The use of a high-quality steam generator for a phyto-barrel is a very important aspect for carrying out medical procedures and sessions. The resulting health effect depends to a certain extent on how efficiently and efficiently the steam is supplied. So how to make a steam generator with your own hands?

First, let's look at what types of steam generators there are. Conventionally, they can be divided into furnace, electrode, heating type (using heating elements) and induction. They all differ in a number of advantages and features. For a cedar barrel, the most suitable device is a device with tubular elements.

Design Features

Such a heat exchanger is small in size and is capable of efficiently converting tap water into light steam. With its use, there is no need to use any type of stove. Moreover, such a device will take up very little space, which is very important in the case of a miniature steam room. To heat a phytobath, which is a cedar barrel, wood or electric stoves are usually used. Nevertheless, a small steam generator is capable of adequately heating and filling the container with excellent steam. Among the main advantages of the device are the following:

- compact appearance;

- the possibility of saving energy and water;

- production of high quality steam.

To ensure that the heated moist air has healing properties and is saturated with biologically active phytoncides, the design of the steam generator designed to serve the phytosauna has a special compartment where medicinal herbs are placed. Thus, a person steaming in a bathhouse receives pleasure from both the healing moist air and the pleasant aromas of nature itself.

Minuses

The disadvantages of homemade steam generators for cedar barrels can also be relative and depend on the tools and materials used during installation, the quality of assembly, the availability of practical experience, the skills and knowledge of the manufacturer. General and obvious disadvantages include:

- Significant time costs and availability of conditions for creation.

- Relative fire and electrical safety. You should especially pay attention to this when using it at home.

- Lack of compactness and difficulty in carrying. When replacing a phyto-barrel, you will need to adjust the device to the new parameters.

- As mentioned above, the lack of convenient options installed on factory models.

- Unobvious disadvantages include the quality of the materials used. For example, using a plastic canister is a questionable solution.

Depending on the quality of the plastic and its heat-resistant properties, thin plastic can interact with steam and heating elements. The penetration of harmful substances into steam and water neutralizes the positive effect of medical procedures. It is better to use a stainless steel container, but in this case you cannot make a steam generator for a cedar barrel with your own hands. You will need specialized equipment, inventory, and premises. Video of those who have it all:

Types of steam generators for phytosaunas

Products in this category are divided into devices of flow-through and storage types.

The first type includes devices that have a water tank in their design. They are used mainly in rooms not equipped with running water. A distinctive feature of such steam generators is mobility, which is very convenient if you need to move the device to another room.

The second version of the steam generator is optimally suited for use in commercial types of phytosaunas. The device is connected to the water supply system and can work non-stop for a long time. In this case, the processes of filling with liquid and turning off its supply are carried out automatically.

Depending on whether the sauna has a central water supply or not, as well as on the cost of the device, the choice of one or another steam generator option is determined.

The process of making a steam generator for a phyto-barrel with your own hands

How to make a steam generator yourself? Let's analyze the materials, and then the algorithm. In order to construct it, you will need the following components:

- Flexible metal hose 1.7-2 m. It is possible to purchase a connection for the mixer.

- 10 liter plastic canister.

- Metal-plastic pipe.

- Insulating tape.

- Tee fitting.

- Thermometer.

- Sealant.

- Drill.

- Drill.

- Heating elements (heating elements).

- Flange.

Brief assembly instructions:

- Installation of heating elements inside the canister. Connecting the terminals to the wire with subsequent insulation.

- Installing the flange on the canister and connecting it to the hose.

- Installation of a metal-plastic pipe inside a cedar barrel with perforations using a drill and connecting the pipe to an external water hose using a fitting.

For those who prefer video format: That's it! The simplest steam generator for a phyto-barrel is ready. It's nice that you can do it yourself.

When using a homemade steam generator, it is necessary to monitor the temperature both inside the phyto-barrel and the device itself, as well as the load on the heating elements.

The homemade product is accordingly not equipped with automatic temperature sensors and shutdown relays.

In addition, in the described device it is impossible to quickly and conveniently use phytoextracts, both in the form of dry herbs and various mixtures. The production time for a steam generator for a bath and hammam may vary depending on:

- availability of raw materials,

- their cost,

- on the functionality, complexity and purpose of the product that we ultimately want to get.

For example, various steam generators with a separate set of characteristics are needed for baths, Finnish saunas, microbaths and herbal barrels.

Selection options

A characteristic feature of a good steam generator is its affordable cost, which determines the high quality and reliability of the device.

In addition, high-quality devices have a durable body made of stainless steel. If you want to purchase a high-quality steam generator for your bath, do not be fooled by models with plastic lining for continuous use in the steam room. In addition, you need to pay attention to the following important factors that determine the choice of a decent device:

- The comfortable temperature in the barrel is adjusted using a thermostat.

- Automatic control of the water level in the tank prevents the liquid from boiling away and the burnout of electric heaters.

- Aroma bowls will create a pleasant atmosphere, rich in the aroma of herbal infusions.

- The presence of product certificates will protect commercial health centers, sanatoriums and spas from problems with various authorities.

There are also options for steam generators for Russian baths, Finnish saunas and hammams.

Advantages of a steam generator for a phyto-barrel with your own hands

The advantages of manufacturing these devices include their relative low cost compared to purchasing factory-made products. But this advantage can be offset by time and labor costs, as well as problems and operating costs that arise. Namely:

- irregular, higher energy consumption compared to more technologically advanced factory devices,

- time costs,

- wear of simple components, etc.

In addition, if you have knowledge and experience, it is possible to create your own customized device to suit your needs and tasks.

This advantage is also relative, that is, factory devices can be equipped with various options. For example:

- the presence of a dosing aroma station and a convenient aroma container for both dry preparations and herbal oils,

- built-in water filters,

- the presence of a magnetizer to neutralize the harmful effects of hard salts, etc.

Many additional optional parts that are installed standard in factory models are therefore not available for home-made ones, and their production in artisanal conditions is impossible. Experts make such devices with their own hands many times. They make fewer mistakes and spend less time on one product.

Getting to know the models

The PGN-Ratar heat exchanger (1.6 kW) is equipped with a 3-liter water tank. Thanks to its compact dimensions (350x300x150 mm) and low weight, the device can be easily hung from one wall to another. In addition, this device does not require connection to a water supply. The case, made of stainless steel, has a control panel that allows you to set the temperature up to 100 °C. A single heating element, as well as a built-in container for storing aromatic substances and herbal infusions, complete the design of the device. The device is connected to a network with a voltage of 220 V. Its cost is 12.5 thousand rubles.

The SibPar PGN steam generator is ideal for generating heated moist air for a cedar barrel. A mobile device with dimensions of 450x330x222 mm does not require connection to a water supply system, which makes it easier to hang it on one of the walls of the room. Equipped with a control panel allows you to set the required temperature from any distance.

To heat a phytobarrel, it is customary to set the value to 450 degrees. Above the electric heater, which is constantly in the water, a vertical sensor is installed that monitors the filling level of a 7-liter tank. If the amount of liquid noticeably decreases, exposing the heating element, this element automatically turns off and an audible signal sounds. Therefore, if you want to extend the operation of the device, you need to fill the tank with water to the required level.

Aromatic fillers and herbal mixtures are placed in a special container built into the steam generator. The cost of the device is 17.8 thousand rubles.

Lifehacks and recommendations

- During manufacturing, the length of the steam supply wire should be taken into account, i.e. the smaller it is, the better - the longer the hose, the higher the likelihood of condensation forming.

- When using tap water, you should take into account the presence of hardness and additional impurities, which can lead to scale formation and are simply harmful to health. It is necessary to use distilled water; it is not easy to make it yourself.

- The power of the heating elements should be 3 kW per volume of water 10 liters.

- Insulate contacts and remember to be safe when handling electrical devices.

- Monitor the temperature.

- When posing the question - whether to make a steam generator with your own hands or purchase a ready-made factory one, we recommend analyzing all the advantages and disadvantages, nuances, as well as time costs and your own experience in assembly.

Design and principle of operation

The simplest products consist of:

- water tank;

- heating element

- supply tube.

Industrial units have many additional elements that provide expanded functionality of the device. For home use, such equipment will definitely come in handy, but the main disadvantage will be the high price. That is why you should pay attention to the possibility of making a steam generator for cars and other household needs with your own hands.

The essence of the steam generator:

- Water is supplied to the reservoir, preferably filtered and cleared of metal suspensions. This will increase the service life of the homemade device and help avoid frequent cleaning of the nozzle.

- When the heating element is turned on, the water begins to heat up and evaporate, entering the expansion tank, from where it exits through the pipeline through the nozzle.

We invite you to familiarize yourself with DIY wooden crafts for the garden and dacha: how to make them, photos of original ideas

The resulting steam can be directed to a contaminated surface, and can also be used for a sauna or Finnish bath.

In most purchased models, you can adjust the temperature and intensity of evaporation. Despite the fact that home models do not have this advantage, they also cope well with their functions, and most importantly, they are affordable.

Testing and Troubleshooting

Anyone who dares to assemble a steam generator with their own hands will need knowledge of physics within the school curriculum, a little courage and the following set of elements:

- container, old steamer or electric kettle;

- purchasing a heating element of the required power;

- solving the issue of water supply to the device.

We suggest you familiarize yourself with How to make a mold for making cinder blocks.

Making cinder blocks with your own hands The best container for our device is one with thick walls and the ability to be hermetically sealed.

Thick walls and tight lid

A pressure cooker, an old Soviet kettle, some people use a gas cylinder.

The remaining propane is released, the brass valve is unscrewed, and thoroughly washed with running water and soap or other dishwashing detergents. The main sign that the cylinder has been washed is the absence of a gas odor. After washing the container for the future steam generator, it is dried.

Now comes the turn to choose a water heater. Some people use an electric stove or a gas stove that will heat the water, but installing a heating element is considered more effective. Choosing a heater for internal installation in a unit today is not a problem. For 10 liters of water, a heating element with a power of 3 kW is required.

The heater should be installed at a height of at least 1 cm from the bottom of the container. Drill holes, install studs in them, and secure with nuts as tightly as possible. To prevent water from leaking, tightness is required, you can use silicone gaskets inside and outside, or you can achieve tightness in other ways. Then the heating element is attached. The fastening is required to be strong and withstand pressure of 6 atmospheres.

Steam generator device

How to supply water to a steam generator. We make a hole for water supply. We seal it. It is better to use a copper tube. The flow of water must be constant; without water, the steam generator will fail. Water can be supplied from a barrel, a tank installed in the same plane with the steam generator (law of communicating vessels), by installing the other end of a copper tube into the barrel. You will need a tap to control the level of water supplied to the device in order to top it up as it boils.

Now you need to make a device for releasing steam. A hose from a non-working vacuum cleaner, which is mounted in the lid of the steam generator, will come in handy. All. It's time to test.

Important! It is not recommended to install a steam generator in the steam room itself. It’s not difficult to figure out how steam will get into the steam room; make a hole in the wall and insert the other end of the vacuum cleaner hose into it. The main thing is that the device will not be exposed to high temperatures and humidity.

We invite you to familiarize yourself with a soft blind area around the house with your own hands: step-by-step instructions || DIY blind area for a wooden house

Testing is necessary to check the tightness of both containers, the liquid level, and the electrical connection. But the main thing is whether the installation produces a sufficient amount of steam.

Any unit that works with water requires maintenance, descaling, and efficiency testing. It is necessary to test the unit in case of such unpleasant situations as:

- lack of water;

- voltage drop;

- overflow of water.

If this does not happen, the steam generator works for a long time without creating problems. It would be a good idea to install a filter, especially if the water contains a high content of salts and sand.

There are some well-known tricks and devices that protect against overflow. Pressure gauges are installed to monitor the pressure in the housing, and thermometers to record the temperature.

Steam generator Harvia

It is important to know that a homemade steam generator is not only useful, but also dangerous. Incorrect assembly or incorrect calculation can lead to electrical injuries and burns. You should think a hundred times before you start assembling the device. And if it is not possible to purchase good quality equipment, which includes HARIVA, TYLO, SAVO, it may be better to steam the old-fashioned way, splashing water from a wooden ladle onto the stones of a wood-burning stove.

After assembly, the homemade steam generator must be properly tested. The tightness of the container and installed fittings, the speed of heating the water and the operation of the sensors are checked.

To connect to the network, it is preferable to install an RCD (residual current device) and a grounding circuit. After this, you can check the heating rate and the volume of steam produced.

Possible operational problems are eliminated by adjusting the valves and debugging the automatic safety system.

How to make a steam generator for engine washing with your own hands - nuances

Very often, steam machines are used in professional car washes. Steam provides effective cleansing of dirt and germs. Such machines are among the noisiest such special devices in the state (due to the running compressor).

Steam generator working in a car repair shop

Usually this is a unit on wheels, somewhat reminiscent of a vacuum cleaner, with water supplied to it. The operator operates something like a pistol. In this case, steam is supplied under sufficient pressure. But a homemade steam generator for a car can be used for purging the engine and heating hoses.

By the way, containers for a steam generator do not always have to be metal

STEAM GENERATOR DESIGNS

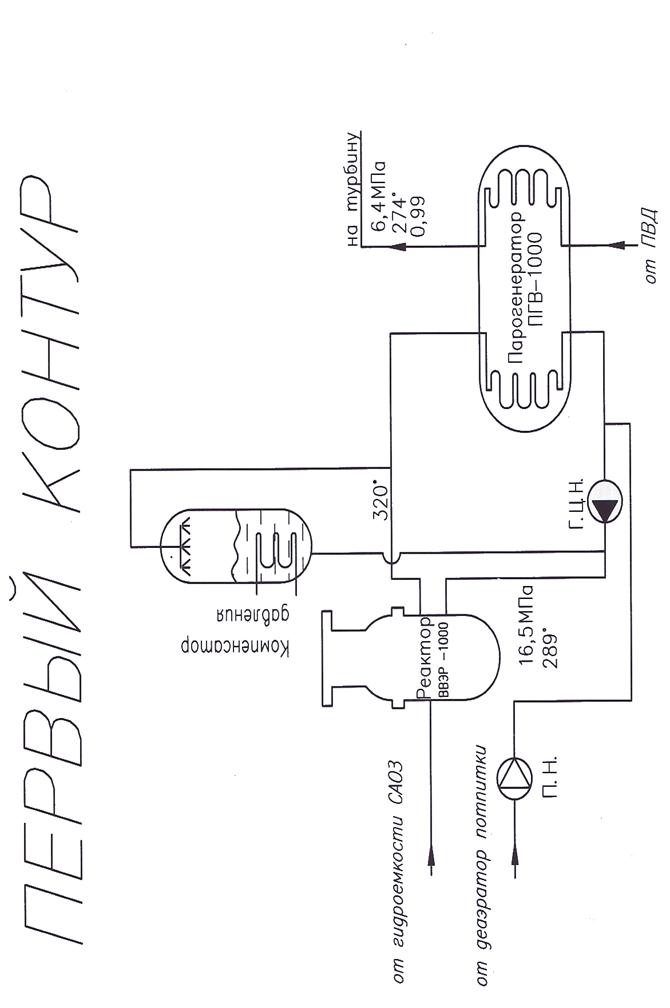

3.1. NPP steam generators with water coolant

Double-circuit nuclear power plants with pressurized water coolant play and will continue to play a major role in nuclear energy.

In the development of steam generators of such stations, several main types can be distinguished:

1. PGW steam generators of horizontal type with a submerged heating surface made of U-shaped coils and coolant distribution using collectors.

2. PGV steam generators of a vertical type with a submerged heating surface of a coil or screen type and distribution of coolant using collectors.

3. Vertical type steam generators with a submerged heating surface made of U-shaped coils and coolant distribution using tube sheets.

4. Direct-flow steam generators.

5. Sectional steam generators.

3.1.1. Steam generators PGV with coolant—water under pressure of horizontal type.

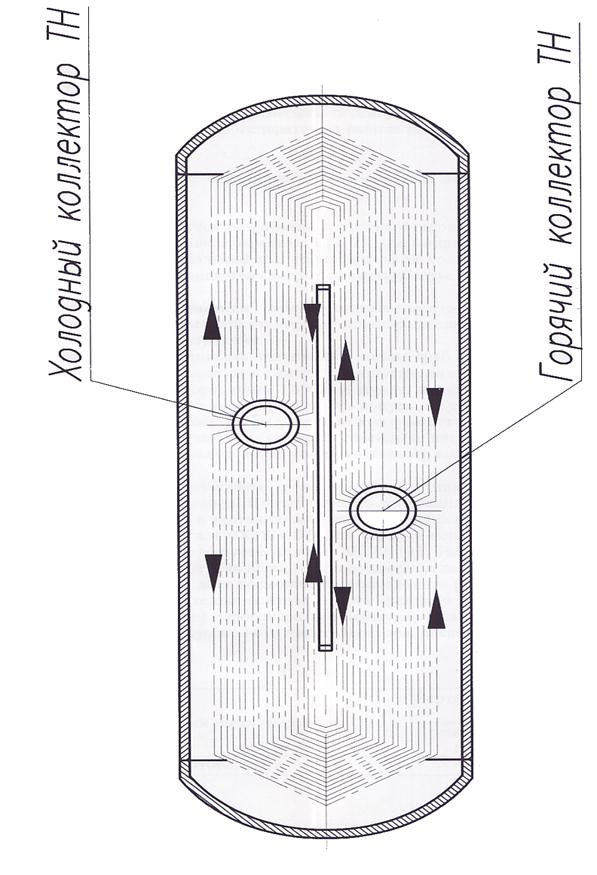

Horizontal steam generators for NPPs with VVER were first put into operation at the Novo-Voronezh NPP. These steam generators are packaged recuperative heat exchangers. The coolant, the pressure of which is 2-3 times higher than the pressure of the generated steam, moves inside the pipes, where it is supplied using collectors. The economizer and evaporative heating surfaces are essentially combined. In the water volume, steam generator water has a saturation temperature. The entire heating surface acts as if it is boiling. The amount of steam produced in this case exceeds that supplied to the consumer. The excess amount of steam, condensing, releases heat to heat the feed water to saturation temperature. Steam generators produce saturated steam. The nature of the washing of the heat transfer heating surface by the working fluid can be considered as natural circulation during non-pressure movement. Feed water heating, steam generation and steam separation are carried out in one housing. The heating surface of the steam generator, in accordance with the requirements for coolant purity, is made of austenitic stainless steel. The heat transfer surface pipes are spaced along the height and width of the bundle using wave-shaped plates and straight strips. Manifolds are made from either stainless steel or perlite grade steel. In the latter case, the inner wall of the collectors, in contact with the coolant, is clad with steel 0Х18Н10Т. The collectors passing through the body are welded to it in its lower part using pipes that form a water jacket. Maintenance of the internal cavities of the collectors in the steam generators of the 1st and 2nd units is carried out from below; in steam generators of blocks 3-5 - from above. The body of the steam generators consists of a cylindrical shell and two elliptical bottoms made of pearlitic steel.

Feedwater is introduced into the housing above the evaporation surface and directed to a feedwater collector located horizontally under the evaporation surface. In steam generators of units 1–4, it is located approximately in the middle part of the tube bundle. Feed water from the manifold holes is directed towards the hot part of the tube bundle, which helps to equalize the steam load of the evaporation mirror. In the steam generator of the 5th block, to equalize the steam load of the evaporation mirror, a submerged perforated shield is installed, and feed water from the collector is supplied to the shield towards the inlet part of the tube bundle.

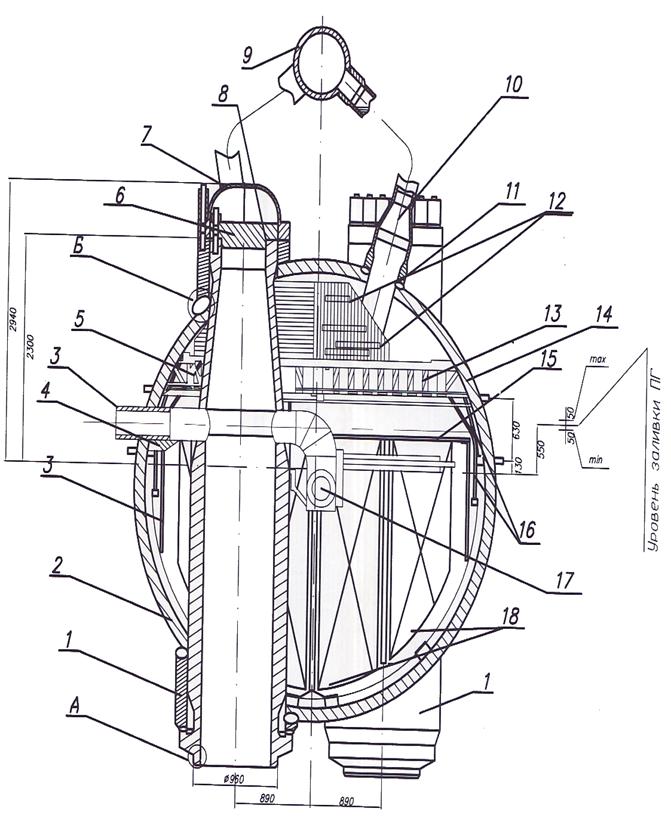

Steam separation is two-stage: I - precipitation stage, II stage - louvered separators. In table Figure 1 shows the characteristics of the operating steam generators of the Novo-Voronezh NPP of units 1–4 and unit 5 for the VVER-1000 reactor. In Fig. Figure 4 shows a diagram of the steam generator of the 4th unit of the NV NPP.

Horizontal steam generators for VVER reactors.

Rice. 4 Steam generator of the 4th unit of the Novo-Voronezh NPP: 1

— steam generator body:

2

— tube bundle;

3

— level meter fittings;

4

- louvered separators;

5 - saturated steam collector; 6

—saturated steam output;

7

— hatch;

8

— periodic purge fitting;

9

— feed water collector;

10

- continuous blowing;

11

— tube supports;

12

— steam generator support;

13

— inlet: coolant collector;

14

— manifold air vent;

15

- drainage of leakage from under the cover gasket;

16

— manifold cover;

17

- cover;

18

—feedwater inlet;

19

— coolant outlet manifold

Table 1

| Main characteristics of steam generators | Steam generators at NV NPP | |||

| 1 block | 2 block | 3.4 block | 5 block | |

| Thermal power, MW | ||||

| Number of steam generators per reactor | ||||

| Coolant pressure, MPa | 9,8 | 10,3 | 12,2 | 15,7 |

| Coolant temperature, °C: at the inlet at the outlet | ||||

| Coolant flow, kg/s | ||||

| Steam capacity, kg/s | 63,9 | 90,3 | 125,5 | |

| Steam pressure, MPa | 3,14 | 3;24 | 4,62 | 6.26 |

| Steam temperature, °C | ||||

| Feedwater temperature, °C | ||||

| Coolant speed in pipes, m/s | 2,94 | 3,36 | 2,7 | 4,89 |

| Heat transfer coefficient, kW/(m2-K) - atm of coolant to the wall from the wall to the water | 19,8 17,3 | 23,2 | 19,4 16,6 | — — |

| Heat transfer coefficient. kW/(m.2-K): | 4,29 | 4,36 | 4,31 | 6,4 |

| Average specific heat flow, kW/m2 | 91,5 | |||

| Average logarithmic temperature difference, °C | 24,7 | 25,5 | 21,2 | ‘24,7 |

| Heat transfer surface taking into account the margin for contamination, m2 | ||||

| Number of tubes | ||||

| Diameter and wall thickness of tubes, mm | 21×1,5 | 16×1,4 | 16×1,4 | 12×1,5 |

| Average tube length, m | 9,5 | 10,1 | 8,7 | 8,9 |

| Hydraulic resistance along the coolant path, MPa | 0.15 | 0,16 | 0,098 | — |

| Reduced speed of steam exit from the evaporation mirror, m/s | 0,172 | 0,196 | 0,2 | — |

| Calculated steam humidity, % | 0,001 | 0,0068 | 0.005 | 0,1 |

| Case dimensions, m: internal diameter length | 3,01 11,57 | 3,01 11,57 | 3,21 11,95 | 4,0 15,0 |

| Internal diameter of collectors, mm | ||||

| Dry steam generator weight, t | ||||

| Specific metal consumption (kg metal per kg steam) | 0.45 | 0.344 | 0.32 | 0.1 |

* A dash in this and other tables means that data is not available.

table 2

| Main characteristics of the steam generator | Horizontal steam generator with superheated steam |

| 1. Thermal power, MW | |

| 2. Coolant temperature. °C: at the inlet at the outlet | 325,5 |

| 3. Coolant pressure. MPa | 15,7 |

| 4. Coolant flow, kg/s | |

| 5. Steam capacity, kg/s | |

| 6. Steam pressure. MPa | 6,09 |

| 7. Steam temperature. °C | |

| 8. Feed water temperature. °C | |

| 9. Coolant speed in pipes, m/s | |

| 10. Diameter and wall thickness of the tube, mm | 12×1,2 |

| 11. Number of tubes in the evaporator | 12 306 |

| 12. Heat transfer coefficient. kW/(m~-K): in the evaporator in the superheater | 7,85 2,32 |

| 13. Average specific heat flow, kW/m: in the evaporator in the superheater | 7.85 2,32 |

| 14. Heat transfer surface, m: in the evaporator in the superheater | 26,2 |

| 15. Steam generator length, m | |

| 16. Steam generator diameter, m | |

| 17. Steam generator weight, t | |

| 18. Specific metal costs (kg metal per kg steam) | 0,18 |

Rice. 5 Horizontal steam generator with steam superheating: 1 - coolant outlet manifold; 2 — steam generator housing; 3 — level gauge fitting; 4—feed water inlet fitting; 5 — drainage of leaks from under the cover gaskets; 6— manifold cover; 7 - cover; 8 — manifold air vent; 9 — steam outlet fitting; 10— protective casing; IT—superheater tube bundle; 12— separators; 13 - pipe for draining water from separators; 14 — perforated shield; 15 — feedwater collector; 16 — bundle of evaporator pipes; 17 - drainage; 18 — evaporator inlet manifold.

In table Figure 2 shows the characteristics of a horizontal type steam generator designed for low steam superheating; Fig. 5 - design design of a steam generator of this type. The superheating beam, as can be seen from Fig. 5, is located behind the separators in the upper part of the separation space. The part of the steam generator housing in the area where the superheated steam exits is protected by screens.

Technical capabilities

Manufacturers strive to make their steam generators not only productive and reliable, but also multifunctional. Modern installations are capable of operating in a variety of modes, which are configured on an intuitive control panel.

One of the useful functions of factory steam generators is the ability to produce steam at a given temperature in the range of 35-95 degrees. In this case, you can set the intensity of steam generation by setting time intervals.

Since a steam generator is more often used for steam rooms, they are often capable of producing steam corresponding to a Finnish or, for example, Russian bath. A few drops of a special aromatic preparation will give it a more pleasant smell.

The main criterion for dividing steam generators into groups is as follows:

- Automatic - just connect the unit to a water supply or other liquid supply device

- Autonomous - you will have to constantly manually add water to the working container

Models of the second type are much less common. They are much more dangerous and very impractical. In addition, they are not equipped with various control devices.

The main characteristic of devices is power. As a rule, for household-type models it ranges from 4 to 12 kW; they operate on a classic outlet (220 V). Industrial installations are more productive, but require a 3-phase network (380 V).

It should be noted that there is a certain relationship between the power and the volume of the serviced premises:

- 4-6 cubic meters – 4-5 kW

- 10-12 cubic meters – 8-10 kW

- 16-18 cubic meters – 12 kW

There are special requirements for the reliability of the device, since they constantly operate in a damp room. However, a large supply of quality tends to significantly increase the cost. Household multifunctional models cost up to 30,000 rubles. Prices for industrial installations for baths can rise to an immodest $10-15 thousand

You may also be interested in our guide on how to make a solid fuel boiler with your own hands

Types of steam generators and their use in the household

Steam generators are most often used for defrosting pipes, arranging baths, saunas and steam rooms. A simple steam converter will cost several times less than building a full-fledged furnace with stones. In order to start using the device, you just need to plug it into the network. Steam converters are used to clean complex mesh or porous equipment and help effectively warm car engines in winter.

No dust! A disinfecting jet of steam will tidy up many devices and ensure their uninterrupted operation.