnations - oil, varnish or wax.

The difference between homemade and factory-made antiseptic preparations lies only in the components that are used for their production.

Ready-made factory impregnation is more effective due to the high content of organic components. It is toxic to humans and animals and must therefore be used in accordance with the manufacturer's recommendations.

Do-it-yourself compositions are less practical and effective, but at the same time they save money. Homemade bioprotection is easy to prepare, environmentally friendly and safe for humans. To determine which antiseptic will be the best, it is worth considering all the conditions for its use.

Proper treatment of wood with an antiseptic

The technique for treating wood surfaces is quite simple, but, nevertheless, it is important to remember safety precautions when working with chemicals of this type.

To work, you will need special protective clothing, a mask, rubber gloves and wood impregnation.

- The surface is thoroughly cleaned of old coating, debris and dust. Next, the wood is treated with mild detergents and dried.

- The antiseptic mixture is applied to the damaged areas using a brush or roller. The next layers are applied 2–3 hours after the first layer has completely dried. Complete drying of the treated surfaces can last from 3 days to 2 weeks.

- It is better to carry out all wood processing work at temperatures from +5 (for organic, oil and combined compositions) and at +10 (for water-soluble ones). Air humidity is at least 85%.

- To kill insects, it is better to use alcohol compounds, which are poured into the holes made by pests with a special syringe. Next, the surface is treated with the selected antiseptic.

Re-protection of wood with antiseptics is carried out in case of chips, cracks and changes in surface color.

Cooking recipes and methods of application.

If you have started building a house or decorating a room using wooden elements, you will definitely need special surface treatment products. But, unfortunately, not everyone has the budget to purchase them. If you are forced to save money, we recommend creating a solution for processing the material yourself.

How to make wood impregnation

You will find out for yourself in our article. Various recipes, proven over the years, can be found on the Internet. We will look at the most popular ones.

Recommendations for selection

What should you follow to choose the right impregnation for the job? Before choosing, you need to answer the following questions:

- Do you only need a water-repellent substance or do you need additional features.

- Do you need to stain wood to give it a natural look?

- What volume do you need to select the amount of impregnation?

Thus, additional processing of wood with your own hands today has become mandatory for every home, as it has a whole set of positive qualities. Extending the life of wooden buildings, resisting fire, moisture and harmful substances is the merit of the modern generation in the construction market.

Recipe for preparing bitumen-based impregnation

To create such a product you will need bitumen, diesel fuel or gasoline.

Bitumen should be poured into a bucket, brought to a boil, and then diesel fuel should be poured in doses. Its volume should be such that after cooling the mixture remains liquid.

This antiseptic penetrates deeply into the structure of the wood, in no way inferior to expensive compounds. The absorption depth can be up to 6 mm. It is also easy to create a quick-drying impregnation; for this, diesel fuel is replaced with gasoline. Please note that in this case heating of the solution is excluded.

After applying bitumen-based impregnation

Additional coating using special oil-based enamels is recommended. The use of nitro paints and nitro varnishes is prohibited.

The main advantages of such antiseptics are reliable protection against the penetration of moisture and oxygen; preventing the development of various microorganisms; eliminates damage by wood-boring insects; creates a durable coating without rotting. As for the disadvantages: toxicity, easy flammability, high soiling, strong unpleasant odor, not suitable for indoor work.

Salt impregnation is no less effective when treating wood.

.

Types of impregnations

Water-repellent substances for wood rarely contain additional components that impart protective properties to the material. It all depends on the use of impregnations, so they come in different types:

- Fireproof impregnations. They are distinguished by their ability to not support combustion at high temperatures, where unimpregnated material would have ignited long ago. The spread of fire is reduced to a minimum. In addition to being anti-flammable, this composition protects the wood from the penetration of parasites and mold, and does not allow pests to multiply inside. You can use such substances without any restrictions, as they are completely safe for the environment. The peculiarity is that the products must be applied regularly, over a period of four to six years.

- Protective liquids against mold and rot are most often used to preserve houses, impregnate facades, wooden panels, lining, and fiberboard. The substance has increased water-repellent capabilities and is used everywhere. Thanks to the colorless composition, there is no need to worry about the preservation of the aesthetic qualities of the structure.

- Tinting agents. In addition to moisture reflectors, they contain dyes. After application, the wood is not only processed, but also acquires color.

Recipe for salt-based impregnation

- The main substance used is sodium fluoride in the amount of 25 kg.

- The product is immersed in a container of 400 liters of water and diluted until smooth.

- Next, the log house is processed using a special apparatus for airless painting under a pressure of 200 bar.

- Simultaneously with processing, the top layer of wood is removed. Then the surface is sanded using a 40 flap wheel and a final treatment is carried out with oil, varnish or other means.

The advantages of salt-based impregnation include lower toxicity compared to aqueous solutions. The disadvantages are a lower degree of protection; ability to be washed off with water; the need to use additional coatings for fixation.

The use of synthetic impregnations is unsafe, especially for interior work. The substances included in the composition are toxic and flammable. To create an environmentally friendly wood treatment, it is recommended to use vegetable or natural beeswax. Wax impregnation

is absolutely safe, gives the surface a pleasant aroma, makes it resistant to mechanical damage, imparts water-repellent properties, emphasizes the beauty and texture of the wood, and creates a beautiful matte finish with shine.

The solution consists of turpentine and wax, taken in a ratio of 1:2. To process food-grade wood products, oil is mixed instead of turpentine in a 2:1 ratio.

Recipe for making wax impregnation

Ingredients: 25 g crushed rosin, 100 g wax, 50 g purified turpentine.

For cooking, it is better to use enamel dishes.

The wax must be melted in a water bath, then add rosin.

After that, turpentine is gradually poured in, which gives the wood a pleasant aroma and generally strengthens the surface.

One of the most effective antiseptics

is copper sulfate. The saturated solution provides reliable protection for boards buried in the ground. Its use on the territory of a personal plot during the harvest period is carried out with caution, because may cause severe poisoning upon contact with fruits.

Antiseptic recipe:

Ingredients: 100 g of iron sulfate, 10 g of potassium permanganate, 10 l of water.

To prepare the solution, it is better to use a 25 liter plastic canister.

The ingredients are diluted in a canister, after which the solution is ready for use.

For interior work, it is possible to use less concentrated salt impregnations. It is recommended to apply the solution with a wide brush or using a spray bottle.

Impregnations based on copper sulfate require a long impregnation time and thorough drying.

Storage of solutions is possible for several days after preparation.

Before creating a mixture, it is recommended to familiarize yourself with the characteristics of the wood intended for processing in order to eliminate errors in the dosage of components. To prepare it yourself requires spending a lot of time, as well as selecting the components in advance. In addition, almost all of the above impregnations are suitable only for external use, because... toxic. That is why, for safety reasons, it is better to use high-quality LuxDecor wood impregnation products.

The range of wood impregnations is huge. Their choice must be approached carefully, so that later you do not have to regret about a damaged wooden item or destroyed walls of the house. Before purchasing a coating, you should find out for what purpose the impregnation is intended.

To prevent wood from being affected by fungus and bacteria, it must be impregnated with an antiseptic.

For work, you can use DIY wood impregnation, which has certain advantages and disadvantages.

Wood and its destructive factors

Today it is fashionable and prestigious to have wooden antiques in your home or to build a wooden bathhouse on your summer cottage. Wooden items are susceptible to destruction by factors such as:

Mold on wood leaves permanent stains and also destroys its structure.

- putrefactive bacteria;

- grinder beetles;

- mushrooms.

Putrefactive bacteria destroy wood in conditions of high humidity. Fungi leave indelible stains on wood and destroy its structure. In a humid environment, mold spores also form in wood.

Impregnation is necessary to rid wood of damage caused to it by various unfavorable environmental factors. The wood preservation process is implemented during each stage of construction, as well as:

- during the preparation of lumber;

- in the manufacture of new structures made of wood;

- to protect wood from fire, moisture, and destruction by harmful microorganisms.

Proven Components

A universal water-repellent impregnation is one that can effectively prevent the penetration of fire, protect wood from dust, dirt, and prevent parasites from multiplying inside.

When the market is overcrowded with construction components, it becomes difficult to choose the necessary impregnation, and if you ask in a store, they will recommend something unclear to you. Forums where people will not cheat will help you solve this problem.

As for truly universal impregnations, it is worth highlighting the Belinka type. This impregnation is in demand and has proven itself well.

No less famous is the Aqualazul brand, which is produced similarly to Belinka in a large assortment.

Used as a tinting agent for exterior and interior decoration. A distinctive feature of this impregnation is that it dries quickly and has no odor. This is the merit of the manufacturer, who chose ordinary water as the base.

Types of antiseptic impregnations for wood

Antiseptic agents help protect wood from wood borers.

Modern protective compounds are made using organic substances, oil-based compounds and water-based ones. Environmentally friendly products are the most successful. They are selected depending on the type of wood.

Primer impregnation is designed to save base material when processing wood. It is used at the initial stage of the technological process, before applying varnish or paint. Treatment with priming impregnation ensures even application of all layers. Many types of primer treatment compounds impart water-repellent properties to wood.

To give the wood a certain shade, color impregnation is used. The stain emphasizes the wood structure and colors the wood in the desired colors. Multifunctional impregnations can perform several actions, for example:

- protect from high temperatures;

- prevent the destruction of wood by wood-boring beetles.

The water-based impregnation is universal in use, easy to apply, and dries in a few hours. Compositions made with organic solvents take much longer to dry, up to 2-3 days.

Nitrocellulose is a compound that ensures the stain dries quickly in 10-15 minutes.

Wood processing must be carried out in special protective suits, masks and gloves.

A good water-based impregnation is characterized by the property of highlighting the internal texture of a wooden surface. The coating is resistant to light rays and has dirt-repellent properties. The process of applying it does not present any great difficulties: drops and streaks do not form on the working surface.

Water-based impregnation protects wood from moss and fungal spores. It can be used to treat furniture, doors, windows. It contains pigments that have the ability to repel light rays. To apply the composition, you must purchase a special brush, when working with which the surface remains smooth and shiny.

Water-based impregnations do not contain organic solvents. There is no strong odor when applying them. To work, you should purchase the following tools in advance:

- brush;

- special device for spraying paint;

- nitro thinner;

- brass brush;

- soil for wood;

- colorless paint azure.

Types of wood impregnations

Solutions for impregnating wood are oil-based and water-based. The latter have the following advantages:

- easy to apply without leaving streaks or drips

- dry quickly

- do not have an unpleasant and cloying odor (due to which they are widely used for interior work)

- do not require perfectly dry wood before application

- are antiallergenic and do not evaporate toxic substances

As with each of the materials in water-based impregnations, several disadvantages can be noted. Firstly, it penetrates a small thickness of wood. Only impregnations that protect the wood from moisture penetrate deeply.

Secondly, such impregnations cannot be used for beams that are constantly in an aquatic environment, and thirdly, they only contribute to surface protection.

Impregnations for outdoor use

Protective and decorative impregnation

Such compositions are usually used when preparing wood for storage or construction.

If you ignore this stage, the material will bloom very quickly, darken and succumb to rotting due to fungal microorganisms.

Such impregnations preserve the color and texture of the natural pattern.

This is relevant for wood, which in the future they plan to only varnish and not use paints in order to preserve the natural “wooden” color.

There are several types of wood impregnations that protect against aggressive environmental factors:

- short-acting (3-5 months)

- long-acting (6-15 months)

One of the most popular materials in this category is “Snowball Eurotrans”. This is a long-term antiseptic impregnation that protects wood for about 7-9 months.

But the manufacturer does not guarantee a 100% result if the rules for storing logs are not followed. They should not come into contact with the ground or asphalt, be exposed to direct sunlight and be stacked on top of each other.

If, nevertheless, fungal infections begin to affect the timber, then it is necessary to carry out bleaching and carefully open the top with an antiseptic drug.

Please note that impregnations for external work can be used not only when preparing doors, but also ready-made buildings can be treated with it. It is advisable to carry out the work in good weather so that the applied product dries quickly.

The top can be coated with paints and varnishes if a colored decorative impregnation was not initially chosen.

Impregnation against fire

The use of impregnations that have fire-resistant properties is most important in timber areas with increased fire hazard. For example, saunas, baths, kitchens with stoves or halls with fireplaces.

Now there are water-based complex impregnations that protect against fire and parasites at the same time.

Fire-fighting treatments are divided into two groups:

- coatings – paints, pastes, varnishes

- water-based impregnations

Coatings fade into the background, as they mask the natural color of the wood, while impregnations, on the contrary, emphasize it, making every feature more expressive.

Due to the huge demand for fire-resistant impregnations, many fakes have appeared on the market. In this regard, experts recommend requiring a quality certificate when purchasing this product, which indicates sanitary conclusions and confirmation of fire safety when using it.

It should be taken into account that impregnations with a complex spectrum of action do not protect against fire so well, therefore, for reliable protection, it is better to use a special product.

Decorative impregnation

When the wood has already been treated with all the necessary compounds, it’s time for water-based decorative impregnation. It is made of acrylates, due to which it lays evenly on the material, does not spread, and does not create streaks.

When dried, it creates an antibacterial, water-repellent film that allows the wood to “breathe.” A layer of high-quality decorative impregnation will last for many years, protecting the building material from aggressive environmental factors.

Typically, such impregnations contain antibacterial elements. But if not, then before applying it it is necessary to treat the material against fungi and parasites.

Such coatings are characterized by a huge selection of colors.

Mechanism for applying water-based impregnating composition

Antiseptic can be applied using a paint brush.

Before you start working with the impregnation, it must be mixed. Coating is carried out using a brush or other device that sprays paint onto a wooden surface. Wood with an uneven texture is coated with a darker color impregnation.

When working with exotic wood species, the surface must be treated with a nitro thinner.

Before applying the impregnation, the wood is swept with a brass brush. Outside, wooden parts are coated with impregnation twice.

Products made from coniferous and hardwood are primed with a special composition. The final layer of coating consists of colorless paint combined with azure. It is unacceptable for impregnation to come into contact with plastic parts.

Mastics, impregnation for wood parts

Any craftsman can make wood impregnation with his own hands using recipes based on bitumen. These compounds are much cheaper and have exceptional properties. When applied, they impregnate the wood to a depth of 7 mm.

Bitumen antiseptic is suitable for working with poorly dried wood: it freely penetrates into wood fibers.

The process of making antiseptics is simple. It is necessary to prepare the following materials for work:

- electric stove;

- bucket;

- bitumen;

- diesel fuel;

- kerosene;

- mastic.

Place a bucket on the electric stove, place M-5 or M-3 bitumen in it, heat it until it boils and bubbles appear. Then the container is removed from the stove and diesel fuel is added to it. Bitumen should become liquid when cold.

To prepare a kerosene-bitumen mixture, kerosene is used, which is introduced into the bitumen with great care. Bitumen is crushed and combined with kerosene until it is completely dissolved in it. The kerosene-bitumen composition is thick, and before starting work it is heated to a boil.

Gasoline-bitumen antiseptic cannot be heated: it can only be diluted with gasoline.

It is easy to apply oil products and enamels to the surface treated with the composition, with the exception of nitro varnish and nitro paint. The coating process consists of three stages: a primer and two paintings.

Using wood biocides at home

Flaxseed oil helps provide wooden products with an even more presentable appearance.

Preservatives used in direct contact with soil or water help preserve wood. The main components of impregnations are compounds of copper, chromium with the addition of zinc, fluorine or boron. Biological impregnations are reliable in operation, and they are easy to make with your own hands at home. It is enough to purchase a special container and antiseptic concentrate. To obtain the finished composition, the concentrate is poured into a prepared container and filled with water, mixing thoroughly.

Natural waxes and oils protect the wooden surface from water and atmospheric factors. The oil penetrates deep into the wood, creating a special layer impenetrable to gas, water, and steam. Wax protects products from the outside by forming a special breathable layer.

Linseed oil is an excellent material for protecting wooden structures. It is added to many products that are used for external and internal work. Linseed oil helps impregnations provide wooden products with a beautiful appearance. The oil is matched to the color of the wood by adding coloring compounds to it. Working with oils is safe for health.

Types of ready-made wood impregnations

Ready-made antiseptics are sold in almost any building materials store. They differ in purpose, consistency, absence or presence of odor, color and degree of penetration deep into the wood.

Impregnations are made on different bases:

- Water. Such antiseptics do not have an unpleasant odor and are suitable for both external and internal use.

- Acrylic. Acrylics also have no odor, are environmentally friendly and can be used to treat wood both inside and outside the house.

- Saline. Rafter systems are most often impregnated with salt-based solutions to prevent the growth of fungus, pests and mold. They also protect wooden elements from easily igniting. As a rule, wood is immersed in such an antiseptic rather than treated with a brush. Therefore, it is rarely used in private households.

- Oily. Garden furniture is treated with oil solutions,

constantly exposed to ultraviolet radiation, moisture and other external factors.

- Based on alkyd resins. The composition includes antiseptic additives, wax and oil. This impregnation well emphasizes the beauty of the wood texture and protects well from negative natural factors. Disadvantage: long drying time.

- Bituminous. It looks like a thick, black mass. It has a pungent odor and is mainly used for external work. Excellent protection against moisture, but flammable.

- Silicone. Serves as a protective screen from the sun, water and biological destruction. An added bonus is that the silicone layer allows the wood to breathe.

There are special purpose antiseptics. Narrowly targeted compositions focus on solving a specific problem - frost protection, water-repellent effect, antiseptic effect, formation of fire resistance. There are also complex impregnations that combine several of the listed properties or all at once.